9

WEEKLY

Perform all daily maintenance recommendations. In addition:

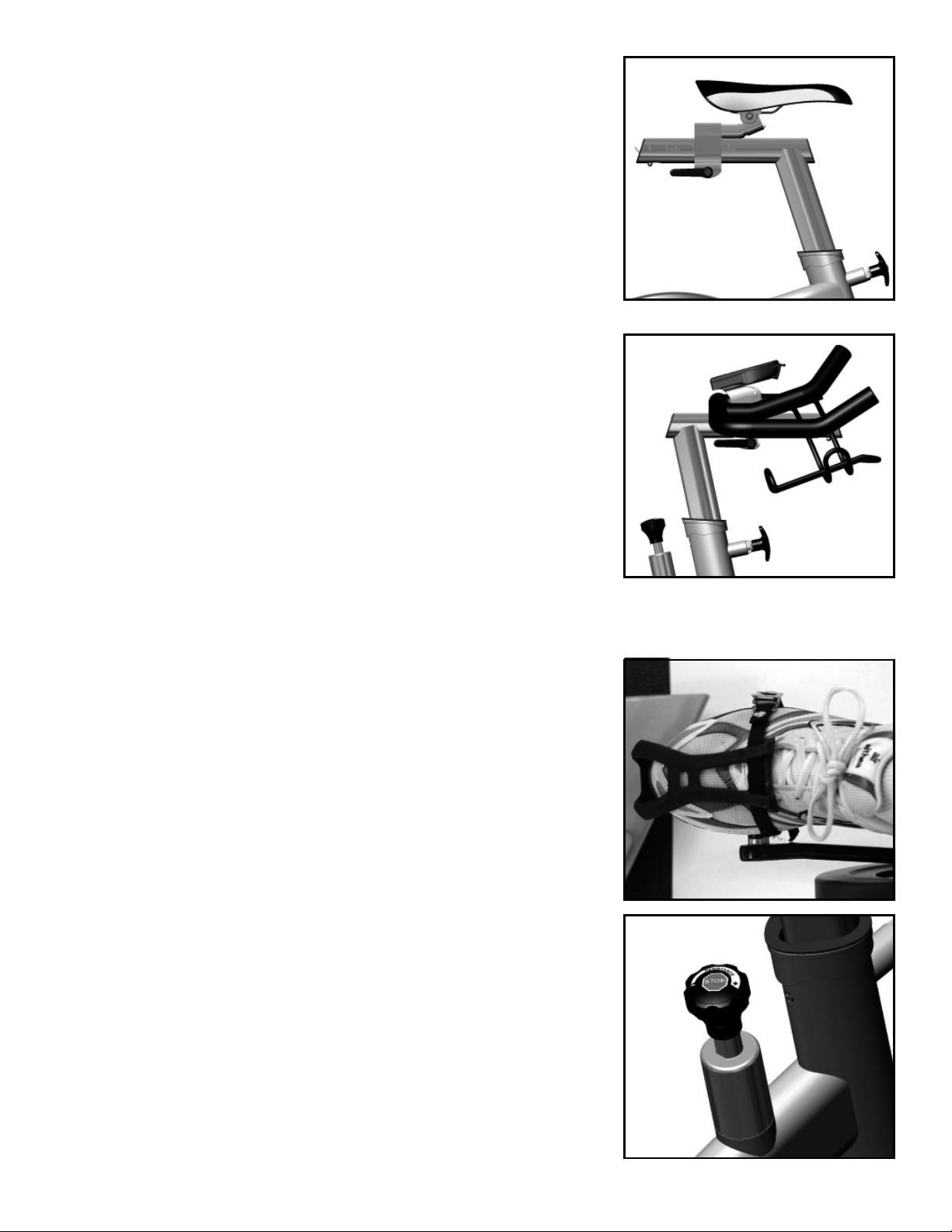

• Inspect screws on console bracket.Tighten if necessary.

• Inspect and properly tighten brake assembly.

• Properly tighten pedals and all hardware attaching toe clips/straps (if applicable)

• Inspect handlebar clamp assembly. Tighten the water bottle holder in necessary

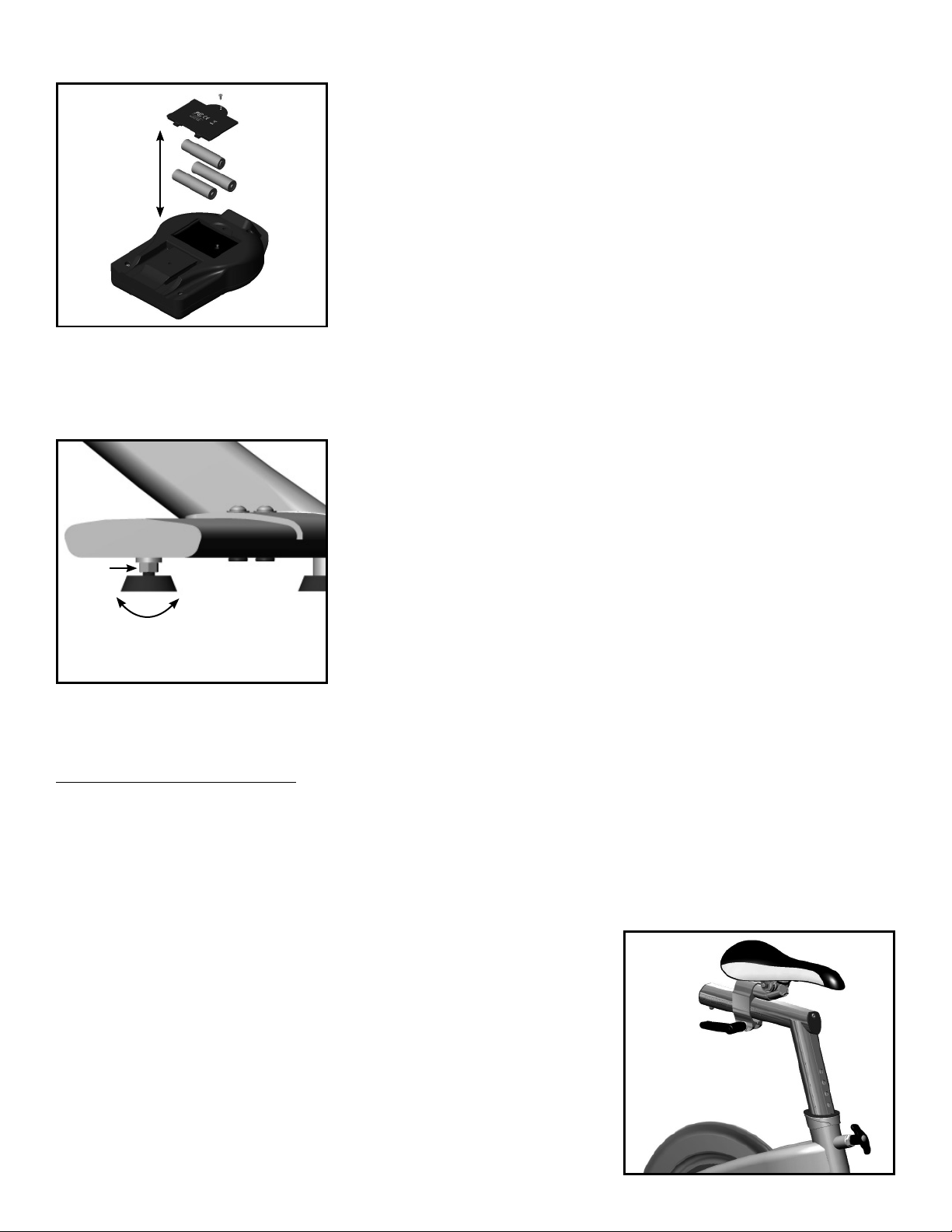

• Inspect seat clamp assembly. Tighten adjustment bolt if necessary

• Inspect stabilizer feet.Tighten if necessary.

• Inspect flywheel. Check for proper alignment.Tighten acorn locking nuts to 75 in-lbs.

• Inspect crank/bottom bracket interface.Tighten to 75 in-lbs

MONTHLY

• Perform all Daily and Weekly maintenance recommendations. In addition:

• Perform thorough cleaning of the CycleOps Indoor Cycle. This includes:

• Remove handlebar tube and seat tube and clean both the stainless steel tube as well as inside the plastic sleeve

• Clean the underside of the stabilizer feet.

• Remove console bracket and clean the handlebar assembly

• Clean the flywheel

• Check the chain tension to ensure that the chain is properly adjusted.See “Adjusting the Chain Tension”for instructions

• Inspect plastic sleeves for damage.Replace if necessary.

• Inspect brake pads for wear. Replace pads if there is less than 2mm of felt pad exposed.

• Lube the drive train. See“Lubrication”for instructions.

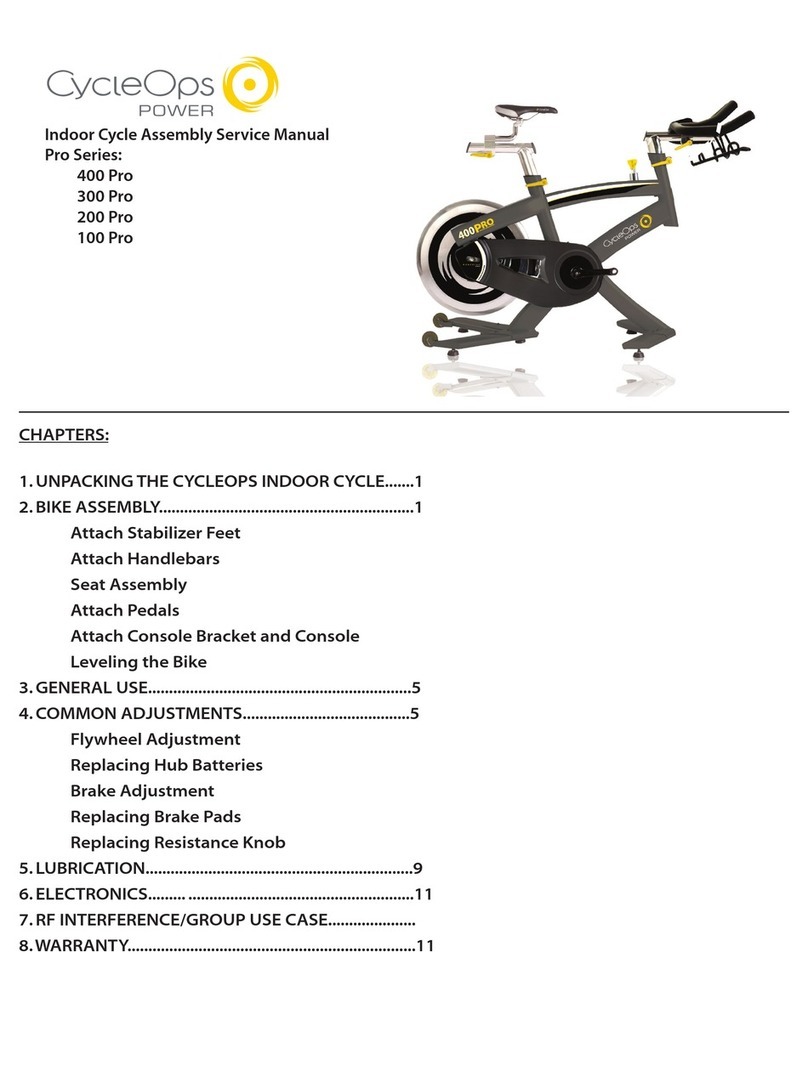

CHAPTER 5:

CONSOLE OVERVIEW (200 and 300 bikes only)

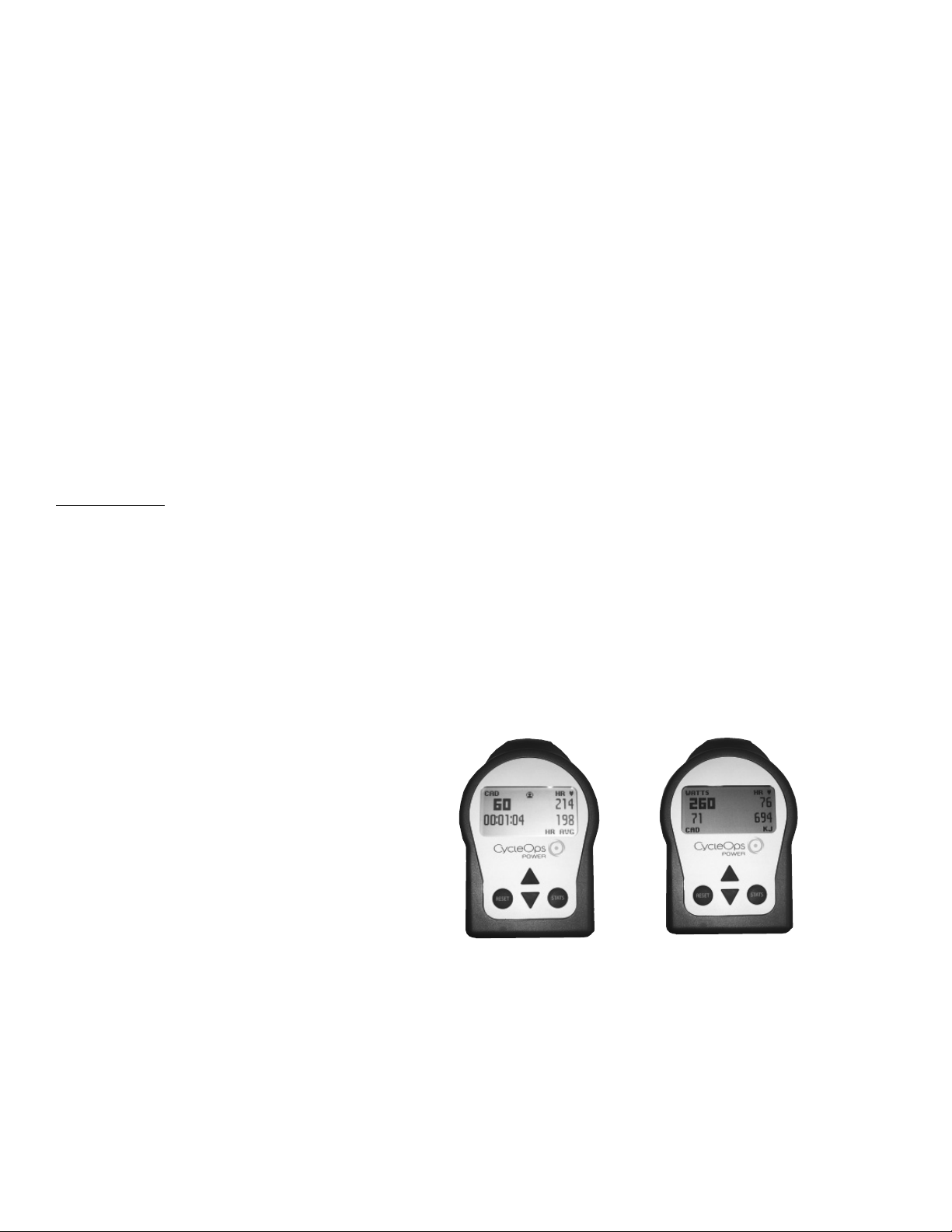

Both the Club Comp 200E and Club Pro 300PT are equipped with a handlebar mounted console unit.The console receives a digi-

tally coded signal from the transmitter in the hub of the flywheel. Cadence on the Club Comp 200E as well as Watts and torque on

the Club Pro 300PT are received from the rear hub. In addition to these metrics, the console displays heart rate via a coded telem-

etry signal (chest strap).

SPECIFICATIONS

Accuracy +/-1.5% (Pro 300PT)

Signal Transmission Digital RF

Operational Temperature 0 to 40 degrees c or 32 to 104 f

Battery Life (Hub) 1000 hours approx.

Battery Life (Console) 100 hours approx.

Battery Type (Hub) AA type 1.5 volt 2 ea)

Battery Type (Console) AAA type, 1.5 volt (3 ea)

Freehub fixing bolt torque 400-450 inch-lbs.

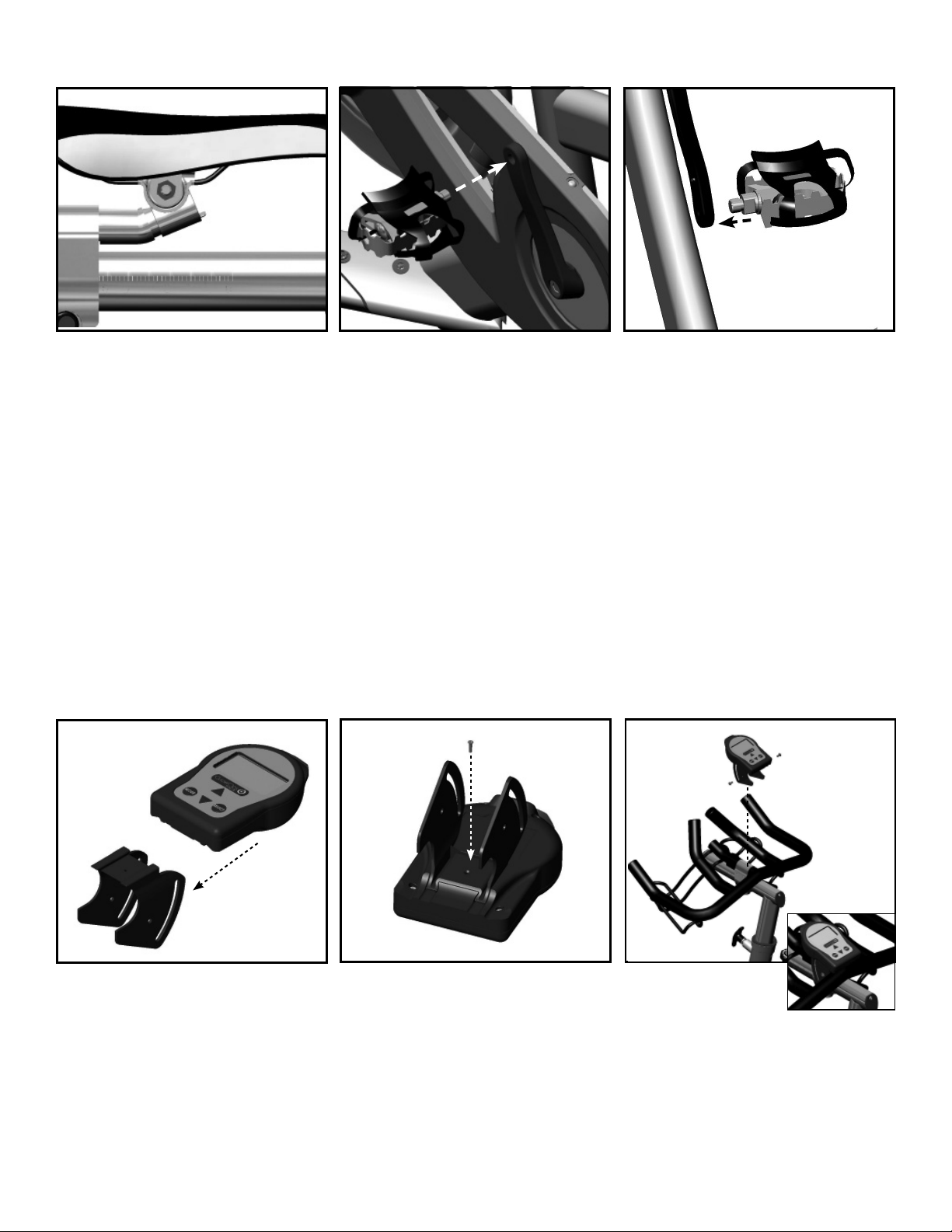

ELECTRONICS INSTALLATION

1. See “Bracket” under installation instructions

Console Operation

Begin pedaling and press any button to wake up the console. It may take up to 90 seconds for the console to recognize the hub.

When searching for the hub, the display will show vertical lines in the WATTS field. Once the console finds the hub, biometric data

will be displayed.To simplify the user interface on the console, there are four buttons; they are the UP ARROW, DOWN ARROW,

STATS and RESET. The functions of the buttons are:

UP ARROW: Pressing and releasing the UP ARROW button allows you to select which data metric you would like to view in

bold.

DOWN ARROW: Pressing and releasing the DOWN ARROW button allows you to select which data metric you would like

to view in bold.

RESET:Pressing and releasing the RESET button twice, clears out all data to start a new ride. Use this button prior to begin-

ning a ride or to reset the console at any point during or after the ride.

Comp 200E Pro 300PT

Console Display