SEM EMP-1000HS Manual

Security Engineered Machinery Co., Inc.

PRODUCT OPERATION PROCEDURE

For

SEM Model EMP-1000HS

High Security, NSA Evaluated

Pulse Degausser

POP-0077 Rev. 0

Created: 04/18/2017

Security Engineered Machinery Co., Inc.

NATIONWIDE SERVICE

Phone Toll Free: (800) 225-9293

Email: [email protected]

Fax: (508) 366-6814

Website: www.semshred.com

For NATIONWIDE SERVICE 800-225-9293 | www.semshred.com

PRODUCT OPERATION & MAINTEANCE PROCEDURE

Model EMP-1000HS

2

Table of Contents

Introduction: ......................................................................................................................................... 3

Items/Packaging: ................................................................................................................................. 3

Lifting and Carrying: ............................................................................................................................ 3

Installing the Unit: ................................................................................................................................ 4

Operation: ............................................................................................................................................. 5

Other Conditions: ............................................................................................................................... 12

Operating Safety ................................................................................................................................ 13

Machine Specifications: .................................................................................................................... 13

Customer Service ............................................................................................................................... 14

For NATIONWIDE SERVICE 800-225-9293 | www.semshred.com

PRODUCT OPERATION & MAINTEANCE PROCEDURE

Model EMP-1000HS

3

Introduction:

Congratulations on your purchase of the SEM EMP-1000HS High Security, NSA Evaluated Pulse

Degausser. This is a highly capable and robust degausser that produces a maximum demagnetizing

field (coercive force) of greater than 20,000 Gauss, which is many times above the field required to

demagnetize the highest density hard disks as of today and the near future.

The EMP-1000HS is capable of running at input voltages of 120 to 240VAC at either 50 or 60Hz.

There are no required changes (no fuses to change or buttons to select) to switch from one voltage to

the other. Just plug in the correct power cord for your country.

Note: Always remember that any type of degausser/demagnetizer by itself is entirely ineffective at

erasing solid state memory or optical storage media. It is only effective for the erasure of magnetic

media (i.e. hard disk drives, magnetically recorded tapes, magnetic strips on credit cards, hotel

passes, floppy disks, Zip and Jaz disks, etc.).

Items/Packaging:

The EMP-1000HS Pulse Degausser should include the following items:

•

(1) Model EMP-1000HS Pulse Degausser unit

•

(1) power cord, U.S. style cord (NEMA 5-15P to IEC320) for use with 120V 60Hz

•

(1) power cord, European style cord (Schuko CEE 7/7 to IEC320) for use with 230V 50Hz

•

(1) EMP-1000HS User’s Manual

Lifting and Carrying:

The EMP-1000HS Pulse Degausser weighs approximately 160 lb (73 kg), so it is recommended that

two people lift this product when moving. Be sure to practice safe lifting technique when handling this

product to reduce the risk of injury or equipment damage.

For NATIONWIDE SERVICE 800-225-9293 | www.semshred.com

PRODUCT OPERATION & MAINTEANCE PROCEDURE

Model EMP-1000HS

4

Installing the Unit:

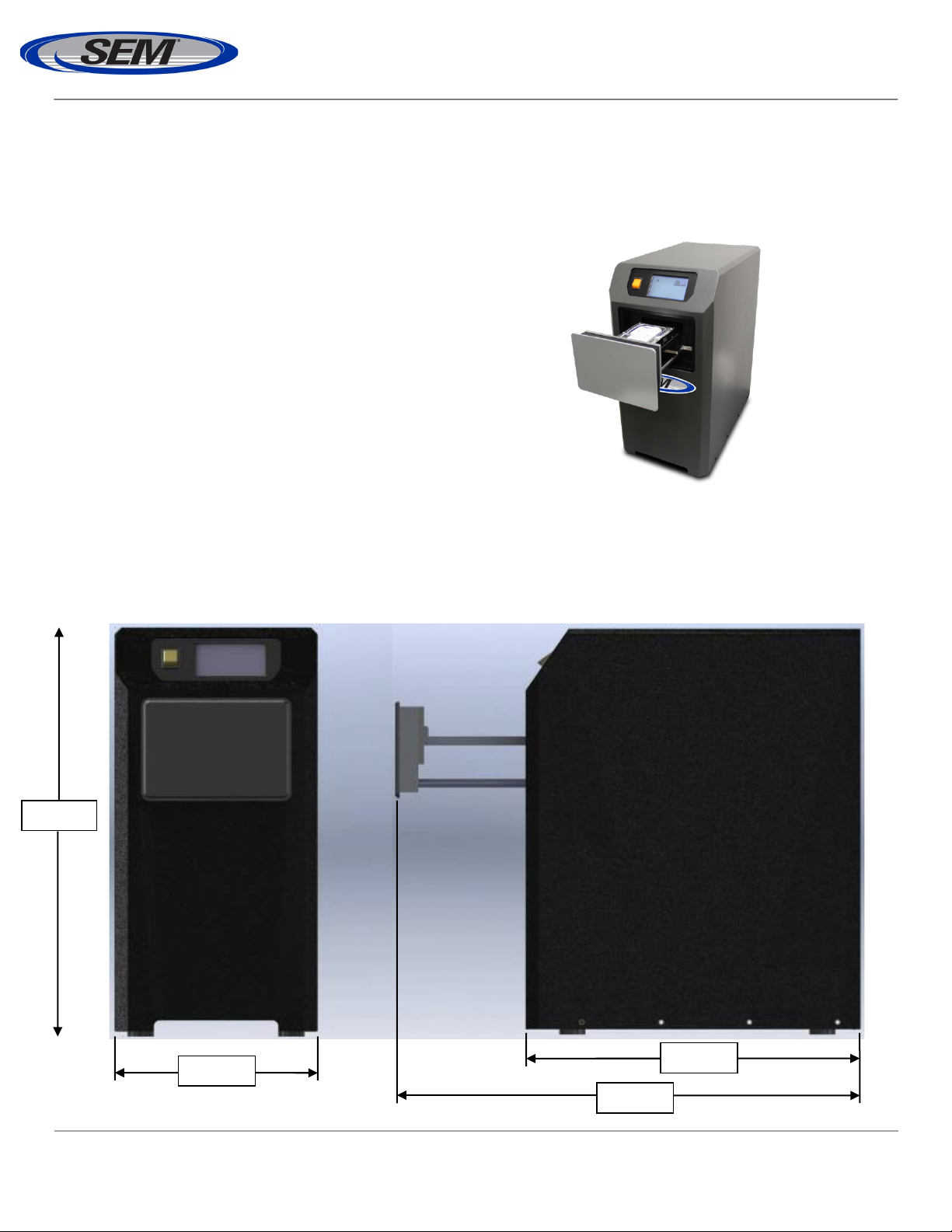

The SEM EMP-1000HS Pulse Degausser was designed to be a very compact unit and to have a

small footprint, so that it can fit onto a countertop or into an area where space is limited. See

dimensioned diagram below for space requirements.

Always mount the unit onto a level surface.

This unit was designed to be used in an

office or light industrial environment.

The rear panel of the unit should be kept at a

minimum of 2 inches from any walls or

obstructions to allow proper exhaust air flow

from the unit.

The EMP-1000HS is designed with extensive magnetic shielding, so external magnetic fields should

be very low at the external surfaces of the unit to zero a few inches beyond that. Other equipment

may be placed alongside the EMP-1000HS as long as the equipment is not highly sensitive to

magnetic fields, does not emit a high level of electromagnetic emissions, and does not emit any

significant level of heat.

26.4in

11.4in

19.0in

23.0in

For NATIONWIDE SERVICE 800-225-9293 | www.semshred.com

PRODUCT OPERATION & MAINTEANCE PROCEDURE

Model EMP-1000HS

5

Operation:

Attach the IEC320 end of the appropriate power cord (US or

European style) to the receptacle on the rear panel of the unit

and the other end into a standard 15A wall receptacle.

Note: Do not replace the power cord with an inadequately

rated cord. Always be sure that any replacement cord is

supplied by SEM, or has an equivalent rating.

Press the Power rocker switch (amber in color) upwards to power up the unit. The Power switch will

illuminate when powered on.

The Touch Screen Display should illuminate and the product splash screen should appear with the

SEM EMP-1000HS product name on a white background. This screen will be displayed for several

seconds.

For NATIONWIDE SERVICE 800-225-9293 | www.semshred.com

6

PRODUCT OPERATION & MAINTEANCE PROCEDURE

Model EMP-1000HS

The Display will now be in the Standby Screen.

•

The Standby Screen is displayed when the unit is first turned on or when any error or failure is

encountered

•

When in this mode, there is no charging of the unit’s capacitors and the Continue button is

always displayed.

•

The triangle icon is the Charge Indicator and indicates the level of charge stored in the unit’s

capacitors. When the border of the triangle is light green (as shown above) the unit is fully

depleted of charge.

Press the Continue button to advance to the User Screen.

For NATIONWIDE SERVICE 800-225-9293 | www.semshred.com

7

PRODUCT OPERATION & MAINTEANCE PROCEDURE

Model EMP-1000HS

The Display will now show the User Screen.

•

The Charge Indicator (triangle) border turns red indicating that the unit is charging. Black bars

inside the triangle appear as the level of charge increases. A blinking icon of a man with a

shovel is displayed as the unit charges.

•

The Open Door icon remains present and allows the user to access the media tray and insert

the media that requires erasure.

•

The green Start button is used to start the degauss cycle.

Follow these next steps which explain how to execute a degauss cycle on the media requiring

erasure:

For NATIONWIDE SERVICE 800-225-9293 | www.semshred.com

8

PRODUCT OPERATION & MAINTEANCE PROCEDURE

Model EMP-1000HS

Press "Open Door" to release the

media tray.

The media tray is now accessible

and the media needing to be erased

can now be installed. The Start

button is disallowed when the door

is open.

For NATIONWIDE SERVICE 800-225-9293 | www.semshred.com

9

PRODUCT OPERATION & MAINTEANCE PROCEDURE

Model EMP-1000HS

Install a disk drive into the media tray, as shown.

If installing a tape, place the tape

onto the center portion of the

media tray, as there is more

clearance area here to

accommodate tapes.

For NATIONWIDE SERVICE 800-225-9293 | www.semshred.com

10

PRODUCT OPERATION & MAINTEANCE PROCEDURE

Model EMP-1000HS

PRESS the Start button to begin

the degauss cycle AFTER the

door has been closed. It will be

disallowed if the door is not

closed.

Close the door manually

by pushing in the

direction shown until it

locks in place.

The Start button may be pressed at ANY

time after the door is closed, regardless

of the charge level. The degauss cycle

will start, but erasure will not occur until

the charge level is full.

The Start Button will change to indicate

that a degauss cycle is in process after it

has been pressed.

The Charge Indicator (triangle) will show

a dark green border and full bars when

the charge level is full. The unit will

automatically discharge shortly after.

For NATIONWIDE SERVICE 800-225-9293 | www.semshred.com

11

PRODUCT OPERATION & MAINTEANCE PROCEDURE

Model EMP-1000HS

After the unit has discharged, the media tray will be released automatically so

that the now erased media can be removed.

NEVER PULL ON THE MEDIA TRAY DOOR!!! This will damage the locking

mechanism.

If the door ever fails to open, it will try again every 5 seconds. If it continues

to fail or an error is displayed, please contact the SEM Service Dept.

The Magnetic Field Strength Indicator is displayed in the upper middle portion

of the screen. This displays the actual measured strength of the magnetic

field produced during the cycle and grades the value PASS or FAIL.

The Magnetic Field Strength is displayed in units of Tesla (flux density). If

PASS is indicated, the media can be removed and the next media to be erased

can be installed and the cycle started again.

If FAIL is indicated then the current media should be run again. If FAIL is

encountered too many times or if an error is present, please contact the SEM

Service Dept.

For NATIONWIDE SERVICE 800-225-9293 | www.semshred.com

12

PRODUCT OPERATION & MAINTEANCE PROCEDURE

Model EMP-1000HS

Other Conditions:

As stated in the previous section, the EMP-1000HS may

encounter an error if there is a buildup of too many cycle

magnetic field failures. This will result in the “Service Needed”

icon appearing. If this appears at anytime, please contact the

SEM Service Dept.

Temperature Errors:

The unit is thermally designed to operate "cool". In any degausser, the maximum demagnetizing field

produced will drop as temperature rises. The EMP-1000HS is designed with internal heat sinks,

optimized routing of air flow, and cooling fans. Under normal operation, the fans are not required and

will not run.

If the temperature rises to a critical level, the fans will come on intermittently after

each discharge cycle.

If the temperature still rises, the fans will come on continuously.

If the temperature reaches the maximum allowed, the unit will display a Red

Thermometer icon and disallow further operation until the unit has cooled down

sufficiently.

Voltage Errors:

The degausser is designed to operate between 115 and 240 VAC ~. During charging

of the capacitors, the line voltage may dip. In the event that the line voltage dips

below the level required to charge the capacitors, the following error will be shown:

If the line voltage is too high, the unit will display the following error in order to

prevent damage to the capacitors:

If either of these errors occur, please contact SEM service department

For NATIONWIDE SERVICE 800-225-9293 | www.semshred.com

13

PRODUCT OPERATION & MAINTEANCE PROCEDURE

Model EMP-1000HS

Operating Safety:

Never attempt to remove the cover, rear panel or disassemble the unit in any way as you could be

exposed to a high level shock.

If you are wearing a pacemaker, it may be affected by magnetic fields. Despite a high level of

external magnetic shielding built into the unit, if you wear a pacemaker you should not operate or

remain near the unit as an extra precaution.

Machine Specifications:

Operating Temperature and Humidity Range:

40-105° F

40% Rel. Humidity

Voltage Input: 115 to 240VAC, Auto Current sensing

Frequency: 50 / 60 Hz, Auto Sensing

Max Current Draw @ 115V: 8A

WARNING!!!

HIGH RISK OF SHOCK COULD CAUSE SERIOUS

INJURY OR DEATH IF DISASSEMBLED!!!

WARNING!!!

MAGNETIC FIELD PRESENT!!! MAY BE HARMFUL

TO PERSONS WEARING A PACEMAKER!!!

For NATIONWIDE SERVICE 800-225-9293 | www.semshred.com

14

PRODUCT OPERATION & MAINTEANCE PROCEDURE

Model EMP-1000HS

Customer Service

Security Engineered Machinery Co., Inc.

5 Walkup Drive

Westborough, MA 01581

Tel: 800-225-9293 Fax: 508-366-6814

Website: www.semshred.com E-mail: [email protected]

Order Online:

www.semshred.com

Important

Only authorized SEM service personnel should be allowed to service this unit.

Table of contents

Other SEM Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Siemens

Siemens 3VA9978-0BF2 Series operating instructions

Xylem

Xylem Lowara Servitec Installation, operating and maintenance instructions

Felder

Felder G 200 operating manual

ABB

ABB HT842956 Operation manual

HEIDENHAIN

HEIDENHAIN LIDA 405 Mounting instructions

Siemens

Siemens 3VA9 1-0WD 0 Series operating instructions

Giacomini

Giacomini GE556-6 Series Datasheet / Operating Instructions

Omron

Omron V330-F Series Connection guide

Siebeck

Siebeck MK III Series Translation of the original operating manual

Edwards

Edwards FL20K instruction manual

Simplex

Simplex 4604-9201 Installation and configuration instructions

Excel Tire Gauge

Excel Tire Gauge PNEUTRONIC PNT-4 instruction manual