TABLE OF CONTENTS

1 Product overview............................................ 4

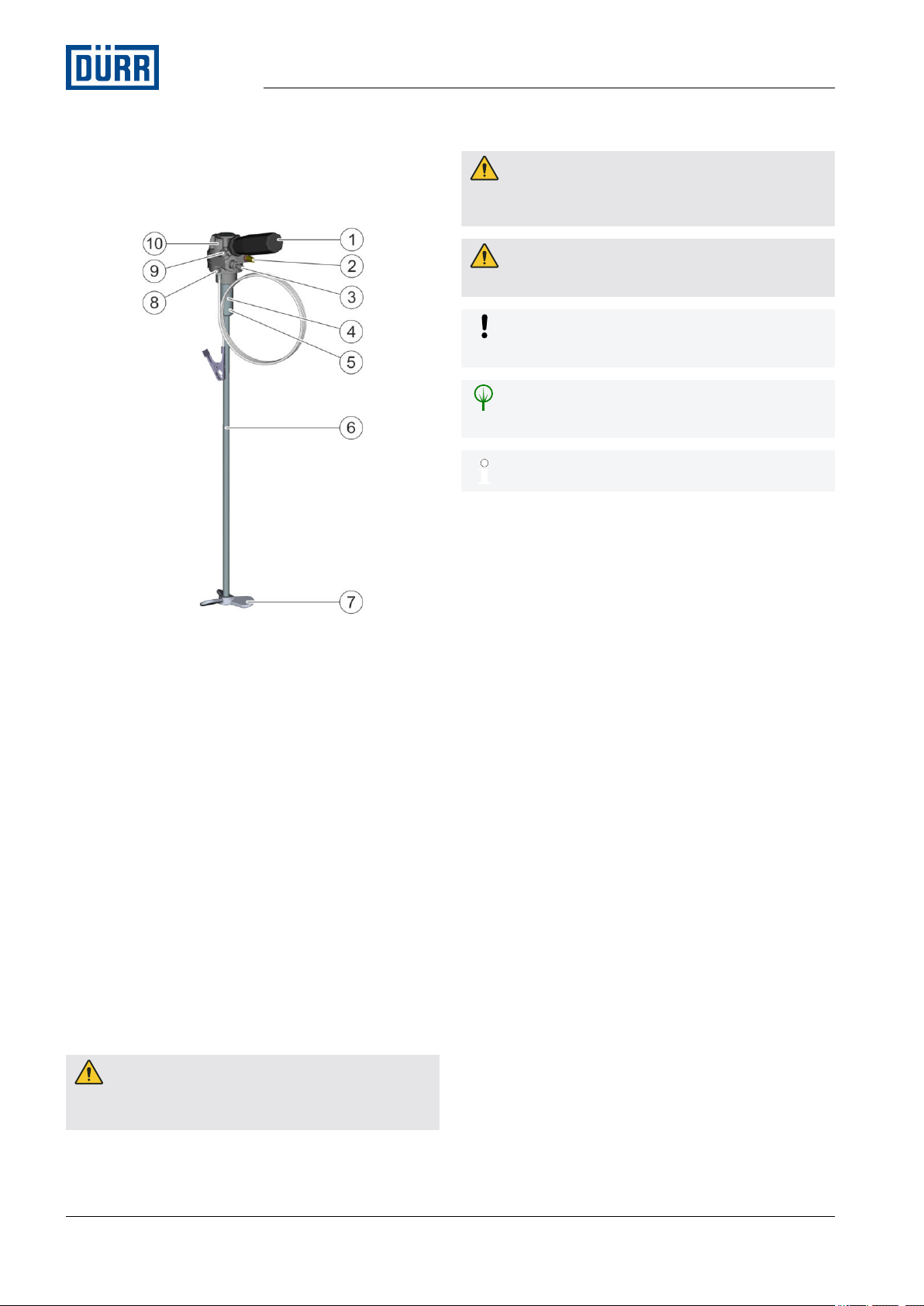

1.1 Overview.................................................. 4

1.2 Short description...................................... 4

2 Safety............................................................... 4

2.1 Presentation of Notes............................... 4

2.2 Intended Use............................................ 4

2.3 Residual risks........................................... 6

2.4 Property damage...................................... 6

2.5 Conduct in the event of a hazardous sit-

uation........................................................ 7

2.6 Staff qualification...................................... 7

2.7 Personal protective equipment................. 7

3 Design and Function...................................... 8

4 Transport, scope of supply and storage...... 8

4.1 Unpacking................................................ 8

4.2 Transport.................................................. 8

4.3 Scope of delivery...................................... 9

4.4 Storage..................................................... 9

5 Assembly......................................................... 9

5.1 Assembly.................................................. 9

5.2 Ground agitator...................................... 10

5.3 Assemble the compressed air hose....... 10

6 Operation....................................................... 11

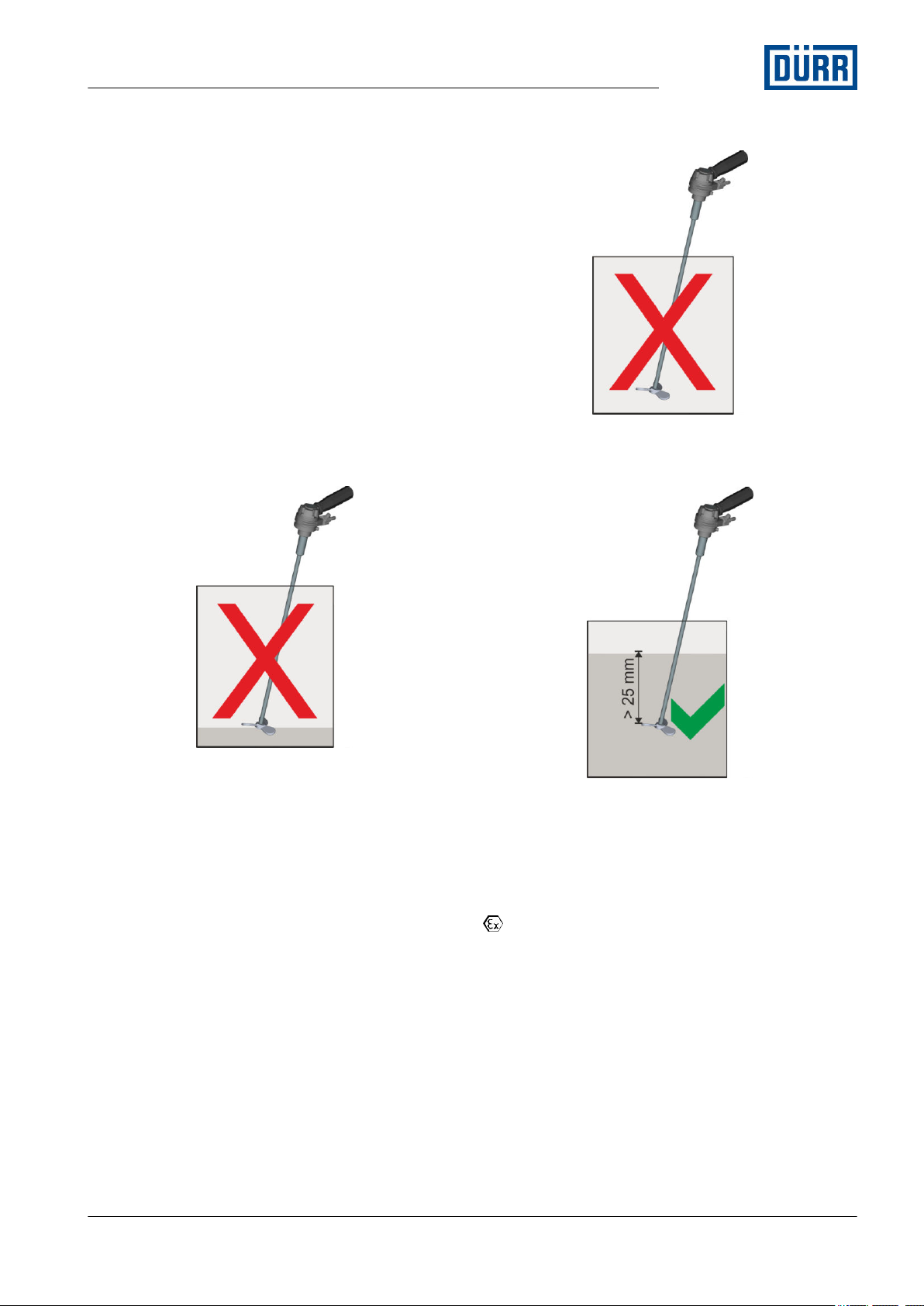

6.1 Safety recommendations........................ 11

6.2 General notes......................................... 12

6.3 Checks................................................... 12

6.4 Agitate.................................................... 13

7 Cleaning........................................................ 14

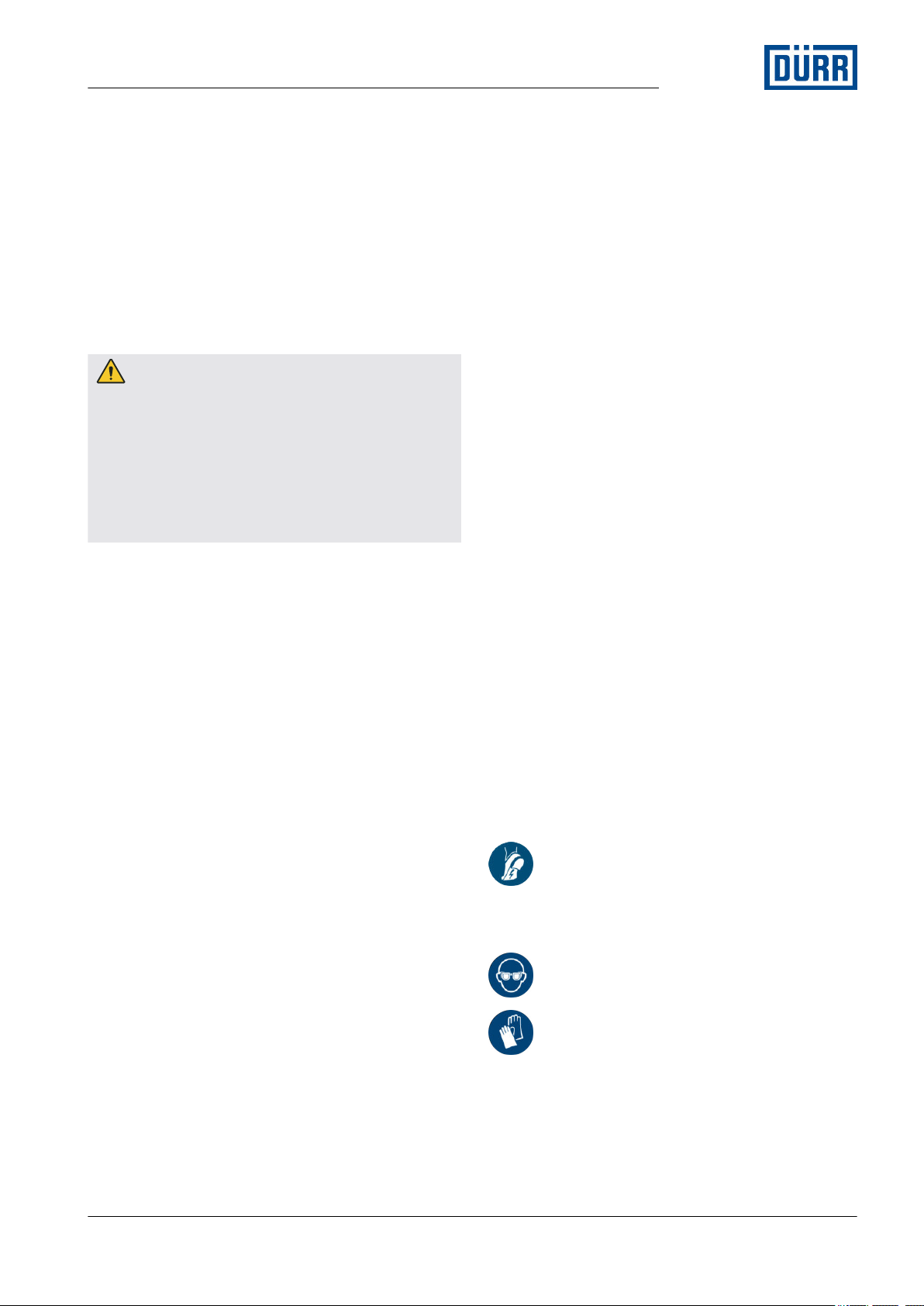

7.1 Safety recommendations ....................... 14

7.2 Overview................................................ 15

7.3 Manual cleaning..................................... 15

7.4 Cleaning container................................. 15

7.5 Cleaning bath......................................... 16

8 Maintenance.................................................. 17

8.1 Safety recommendations........................ 17

8.2 Maintenance schedule........................... 18

8.3 Lubrication schedule.............................. 18

8.4 Lubrication.............................................. 18

9 Faults............................................................. 19

9.1 Safety recommendations ....................... 19

9.2 Behavior during faults............................. 20

9.3 Defects table.......................................... 20

9.4 Troubleshooting...................................... 21

9.4.1 Replace agitator blade........................ 21

9.4.2 Replace agitator shaft......................... 21

9.4.3 Replace throttle valve.......................... 22

9.4.4 Replace pneumatic motor.................... 23

9.5 After troubleshooting.............................. 23

10 Disassembly and Disposal.......................... 23

10.1 Safety recommendations...................... 23

10.2 Disassemble compressed air hose...... 24

10.3 Disassemble ground conductor............ 24

10.4 Disposal ............................................... 24

11 Technical data............................................... 25

11.1 Dimensions and weight........................ 25

11.2 Connections.......................................... 25

11.3 Operating conditions............................. 25

11.4 Emissions............................................. 25

11.5 Operating values.................................. 25

11.6 Compressed air quality......................... 26

11.7 Type plate............................................. 26

11.8 Materials used...................................... 26

11.9 Operating and auxiliary materials......... 26

11.10 Material specification............................ 26

12 Spare parts, tools and accessories............ 27

12.1 Spare parts........................................... 27

12.2 Accessories.......................................... 28

12.3 Order.................................................... 28

13 Index.............................................................. 29

02/2022 Pneumatic Agitator A MAN R PR SE2 - MAG00007EN 3/32