TABLE OF CONTENTS

1 Product overview...................................... 6

1.1 Overview............................................. 6

1.2 Short description................................. 6

2 Safety.......................................................... 6

2.1 Presentation of Notes.......................... 6

2.2 Intended Use....................................... 6

2.3 Safety signs......................................... 7

2.4 Staff qualification................................. 7

2.5 Personal protective equipment............ 8

3 Design and Function................................. 8

3.1 Design................................................. 8

3.2 Front.................................................... 9

3.3 Rear..................................................... 9

3.4 Interior view......................................... 9

3.5 Profibus PA.......................................... 9

3.6 Pneumatic unit................................... 10

4 Transport, scope of supply and

storage..................................................... 10

4.1 Unpacking......................................... 10

4.2 Scope of delivery............................... 11

4.3 Handling of packaging material......... 11

4.4 Storage.............................................. 11

4.5 Transport........................................... 11

5 Assembly.................................................. 11

5.1 Safety recommendations................... 11

5.2 Assembly........................................... 11

5.2.1 Insert battery................................... 11

5.2.2 Assembling the display unit............ 12

5.3 Connecting........................................ 13

5.3.1 Grounding the display unit.............. 13

5.3.2 Connect reed switch....................... 13

5.3.3 Connecting the power supply......... 14

5.3.4 Connect compressed air supply..... 14

6 Visualizer.................................................. 15

6.1 Controls and displays........................ 15

6.2 Menus................................................ 16

6.2.1 Overview........................................ 16

6.2.2 Main menu...................................... 17

6.2.3 Actual parameter............................ 17

6.2.4 Set parameter................................. 17

6.2.5 Maintenance................................... 20

7 Commissioning....................................... 21

7.1 Safety Instructions............................. 21

7.2 General notes.................................... 21

7.3 Commissioning.................................. 21

7.3.1 Setting operating parameters ........ 21

8 Operation................................................. 22

8.1 Safety recommendations................... 22

8.2 General notes.................................... 22

8.3 Switching on...................................... 22

8.4 Switching off...................................... 22

8.5 Voltage check.................................... 22

8.6 Bleed pump....................................... 23

9 Cleaning................................................... 23

9.1 Safety recommendations .................. 23

9.2 Cleaning............................................ 24

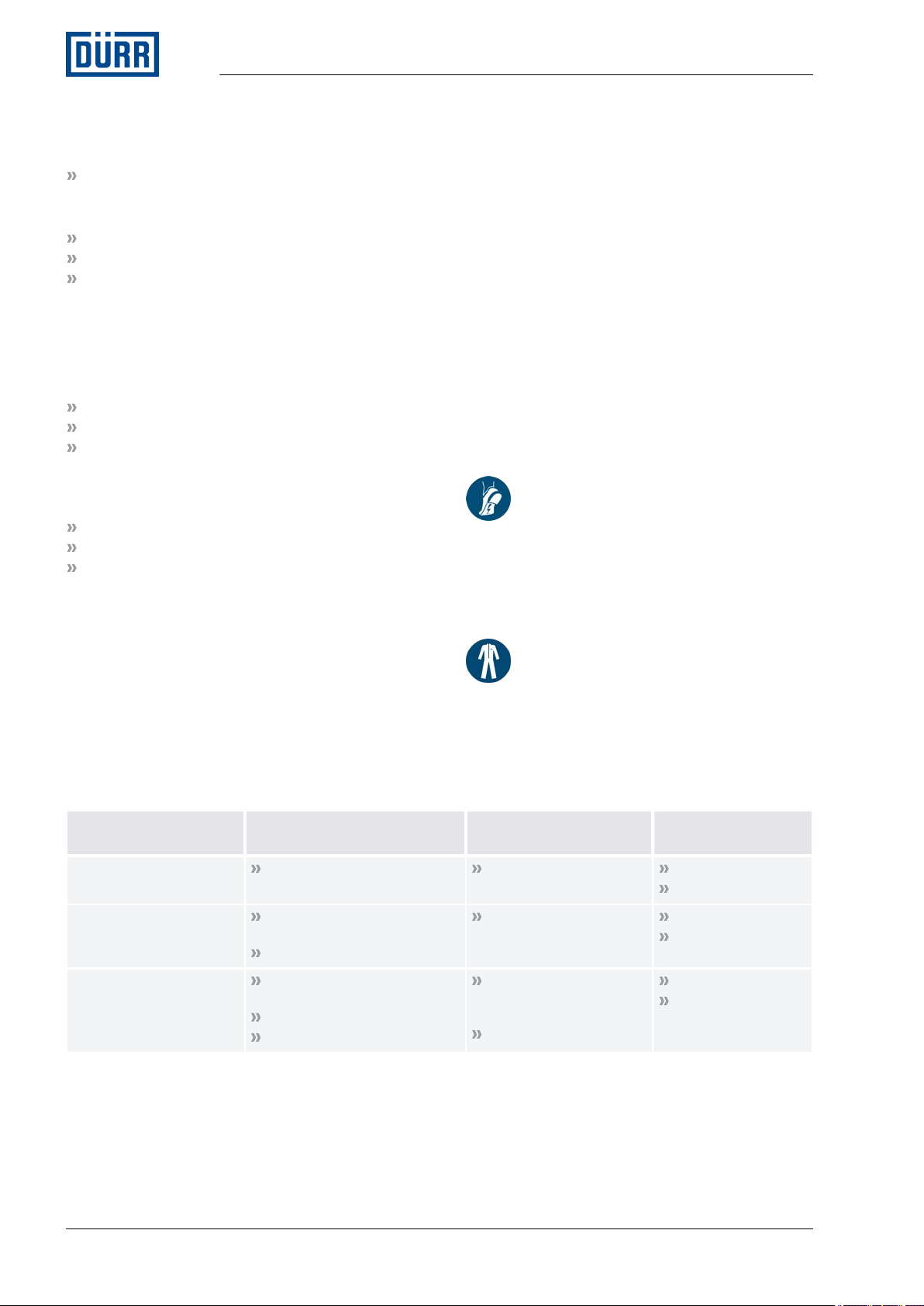

10 Maintenance............................................. 24

10.1 Safety notes.................................... 24

10.2 Maintenance schedule.................... 24

11 Faults........................................................ 24

12 Disassembly and Disposal..................... 25

12.1 Safety recommendations................. 25

12.2 Disassembly.................................... 25

12.2.1 Disconnect compressed air

supply........................................... 25

12.2.2 Disassembling reed switch........... 25

12.2.3 Disassembling Profibus PA.......... 26

12.2.4 Assemble display unit................... 26

12.2.5 Remove battery............................ 27

12.3 Disposal .......................................... 28

13 Technical data.......................................... 28

13.1 Dimensions and weight................... 28

13.2 Connections.................................... 28

13.3 Operating conditions....................... 28

13.4 Operating values............................. 29

13.5 Compressed air quality.................... 29

13.6 Type plate........................................ 29

13.7 Operating and auxiliary materials.... 29

14 Replacement parts, tools and accesso-

ries............................................................ 29

14.1 Replacement parts.......................... 29

14.2 Tools................................................ 29

14.3 Accessories..................................... 30

14.4 Order............................................... 30

15 Index......................................................... 31

Appendix.................................................. 34

A Profibus data exchange....................... 35

B Profibus process data.......................... 36

C Profibus standard parameters............. 38

12/2018EcoPUC A - MCU00002EN4/40