Table of contents

Introductory information.....................................................4

Target group of these operating instructions.....................4

Special qualifications and regulations...............................5

Meaning of symbols..........................................................6

Field of use of the stud welding equipment ......................7

Features of the stud welding equipment...........................7

Safety information ...............................................................8

Installation and connection ..............................................12

Checking scope of delivery.............................................12

Choosing place of installation.........................................13

Transport.........................................................................13

Connection......................................................................14

Setting-up equipment and welding gun...........................15

Connecting earth cables to work piece...........................15

Setting-up welding gun...................................................15

Adjusting equipment .......................................................20

Welding...............................................................................21

Tips for stud welding.........................................................22

Studs, chucks and ceramic ferrules................................22

Adjustments....................................................................22

Avoiding magnetic blowing action...................................24

Vertical weldings.............................................................25

Checking weld joints.......................................................26

Cleaning and attendance ..................................................28

Maintenance.......................................................................29

Blowing out equipment interior .......................................29

Checking plugs and cables.............................................30

Eliminating faults...............................................................31

Technical data ....................................................................32

Guarantee...........................................................................33

Where to put the old equipment.......................................34

Certificate of EC-conformity.............................................35

Index....................................................................................36

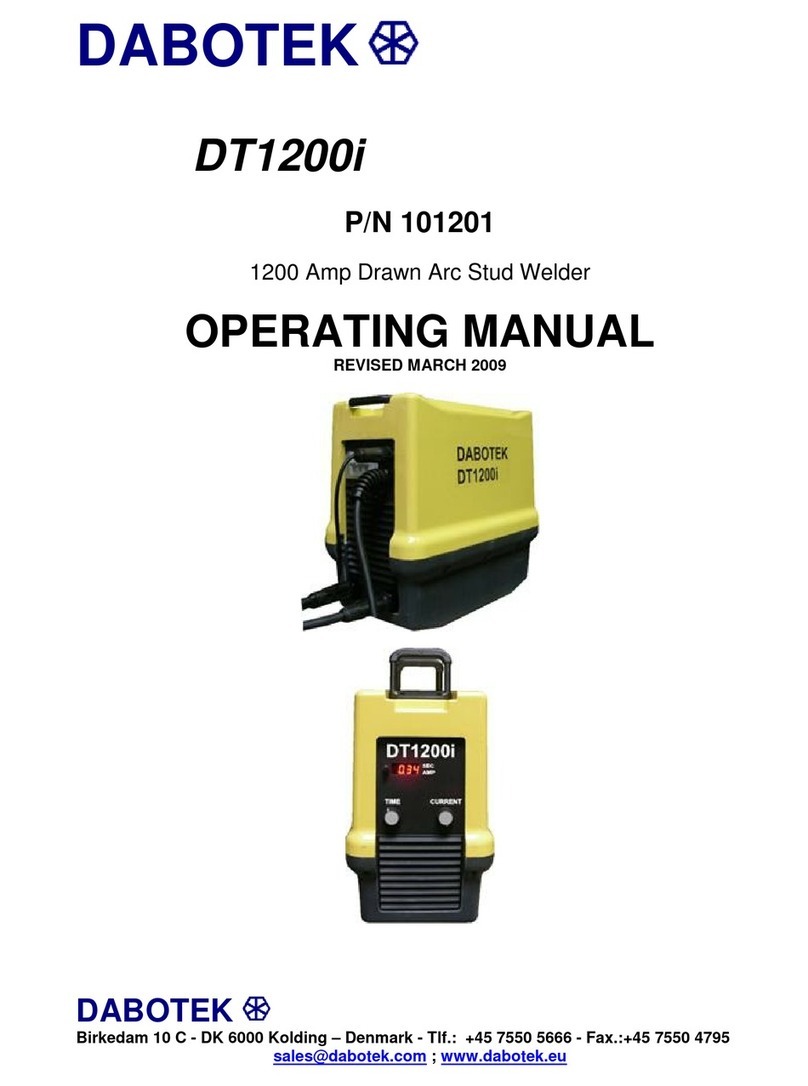

Your equipment in overview .............................................39

After-sales service.............................................................40

Tip:

Ifyouunfoldthelast

page you will find an

overview of the

equipment.

3