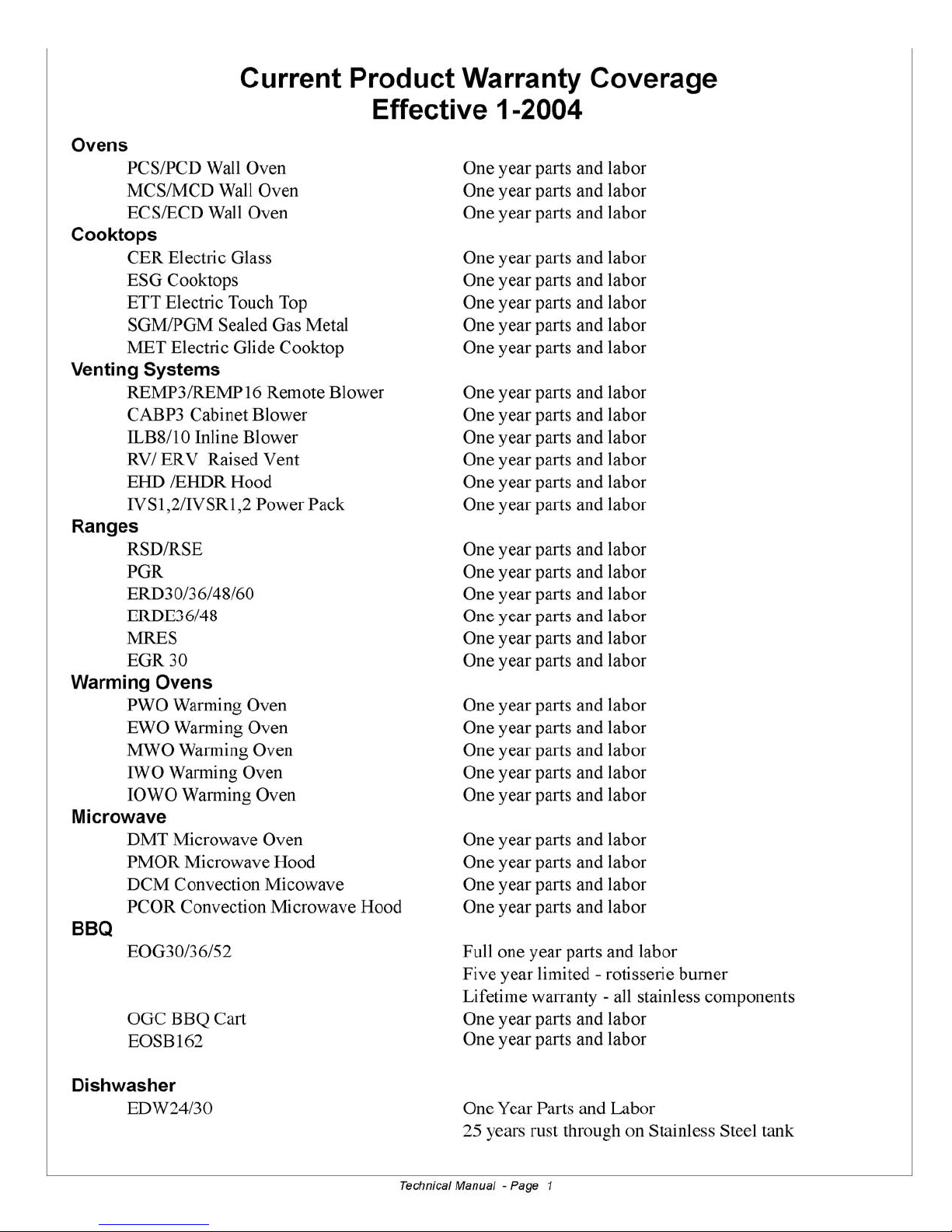

Technical Manual - Page 2

POLICIES

AND

PROCEDURES

Product UL label location

CABP3 UL marking is on the serial number label attached to the housing cover next to the access plate.

DMO UL marking is on the serial number label inside the oven against the left wall. To view, open the oven door.

EHD UL marking is on the serial number label located in the rear panel. To view, remove the filters.

ERD30S06 UL marking is in the Rating Label located in the left side of the kick panel. To view, open the door.

UL label is also in the serial number located inside the unit in the right hand side wall. To view, look

through the intake grill slots.

ERSD30 UL marking is in the Rating Label located in the left side of the kick panel. To view, open the door.

UL label is also in the serial number located inside the unit in the right hand side wall. To view, look

through the intake grill slots.

ERSD36 UL marking is in the Rating Label and serial number label located in the wall behind the door latch. To

view, open the oven door and look through the intake grill slots.

ERSD48 UL marking is in the Rating Label and serial number label located in the wall behind the door latch of the

36” oven. To view, open the 36” oven door and look through the intake grill slots.

ESG UL marking is in the Rating Label located in the back of the unit right behind the left rear burner.

ETT/CER UL marking is on the serial number label located on the bottom of the unit next to the electrical connection.

MODULES. UL marking (if any), is on the serial number label located in the opposite side of the electrical connection

(beneath the handle).

PGR UL marking is on the front of the front case top. To view, open the oven door and look through the

intake grill slots.

REMP3 UL marking is on the serial number label attached to the main housing wrap behind the protective rack

left of the access plate.

RSD UL marking is in the Rating Label and serial number label located inside the storage compartment at the

left hand side wall.

RSE UL marking is on the serial number label located inside the storage compartment at the left hand side wall.

RV UL marking is on the serial number label located in the front plenum above the access panel.

SGM/SGMEM UL marking is in the Rating Label underneath of unit next to gas connection. For SGM’s only the UL

marking is also on the serial number label located next to the rating label.

WALL OVENS.

DOUBLE OVENS UL marking is on the serial number label located inside the intake grill, at the left hand side of the door

latch. To view, open the upper door and look through the slots of the intake grill.

SINGLE OVENS UL marking is on the serial number label located inside the intake grill, at the left hand side of the door

latch. To view, open the door and look through the slots of the intake grill.

WARMING OVENS UL marking is on the serial number label located at the bottom of the cabinet at the left hand side. To view,

the drawer must be pulled completely open or removed.