1. Completely unpack the Mini Melter and identify:

1 melting grid,

1 uncapping cross bar,

1 small perforated screen,

1 large perforated screen,

1 adjustable honey outlet assembly.

1 200OW immersion heater and

1 elbow/nut assembly

2. A third screen should be located in the honey

baffle/honey outlet of the tank.

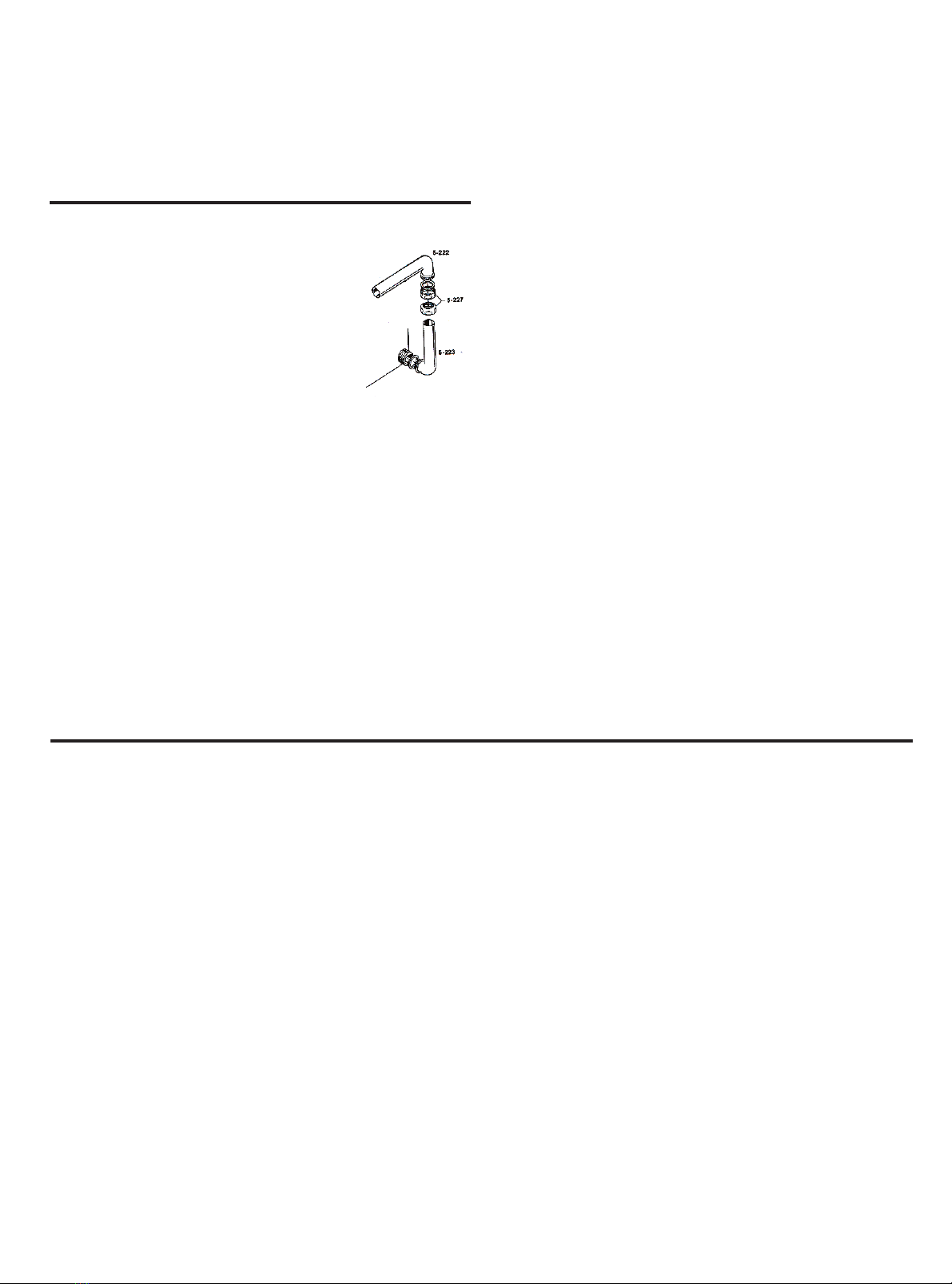

3. Assemble the adjustable honey outlet tube as

shown in the diagram and attach to the tank.

(Refer to photo on cover.)

4. If uncapping with a hand knife, attach the uncap-

ping cross bar to the exposed edges of the tank

and tank baffle respectively. (Bar is not needed if

power uncapping.)

5. Place grid in tank on grid rests (See photo on

cover.)

6. Install small perforated screen over wax outlet.

(This screen prevents foreign material from flow-

ing through wax outlet.)

7. The large perforated screen is for slum removal.

8. In the tank water drain outlet, a 1'' plug has

already been installed.

9. Using a good pipe thread compound, install the

immersion heater in the 1'' female tank port.

10. The elbow/nut assembly with gasket is the water

fill pipe. Attach it to the 1 ½'' pipe thread nipple

extending from the tank and tighten in a vertical

position.

The cappings resulting from frames of honey being uncapped con-

sist of honey, beeswax, and foreign material. Dadant's Mini Melter

was designed to separate these cappings into pure honey, quality

(undamaged) beeswax and foreign material (slum). When properly

operated, best honey experts are unable to determine which honey is

or is not melter honey, and wax tests show the highest quality wax.

The cappings melter is a great labor saving piece of equipment as cap-

pings are continually processed while uncapping is being done. At the

day's end, all the day's cappings have been processed. The pure honey

is in storage, the extra fine beeswax is in cakes, and the slum is bar-

reled. No extra steps are required.

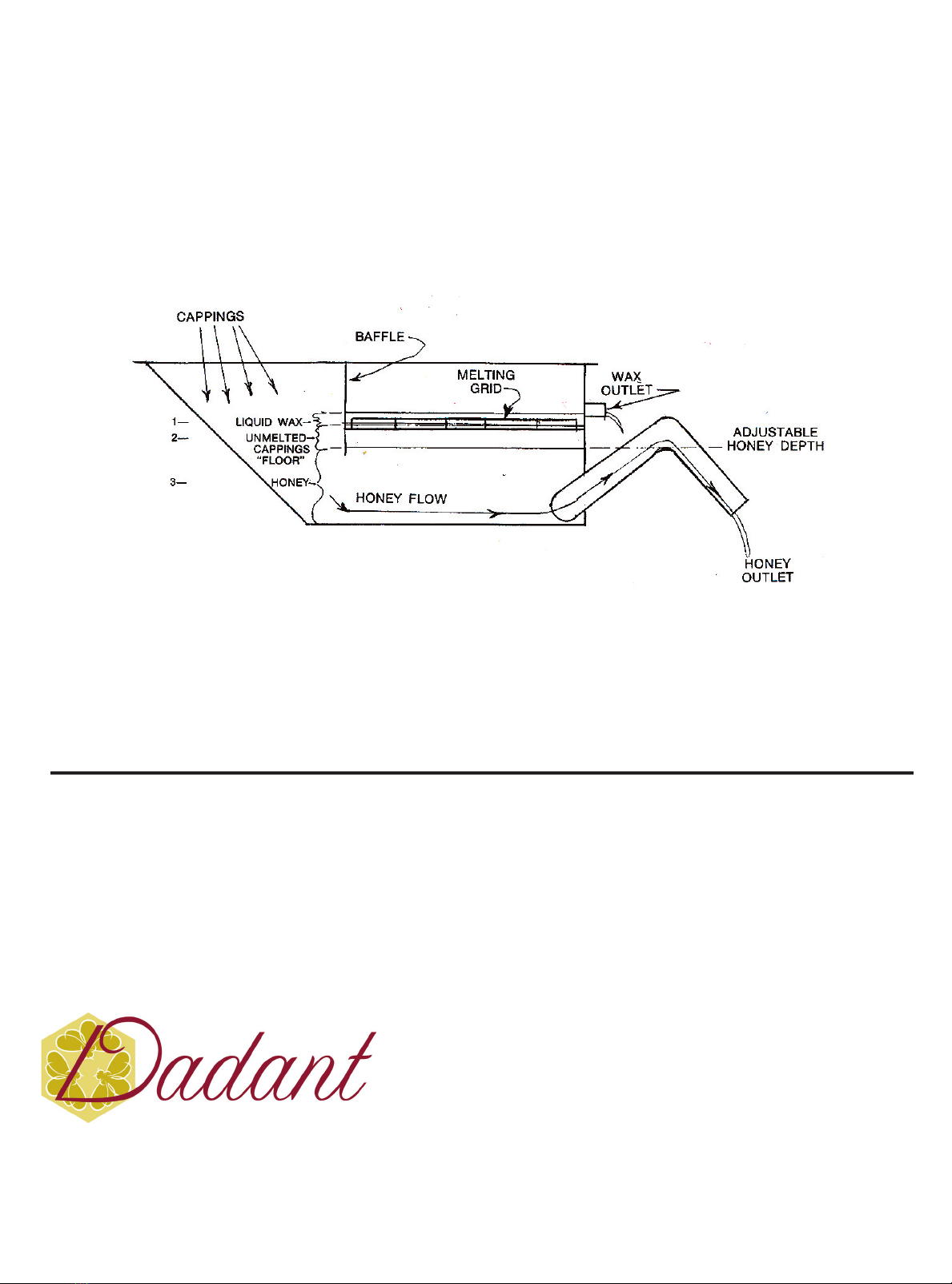

The cappings drop into the hopper area and flow under the melt-

ing grid. When the cappings begin to flow through the melter, separa-

tion of honey and wax occurs. The honey, being the heaviest, settles

to the bottom of the tank and the wax particles and foreign material

float on the honey. On those waterjacketed units, the heat from the

warm water in the waterjacket, speeds this separation process. As the

wax particles float on the honey, they come in contact with the melt-

ing grid and are melted. A pool or layer of melted wax entirely covers

the melting grid. As the cappings float to the surface a great bulk of

the wax particles are now melted by coming into contact with this

layer of melted wax. As the quantity of melted wax increases, it flows

out of a wax outlet. Meanwhile, the honey that has been separating

from the wax flows along the bottom of the tank, under the honey baf-

Assembly

Operation

Dadant Mini Melter

fle, and flows out of the melter through an adjustable honey outlet.

This honey outlet maintains the honey level in the tank, thereby hold-

ing the unmelted wax particles up against the melting grid as they float

on the honey. As the unmelted wax particles continue to rise, the for-

eign material (slum) is carried upward and collects on top of the

unmelted cappings just below or in the melted wax. The slum is peri-

odically removed (usually once an hour) with the larger perforated

screen that was supplied with the Mini Melter. Refer to the diagram

and please note the liquid levels and visualize how the setting of the

adjustable honey tube is the key to maintaining proper operation.

For most operating conditions, the honey outlet tube is adjusted to

a level that allows honey to flow out of the tube when honey level in

the tank is 1'' below the bottom of the melting grid. This 1'' allows for

the layer of unmelted cappings to be maintained which in turn holds

the foreign material (slum) up thus preventing the slum stain from fil-

tering through and discoloring the honey. During operation, it is

important to maintain this "floor" of unmelted cappings. This floor

depth may be "felt" by pushing a thin board between the melting grid

bars down through the liquid levels and "feeling" the depth of unmelt-

ed cappings by noting the resistance to pushing the board. The elec-

tric grids make heat control extremely easy as the electric grid has a

very sensitive thermostat control that is easily adjusted. The heat sup-

ply should be regulated so as to keep a "floor" of unmelted cappings

under the hot liquid wax yet keep the bottom of the tank from plugging

D/Manuals/Mini Melt/Mini Melt-7/99