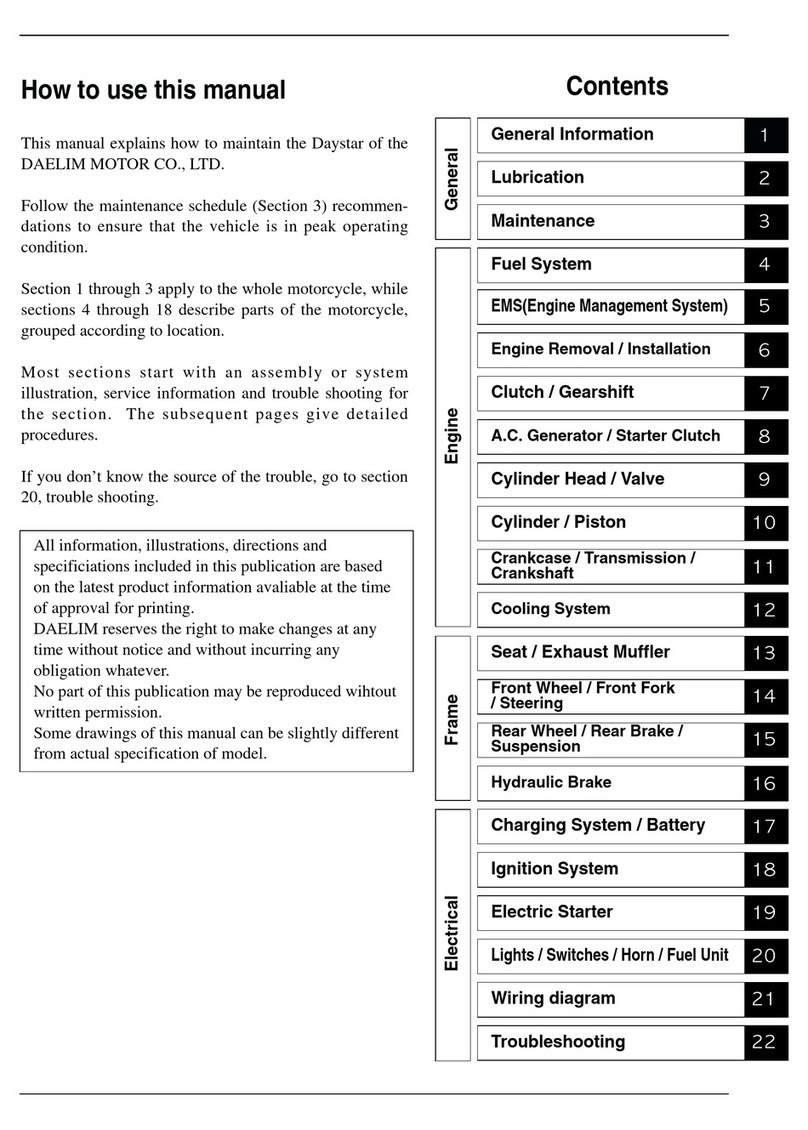

SYMBOL SYMBOLMEANING MEANING

Indicates dangerous areas.

Serious accidents may result if instructions are not

followed.

Indicates important work. Minor injury or vehicle part damage

may result if instruction are not followed

Indicates general cautions. Provides safety and

appropriate handling procedures.

The following symbols are used in this manual to represent job-related warnings or cautions

The following abbreviations are used in this manual.

ASS’Y

LH.

RH.

Assembled part

Left

Right

In case of special greases not written on above, they have not any specific symbols.

Indicates oil applying. If there is no specific oil indicated, use the designated or recommended engine oil

Indicates molybdenum solution applying. Molybdenum solution is made by mixing engine oil and molybdenum

grease as 1:1 mixing ratio.

Indicates to apply grease(NLG 1#2)

Indicates to apply molybdenum grease(Containing more than 30% molydenum disulfide, NLG 1#2 or equivalent)

Indicates to apply molybdenum best(Containing more than 40% molydenum disulfide, NLG 1#2 or equivalent)

Indicates to apply silicone grease.

Indicates to apply ointment onto screw lock.

If not designated, use medium strength one.

Indicates to seal

Indicates the replacement part as new one whenever disassembly

Indicates to apply brake fluid. Use the recommended one(DOT3 or DOT4)

Indicates to apply the recommended oil

Indicates to use special tools

Indicates to use optional tools. Because this kind of tool is dealt as spare part, refer to the parts list to check the correct

tool number.

Indicates the reference. For left example, indicates the reference 3-1.

( 3-1)

SYMBOLS /ABBREVIATIONS

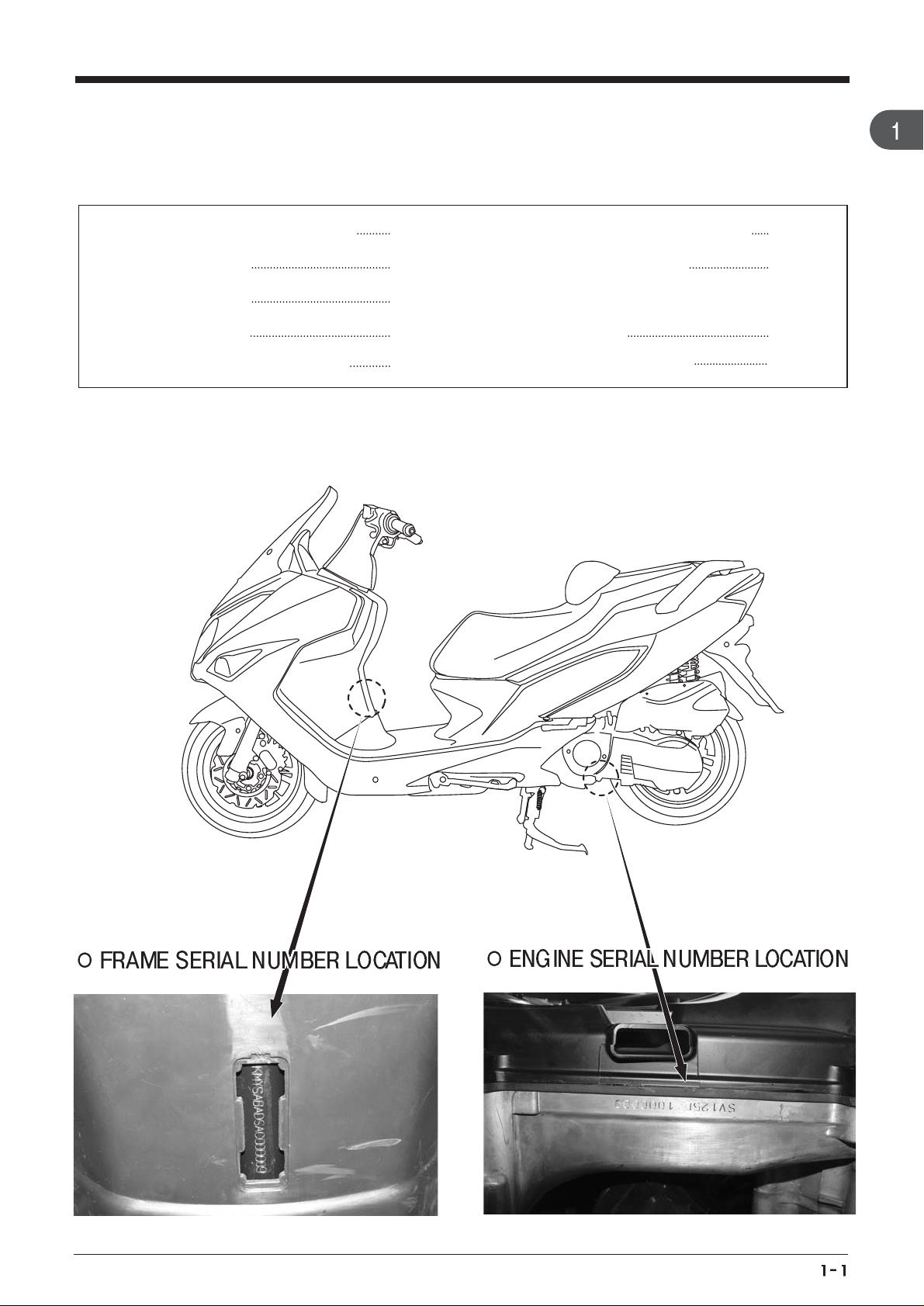

SERVICE INFORMATION

WARNING WARNING

WARNING