1

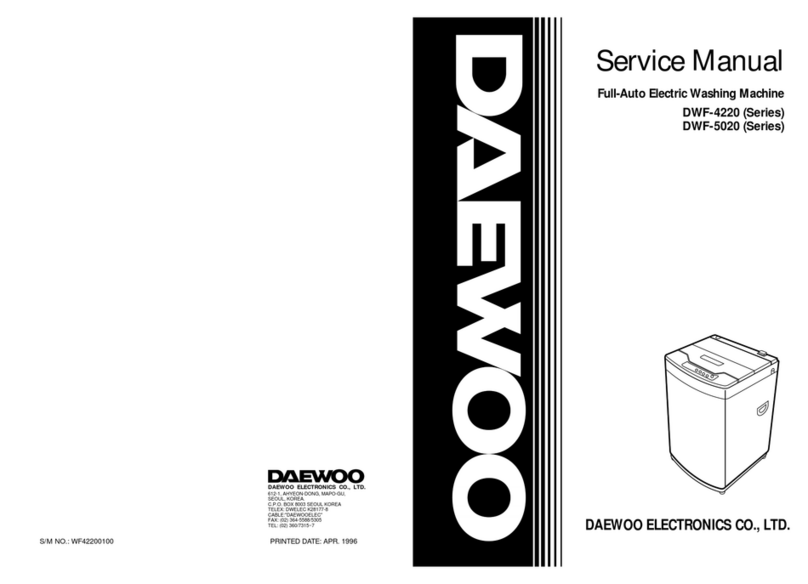

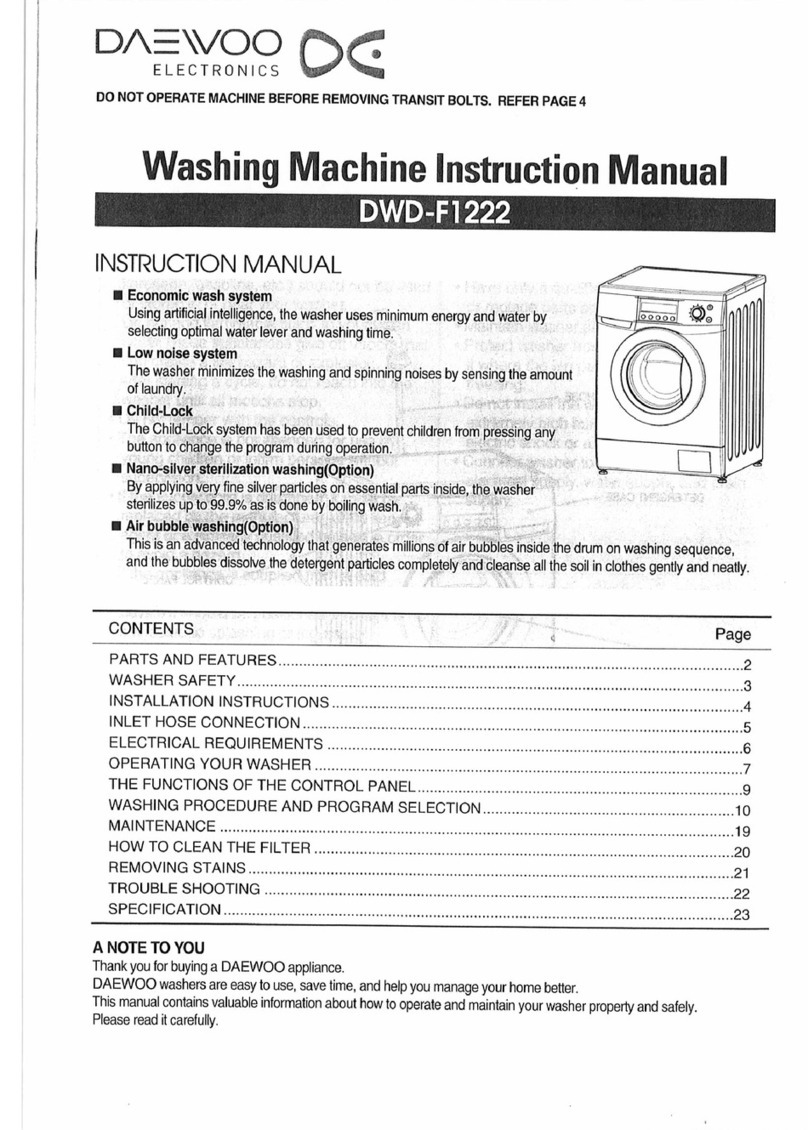

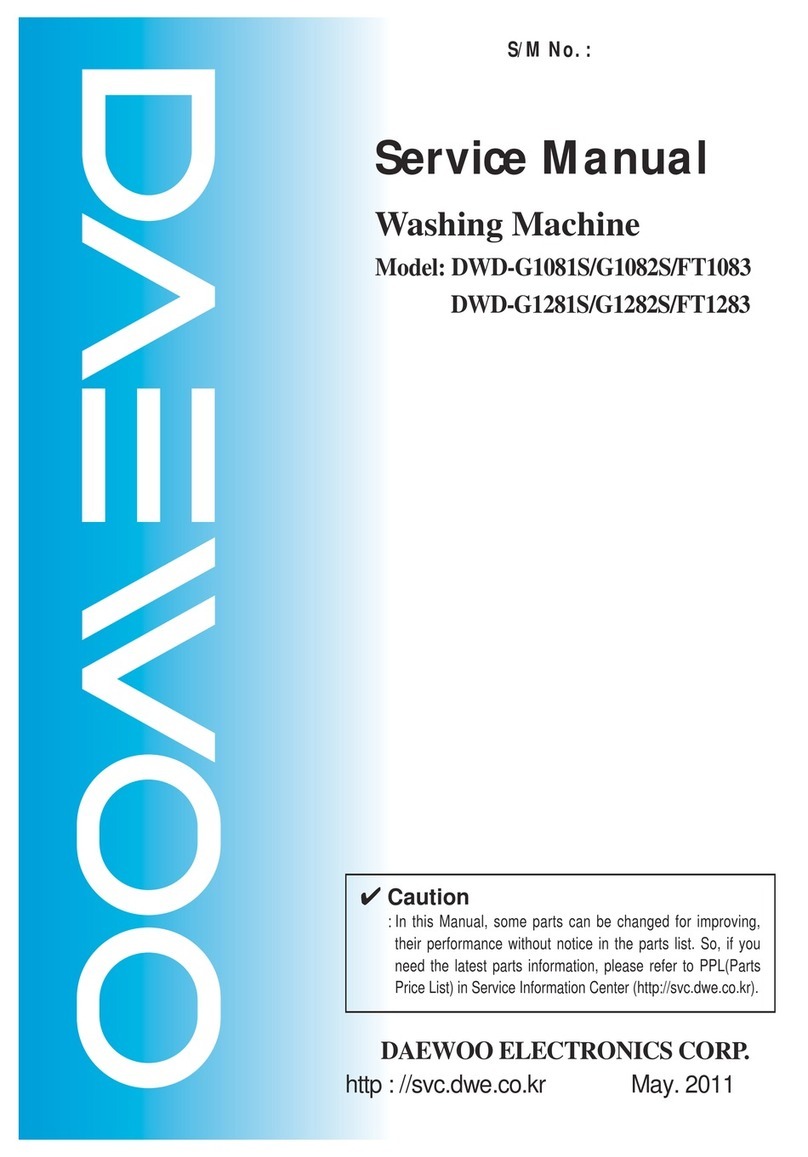

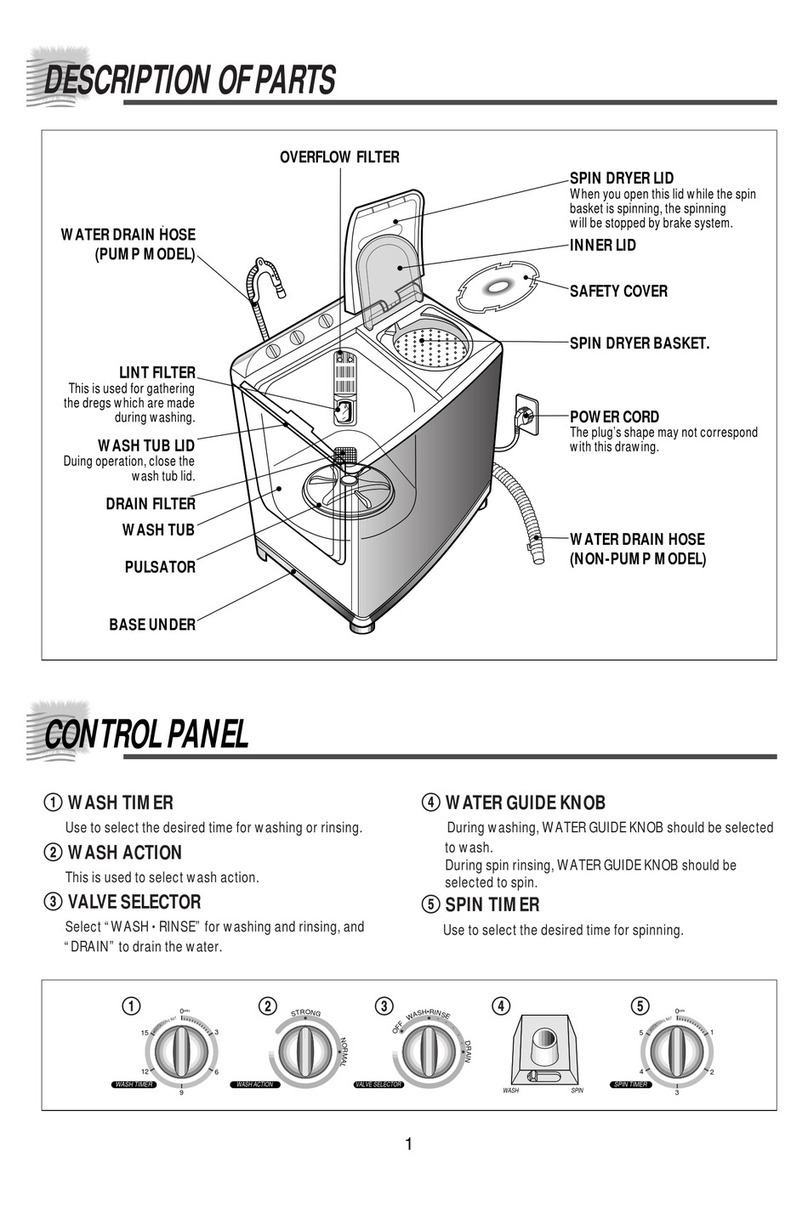

CONTROL PANEL

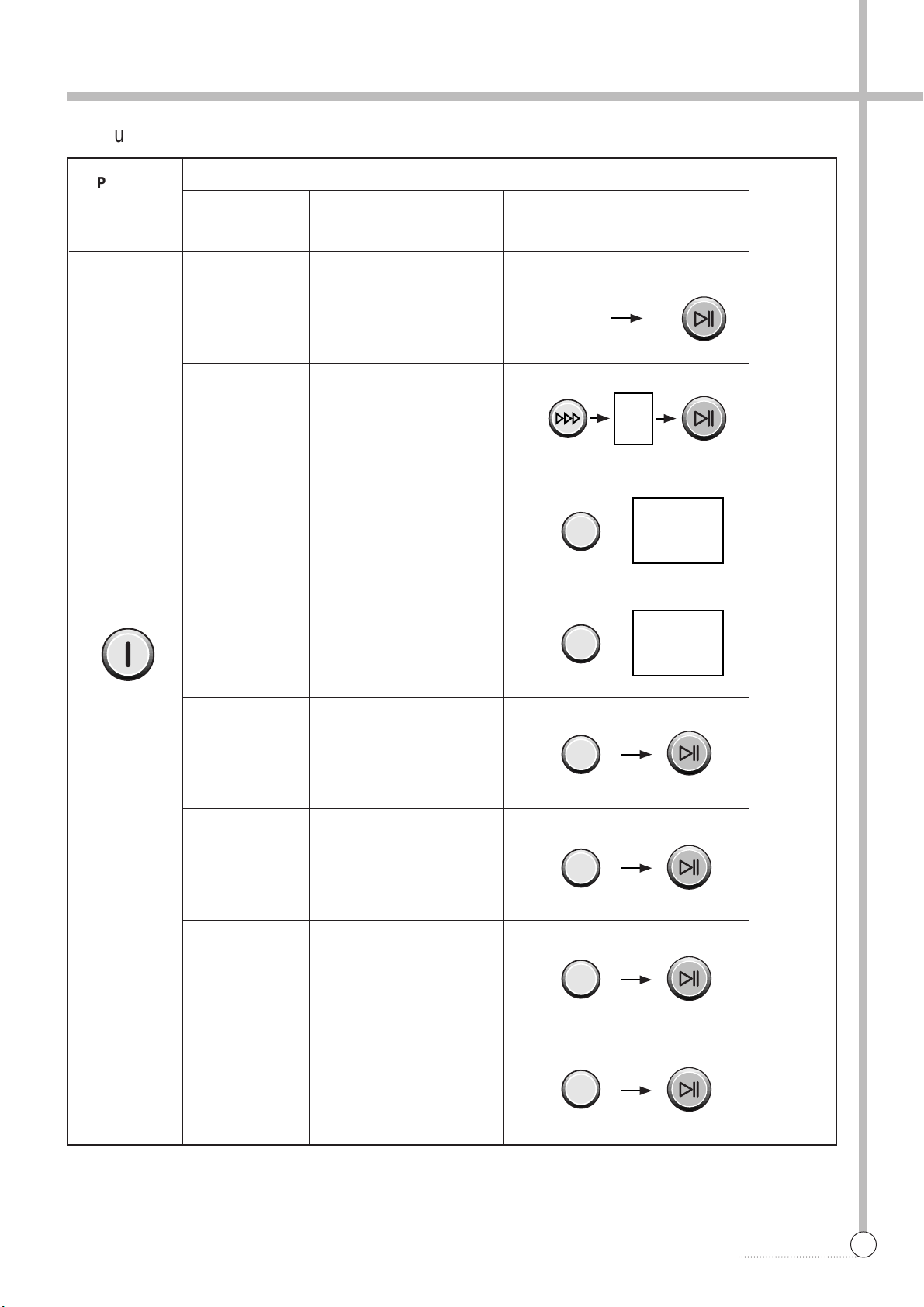

3. FUNCTIONS OF THE CONTROL PANEL

TIME DISPLAY

• The lamps easily indicate the

option selection of washing

program and process by letters.

START/HOLD BUTTON

• Operation and temporary stop

are repeated as it is pressed it

will be repeated¡‚Operation¡„,

¡‚Temporary stop¡„according to

the one time pressing or two

times pressing.

When you want to change

course in operating;

- Press the S/H button.

- Select the course that you

want to change.

- Press the S/H button again!

WASH TEMPERATURE

SELECTOR

• It can be used to choose water

temperature to be supplied.

• As the button is pressed, it will

be repeated following sings ;

COLD ¤AHOT ¤AWARM

• In case of the single valve

model, there is no water

FEED

• In case of the pump model,

there is no FEED function.

TEMP. : TEMPERATURE

WARM :

COLD+HOT WATER

COLD : COLD WATER

HOT : HOT WATER

WATER LEVEL SELECTOR

• It can be used to adjust amount

of water according to the size of

the load to be washed.

• As the button is pressed. Water

level is selected by

H.¤AM.¤AL.¤AS.¤AE.S

LEVEL. : WATER LEVEL

H. : HIGH LEVEL

M. : MIDDLE LEVEL

L. : LOW LEVEL

S. : SMALL LEVEL

E.S. : EXTRA SMALL LEVEL

COURSE SELECTOR

• It can be used to select the full-

automatic course.

• As the button is pressed, it will be

selected following order:

MEM.¤ADRY¤ASILK¤AECO.¤A

STRO.¤ANIGHT¤ABLAN¤AFUZZY

COURSE

MEM : MEMORY

DRY : DRY

SILK : SILK

ECO. : ECONOMICAL

STRO. : STRONG

NIGHT : NIGHT

BLAN : BLANKET

FUZZY : FUZZY

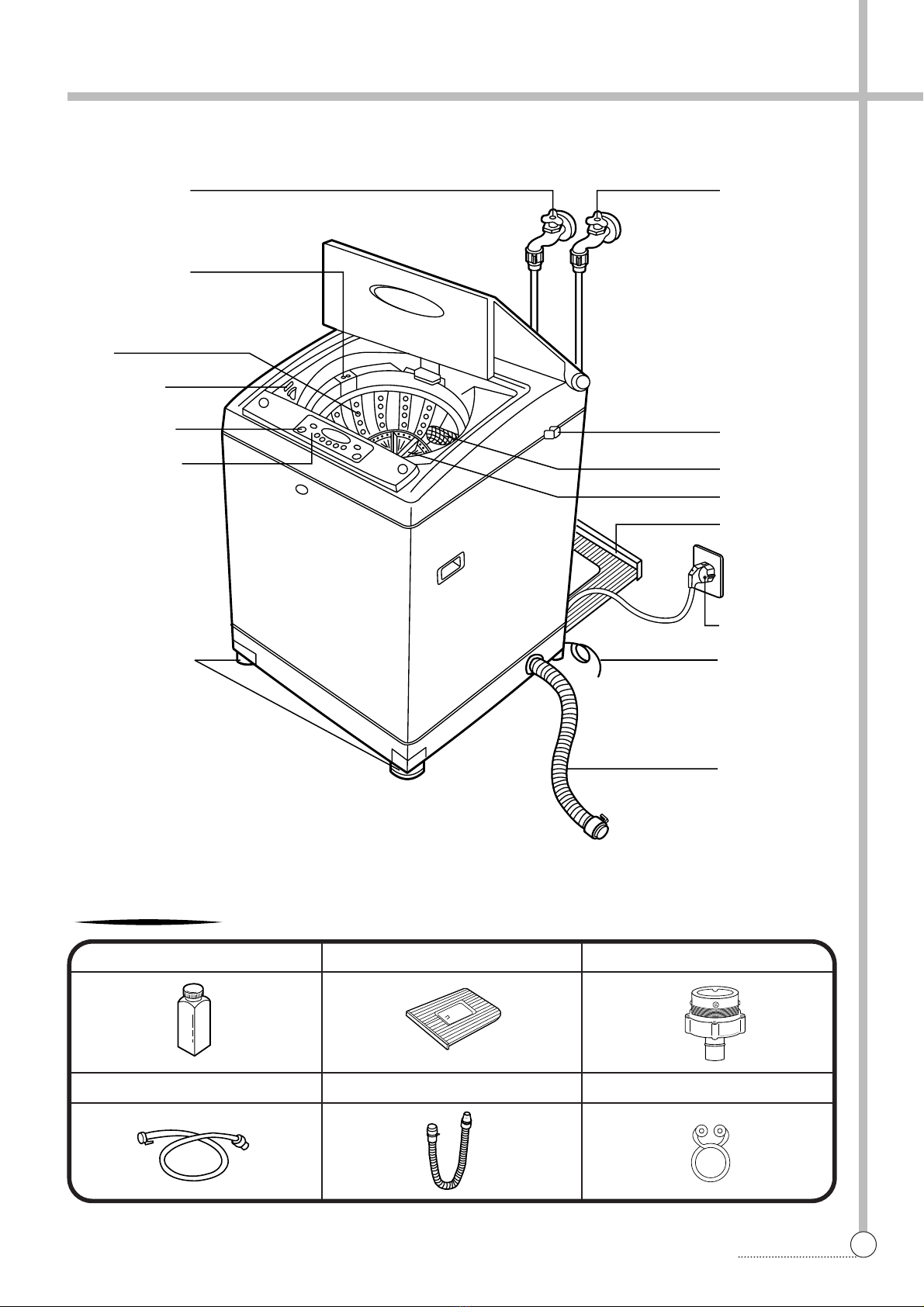

ALL AUTOMATIC WASHER

AERO FUZZY & AIR POWER

POWER START/

HOLD

CANCEL WASH RINSE SPIN

COURSE

WATER LEVEL

WASH TEMP.

1

4

6

10 359

1

2

3

4

5

12

14 18

FUZZY MEM. DRY

SOAK

FEED

SILK ECO. STRO. NIGHT BLAN

WASH

RES.

RINSE

SPIN

HOUR

MIN.

TIME

H.

M.

L.

S.

E.S

WARM

COLD

HOT

RES.

HOW TO USE SWITCH

• Press this Switch to turn the

power ON or OFF .

After turning OFF the power,

wait for more than 3 seconds

and then turn it ON again.

It has micom sensor.

As the buttons are pressed, the

lamps indicating the selection

of you desired washing

program will light up.

PRE-ENGAGEMENT

• It can be used to pre-engage

time for wash

BUTTON FOR PROGRAM

CANCEL

• It can be used to cancel the full-

automatic course.

• When the button is pressed the

display will be light down. If you

want to wash, rinse or spin, you

can press one of the button.

WASHING TIME

• It can be used to adjust washing

time

• As the button is pressed, you’ll

see the repeated.

4¤A6¤A10¤A12¤A14¤A18¤A

SOAK.

RINSE TIME SELECTOR

• This button selects the number

or times you want to rinse.

• As the button is pressed, it will

be repeated

* Non-pump Model

¤A1 time rinse ¤A1 times feed

¤A2 time rinse ¤A2 times feed

¤A3 time rinse ¤A3 times feed

¤A4 time rinse ¤A4 times feed

¤A5 time rinse ¤A5 times feed

* Pump Model

¤A1 time rinse ¤A2 times rinse

¤A3 times rinse ¤A4 times rinse

¤A5 times rinse

SPIN TIME SELECTOR

• It can be used to change spin

time.

• As the button is pressed, it will

be repeated

1¤A3¤A5¤A9 signs.

Rinse : Normal Rinse

Feed : Feed Rinse

Control Panel