Table of contents

Installation and operation manual

3

SV1A25AJV1B+SV4~8A14AJV1B

VRV 5 safety valve unit

4P709466-1 – 2023.09

Table of contents

1 About this document 4

2 Specific installer safety instructions 4

2.1 Instructions for equipment using R32 refrigerant ...................... 6

For the user 7

3 User safety instructions 7

3.1 General...................................................................................... 7

3.2 Instructions for safe operation ................................................... 7

4 About the system 9

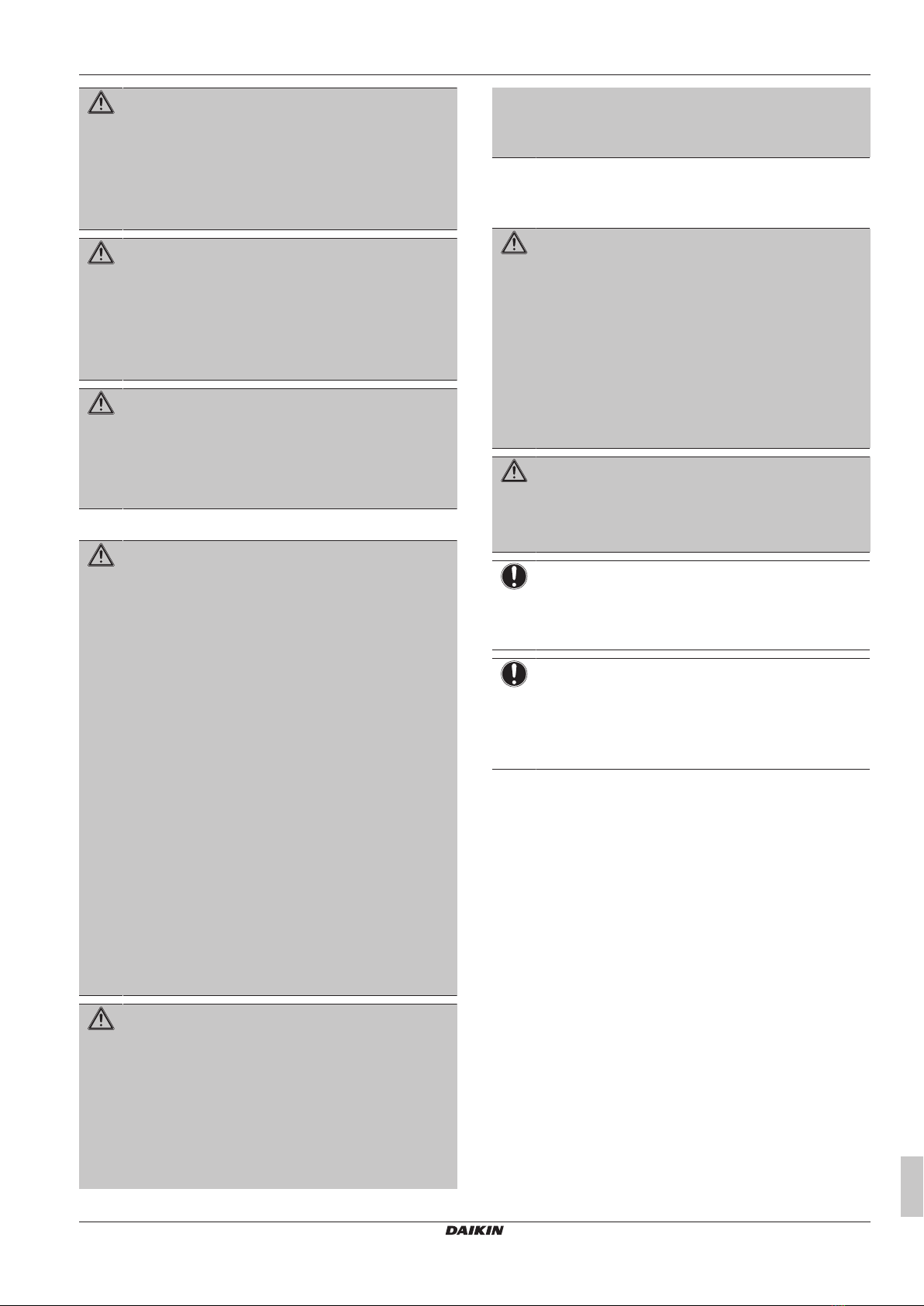

4.1 System layout............................................................................ 10

5 Before operation 10

6 Maintenance and service 10

6.1 Precautions for maintenance and service ................................. 10

6.2 About the refrigerant.................................................................. 10

6.2.1 About the refrigerant leakage sensor.......................... 10

7 Troubleshooting 11

7.1 Symptoms that are NOT system malfunctions .......................... 11

7.1.1 Symptom: noise .......................................................... 11

8 Relocation 11

9 Disposal 11

For the installer 12

10 About the box 12

10.1 To remove the accessories ....................................................... 12

11 About the unit and options 12

11.1 Identification .............................................................................. 12

11.1.1 Identification label: SV unit.......................................... 12

11.2 About the operation range......................................................... 12

11.3 System layout............................................................................ 12

11.4 Combining units and options ..................................................... 13

11.4.1 Possible options for the SV unit.................................. 13

12 Special requirements for R32 units 13

12.1 Installation space requirements................................................. 13

12.2 System layout requirements...................................................... 13

12.3 To determine the required safety measures.............................. 14

12.3.1 Overview: flowchart..................................................... 15

12.4 Safety measures ....................................................................... 16

12.4.1 No safety measure...................................................... 16

12.4.2 External alarm............................................................. 16

12.4.3 Natural ventilation ....................................................... 16

12.4.4 Ventilated enclosure ................................................... 17

12.4.5 Overview: flowchart..................................................... 21

12.5 Combinations of ventilated enclosure configurations ................ 22

12.6 Combinations of safety measures ............................................. 22

13 Unit installation 23

13.1 Preparing the installation site .................................................... 23

13.1.1 Installation site requirements of the unit ..................... 23

13.2 Possible configurations ............................................................. 24

13.3 Opening and closing the unit..................................................... 25

13.3.1 About opening the unit................................................ 25

13.3.2 To open the unit.......................................................... 25

13.3.3 To close the unit.......................................................... 25

13.4 Mounting the unit....................................................................... 25

13.4.1 To mount the unit........................................................ 25

13.4.2 To connect the drain piping.......................................... 26

13.4.3 To install the drain piping ............................................. 27

13.5 Installing the ventilation ducting ................................................. 27

13.5.1 To install the ducting .................................................... 27

13.5.2 To install the duct closing plate.................................... 27

13.5.3 To switch the air in- and outlet side ............................. 28

14 Piping installation 30

14.1 Installation limitations ................................................................. 31

14.1.1 Piping installation limitation.......................................... 31

14.2 Preparing refrigerant piping........................................................ 31

14.2.1 Refrigerant piping requirements................................... 31

14.2.2 Refrigerant piping material........................................... 31

14.2.3 Refrigerant piping insulation ........................................ 31

14.3 Connecting the refrigerant piping ............................................... 32

14.3.1 To connect the refrigerant piping ................................. 32

14.3.2 Joining branch pipe ports............................................. 32

14.4 To insulate the refrigerant piping................................................ 32

15 Electrical installation 33

15.1 Specifications of standard wiring components ........................... 33

15.2 Connecting the electrical wiring.................................................. 34

15.3 To connect the electrical wiring .................................................. 34

15.4 To finish the electrical wiring ...................................................... 36

15.5 To set the DIP switches.............................................................. 36

15.6 To connect the external outputs ................................................. 36

16 Configuration 37

16.1 Making field settings................................................................... 37

16.1.1 About making field settings .......................................... 37

16.1.2 To access the field setting components....................... 38

16.1.3 Field setting components ............................................. 38

16.1.4 To access mode 1 or 2 ................................................ 38

16.1.5 To use mode 1 ............................................................. 38

16.1.6 To use mode 2 ............................................................. 39

16.1.7 Mode 1: monitoring settings......................................... 39

16.1.8 Mode 2: field settings ................................................... 39

16.1.9 Mode 2: default field settings ....................................... 41

17 Commissioning 41

17.1 Checklist before commissioning................................................. 41

17.2 SV unit test run........................................................................... 41

17.2.1 About the SV unit test run............................................ 41

17.2.2 About airflow requirements .......................................... 42

17.2.3 About measuring the airflow rate ................................. 42

17.2.4 To perform a SV unit test run....................................... 43

17.2.5 Troubleshooting during a SV unit test run.................... 43

17.3 System test run .......................................................................... 43

17.3.1 Checklist before commissioning .................................. 43

17.3.2 System test run ............................................................ 43

18 Hand-over to the user 44

19 Maintenance and service 44

19.1 Before the maintenance and service of the SV unit ................... 44

19.2 SV unit maintenance and service label ...................................... 44

20 Troubleshooting 44

20.1 Overview: Troubleshooting......................................................... 44

20.2 Precautions when troubleshooting ............................................. 44

20.3 Solving problems based on error codes..................................... 44

20.3.1 Error codes: Overview ................................................. 44

21 Disposal 45

22 Technical data 45

22.1 Wiring diagram ........................................................................... 45

23 Glossary 46