▪The guarantee offered by DALEMANS will be void if this equipment is not installed, used and

maintained in strict compliance with these instructions, warnings and limits of use.

▪By following these instructions, you guarantee the proper functioning of the equipment. Please

contact DALEMANS for any information on the installation, use or maintenance of this

equipment.

▪Always follow the following instructions to prevent premature wear to the sensor and guarantee

its proper functioning. These recommendations are general guidelines.

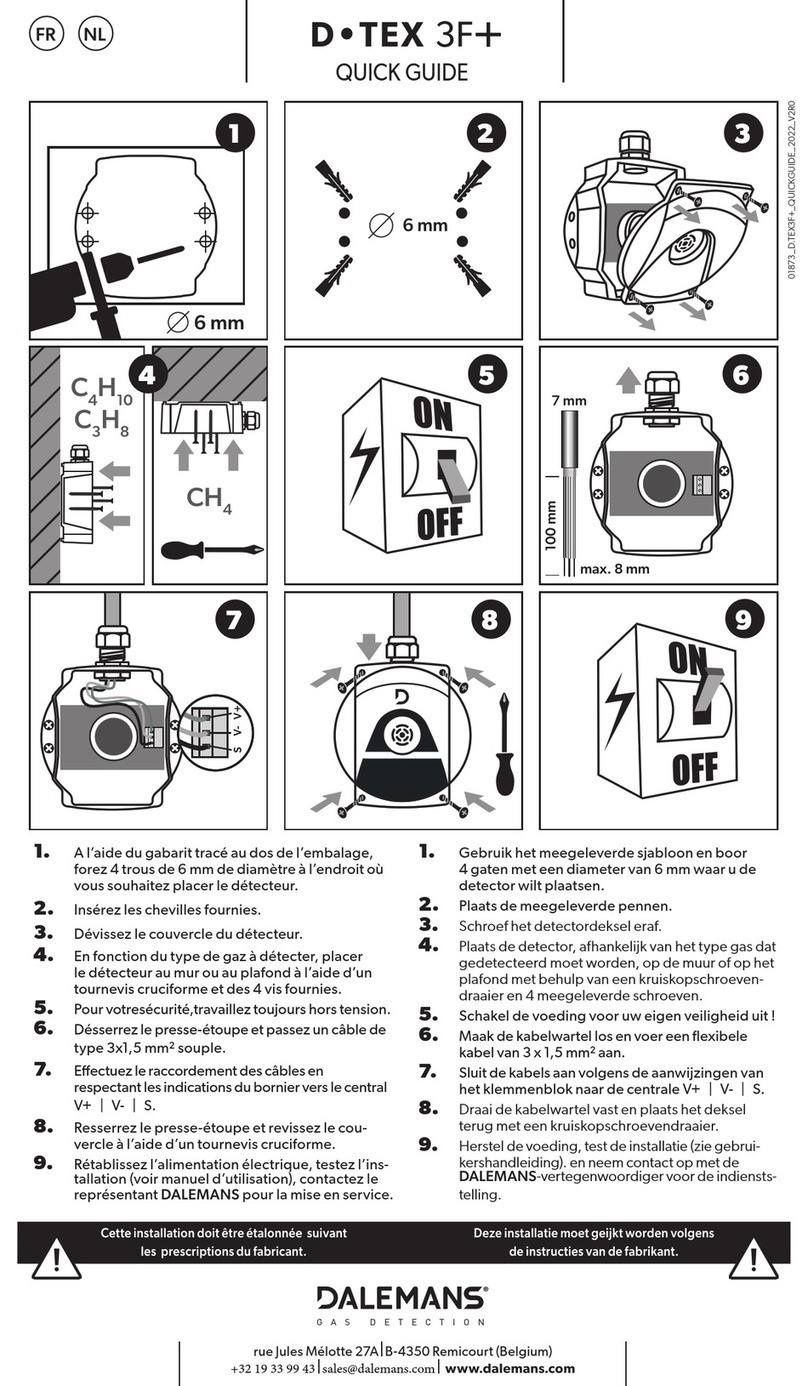

▪Always refer to current regulations and standards before proceeding with the installation (e.g.

standards IEC 60079-14 and IEC 60079-29-2). These take precedence over the manufacturer’s

recommendations.

▪Maintenance must be carried out according to the procedures given by DALEMANS or its local

representative. Any repair or maintenance performed without respecting these instructions or

without help from DALEMANS may prevent the equipment from working correctly and, as a

result, prevent guaranteeing the safety of the occupants of the installations being monitored.

▪The modification, disassembly and total or partial destruction of this equipment may lead to

invalidity of the essential safety requirements of the installations as a whole.

▪Only use original DALEMANS spare parts. Using unoriginal spare parts may invalidate the

certification and the guarantee covering this equipment.

LIMITATIONS

▪The sensors may be sensitive to several gases. Consult DALEMANS for more information.

▪The catalytic sensors can lose sensitivity in the presence of inhibitors and pollutants such as

silicone, halogen and heavy metals. When these inhibitors are permanently present,

DALEMANS recommends the use of gas detectors equipped with infra-red sensors immune to

these pollutants and inhibitors.

▪The catalytic sensors are not suitable for use in atmospheres with variable oxygen levels, at

over 21% oxygen or less than 15% oxygen. Prolonged exposure to explosive gas

concentrations greater than 100% of the Lower Explosive Limit (LEL) may significantly reduce

its useful life.

▪During construction, repackaging or maintenance works concerning the installations, gas

detectors must be installed as late as possible but nevertheless before any risk of the presence

of gas or gas vapours. This is to avoid any damage to the sensor resulting from works such as

welding or painting. If they are already installed, the detectors must be protected using a sealed

cover for the duration of the work and be clearly marked as being non-operational.

▪The gas detectors must be protected against any direct exposure to solar rays, against

vibrations and risks of mechanical impacts.