CONTENTS

1. GENERAL REMARKS ................................................................................. 5

1.1RESPONSIBILITIES –GUARANTEES ................................................... 5

1.2 SAFETY INFORMATION ............................................................ 6

1.3ENVIRONMENT ....................................................................................... 7

1.4U•H1 CONTROL UNIT ............................................................................. 7

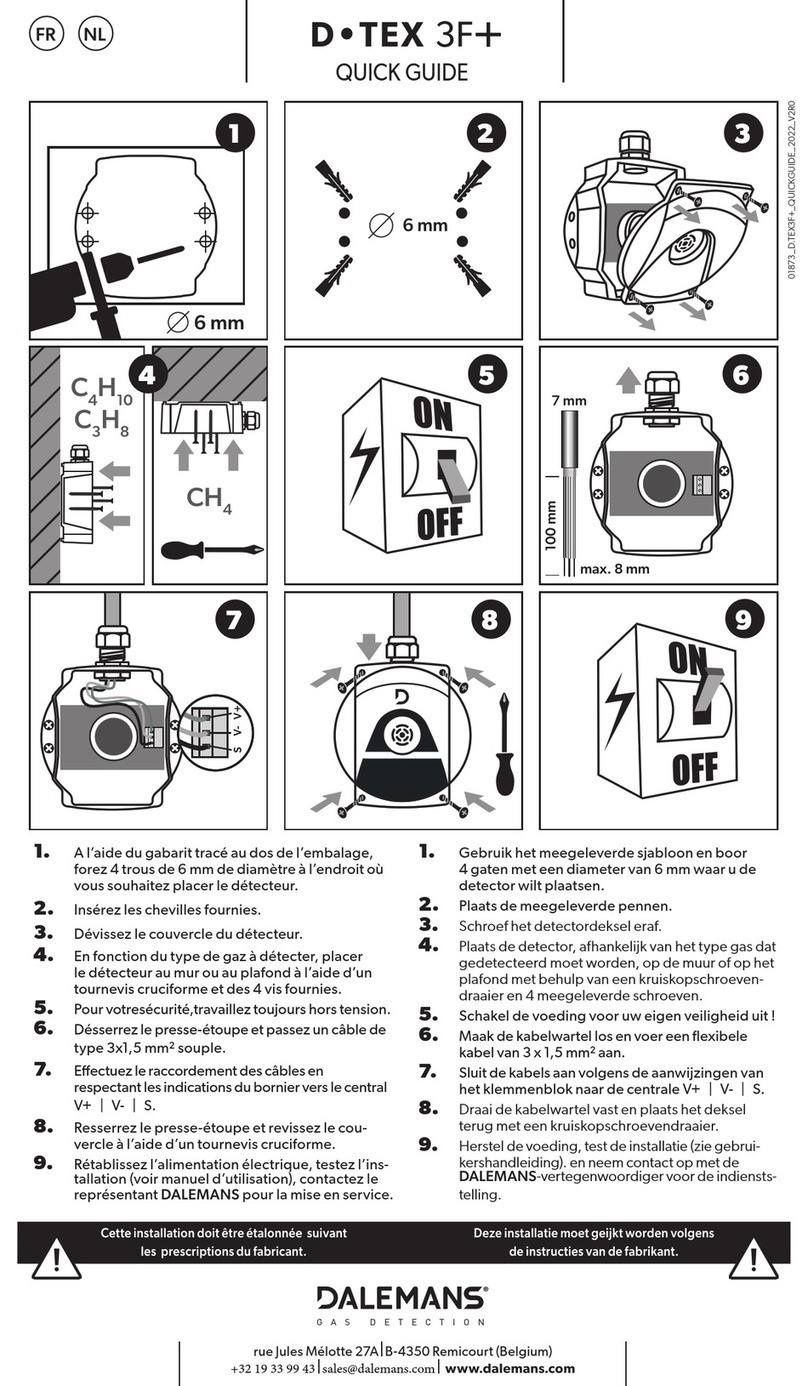

2. INSTALLATION OF THE CONTROL UNIT........................................... 10

2.1 PRECAUTIONS FOR USE .................................................................... 10

2.2 PLACEMENT OF THE U•H1 CONTROL UNIT ..................................... 10

2.3 CONNECTING THE CONTROL UNIT ................................................... 11

2.4 CONNECTING THE DETECTOR ........................................................... 12

2.5POWER CONNECTION ......................................................................... 12

2.6 CONNECTING THE SIREN ................................................................... 13

2.7 CONNECTING THE RELAYS ............................................................... 13

3. INSTALLATION CONTROL ..................................................................... 14

4. INSTALLATION CONFIGURATION ....................................................... 14

4.1 FACTORY CONFIGURATION ............................................................... 14

4.2 GENERAL MENU .................................................................................. 15

System information..........................................................................................15

History .....................................................................................................16

Ages of the calibration parameters........................................................16

Date and time ..........................................................................................16

Configuration of the U•H1 control unit ..................................................17

• Basic standard configuration ................................................................... 17

• Alarm thresholds ..................................................................................... 18

• Relay failsafe mode configuration ........................................................... 18

• Reset mode for level 1 alarms ................................................................ 18

• “Siren” mode ............................................................................................ 18

• Behaviour of the external alarm .............................................................. 19

• Normal state of the external alarm .......................................................... 19

• Errors reset mode .................................................................................... 19