7

DAX 3F-I

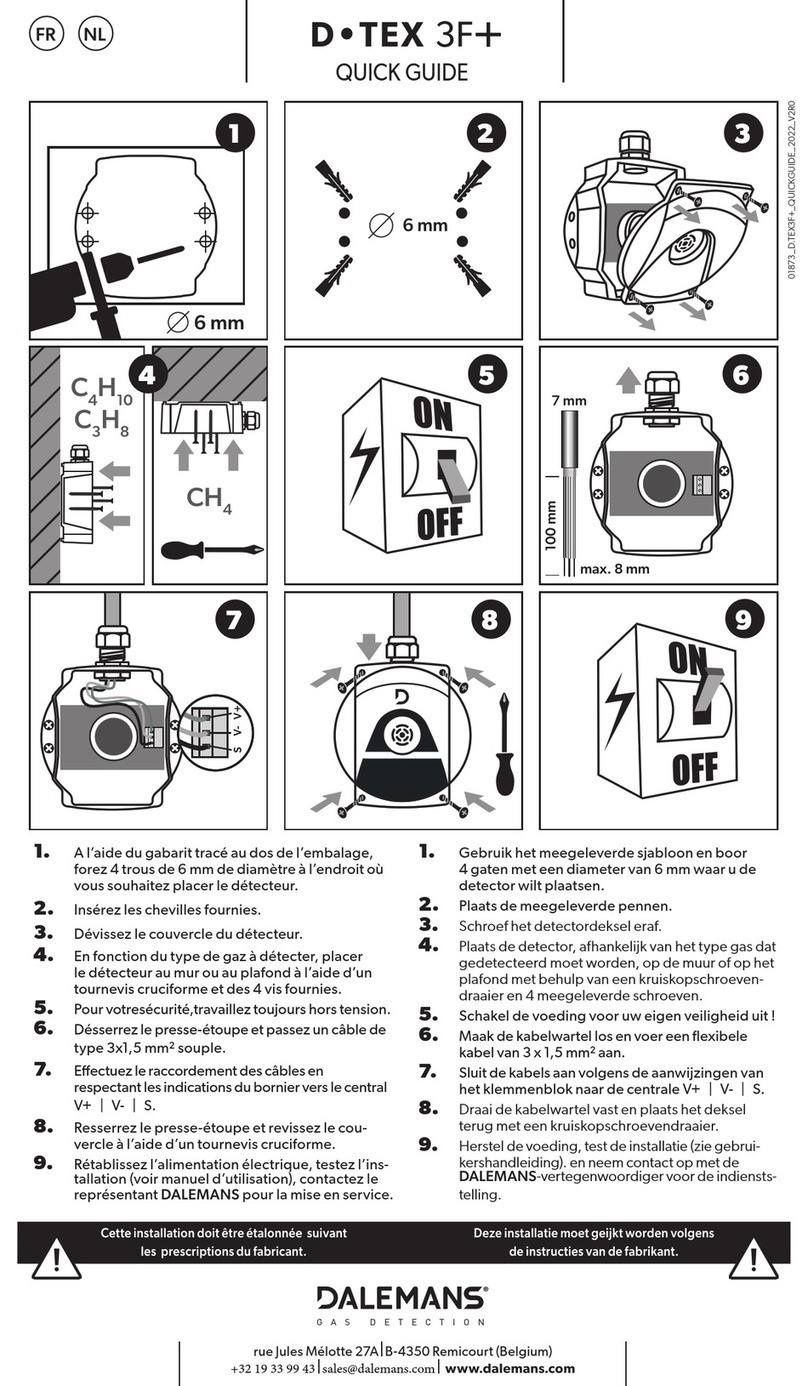

Installation & commissioning

I

nstallation and commissioning must be carried out by the manufacturer or his local representa-

tive. All the operations described hereafter can be carried out only by specialized personnel who

will have been trained beforehand exclusively by Dalemans.

Gas detection equipment should be installed as late as possible in any program of construction

operations (i.e. construction of a new plant, refitting or maintenance) but before the presence of

gas or vapours in the system, so as to avoid damage to sensors resulting in particular from such

activities as welding and painting. If already installed, sensors should be protected by an airtight

seal to avoid contamination during construction works, and should be clearly marked as being

non-operational.

Please follow the recommendations hereafter so as to avoid premature ageing of the detector and

to guarantee its optimal operation. These recommendations are general directives. Always refer

to local regulations/standards in force before proceeding with installation works (i.e. standards

IEC60079-14andIEC60079-29-2).Localregulations/standardsinforcehavealwaysprecedenceon

the recommendations of the manufacturer.

Location

Detectors must be placed so that potential gas accumulations are detected before they create a

significant hazard. Inappropriate location of a detector can nullify the effect and the integrity of

the gas detection system. The placement of the detectors should be determined in consultation

with experts having specialist knowledge of gas dispersion, with those who have knowledge of

process plant system and equipment involved, and with safety and engineering personnel. Should

you require any further guidance or assistance please contact Dalemans.

Detectors should be readily accessible to permit regular calibration, maintenance and electrical

safety inspection. It must be possible to access and fit all accessories or test equipment needed

for these operations on the detector. The location of every detector must be recorded and avai-

lable to the safety personnel. The following points should be taken into account when selecting

locations to install the gas detector :

• Hazardlevelandpotentialsourcesofgasleak.

• Thecombinationofsourcesofgasreleasewithpropagationeffects.

• Accessformaintenanceincludingcalibrationandverification.

• Protectionofthesystemagainstoperationalhazardsoftheplant.

• Protectionofthedetectoragainstmechanicalimpact.

• Vibrationisolationmountingsifnecessary.

• Thedetectorshouldneverbepositioneddirectlyaboveorbelowawaterpoint.

• Foroutdoorinstallation,aprotectionagainstrainand/orsunexpositionshallbeinstalled.

• Detectorshouldnotbelocatedinaircurrents,closetoairextractorsorinventilationducts.

• Alwaysobservetheoperationaltemperaturerangeofthesensor(refertospecifications).

• Iftargetgasislighterthanair(densitywithrespecttoair<1),placethe detector at a high level.

• Iftargetgasisheavierthanair(densitywithrespecttoair>1),placethe detector at a low level.

• If target gas has a unit weight close to air unit weight, place detectors at both high and low level.

• Gasdensityincreaseswhentemperaturedecreases.