TSM-0064 - TE27/32 4-Speed LD with Full Flow Control Valve Service Manual Dana Holding Corporation i

CONTENTS .................................................... i

Towing or Pushing ...........................................1

Introduction ..................................................... 2

Foreword .......................................................... 2

Safety Precautions ........................................... 2

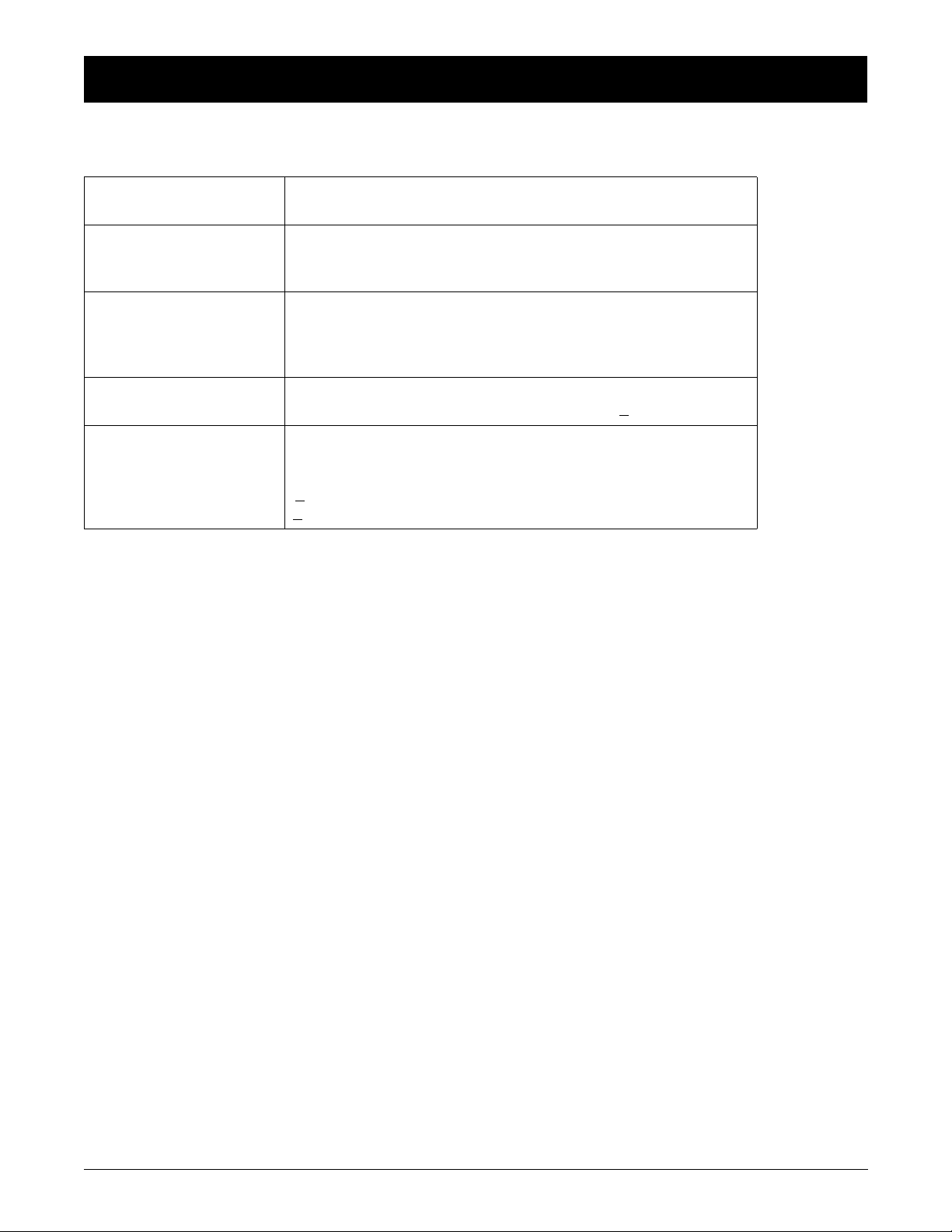

SPECIFICATIONS ..........................................3

Identification Tag .............................................. 3

General Specifications ..................................... 3

Hydraulic Cooler Lines Specifications .............. 3

Pressure and Temperature Specifications ....... 4

Electrical Specifications ................................... 5

Maintenance ...................................................6

Sump preheaters ............................................. 6

Filters ............................................................... 6

Clutch Calibration ............................................ 6

Lubricants ........................................................ 6

Servicing Machine After Component Overhaul 7

Automatic Calibration Procedure ..................... 8

Drive Plate Installation .................................... 12

Transmission to Engine Installation ................13

EXTERNAL PLUMBING INSTALLATION .......14

SPEED SENSOR INSTALLATION ..................15

TEMPERATURE SENSOR INSTALLATION ...17

TRANSMISSION OPERATION .......................18

Converter, Pump Drive, & Pressure Regulating

Valve ................................................................ 19

Input Shaft and Directional Clutches ................ 20

Range Clutches ............................................... 21

Transmission Controls ..................................... 22

Electric Solenoid Controls ................................ 23

Power Flows, Activated Solenoids, & Hydraulic

Circuits ............................................................. 24

Gear & Clutch Layout ...................................... 42

TROUBLESHOOTING ....................................43

Transmission Problems ................................... 43

Troubleshooting Procedures ............................ 43

Troubleshooting Guide ..................................... 46

Check Points .................................................... 47

Checkports ....................................................... 50

Full Flow Valve Components ........................... 51

Speed Sensor Static Standalone Test .............. 52

EXPLODED VIEWS ........................................53

Converter Housing Group ................................ 53

Transmission Case & Rear Cover Group ........ 55

Turbine Shaft Group ........................................ 57

Charging Pump Drive Group ............................ 59

Torque Converter Assembly Group .................. 61

Forward, Reverse/Second, & Third or Fourth Clutch

Shaft Assembly ................................................ 63

Forward Clutch Shaft Group ............................ 65

Third Clutch Shaft Group ................................. 67

Third Speed Gear Group ..................................69

Reverse/Second Clutch Shaft Group ...............71

First Shaft Group ..............................................73

Fourth Clutch Shaft Group ...............................75

First Speed Gear Group ...................................77

Output Shaft Group ..........................................79

Regulator Valve Group .....................................81

Control Valve Group .........................................83

Remote Filter Adapter Group ...........................85

Converter Housing Cover Group ......................87

Input Flange Group ..........................................89

Idler Shaft Gear Group .....................................91

Idler Shaft Group ..............................................93

External Dipstick Group ....................................95

INSTALLATION DIAGRAMS ...........................97

Transmission Assembly Instructions ................97

Control Valve Assembly Instructions ................102

Cleaning and Inspection ..................................103

DISASSEMBLY & REASSEMBLY ...................104

Getting Started .................................................104

Transmission Case Disassembly ....................104

Converter Housing Disassembly ......................120

Reverse & Second Clutch Disassembly ...........121

Reverse & Second Clutch Reassembly ...........124

Forward Clutch Disassembly ............................128

Forward Clutch Reassembly ............................131

Third Clutch Disassembly .................................134

Third Clutch Reassembly .................................136

Fourth Clutch Disassembly ..............................138

Fourth Clutch Reassembly ...............................140

First Clutch Disassembly ..................................143

First Clutch Reassembly ..................................145

Idler Shaft Disassembly ....................................149

Idler Shaft Reassembly ....................................150

Turbine Shaft Disassembly ...............................150

Turbine Shaft Reassembly ...............................151

Impeller Disassembly .......................................152

Impeller Reassembly ........................................153

Impeller Cover & Turbine Disassembly ............155

Impeller Cover & Turbine Assembly .................155

Converter Cover Disassembly ..........................156

Converter Cover Reassembly ..........................156

Pump Drive Gear Disassembly ........................156

Pump Drive Gear Reassembly .........................157

Converter Housing Reassembly .......................157

Transmission Case Reassembly ......................159

TORQUE SPECIFICATIONS ..........................175

Lubricated or Plated Screws ............................175

Pipe Plugs ........................................................177

SPECIAL TOOLS ............................................178

CONTENTS