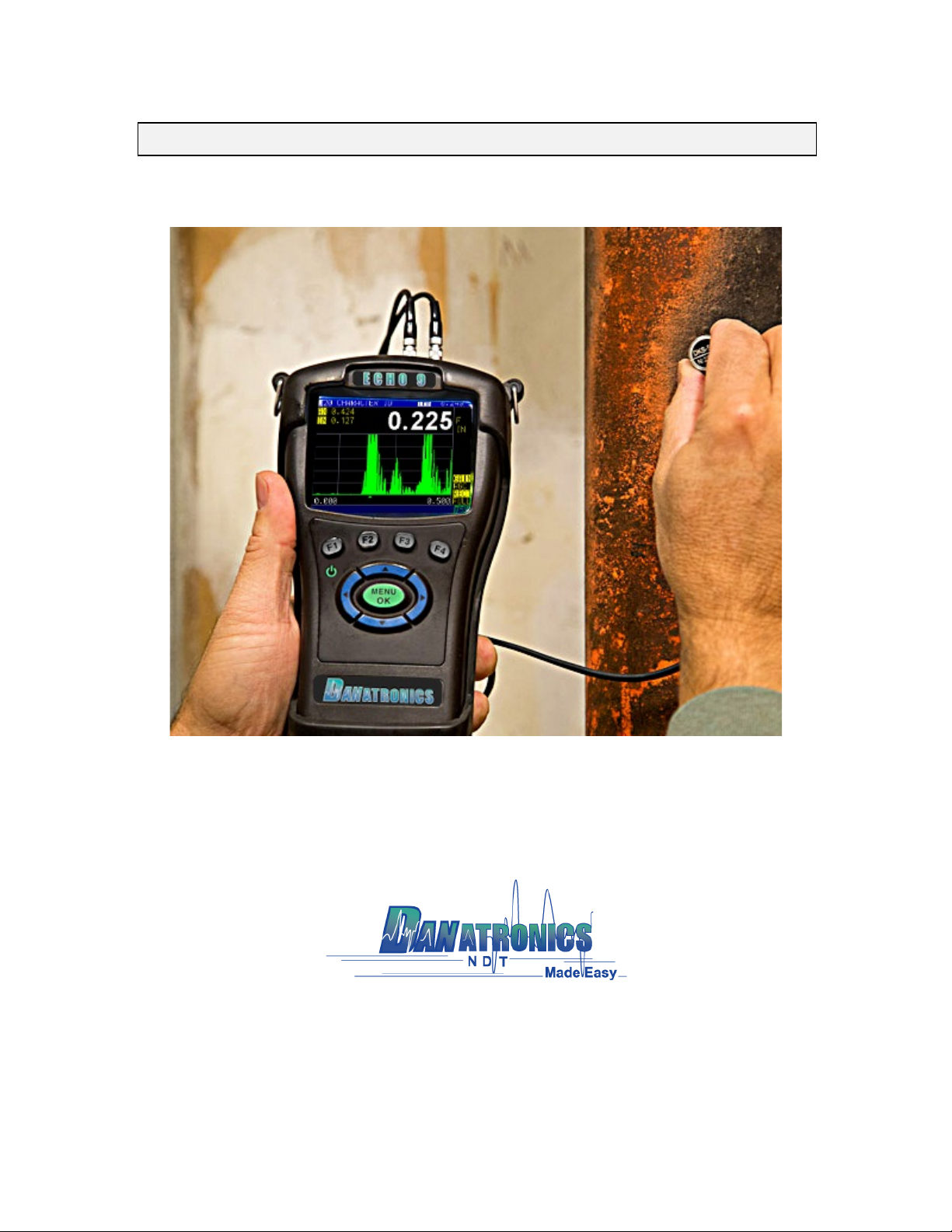

ECHO Series Ultrasonic Thickness Gages

3

Table of Contents

Liability .......................................................................................................................................... 2

1 Getting Started ........................................................................................................................... 6

About the ECHO Series............................................................................................................ 6

Latest Software Updates.......................................................................................................... 6

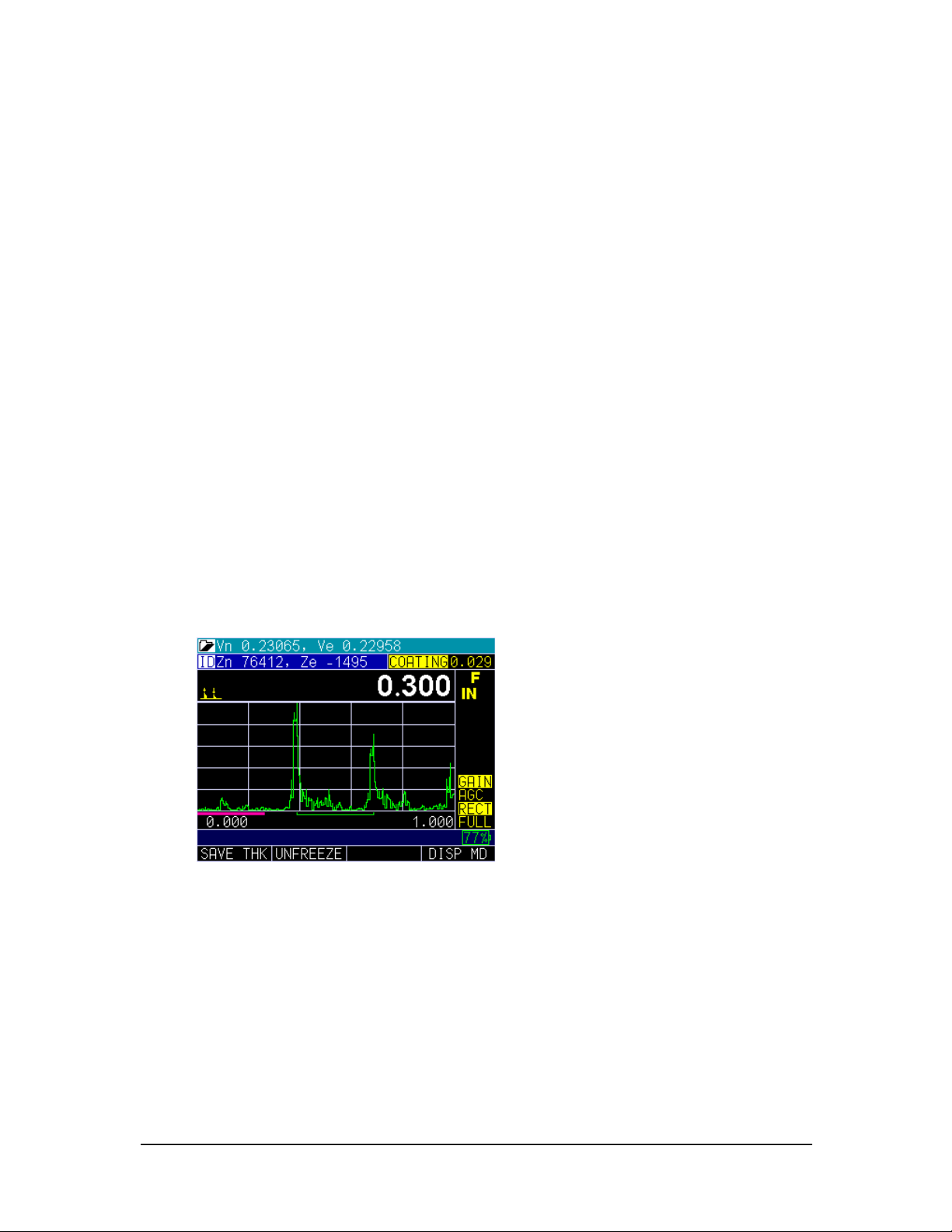

Coating Thickness.................................................................................................................. 7

Temperature Correction ......................................................................................................... 7

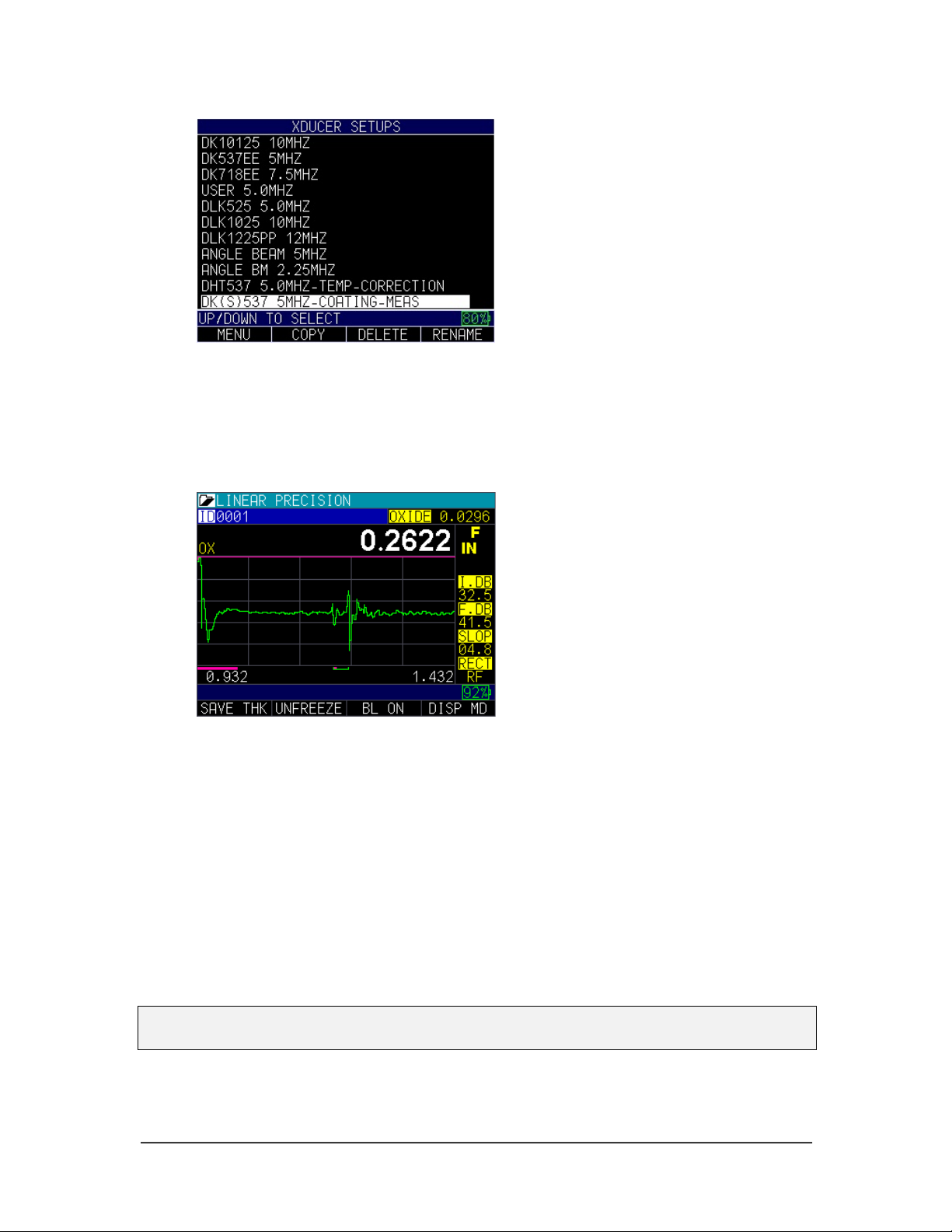

Stored Setups......................................................................................................................... 8

Oxide Scale.......................................................................................................................... 10

Setup Instructions .................................................................................................................. 11

Keypad Functions .................................................................................................................. 12

Function Keys......................................................................................................................... 13

Display Screen........................................................................................................................ 14

Battery Pack............................................................................................................................ 15

Monitoring the Battery Charge from the Display Screen...................................................... 15

Re-charging the Battery ....................................................................................................... 16

Using Non-rechargeable AA Batteries ................................................................................. 17

Boot, Bail, and Strap Features .............................................................................................. 18

Placing the Boot on the Gage .............................................................................................. 18

Removing the Boot from the Gage....................................................................................... 18

Using the Boot Strap and Bail .............................................................................................. 18

Other Gage Features .............................................................................................................. 18

Using the T/R 1 and T/R 2 Ports .......................................................................................... 18

Locating the USB Slot .......................................................................................................... 18

Using the Accessory Mount.................................................................................................. 18

Locating the Altitude Change Release Regulator ................................................................ 19

2 Using Basic Gage Operations ................................................................................................ 20

Power on the Gage ................................................................................................................. 20

Selecting the Menu Option .................................................................................................... 20

Performing a Reset................................................................................................................. 21

Database Reset.................................................................................................................... 22

Parameter Reset .................................................................................................................. 22

Database/Parameter Reset.................................................................................................. 23

About Screen .......................................................................................................................... 23

Backlight ................................................................................................................................. 24

3 Calibrating the Gage................................................................................................................ 25

Velocity Calibration Only ....................................................................................................... 25

Velocity and Zero Calibration................................................................................................ 26

Zero Calibration Only ............................................................................................................. 27

Delay Line Calibration............................................................................................................ 28

Automatic Zero ....................................................................................................................... 28

Measurement Mode with a Datalogger ................................................................................ 29

4 Customizing Display Options................................................................................................. 30

Backlight ................................................................................................................................. 30

Color ........................................................................................................................................ 30

User.......................................................................................................................................... 32

Waveform ................................................................................................................................ 32

Grid View ................................................................................................................................. 33

5 Adjusting the Initial Settings .................................................................................................. 36

About ....................................................................................................................................... 36

Auto Off ................................................................................................................................... 36

Clock........................................................................................................................................ 37

Language................................................................................................................................. 38