IMPORTANT SAFETY INFORMATION

SAFETY

PRECAUTIONS •Do not defrost this appliance using other

electric appliances (i.e. hair dryer) and never

attempt to scrape or remove ice/frost

from the evaporator (cold plate) with sharp

objects.

•Always disconnect the appliance from the

power supply before cleaning and/or

attempting repairs/servicing.

WARNING:

Repairs should be

performed by qualified service

personnel only.

DON’T WAIT,

DO THIS NOW!

Improper disposal of worn

out appliances pose a risk

of entrapment to children.

•If you have purchased this appliance to replace an old

one remove either the gaskets, latches, lids or doors

from the unused appliance. If it was equipped with a

door lock that cannot be opened from the inside, (lock

bolt) make sure the lock is removed, disabled or

destroyed before discarding, this will make it impossible

for children to accidentally lock themselves inside the

appliance and suffocate.

•The refrigerator system of this appliance is filled with

refrigerant and insulating substances which should be

treated and processed separately. Call your nearest

service agent or specialized servicing center. If you are

unable to locate one, contact your local authorities for

proper disposal instructions. Be careful not to damage

any of the refrigeration lines of the appliance.

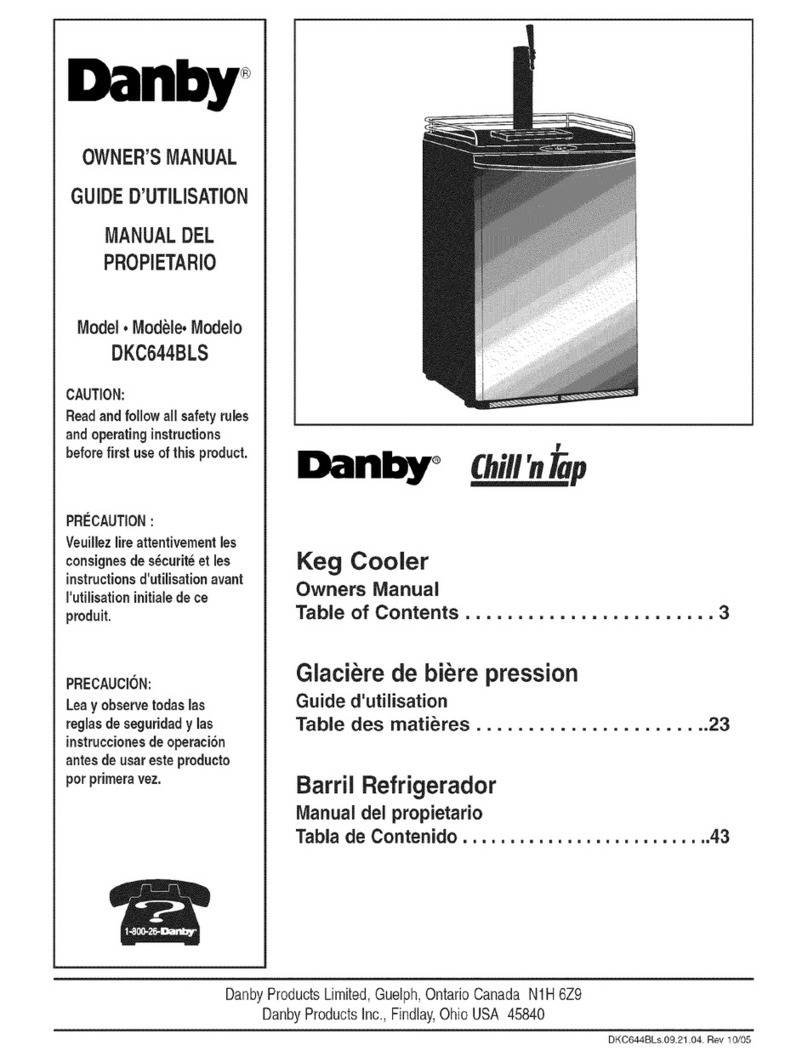

Beer is easily available with Danby's new Keg Cooler, however,

it is not intended to be available to people under the legal age

to consume beer. A beer faucet lock kit for the purpose of

limiting access, is readily available and can be purchased

through our after sales service department (

see ‘Optional

Accessories’ on pg 7

).

Danby does not assume liability for the

unlawful use or consumption of the beer.

PLEASE DRINK RESPONSIBLY AND PLEASE DON'T

DRINK AND DRIVE!

IMPORTANT

NOTICE

•This appliance must be connected to a

properly grounded electrical outlet (

see

Grounding Instructions on pg. 4

)

•Do not operate this appliance if it has a

damaged power cord or plug.

•Do no use this product near water, for

example: in a wet basement, near a

swimming pool or sink.

5