D

GB

F

I

TR

© Danfoss | Climate Solutions | 2023.07 AQ451838788471en-000201 | 5

1|Safety

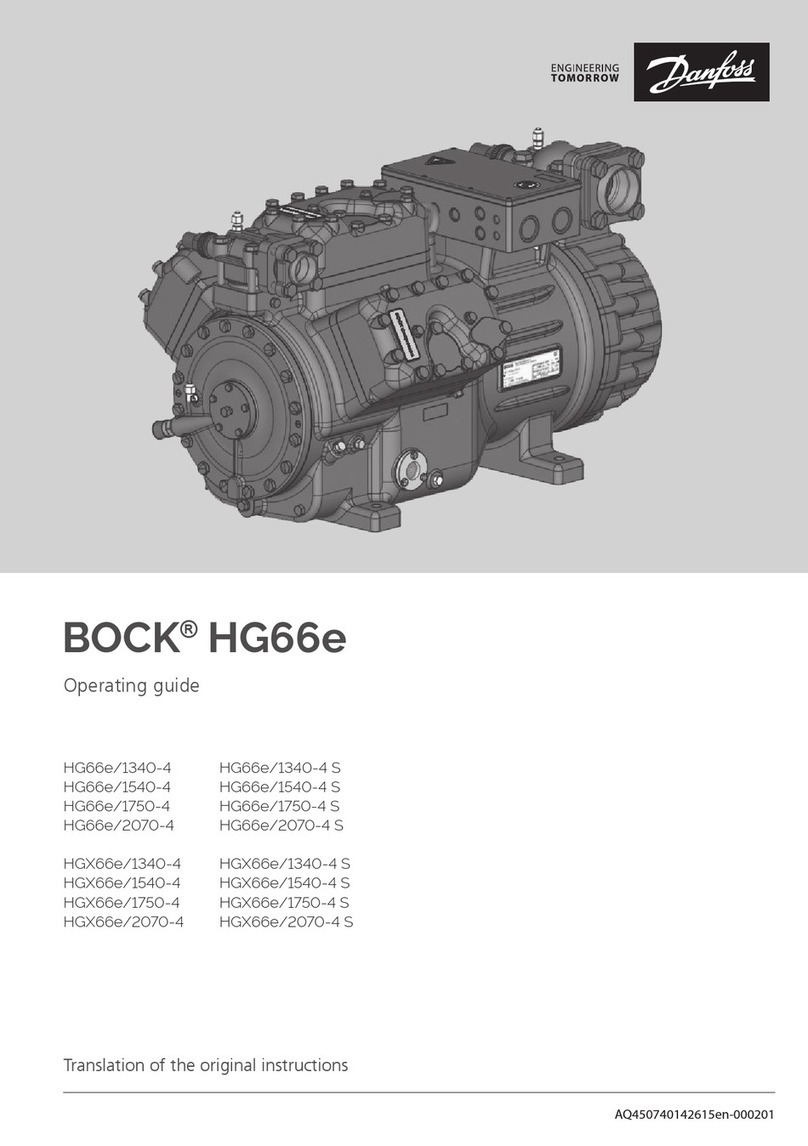

These assembly instructions describe the standard version of the FK20 manufactured by Bock. The

compressor is intended for use in refrigeration systems in compliance with the limits of application.

Onlytherefrigerantspeciedintheseinstructionsmaybeused.

Any other use of the compressor is prohibited!

The Bock refrigerating compressor named in the title is intended for installation in a machine (with-

in the EU according to the EU Directives 2006/42/EC Machinery Directive, 2014/68/EU Pressure

EquipmentDirective).

Commissioning is permissible only if the compressor has been installed in accordance with these as-

sembly instructions and the entire system into which it is integrated has been inspected and approved

in accordance with legal regulations.

1.5 Intended use

1.4 General safety instructions

1.3 Danger to life and limb in the event of faults during operation

WARNING! If a compressor continues to be operated during extreme running

noise and/or a sharp reduction in refrigerating capacity, there is

the danger of further events occurring, such as the fracture

of the housing wall. If people are standing in the immediate

surroundings, there is the risk of severe injury or even death from

yingparts.

• In the event of extreme running noise, switch the compressor off

immediately.

• If there is a sharp reduction in refrigerating capacity, switch the

compressor off immediately.

• Secure the compressor against being switched on again.

• In such cases do not continue to operate the compressor under

any circumstances.

DANGER! • Refrigerating compressors are pressurised machines and as

such call for heightened caution and care in handling.

The maximum permissible overpressure must not be exceeded,

even for testing purposes.

WARNING! • Risk of burns! Depending on the operating conditions,

surface temperatures of over 60 °C on the discharge side or

below 0 °C on the suction side can be reached.