Instructions

4 | AN309640488445en-000201 - 8510290P02B © Danfoss | DCS (CC) | 2020.10

5 – Handling and storage

• Handle the compressor with care. Use the

dedicated handles in the packaging. Use the

compressor lifting lug and use appropriate and

safe lifting equipment.

• Store and transport the compressor in an

upright position.

• Store the compressor between Ts min and Ts

max values for LP side indicated on compressor

nameplate.

• Don’t expose the compressor and the

packaging to rain or corrosive atmosphere.

6 – Safety measures before assembly

Never use the compressor in a flammable

atmosphere.

• Check before assembly that the compressor

does not show any obvious signs of

deterioration that could have occurred during

inappropriate transportation, handling or

storage.

• The compressor ambient temperature may not

exceed Ts max value for LP side indicated on

compressor nameplate during off-cycle.

• Mount the compressor on a horizontal flat

surface with less than 3° slope.

• Verify that the power supply corresponds to

the compressor motor characteristics (see

nameplate).

• Use clean and dehydrated refrigeration-grade

copper tubes and silver alloy brazing material.

• Use clean and dehydrated system components.

• The piping connected to the compressor must be

flexible in 3 dimensions to dampen vibrations.

7 – Assembly

• The compressor must be mounted on rails or

chassisaccordingto Danfoss recommendations

described in related product guidelines (type

of spacer, tightening torques).

• Slowly release the nitrogen holding charge

through the schrader port.

• Remove the gaskets when brazing rotolock

connectors.

• Always use new gaskets for assembly.

• Connect the compressor to the system as soon

as possible to avoid oil contamination from

ambient moisture.

• Avoid material entering into the system while

cutting tubes. Never drill holes where burrs

cannot be removed.

• Braze with great care using state-of-the-art

technique and vent piping with nitrogen gas

flow.

• Connect the required safety and control

devices. When the schrader port is used for

this, remove the internal valve.

• Do not exceed the maximum tightening

torque for rotolock connections:145 Nm.

8 – Leak detection

Never pressurize the circuit with oxygen or dry

air. This could cause fire or explosion.

• Pressurize the system on HP side first and then

on LP side. Never let the pressure on LP side

exceed the pressure on HP side with more than

5 bar. Such pressure difference could cause

internal compressor damage.

• Do not use dye for leak detection.

• Perform a leak detection test on the complete

system.

• The test pressure must not exceed 1.1 x PS

value for LP side and HP side indicated on

compressor nameplate.

• When a leak is discovered, repair the leak and

repeat the leak detection.

9 – Vacuum dehydration

• Never use the compressor to evacuate the

system.

• Connect a vacuum pump to both the LP & HP

sides.

• Pull down the system under a vacuum of 500

µm Hg (0.67 mbar) absolute.

• Do not use a megohmmeter nor apply power

to the compressor while it is under vacuum as

this may cause internal damage.

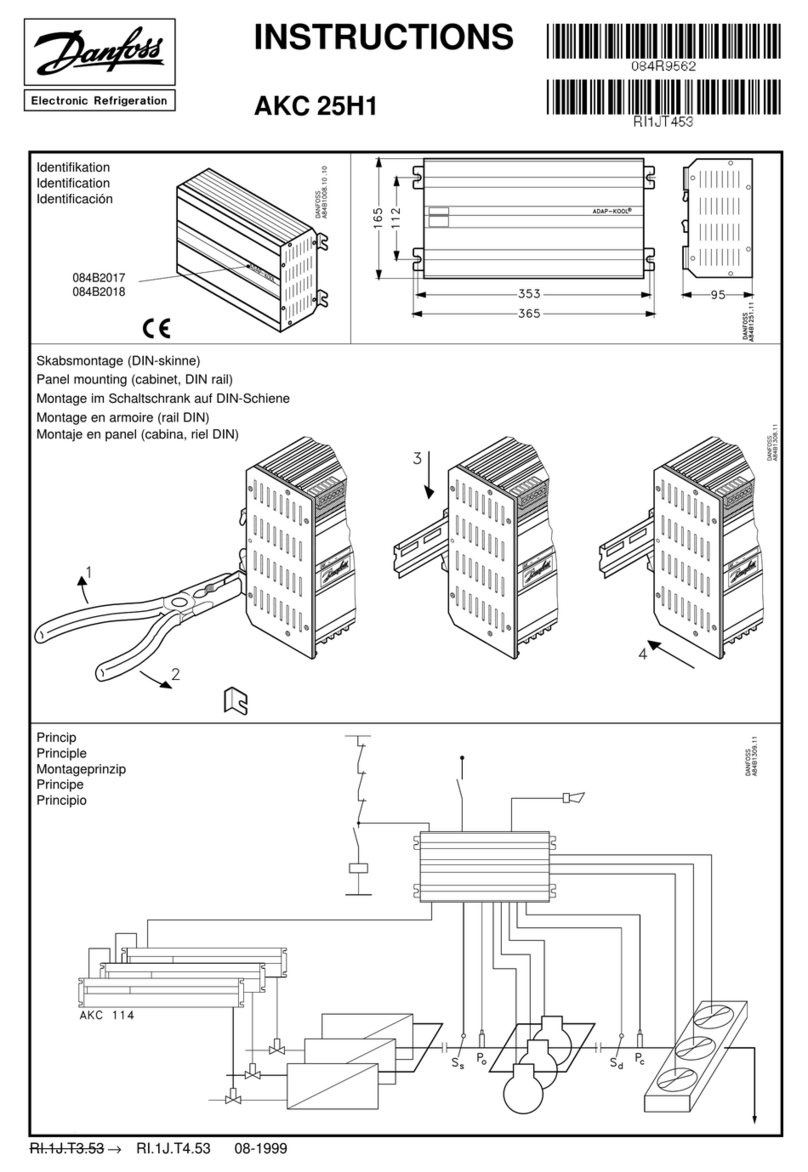

10 – Electrical connections

• Switch off and isolate the main power supply.

See overleaf for wiring details.

• All electrical components must be selected

as per local standards and compressor

requirements.

• Refer to section 4 for electrical connections

details.

• The Danfoss scroll compressors only works

correctly in one rotation direction. Line phases

L1, L2, L3 must absolutely be connected

to compressor terminals T1, T2, T3 to avoid

reverse rotation.

• Electrical power is connected to the

compressor terminals by M5 studs and nuts

. Use appropriate ring terminals, fasten with

3Nm torque.

• The compressor must be connected to earth

with the 5 mm earth terminal screw. The

maximum torque is 4Nm.

11 – Filling the system

• Keep the compressor switched off.

• Fill the refrigerant in liquid phase into the

condenser or liquid receiver. The charge must

be as close as possible to the nominal system

charge to avoid low pressure operation and

excessive superheat. Never let the pressure

on LP side exceed the pressure on HP side

with more than 5 bar. Such pressure difference

could cause internal compressor damage.

• Keep the refrigerant charge below the

indicated charge limits if possible. Above this

limit; protect the compressor against liquid

flood-back with a pump-down cycle or suction

line accumulator.

• Never leave the filling cylinder connected to

the circuit.

Compressor models Refrigerant charge

limit (kg)

DSF270, DSF325 15

DSF485, DSF530 17

12 – Verification before commissioning

Use safety devices such as safety pressure

switch and mechanical relief valve in compliance

with both generally and locally applicable

regulations and safety standards. Ensure that

they are operational and properly set.

Check that the settings of high-pressure

switches and relief valves don’t exceed the

maximum service pressure of any system

component.

• A low-pressure switch is recommended to

avoid vacuum operation. Minimum setting for

1.7 bar g.

• Verify that all electrical connections are

properly fastened and in compliance with local

regulations.

• When a crankcase heater is required, it must be

energized at least 12 hours before initial start-

up and start-up after prolonged shutdown for

belt type crankcase heaters (6 hours for surface

sump heaters).

13 – Start-up

Never operate the compressor without the

electrical box cover fitted.

• Never start the compressor when no refrigerant

is charged.

• All service valves must be in the open position.

• Balance the HP/LP pressure.

• Energize the compressor.It muststartpromptly.

If the compressor does not start, check wiring

conformity and voltage on terminals.

• Eventual reverse rotation can be detected by

following phenomena; the compressor doesn’t

build up pressure, it has abnormally high sound

level and abnormally low power consumption.

In such case, shut down the compressor

immediately and connect the phases to

their proper terminals. DSF compressors are

protected against reverse rotation by the

external electronic protection module. They

will shut off automatically.

• If the internal pressure relief valve is opened

the compressor sump will be warm and

the compressor will trip out on the motor

protector.

14 – Check with running compressor

• Check current draw and voltage.

• Check suction superheat to reduce risk of

slugging.

• Observe the oil level in the sight glass for about

60 minutes to ensure proper oil return to the

compressor.

• Respect the operating limits.

• Check all tubes for abnormal vibration.

Movements in excess of 1.5 mm require

corrective measures such as tube brackets.

• When needed, additional refrigerant in liquid

phase may be added in the low-pressure side

as far as possible from the compressor. The

compressor must be operating during this

process.

• Do not overcharge the system.

• Never release refrigerant to atmosphere.

• For reversible systems, ensure that the 4-way

valve does not reverse when the compressor

is stopped due to heating or cooling demand

(stop on thermostat)

• Before leaving the installation site, carry out

a general installation inspection regarding

cleanliness, noise and leak detection.

• Record type and amount of refrigerant charge

as well as operating conditions as a reference

for future inspections.

15 – Maintenance

Internal pressure and surface temperature

are dangerous and may cause permanent injury.

Maintenance operators and installers require

appropriate skills and tools. Tubing temperature

may exceed 100°C and can cause severe burns.