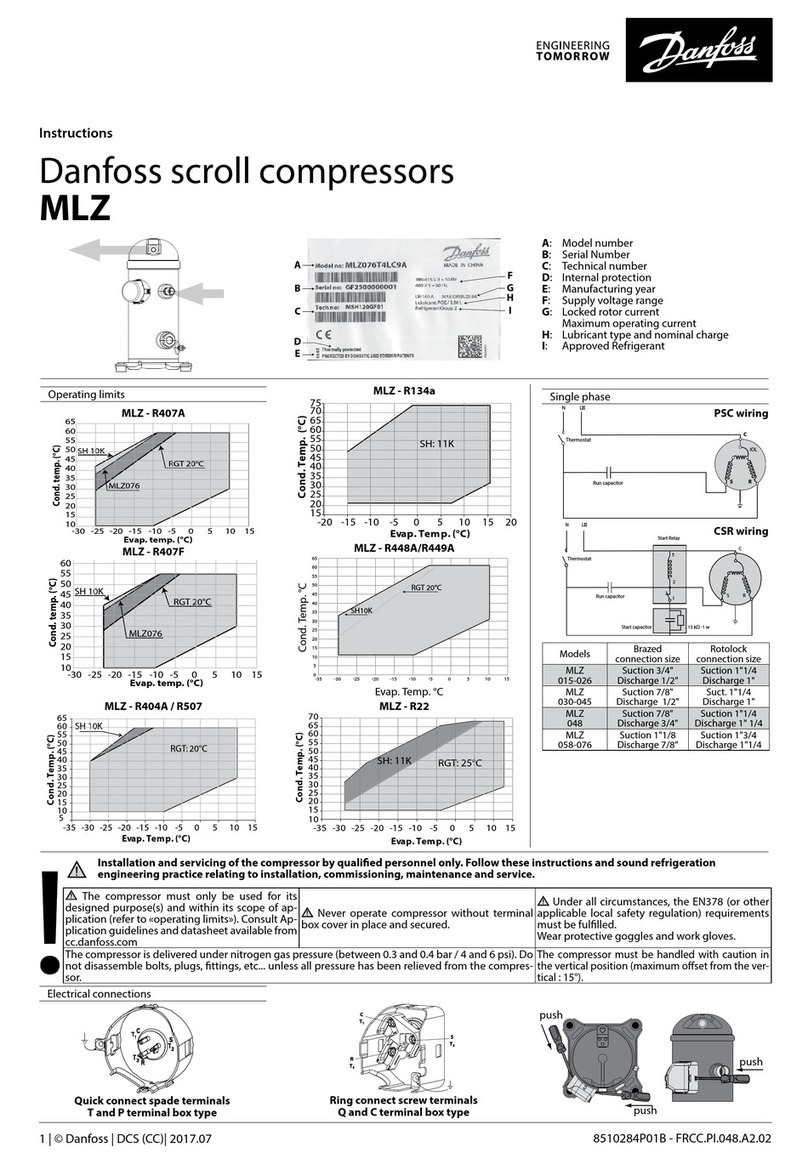

1 - Introduction

These instructions pertain to the Maneurop® MT,

MTZ & NTZ compressors used for refrigeration

systems. They provide necessary information re-

garding safety and proper usage of this product.

2 – Handling and storage

• Handle the compressor with care. Use the

dedicated handles in the packaging. Use the

compressor lifting lug and use appropriate and

safe lifting equipment.

• Store and transport the compressor in an

upright position.

• Store the compressor between -35°C and

50°C.

• Don’t expose the compressor and the packa-

ging to rain or corrosive atmosphere.

3 – Safety measures before assembly

Never use the compressor in a flammable at-

mosphere.

• Thecompressorambienttemperaturemaynot

exceed 50°C during off-cycle.

• Mountthecompressoronahorizontalatsur-

face with less than 3° slope.

• Verifythatthepowersupplycorrespondsto

the compressor motor characteristics (see

nameplate).

• When installing MTZ or NTZ, use equipment

specifically reserved for HFC refrigerants which

was never used for CFC refrigerants.

• Usecleananddehydratedrefrigeration-grade

coppertubesandsilveralloybrazingmaterial.

• Usecleananddehydratedsystemcomponents.

• Thepipingconnectedtothecompressormustbe

flexible in 3 dimensions to dampen vibrations.

4 - Assembly

• Slowly release the nitrogen holding charge

through the schrader port.

• Remove the gaskets when brazing rotolock

connectors.

• Alwaysusenewgasketsforassembly.

• Connectthecompressortothesystemassoon

as possible to avoid oil contamination from

ambient moisture.

• Avoidmaterialenteringintothesystemwhile

cutting tubes. Never drill holes where burrs

cannot be removed.

• Braze with great care using state-of-the-art

technique and vent piping with nitrogen gas

flow.

• Connect the required safety and control de-

vices.Whentheschraderportisusedforthis,

remove the internal valve.

5 – Leak detection

Neverpressurizethecircuitwithoxygenordry

air. This could cause fire or explosion.

• Donotusedyeforleakdetection.

• Performaleakdetectiontestonthecomplete

system.

• Thelowsidetestpressuremustnotexceed25

bar.

• Whenaleakisdiscovered,repairtheleakand

repeat the leak detection.

6 – Vacuum dehydration

• Never use the compressor to evacuate the

system.

• ConnectavacuumpumptoboththeLP&HP

sides.

• Evacuatethesystem toa pressureof 500µm

Hg (0.67 mbar) absolute.

• Donotuseamegohmmeternorapplypower

to the compressor while it is under vacuum as

this may cause internal damage.

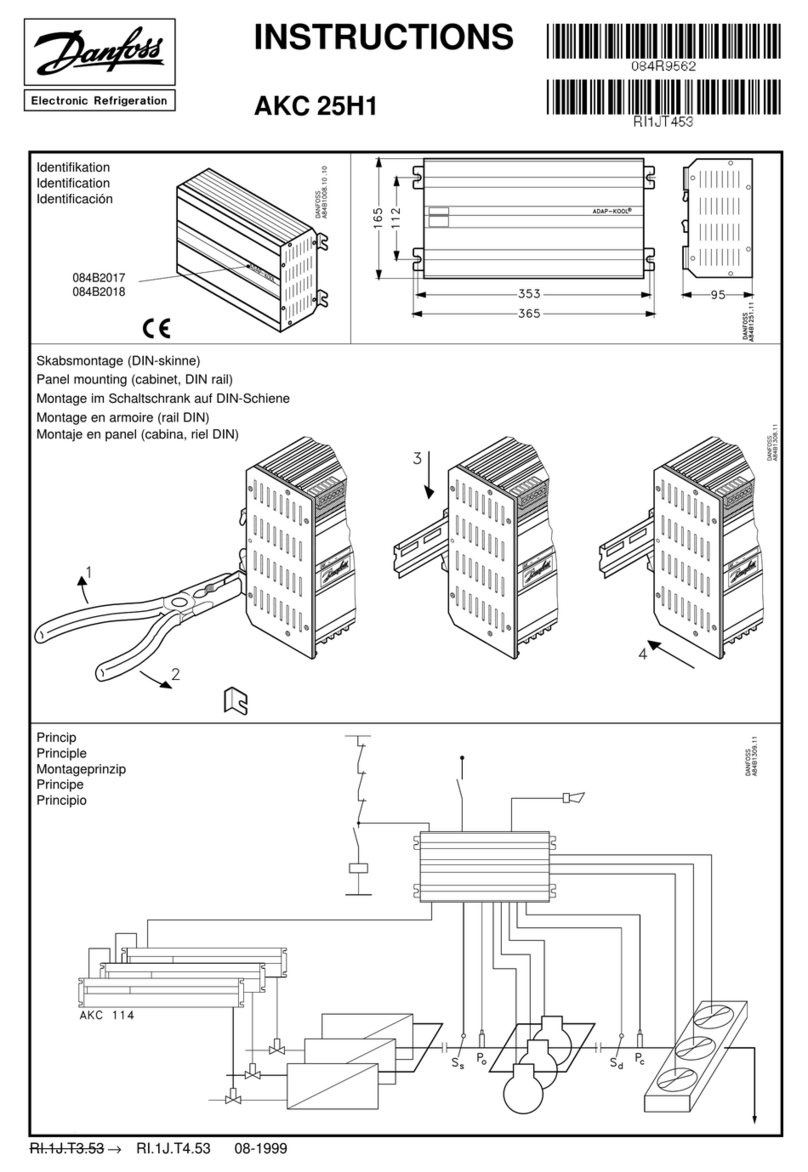

7 – Electrical connections

• Switchoandisolatethemainpowersupply.

Seeoverleafforwiringdetails.

• The compressor is protected against excess

current and temperature by an internal over-

load protector. Follow local regulations regar-

ding power line protection. The compressor

must be connected to earth.

• Allelectricalcomponentsmustbeselectedasper

local standards and compressor requirements.

8 – Filling the system

• Keepthecompressorswitchedo.

• Fill the refrigerant in liquid phase into the

condenser or liquid receiver. The charge must

be as close as possible to the nominal system

charge to avoid low pressure operation and ex-

cessive superheat.

• Keepthe refrigerantchargebelow 2.5kgper

compressor cylinder if possible. Above this

limit; protect the compressor against liquid

flood-back with a pump-down cycle or suction

line accumulator.

• Never leave the lling cylinder connected to

the circuit to avoid overfilling.

9 – Verification before commissioning

Use safety devices such as safety pressure

switch and mechanical relief valve in compliance

with both generally and locally applicable regu-

lations and safety standards. Ensure that they are

operational and properly set.

Check that the settings of high-pressure swit-

chesandreliefvalvesdon’texceedthemaximum

service pressure of any system component.

• A low-pressure switch is recommended to

avoid vacuum operation. Minimum setting 0.1

bar.

• Verify that all electrical connections are pro-

perly fastened and in compliance with local

regulations.

• Whenacrankcaseheaterisrequired,itmustbe

energizedatleast12hoursbeforeinitialstart-

up and start-up after prolonged shutdown.

10 – Start-up

• All service valves must be in the open posi-

tion.

• BalancetheHP/LPpressure.

• Energizethecompressor.Itmuststartpromptly.

Ifitdoesnot,switchitoimmediately.Possible

single phase miswiring can cause burn-out

within seconds.

• Ifthecompressordoesnotstart,checkwiring

conformity and voltage on terminals.

• If the internal overload protector trips out, it

must cool down to 60°C to reset. Depending

on ambient temperature, this may take up to

several hours.

11 – Check with running compressor

• Checkcurrentdrawandvoltage.

• Check suction superheat to reduce risk of

slugging.

• Whenasightglassisprovidedobservetheoil

level at start and during operation to confirm

that the oil level remains visible.

• Respecttheoperatinglimitsasprintedoverleaf.

• Checkalltubesforabnormalvibration.Move-

ments in excess of 1.5 mm require corrective

measures such as tube brackets.

• When needed, additional refrigerant in the

liquid phase may be added in the low-pressure

side as far as possible from the compressor.

The compressor must be operating during this

process.

• Donotoverchargethesystem.

• Neverreleaserefrigeranttotheatmosphere.

• Before leaving the installation site, carry out

a general installation inspection regarding

cleanliness, noise and leak detection.

• Recordtypeandamountofrefrigerantcharge

as well as operating conditions as a reference

for future inspections.

12 - Maintenance

Internal pressure and surface temperature

are dangerous and may cause permanent injury.

Maintenance operators and installers require

appropriate skills and tools. Tubing temperature

may exceed 100°C and can cause severe burns.

Ensure that periodic service inspections to

ensure system reliability and as required by local

regulations are performed.

To prevent system related compressor problems,

following periodic maintenance is recommended:

• Verify thatsafetydevices areoperational and

properly set.

• Ensurethatthesystemisleaktight.

• Checkthecompressorcurrentdraw.

• Conrmthatthesystemisoperatinginaway

consistent with previous maintenance records

and ambient conditions.

• Check that all electrical connections are still

adequately fastened.

• Keepthecompressorcleanandverifytheab-

sence of rust and oxidation on the compressor

shell, tubes and electrical connections.

13 - Warranty

Always transmit the model number and serial

number with any claim filed regarding this pro-

duct.

The product warranty may be void in following

cases:

• Absenceofnameplate.

• External modications; in particular, drilling,

welding, broken feet and shock marks.

• Compressoropenedorreturnedunsealed.

• Rust, water or leak detection dye inside the

compressor.

• Useofarefrigerantorlubricantnotapproved

by Danfoss.

• Anydeviationfromrecommendedinstructions

pertaining to installation, application or main-

tenance.

• Useinmobileapplications.

• Useinexplosiveatmosphericenvironment.

• Nomodelnumberorserialnumbertransmitted

with the warranty claim.

14 – Disposal

Danfoss recommends that compressors

and compressor oil should be recycled by

a suitable company.

2FRCC.EI.002.A1.02 © Danfoss Commercial Compressors 04/08

Instructions