1 Introduction

1.1 Purpose of the Manual

The programming guide provides information required for

commissioning and programming the frequency converter,

including complete parameter descriptions.

1.2 Additional Resources

Available literature:

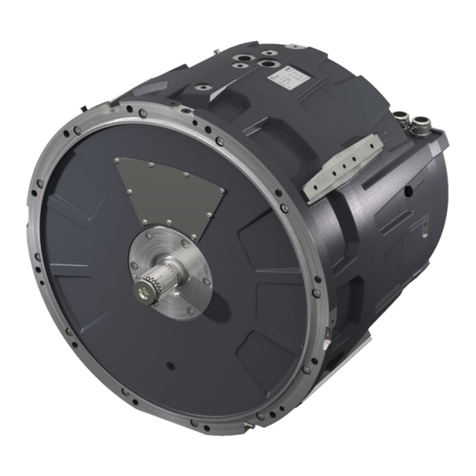

•VLT

®

DriveMotor FCP 106/FCM 106 Operating

Instructions, for information required to install and

commission the frequency converter.

•VLT

®

DriveMotor FCP 106/FCM 106 Design Guide

provides information required for integration of

the frequency converter into a diversity of

applications.

•VLT

®

DriveMotor FCP 106/FCM 106 Programming

Guide, for how to program the unit, including

complete parameter descriptions.

•VLT

®

LCP Instruction, for operation of the local

control panel (LCP).

•VLT

®

LOP Instruction, for operation of the local

operation pad (LOP).

•Modbus RTU Operating Instructions and VLT

®

DriveMotor FCP 106/FCM 106 BACnet Operating

Instructions for information required for

controlling, monitoring, and programming of the

frequency converter.

•The VLT

®

PROFIBUS DP MCA 101 Installation Guide

provides information about installing the

PROFIBUS and troubleshooting.

•The VLT

®

PROFIBUS DP MCA 101 Programming

Guide provides information about conguring the

system, controlling the frequency converter,

accessing the frequency converter, programming,

and troubleshooting. It also contains some typical

application examples.

•VLT

®

Motion Control Tool MCT 10 enables congu-

ration of the frequency converter from a

Windows™-based PC environment.

•Danfoss VLT

®

Energy Box software, for energy

calculation in HVAC applications.

Technical literature and approvals are available online at

vlt-drives.danfoss.com/Support/Service/.

Danfoss VLT®Energy Box software is available at

www.danfoss.com/BusinessAreas/DrivesSolutions, PC software

download area.

1.3 Document and Software Version

This manual is regularly reviewed and updated. All

suggestions for improvement are welcome. Table 1.1 shows

the document version and the corresponding software

version.

In the frequency converter, read the software version in

parameter 15-43 Software Version.

Edition Remarks Software version

MG03N2xx Software update.

PROFIBUS available. 5.00

Table 1.1 Document and Software Version

1.4 Symbols, Abbreviations, and Denitions

The following symbols are used in this manual.

WARNING

Indicates a potentially hazardous situation which could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which could

result in minor or moderate injury. It may also be used

to alert against unsafe practices.

NOTICE

Indicates important information, including situations that

may result in damage to equipment or property.

60°AVM 60°asynchronous vector modulation

A Ampere/AMP

AC Alternating current

AD Air discharge

AEO Automatic energy optimization

AI Analog input

AMA Automatic motor adaptation

AWG American wire gauge

°CDegrees celsius

CD Constant discharge

CDM Complete drive module: The frequency converter,

feeding section, and auxiliaries

CM Common mode

CT Constant torque

DC Direct current

DI Digital input

DM Dierential mode

D-TYPE Drive dependent

EMC Electromagnetic compatibility

Introduction Programming Guide

MG03N202 Danfoss A/S © 11/2015 All rights reserved. 5

11