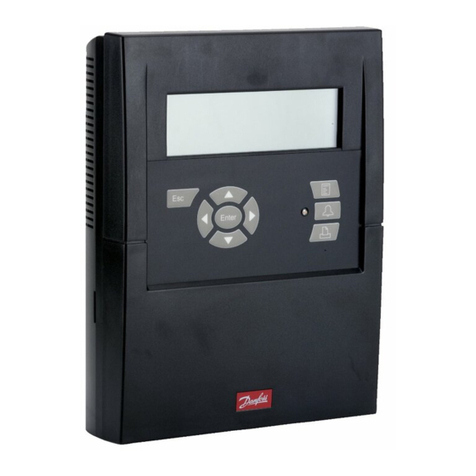

6 Vickers by Danfoss Target-Pro 2 Analyzer and Sampler Operat ion Manual V-PP-MC- 2-E July 2 23

C o n t i n u o u s S a m p l i n g — S e t I n t e r v a l s

The analyzer can run continuous tests at set time intervals.

Once continuous sam ling has started, the flush valve

o ens and closes automatically before each test. This lets

fluid reach the sensing arrangement before the 15ml sam-

ling test begins.

The flush valve automatically o ens at the end of the sam-

ling cycle and remains o en while the analyzer is em tying

the sam le fluid from the revious test.

De ending on the time set for minutes between tests, the

flush valve o erates as follows:

Time set to 0:

At the end of the em tying cycle, the flush valve automati-

cally closes and the next sam ling test beginsimmediately.

Time set etween 1 and 5:

After the em tying cycle ends, the flush valve remains o en

for the time set, then closes automatically before the next

sam ling test.

Time set etween 6 and 30000:

Flush valve automatically closes after the em tying cycle

ends, and remains closed until 5 minutes before the next

sam le test is rogrammed to begin.

Notes:

When the flush valve ushbutton is lighted, the valve is

o en; when the ushbutton light is off, the valve is closed.

The flush valve servo motor makes a slight ‘ticking’

noise, whether the valve is o en or closed. This is normal.

Do not connect the waste fluid hose to a ressurized sys-

tem; this will cause the analyzer to malfunction and could

cause internal leakage. Discharge the waste fluid hose into

the bottle rovided, or into a tank or vessel vented to the

atmos here.

To conserve battery life, connect the analyzer to the ower

ada ter for continuous o eration.

Con ti nu ou s Sa mp li ng —B as ic O pe rat io n

1. Follow instructions 1–5 on age 4 to select

analyzer settings. On the O erations Screen,

ress [5] until Continuous is selected.

2. Test Options—Press [6], then ress the rele-

vant key to switch between o tion selections:

1. Set minutes etween tests: Press [1], enter the time in

minutes required between tests (value must be between 1

and 30000), and ress [Return].

2. Set ISO Target Level: Press [2], enter 0 (zero), and ress

[Return].

3. Set NAS Target Level: Press [3], enter 0 (zero), and ress

[Return].

4. Set logging: Press [4] once to log every test, re eat; ress

[4] again to deselect logging.

Note: If you deselect log every test, the analyzer will not store

any test results in its memory.

3. Press the ush valve ushbutton to o en the valve; the

ushbutton will light u . Leave the valve o en for at least 1

minute or 200ml of fluid—more if the HP sam ling hose is

longer than 1.5m.

4. Press the ush valve ushbutton to close the valve; the

ushbutton light will go o.

Alternate method: Proceed to ste 5— ressing

the start button [1] automatically closes the flush

valve before sam ling begins.

5. Press the start utton [1].The analyzer will

begin the sam ling cycle.

6. The completion progress ar indicates test status:

Results will be dis layed automatically on the screen; if

auto rint mode is on, results will be automatically rinted

at the end of the sam ling cycle; if auto rint is off, ress

the rint key for a co y of the rinted results.

7. Between tests, status will show Waiting.

8. Press the stop utton [2] at any oint in the cycle to end

continuous sam ling. Test status will show Idle.

Continuous

Sampling