4 | © Danfoss | DHS-SRMT/SI | 2016/01

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

All trademarks in this material are property of the respec

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Operating Guide/RAVK (10-30 °C / 25-45 °C / 25-65 °C / 35-75 °C)

VI.FC.C2.2Z/73693070

ENGLISH

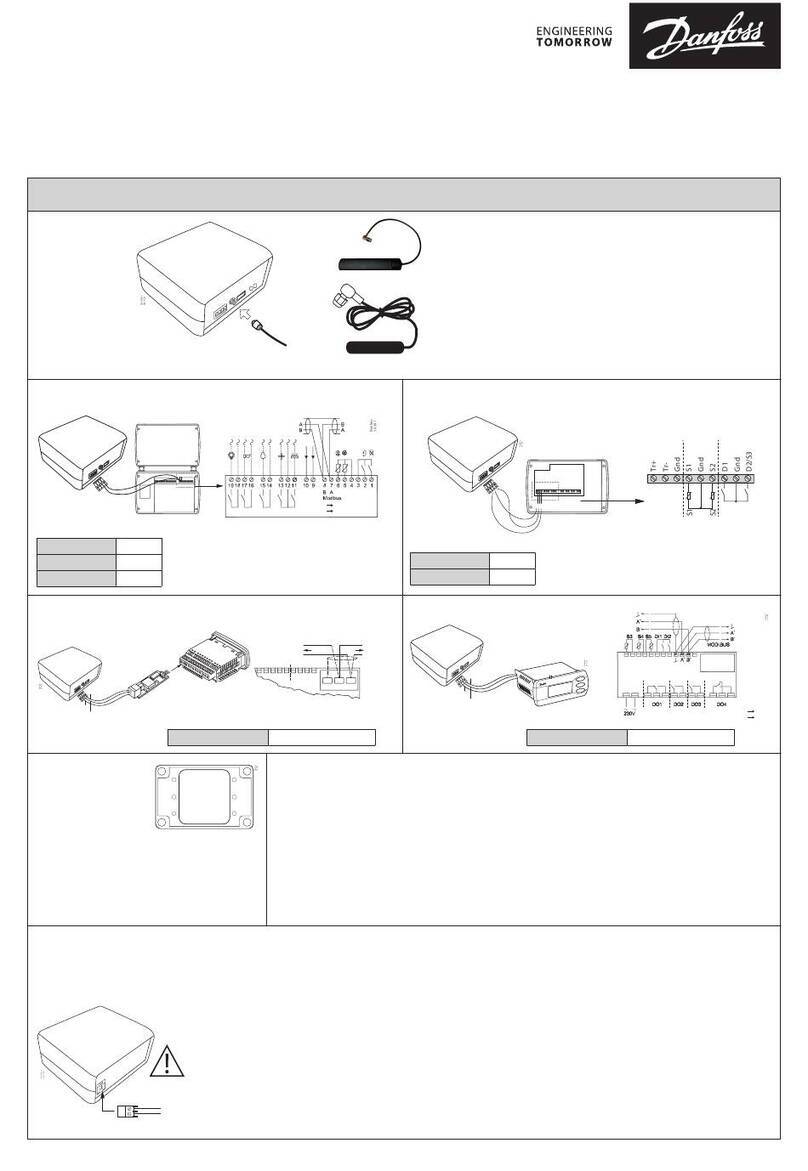

Fitting ❶

Install sensor ❸

• Install sensor part as shown on g. ①

in order to assure at least 5 mm distance

between sensor housing made of brass

and other metal parts.

• Consider adequate distance over the

whole side length and end part of the

sensor (g. ①).

• Assure that sensor is properly xed;

larger dimension of capillary tube has

to be xed with stung box (2 washers

with rubber gasket in between,

tightened with screw), (g. ①).

POLSKI

Montaż ❶

Zamontuj czujnik ❸

• Zamontuj czujnik tak jak pokazano na

Rys. ①zachowując 5 mm odległości

pomiędzy czujnikiem i obudową

wykonaną z mosiądzu lub innymi

metalowymi elementami.

• Oszacuj odpowiednią odległość

porównując długość całkowitą i

końcówkę czujnika (Rys. ①).

• Upewnij się, że czujnik jest prawidłowo

ustalony; uszczelnić zestawem

uszczelniającym na większej średnicy

rurki kapilarnej (2 podkładki z gumową

uszczelką pomiędzy, ściągnięte śrubą ),

(Rys. ①).

• By installation shown on gure ①you

also assure the optimal arm (distance

between stung box where sensor

is xed and end part of the sensors

inserted in the media in heat exchanger

or boiler) which will reduce the risk of

vibrations which could cause a metal

contact.

• Please avoid installation which is shown

on gure ②(thinner diameter of

capillary tube ts in stung box, longer

arm etc.).

• If you can not avoid or at least you

assume the possibility of metal contact,

than you have to use a protecting

pocket (sleeve) made of stainless steel

(gure ③).

By using this standard type of accessory

you will be faced with longer response

time of RAV’s performance due to

slower heat transition.

Setting ❹

Limiting or locking of

setting range ❺

• Przy montażu pokazanym na Rys. ①

sprawdź czy czujnik jest zanurzony

optymalnie (odległość końca czujnika

zanurzonego w czynniku w wymienniku

lub podgrzewaczu od jego miejsca

stałego zamocowania w zestawie

uszczelniającym ) co zmniejszy ryzyko

wzbudzenia wibracji, które mogą grozić

kontaktem czujnika z metalem.

• Należy unikać montażu pokazanego na

Rys. ②(cieńsza średnica rurki kapilarnej

na wysokości uszczelnienia, dłuższe

ramie itp.).

• Jeżeli nie można tego uniknąć, lub

oceniasz zagrożenie wystąpienia

kontaktu z częściami metalowymi,

konieczne jest użycie tulei ochronnej

(kieszeni) ze stali nierdzewnej (Rys. ③).

Przy zastosowaniu tego typu

standardowych akcesoriów

wydłuży się czas reakcji regulatora

RAV spowodowany wolniejszym

przewodzeniem ciepła.

Nastawa ❹

Ograniczanie lub blokowanie

zakresu nastawy ❺