Data Aire DAFC User manual

Fluid Coolers

Selection Guide

and

User Manual

Data Aire, Inc.

230 W. BlueRidge Ave.

Orange, CA 92865

www.dataaire.com

3

TABLE OF CONTENTS

External Fluid Coolers

DAFC - Standard Outdoor Fluid Cooler Selection Guide..................... 4

DAFC - Low Decibel Outdoor Fluid Cooler Selection Guide................. 6

DAFC-PB - Indoor Fluid Cooler Selection Guide ................................. 8

Fluid Cooler Capacity Chart ................................................................ 10

Fluid Cooler Internal Volumes ............................................................. 11

Copper Piping Internal Volume............................................................ 11

Installation and Maintenance............................................................... 12

Preventive Maintenance...................................................................... 16

This manual is intended to assist trained service personnel by providing necessary guidelines for this

particular equipment. Service to Data Aire units should be accomplished by qualied individuals with

an adequate background in areas such as HVAC, electrical, plumbing, and electronics, as applicable.

Service performed by unauthorized or unqualied technicians may void manufacturer’s

warranties and could result in property damage and/or personal injury.

4

STANDARD REMOTE OUTDOOR TYPE – MODEL DAFC

Unit cabinets are constructed of heavy duty aluminum, thoroughly reinforced with riveted

gussets. Fan outlets provide additional strength to fan panel and assure even air ow for

quiet operation. Mounting legs are constructed of heavy duty aluminum and are shipped with

the unit for eld installation.

The condenser coil is constructed of plate type die formed, aluminum ns mechanically

bonded to copper tubes and employ full height, self-spacing collars which completely cover

the tube surface. The coil is pressure and leak tested at 425 PSIG air under warm water,

evacuated, dehydrated, and sealed with caps on connections.

Propeller type fans, carefully matched to the coil, cover a large percentage of the coil face

area providing a uniform air distribution. The direct drive fans have heavy duty gauge alumi-

num blades securely riveted to zinc plated, chromate treated center hubs. All fans are stati-

cally and dynamically balanced before shipment and operate at low tip speeds for minimum

vibration and low sound levels.

The fan motors are heavy duty PSC or three phase motors with permanently lubricated ball

bearings. All motors are thermally protected against burn-out and may be started by a single

contactor. Protective slingers shield the motors from weather damage.

All motors are factory wired with leads terminating in a weather protected junction box lo-

cated on the outside of the unit casing. Fan motors are ___ horsepower, 1075 RPM. The

fan guards are constructed of heavy gauge, close meshed steel wire powder coated for cor-

rosion resistance.

All Data Aire DAFC type condensers are E.T.L. listed.

5

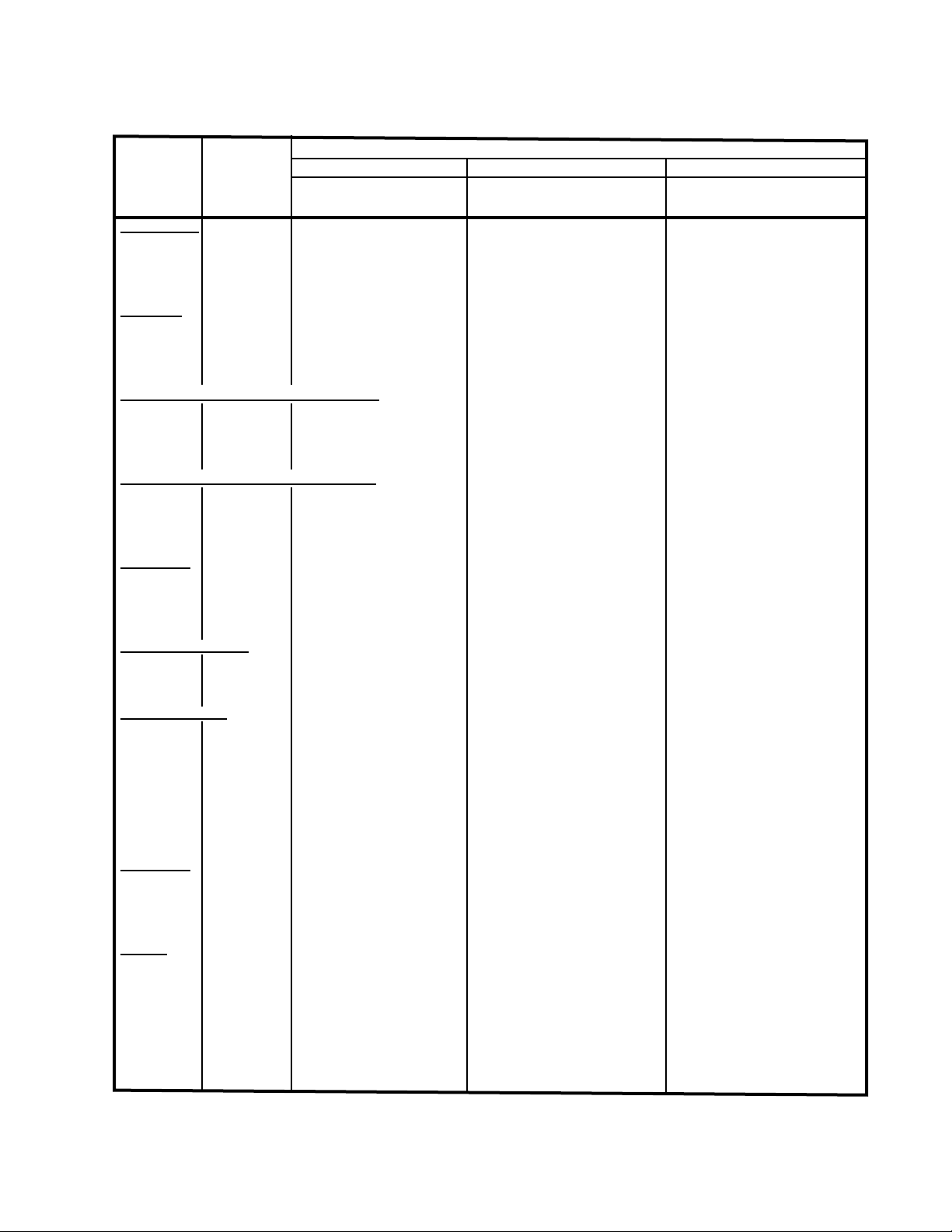

Standard Fluid Cooler Selection Chart

All selections based on 40% Glycol

Ambient Temperature

95 100 1051

Fluid PD Fluid PD Fluid PD

Model THR GPM Cooler MBH (FT) Cooler MBH (FT) Cooler MBH (FT)

Mini Ceiling

DAM* 01 15 3.5 DAFC 06 31 0.2 DAFC 06 25 0.2 DAFC 06 19 0.2

DAM* 1.5 23 5.3 DAFC 06 38 0.5 DAFC 06 30 0.5 DAFC 06 23 0.5

DAM* 02 30 7.0 DAFC 06 49 1.1 DAFC 06 39 1.1 DAFC 09 36 1.6

DAM* 2.5 36 8.8 DAFC 06 57 1.6 DAFC 06 45 1.6 DAFC 09 42 2.5

Mini Plus

DAP* 2.5 39 8.8 DAFC 06 57 1.6 DAFC 06 45 1.6 DAFC 09 42 2.5

DAP* 03 49 10.5 DAFC 06 63 2.2 DAFC 06 50 2.2 DAFC 09** 46 3.4

DAP* 04 72 14.0 DAFC 06 72 3.7 DAFC 09** 71 5.7 DAFC 28** 68 0.3

DAP* 05 88 17.5 DAFC 07 89 7.1 DAFC 15** 87 1.1 DAFC 30 94 1.8

Large Ceiling Units - Single Compressor

DAL* 06 104 21 DAFC 11 104 3.0 DAFC 17** 102 0.9 DAFC 30 108 2.5

DAL* 08 136 28 DAFC 15 139 2.5 DAFC 21 147 3.3 DAFC 37 137 2.3

DAL* 10 181 35 DAFC 21 207 5.0 DAFC 28 182 1.9 DAFC 50 183 2.9

DAL* 13 230 46 DAFC 21 233 8.2 DAFC 30 232 10.1 DAFC 50** 220 4.7

Large Ceiling Units - Dual Compressors

DAL* 06 103 21 DAFC 11 104 3.0 DAFC 17** 102 0.9 DAFC 30 108 2.5

DAL* 08 138 28 DAFC 15 139 2.5 DAFC 21 147 3.3 DAFC 37** 137 2.3

DAL* 10 174 35 DAFC 21 207 5.0 DAFC 24 175 2.8 DAFC 44 179 4.1

DAL* 13 224 46 DAFC 21 233 8.2 DAFC 30 232 10.1 DAFC 50** 220 4.7

Data Temp

DT*D/U 02 36 7.0 DAFC 06 49 1.1 DAFC 06 39 1.1 DAFC 09 36 1.6

DT*D/U 03 49 10.5 DAFC 06 63 2.2 DAFC 06 50 2.2 DAFC 09** 46 3.4

DT*D/U 04 72 14.0 DAFC 06 72 3.7 DAFC 09** 71 5.7 DAFC 28** 68 0.3

DT*D/U 05 88 17.5 DAFC 07 89 7.1 DAFC 15** 87 1.1 DAFC 30 94 1.8

Modular Data Temp

DT*D/U 08 136 28 DAFC 15 139 2.5 DAFC 21 147 3.3 DAFC 37 137 2.3

DT*D/U 10 172 35 DAFC 21 207 5.0 DAFC 24 175 2.8 DAFC 44 179 4.1

DT*D/U 13 224 46 DAFC 21 233 8.2 DAFC 30 232 10.1 DAFC 50** 220 4.7

Data Aire Series

DA*D/U 06 100 21 DAFC 11 104 3.0 DAFC 17 102 0.9 DAFC 30 108 2.5

DA*D/U 08 146 28 DAFC 17 148 1.4 DAFC 21 147 3.3 DAFC 44 152 2.8

DA*D/U 10 162 35 DAFC 17 163 2.1 DAFC 21 166 5.0 DAFC 40 164 2.4

DA*D/U 13 224 46 DAFC 21 233 8.2 DAFC 30 232 10.1 DAFC 50** 220 4.7

DA*D/U 16 245 56 DAFC 24 269 6.5 DAFC 30 247 14.4 DAFC 50 245 6.7

DA*D/U 20 310 70 DAFC 37 360 12.1 DAFC 40** 304 8.4 DAFC 75 317 3.5

DA*D/U 26 387 91 DAFC 40 404 13.4 DAFC 50 393 16.0 DAFC 88 422 6.6

DA*D/U 30 482 105 DAFC 50 509 20.7 DAFC 61 483 12.8 DAFC 100** 475 6.0

gForce GT

GT*D/U007 36 7.0 DAFC 06 49 1.1 DAFC 06 39 1.1 DAFC 09 36 1.6

GT*D/U011 49 10.5 DAFC 06 63 2.2 DAFC 06 50 2.2 DAFC 09** 46 3.4

GT*D/U014 72 14.0 DAFC 06 72 3.7 DAFC 09** 71 5.7 DAFC 28** 68 0.3

GT*D/U018 88 17.5 DAFC 07 89 7.1 DAFC 15** 87 1.1 DAFC 30 94 1.8

gForce

GF*D/U021 100 21 DAFC 11 104 3.0 DAFC 17 102 0.9 DAFC 30 108 2.5

GF*D/U028 146 28 DAFC 17 148 1.4 DAFC 21 147 3.3 DAFC 44 152 2.8

GF*D/U035 162 35 DAFC 17 163 2.1 DAFC 21 166 5.0 DAFC 40 164 2.4

GF*D/U046 224 46 DAFC 21 233 8.2 DAFC 30 232 10.1 DAFC 50** 220 4.7

GF*D/U056 245 56 DAFC 24 269 6.5 DAFC 30 247 14.4 DAFC 50 245 6.7

GF*D/U070 310 70 DAFC 37 360 12.1 DAFC 40** 304 8.4 DAFC 75 317 3.5

GF*D/U091 387 91 DAFC 40 404 13.4 DAFC 50 393 16.0 DAFC 88 422 6.6

GF*D/U106 482 105 DAFC 50 509 20.7 DAFC 61 483 12.8 DAFC 100** 475 6.0

* Insert: W - Water Cooled or G - Glycol

** The capacity of the selected uid cooler is less than the total heat rejection (THR) specied for the given unit. The result will be

slightly higher water temperatures which can cause a small decrease in unit capacity.

1 Fluid coolers are not recommended for higher ambient temperature

6

LOW DECIBEL REMOTE OUTDOOR TYPE – MODEL DAFC-LD

Unit cabinets are constructed of heavy duty gauge aluminum, thoroughly reinforced with

riveted gussets. The interior panels are insulated for sound attenuation. Fan outlets provide

additional strength to fan panel and assure even air ow for quiet operation. Mounting legs

are constructed of heavy duty aluminum and are shipped with the unit for eld installation.

The condenser coil is constructed of plate type die formed, aluminum ns mechanically

bonded to copper tubes and employ full height, self-spacing collars which completely cover

the tube surface. The coil is pressure and leak tested at 425 PSIG air under warm water,

evacuated, dehydrated, and sealed with caps on connections.

Propeller type fans, carefully matched to the coil, cover a large percentage of the coil face

area providing a uniform air distribution. The direct drive fans have heavy duty gauge alumi-

num blades securely riveted to zinc plated, chromate treated center hubs. All fans are stati-

cally and dynamically balanced before shipment and operate at low tip speeds for minimum

vibration and low sound levels.

The fan motors are heavy duty PSC or three phase motors with permanently lubricated ball

bearings. All motors are thermally protected against burn-out and may be started by a single

contactor. Protective slingers shield the motors from weather damage. All motors are factory

wired with leads terminating in a weather protected junction box located on the outside of the

unit casing. Fan motors are 1/2 horsepower, 850 RPM. The fan guards are constructed of

heavy gauge, close meshed steel wire powder coated for corrosion resistance.

All Data Aire DAFC-LD type condensers are E.T.L. listed.

7

Low Decibel Fluid Cooler Selection Chart

All selections based on 40% glycol

Ambient Temperature

95 100 1051

Fluid PD Fluid PD Fluid PD

Model THR GPM Cooler MBH (FT) Cooler MBH (FT) Cooler MBH (FT)

Mini Ceiling

DAM* 01 15 3.5 DAFC 06 30 0.2 DAFC 06 24 0.2 DAFC 06 18 0.2

DAM* 1.5 23 5.3 DAFC 06 36 0.5 DAFC 06 29 0.5 DAFC 07 26 0.6

DAM* 02 30 7.0 DAFC 06 49 1.1 DAFC 06 37 1.1 DAFC 09 34 1.6

DAM* 2.5 36 8.8 DAFC 06 57 1.6 DAFC 06 42 1.6 DAFC 17 40 0.2

Mini Plus

DAP* 2.5 39 8.8 DAFC 06 57 1.6 DAFC 06 42 1.6 DAFC 17 40 0.2

DAP* 03 49 10.5 DAFC 06 63 2.2 DAFC 07 52 2.8 DAFC 24 52 0.3

DAP* 04 69 14.0 DAFC 06 72 3.7 DAFC 21 74 0.6 DAFC 28** 66 0.3

DAP* 05 83 17.5 DAFC 07 89 7.1 DAFC 21 102 1.4 DAFC 30 90 1.8

Large Ceiling Units - Single or Dual Compressor

DAL* 06 104 21.0 DAFC 11 104 3.0 DAFC 21 116 2.0 DAFC 37 105 1.4

DAL* 08 136 28.0 DAFC 21 170 3.3 DAFC 28 146 1.3 DAFC 44 144 2.8

DAL* 10 188 35.0 DAFC 21 188 5.0 DAFC 37 195 3.5 DAFC 50 172 2.9

DAL* 13 225 45.0 DAFC 28 230 3.1 DAFC 40 229 3.9 DAFC 88 244 1.9

Data Temp

DT*D/U 02 33 7.0 DAFC 06 49 1.1 DAFC 06 37 1.1 DAFC 09 34 1.6

DT*D/U 03 49 10.5 DAFC 06 63 2.2 DAFC 07 52 2.8 DAFC 24 52 0.3

DT*D/U 04 69 14.0 DAFC 06 72 3.7 DAFC 21 74 0.6 DAFC 28** 66 0.3

DT*D/U 05 83 17.5 DAFC 07 89 7.1 DAFC 21 102 1.4 DAFC 30 90 1.8

Modular Data Temp

DT*D/U 08 135 28.0 DAFC 21 170 2.3 DAFC 28 146 1.3 DAFC 44 144 2.8

DT*D/U 10 172 35.0 DAFC 21 188 5.0 DAFC 30 185 6.2 DAFC 50** 172 2.9

DT*D/U 13 226 46.0 DAFC 28 230 3.1 DAFC 40 229 3.9 DAFC 88 244 1.9

Data Aire Series

DA*D/U 06 100 21.0 DAFC 11 104 3.0 DAFC 21 116 2.0 DAFC 30 103 2.5

DA*D/U 08 143 28.0 DAFC 21 170 3.3 DAFC 28 146 1.3 DAFC 44 144 2.8

DA*D/U 10 161 35.0 DAFC 21 188 5.0 DAFC 30 185 6.2 DAFC 50 172 2.9

DA*D/U 13 224 45.0 DAFC 28 230 3.1 DAFC 40 229 3.9 DAFC 88 244 1.9

DA*D/U 16 247 56.0 DAFC 30 277 14.4 DAFC 44 283 9.6 DAFC 75 258 2.3

DA*D/U 20 326 70.0 DAFC 40 331 8.4 DAFC 57 331 1.9 DAFC 88 336 4.1

DA*D/U 26 395 91.0 DAFC 44 405 23.1 DAFC 61 417 9.9 DAFC 100 402 4.6

DA*D/U 30 484 105.0 DAFC 61 543 12.8 DAFC 80 484 5.0 N/A N/A N/A

gForce GT

GT*D/U007 33 7.0 DAFC 06 49 1.1 DAFC 06 37 1.1 DAFC 09 34 1.6

GT*D/U011 49 10.5 DAFC 06 63 2.2 DAFC 07 52 2.8 DAFC 24 52 0.3

GT*D/U014 69 14.0 DAFC 06 72 3.7 DAFC 21 74 0.6 DAFC 28** 66 0.3

GT*D/U018 83 17.5 DAFC 07 89 7.1 DAFC 21 102 1.4 DAFC 30 90 1.8

gForce

GF*D/U021 100 21.0 DAFC 11 104 3.0 DAFC 21 116 2.0 DAFC 30 103 2.5

GF*D/U028 143 28.0 DAFC 21 170 3.3 DAFC 28 146 1.3 DAFC 44 144 2.8

GF*D/U035 161 35.0 DAFC 21 188 5.0 DAFC 30 185 6.2 DAFC 50 172 2.9

GF*D/U046 224 45.0 DAFC 28 230 3.1 DAFC 40 229 3.9 DAFC 88 244 1.9

GF*D/U056 247 56.0 DAFC 30 277 14.4 DAFC 44 283 9.6 DAFC 75 258 2.3

GF*D/U070 326 70.0 DAFC 40 331 8.4 DAFC 57 331 1.9 DAFC 88 336 4.1

GF*D/U091 395 91.0 DAFC 44 405 23.1 DAFC 61 417 9.9 DAFC 100 402 4.6

GF*D/U106 484 105.0 DAFC 61 543 12.8 DAFC 80 484 5.0 N/A N/A N/A

* Insert: W - Water or G - Glycol

** The capacity of the selected uid cooler is less than the total heat rejection (THR) specied for the given

unit. The result will be slightly higher water temperatures which can cause a small decrease in unit capacity.

1 Fluid coolers are not recommended for higher ambient temperatures.

8

INDOOR FLUID COOLERS – MODEL DAFC-PB

Cabinets are constructed from 14 gage welded tubular steel and are coated with a heavy

corrosion inhibiting nish for long life. The unit has complete front and side access by means

of high quality furniture grade steel panels with heavy duty hinges. The panels are lined with

1 inch thick, 1.5 pound density insulation. Each door is provided with sure close latches.

Cabinets are painted to match or contrast with other equipment in the space.

The blower is a belt driven centrifugal type, double width, double inlet and is statically and

dynamically balanced as a complete assembly to a maximum vibration level of two mills in

any plane. The blower wheel is supported on a heavy steel shaft with self-aligning ball bear-

ings with minimum life span of 100,000 hours. The blower is driven by a motor mounted on

an adjustable slide base. The drive motor is 1750 RPM. The drive package is belt driven with

dual belts and a variable pitch sheave sized for 200% of the fan motor horsepower. A factory

mounted and wired disconnect is optional.

The coil is constructed with copper tubes and aluminum ns. The coil sits in stainless steel

drain pan. All piping terminates inside the unit cabinet. Standard piping is through the bottom

of the unit. Options are available for either top piping or side piping with short right hand side

door.

Circulating pump(s) may be ordered factory installed as an option.

Air intake is horizontal. Standard discharge is horizontal with top air discharge available as

an option. An optional integral lter rack with 4″ thick, 30% efcient lters (based on ASHRAE

Std. 52-76)MERV 8 is available for the air intake.

All Data Aire DAFC-PB type condensers are E.T.L. listed.

9

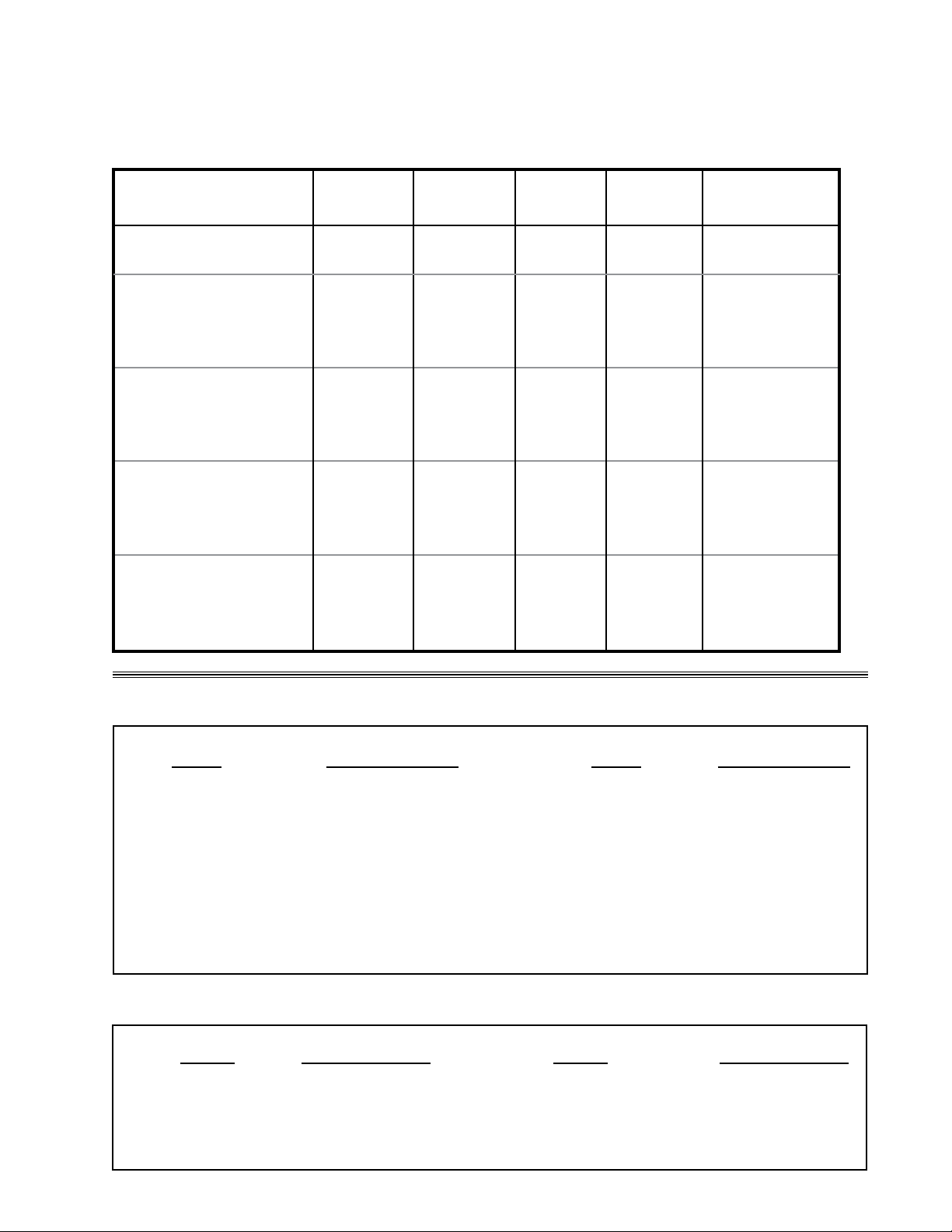

Indoor Fluid Cooler Selection Chart

95° Ambient

Model THR GPM Fluid Cooler MBH PD

Data Temp

DT*D/U-02 36 7.0 DAFC-06-PB 49 1.1

DT*D/U-03 49 10.5 DAFC-06-PB 63 2.2

DT*D/U-04 72 12.0 DAFC-07-PB 81 4.7

DT*D/U-05 88 17.5 DAFC-07-PB 89 7.1

Modular Data Temp

DT*D/U-08 136 28.0 DAFC-15-PB 139 2.5

DT*D/U-10 172 35.0 No Selection

DT*D/U-13 224 46.0 No Selection

Data Aire Series

DA*D/U-06 100 21.0 DAFC-11-PB 104 3.0

DA*D/U-08 146 28.0 DAFC-17-PB 148 1.4

DA*D/U-10 162 35.0 DAFC-17-PB 163 2.1

DA*D/U-13 224 46.0 No Selection

DA*D/U-16 245 56.0 No Selection

DA*D/U-20 310 70.0 No Selection

DA*D/U-26 387 91.0 No Selection

DA*D/U-30 482 105.0 No Selection

* Insert W - Water, G-Glycol

All selections are based on the following conditions:

40% glycol, 125° condensing temperature and 115° uid temperature

DAFC-PB Indoor Fluid Cooler

Electrical Data

Model Motor HP 208-230/3/60* 460/3/60*

DAFC-06-PB 3 9/11/20 4.4/5.5/15

DAFC-07-PB 3 9/11/20 4.4/5.5/15

DAFC-09-PB 3 9/11/20 4.5/5.5/15

DAFC-11-PB 7.5 23/28/50 11/14/20

DAFC-15-PB 7.5 23/28/50 11/14/20

DAFC-17-PB 7.5 23/28/50 11/14/20

DAFC-21-PB 3 27/24/60 13/17/25

DAFC-21-PB 3 27/24/60 13/17/25

DAFC-28-PB 3 27/24/60 13/17/25

* FLA/MCA/MOP (FLA -Full load amps, MCA-Minimum circuit amps wire sizing amps, MOP-Maximum over-

current protection device amp.)

10

DAFC Fluid Cooler Capacity Breakdown

Based on 40% Glycol

DAFC 06 DAFC 07 DAFC 09 DAFC 11 DAFC 15 DAFC 17 DAFC 21

GPM MBH/PD MBH/PD MBH/PD MBH/PD MBH/PD MBH/PD MBH/PD

5 36.9/.04 41.7/.05

10 61.0/2.0 69.2/2.6 72.0/3.1

15 73.9/4.2 83.7/5.4 90.6/6.5

20 82.0/7.1 92.4/9.0 99.5/10.9 101.6/2.7

25 86.2/10.6 97.0/13.4 112.8/4.1 172.6/2.7

30 121.5/5.7 143.6/2.9 191.2/3.8

35 126.7/7.5 152.8/3.8 206.8/5.0

40 132.1/9.5 160.1/4.8 171.7/2.7 220.4/6.4

45 136.7/11.8 166.0/6.0 178.7/3.4 231.5/7.9

50 140.6/14.2 168.9/7.2 184.5/4.1 237.5/9.5

55 173.0/8.6 189.4/4.8 244.7/11.3

60 176.5/10.1 193.4/5.7 250.9/13.2

65 179.5/11.6 196.7/6.5

70 182.2/13.3 198.0/7.5

75 200.5/8.5

80 202.8/9.5

85 204.9/10.6

100 206.7/11.8

DAFC 24 DAFC 28 DAFC 30 DAFC 37 DAFC 40 DAFC 44 DAFC 50

GPM MBH/PD MBH/PD MBH/PD MBH/PD MBH/PD MBH/PD MBH/PD

30 229.7/4.7 229.7/4.7

35 219.2/2.8 251.5/6.2 251.5/6.2 298.4/4.1 305.6/2.9

40 233.9/3.9 244.2/2.5 270.7/7.9 285.1/4.4 295.8/3.1 325.9/5.3 336.1/3.6

45 246.4/4.4 257.6/3.1 286.7/9.7 303.0/5.5 315.3/3.8 349.8/6.5 362.5/4.5

50 257.4/5.3 268.9/3.7 296.5/11.7 318.9/6.6 331.4/4.6 370.5/7.9 385.4/5.5

55 267.0/6.3 278.7/4.4 307.3/13.9 332.9/7.8 345.7/5.4 388.6/9.3 405.3/6.5

60 275.1/7.4 287.3/5.1 344.9/9.2 358.5/6.3 404.6/10.9 422.8/7.6

65 281.2/8.6 294.9/5.9 354.3/10.6 369.8/7.3 418.8/12.6 438.0/8.7

70 284.3/9.8 301.6/6.8 359.7/12.1 379.7/8.4 429.0/14.4 451.5/10.0

75 289.0/11.1 307.1/7.7 367.0/13.7 388.1/9.5 463.5/11.3

80 293.2/12.4 311.3/8.6 394.7/10.4 474.3/12.7

85 297.0/13.9 313.1/9.6 398.0/11.9 481.5/14.2

90 316.5/10.7 400.3/13.2

** Continued on next page **

11

Fluid Cooler Internal Volume

Fluid Cooler Internal Volume Fluid Cooler Internal Volume

Model Volume, Gallons Model Volume, Gallons

DAFC 06 2.5 DAFC 37 13.0

DAFC 07 3.4 DAFC 40 16.3

DAFC 09 4.2 DAFC 44 16.2

DAFC 11 3.3 DAFC 50 20.3

DAFC 15 4.9 DAFC 57 24.6

DAFC 17 6.6 DAFC 61 19.6

DAFC 21 7.4 DAFC 75 26.0

DAFC 24 9.8 DAFC 80 32.6

DAFC 28 12.3 DAFC 88 32.4

DAFC 30 9.8 DAFC 100 40.6

Copper Piping Internal Volume

Pipe Diameter Volume per 100 Feet Pipe Diameter Volume per 100 Feet

inches of Pipe, Gallons inches of Pipe, Gallons

5/8 1.2 2-1/8 16.1

3/4 1.8 2-5/8 24.8

7/8 2.5 3-1/8 35.4

1-1/8 4.3 4-1/8 62.2

1-5/8 9.2

DAFC Fluid Cooler Capacity Breakdown - Continued

Based on 40% Glycol

DAFC 57 DAFC 61 DAFC 75 DAFC 80 DAFC 88 DAFC 100

GPM MBH/PD MBH/PD MBH/PD MBH/PD MBH/PD MBH/PD

45 379.7/2.8

50 408.8/3.4

55 435.2/4.0

60 459.4/4.7 480.0/2.6

65 482.0/5.4 505.5/3.0

70 503.1/6.2 528.9/3.5 596.8/4.1

75 522.9/7.0 550.3/3.9 625.4/4.7 642.8/3.3

80 488.3/2.5 541.4/7.9 570.1/4.4 591.6/3.1 651.8/5.3 672.2/3.6

85 502.4/2.8 558.3/8.8 588.6/4.9 611.6/3.4 676.6/5.9 699.4/4.1

90 515.2/3.1 573.4/9.7 606.0/5.5 629.9/3.8 699.6/6.5 725.0/4.5

95 527.0/3.4 586.2/10.7 622.4/6.0 647.0/4.2 721.0/7.2 748.6/5.0

100 537.8/3.7 593.0/11.7 637.8/6.6 662.8/4.6 741.0/7.9 770.8/5.5

110 557.4/4.4 614.5/13.9 665.8/7.8 691.5/5.4 777.2/9.3 810.6/6.5

120 574.6/5.1 689.8/9.2 717.0/6.3 809.2/10.9 845.6/7.6

130 589.9/5.9 708.5/10.6 739.6/7.3 837.6/12.6 876.0/8.7

140 603.1/6.8 719.5/12.1 759.4/8.4 858.0/14.4 903.0/10.0

150 614.2/7.7 734.0/13.7 776.2/9.5 927.0/11.3

160 622.7/8.6 789.4/10.7 948.6/12.7

170 626.2/9.6 796.1/11.9 963.0/14.2

180 633.0/10.7 806.7/13.2

190 639.1/11.7 816.2/14.5

200 644.6/12.9

12

Installation and Maintenance

Inspection

This Data Aire unit has been factory run-tested and passed a comprehensive inspection

prior to its packaging and shipment to ensure that it arrives in excellent condition. However,

shipping damage can occur and a visual inspection of the outer crating immediately upon

delivery should be performed.

Note any external damage or other transportation damage on the freight carrier’s forms.

Inspect the unit itself for internal damage. A claim should be led with the shipping company

if the equipment is damaged or incomplete.

Loose items such as remote control panels, disconnect switch handles, or other items are

packed inside the unit. Refer to the yellow shipping tag located on the unit door for details.

Freight damage claims are the responsibility of the purchaser. Action to recover

losses should be led immediately. Please notify factory personnel of any claims.

Location

Remote heat exchangers must be located in an area that will ensure free air ow into and

out of the unit plus adequate service clearance. The unit should not be placed any closer

than 36” from any wall, with no more than two walls, or other obstruction.

With proper clearance on all other sides, two units can be placed side by side. Additional

units should be placed no closer than 48” apart.

Leg Assembly

The legs must be unbolted from their collapsed shipping position and extended prior to

placing the unit on its pad. Each leg extends down approximately 18” and reattaches using

the same bolts (see detail “A-A”, drawing entitled Fluid Coolers DAFC Model 05-50 on page

14). Note: Failure to extend the legs will result in poor air distribution over the cooling coil

resulting in signicant capacity reduction.

Concrete pads are often used to provide support for the heat exchanger when set on the

ground. Bolt holes in the bottom of each leg can be used to anchor the unit. Units mounted

on a roof should be placed on rails designed to distribute the unit’s weight. Standard practices

and local codes should be followed in either instance.

Rigging

The heat exchanger should be moved to its (typically rooftop) mounting location using a

crane or fork lift. Each fan section has heavy, steel leg supports with lifting holes at the top.

Do not lift with a choke sling around the unit. Spreader bars are recommended for lifting

multiple fan units. Under no circumstances should the coil headers or piping be used for

lifting the unit. Ideally, the unit should be kept in its shipping crate until it is ready to be set in

place.

(See drawing on next page.)

13

Fan Motor Controls

Fluid cooler fan motors are cycled on and off by individual water-sensing thermostats

strapped to the leaving water header. The rst fan motor will only have a thermostat if the

unit has an energy saver coil. Without the optional energy saver coil, the rst fan motor runs

whenever there is a call for cooling via an auxiliary signal sent by the indoor evaporator.

The water-sensing thermostats have adjustable setpoints which are typically staggered

to maintain water temperature in the 85° to 105° F range. This is generally the desired range

for glycol cooled systems. These set points are factory set but may require eld adjustment

based on local conditions and application.

Energy Saver Cooling

In colder climates, the evaporator will often be equipped with an additional free cooling

coil to take advantage of the colder ambient temperatures. When incoming uid falls below

the setpoint of a water-sensing thermostat in the evaporator (typically about 50° F), energy

saver cooling becomes available.

Systems with an energy saver coil should have at least one uid-sensing thermostat on

the uid cooler set lower to take advantage of colder ambient temperatures. The desired uid

temperature for energy saver cooling is 45° F. Field adjustment of uid-sensing thermostats

is not unusual.

It is desirable to use the energy saver mode as much as possible. However, uid

temperature that is too cold can cause excessive dehumidication and coil sweating. Fluid

temperature that is too high can cause the indoor space temperature to rise. This can cause

the indoor microprocessor controls to lock out the energy saver mode for one hour while it

reverts back to compressorized cooling. Adjust the setpoints of the thermostats to allow the

maximum free cooling time. Overcooling or undercooling the uid should be avoided.

Every application will have a different ambient temperature and indoor heat load/air

distribution prole. Therefore it is not possible to dictate the exact water-sensing thermostat

setpoints. Field adjustments are typical to allow ne-tuning to specic conditions.

14

Glycol System Concentration

Fill the system with water and sufcient antifreeze (ethylene or propylene glycol) to

protect the system against winter freeze-up. Refer to the chart below for amount of glycol

required to prevent freezing.

Freezing Point of Aqueous Solutions

Ethylene Glycol Freezing Point Propylene Glycol Freezing Point

% by Volume Degrees F % by Volume Degrees F

0 32° 0 32°

10 24° 10 27°

20 15° 20 18°

30 4° 30 8°

40 -13° 40 -6°

50 -33° 50 -26°

In order to achieve the appropriate glycol concentration it is necessary to know the vol-

ume that the system contains. The total volume includes the amount of liquid required by the

Data Aire indoor evaporator, uid cooler, and the interconnecting piping. Glycol percentage

must be checked after installation and on periodic intervals to insure satisfactory protection.

Hydrometers are required to insure an accurate reading.

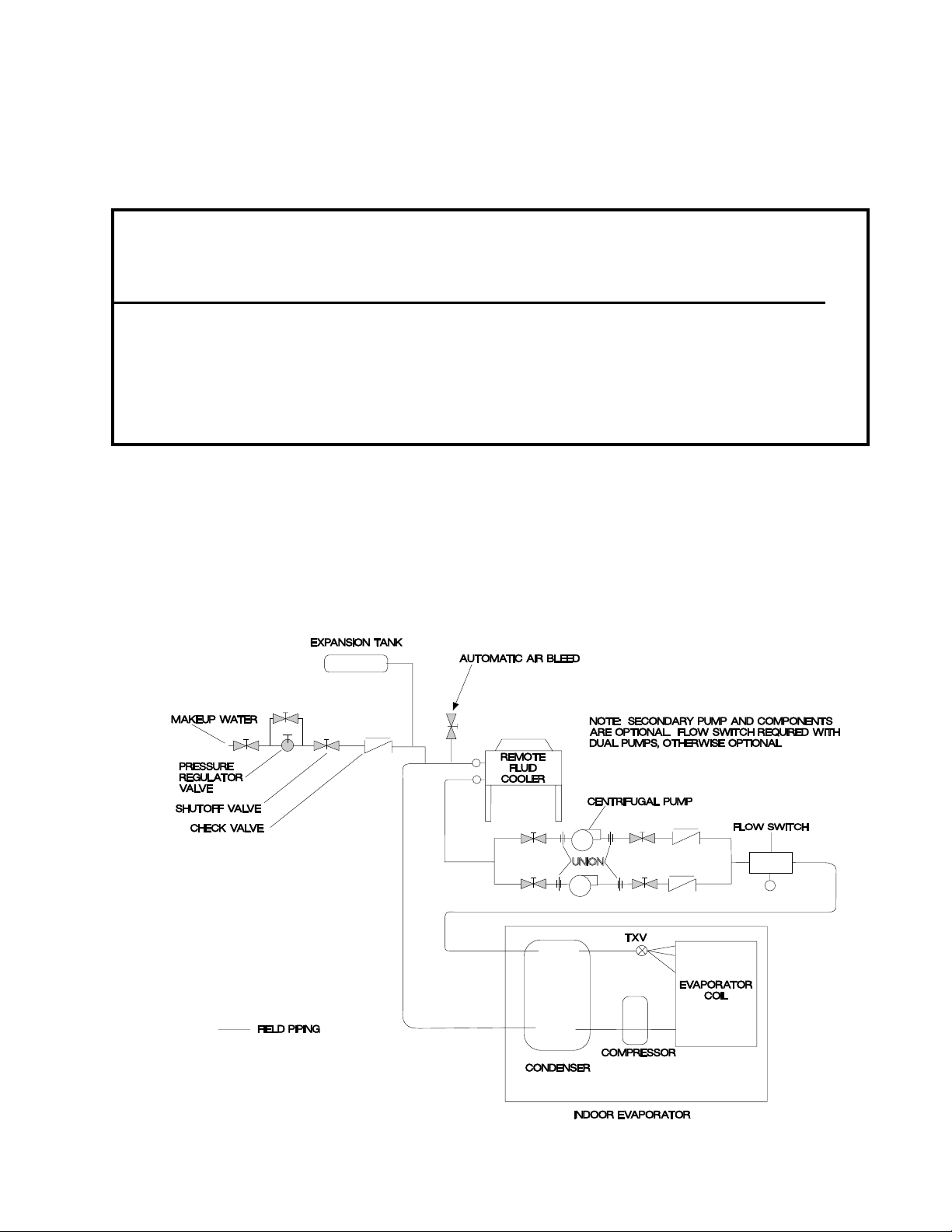

Field Piping

15

Electrical Service

Check to be sure the service provided by the utility is sufcient to handle the additional

load imposed by the uid coolers. Most units with secondary heat exchangers will require a

separate power source and eld-provided, interconnecting control wires.

Glycol systems with uid coolers and loose pump(s) typically require one power source

for the uid cooler and will require one additional source for a single pump or two additional

sources for dual pumps. Systems where the pump(s) are mounted and piped integral to the

Fluid Cooler will usually require a single power source.

Nameplate Ratings

Refer to the unit electrical nameplate for equipment electrical requirements. Minimum

circuit ampacity (MCA), also known as wire sizing amps, will dictate the minimum required

wire gauge. Maximum overcurrent protection (MOP) device amps will dictate the maximum

circuit breaker or fuse size.

Grounding

The unit cabinet must have an uninterrupted true earth ground. An electrical ground wire of

adequate size must be connected to the ground lug provided inside the main electrical box.

Voltage Tolerance

The supply voltage to the unit must be within 10% (under by 5% when voltage is 208V)

of the voltage indicated on the unit electrical nameplate. Phase to phase imbalance must

not exceed 3%. The local utility company should be contacted for correction of improper line

voltage. Deviation from voltage ratings can cause premature failures and possibly void unit

warranties.

Auxiliary Control Wiring

For control wiring to the uid coolers connect two 18 gauge wires from the electrical box

of the indoor evaporator to the electrical box of the remote uid cooler. Follow the wiring

diagrams for each of these pieces of equipment. On most evaporators the terminals will

be #46 and #47 (older units with the Data Alarm Processor (DAP) II and III, the terminals

are #42 and #43). On most remote heat exchangers the terminals will be #39 and #40. All

control wiring on Data Aire equipment is 24 VAC or less. Refer to wiring diagrams.

Check the wiring connections in the unit control panel to ensure they are tight. Screw

terminals may become loose in transit. Tightening of wiring connections is the responsibility

of the installing contractor.

16

Preventive Maintenance

The operating life of the DAFC uid cooler can be extended by following a simple preven-

tive maintenance schedule. This schedule will reduce the possibility of failure of compo-

nents and unnecessary malfunction of the system. Although the service technicians must

be thoroughly familiar with the special design features of this equipment before attempting

any service or repair, an inexperienced technician can perform certain simple maintenance

functions to assure normal, trouble-free operation.

Maintenance Functions

Monthly

Check heat exchanger for obstruction to the inlet air side of coil.

Bleed air from glycol system.

Seasonally

Check electrical components for loose wire connections.

Check contactor contacts for pitting.

Check glycol solution level in the system.

Check fan motor(s)

Bi-Annually

Check the glycol solution inhibitors. Inhibitor level prevents corrosion and

glycol concentration prevents freezing. Flush as necessary.

Clean the coil.

Annually

Check the glycol system for leaks and corrosion.

17

Notes

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

Notes

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

Data Aire, Inc.

230 W. BlueRidge Ave. ISO 9001-2008 Certied

Orange, CA 92865 A Member of the C/S Group of Companies

800-347-2473 Creating Products That Make Building Better

www.dataaire.com

Data Aire, Inc. reserves the right to make design changes for the purpose

of product improvement or to withdraw any design without notice.

FluidCoolerSGIOM 04/2015

This manual suits for next models

1

Table of contents

Other Data Aire Accessories manuals

Popular Accessories manuals by other brands

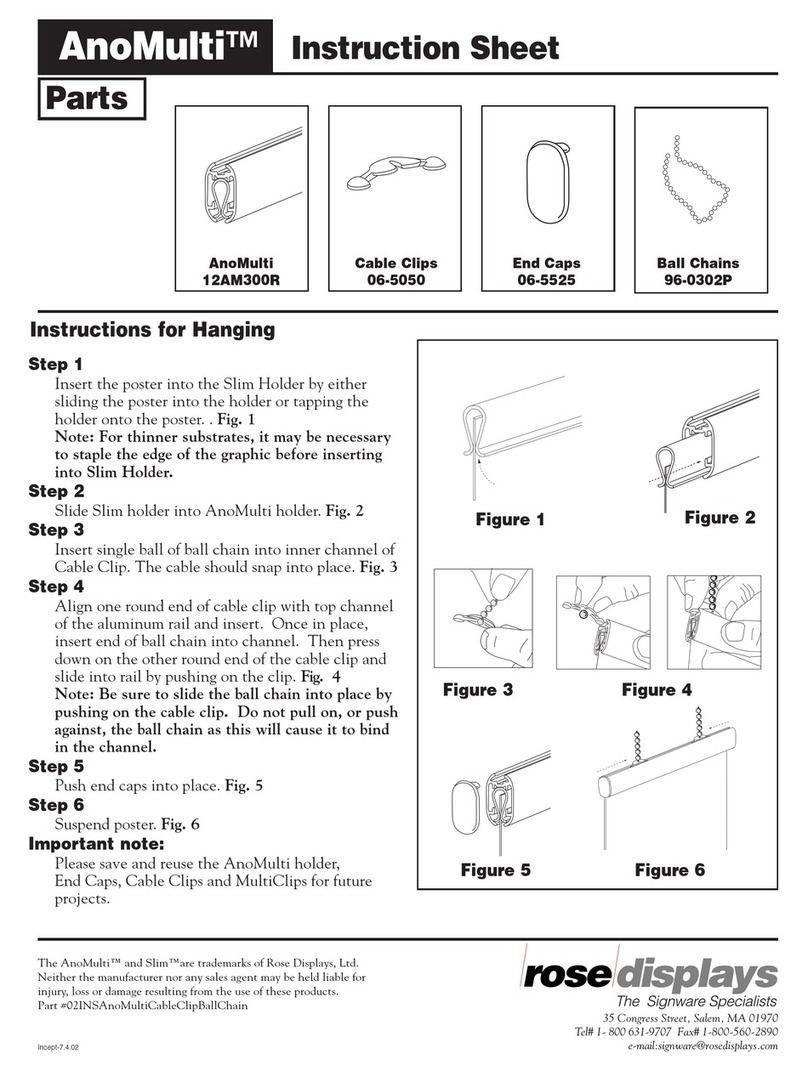

ROSE DISPLAYS

ROSE DISPLAYS ANOMULTI ROUND WITH CABLE CLIP AND BALL... instruction sheet

Linea 2000

Linea 2000 DOMO DO601ED Instruction booklet

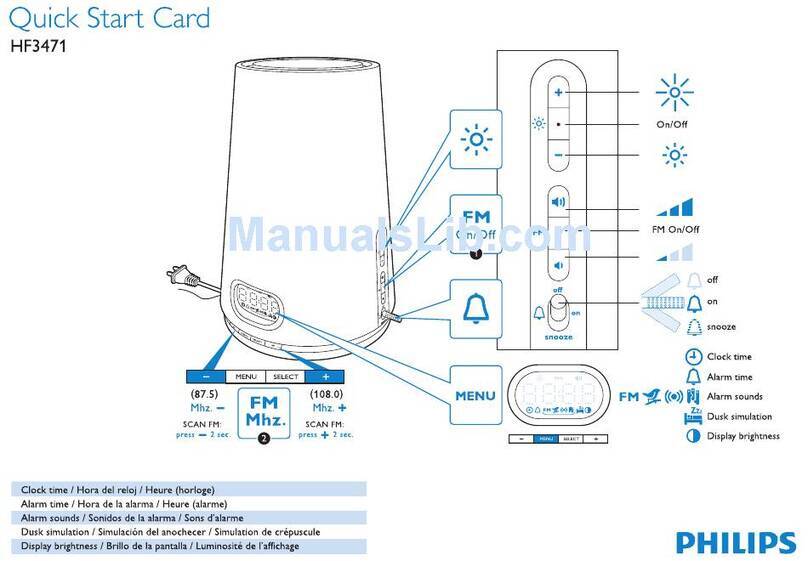

Philips

Philips HF3471/60 quick start guide

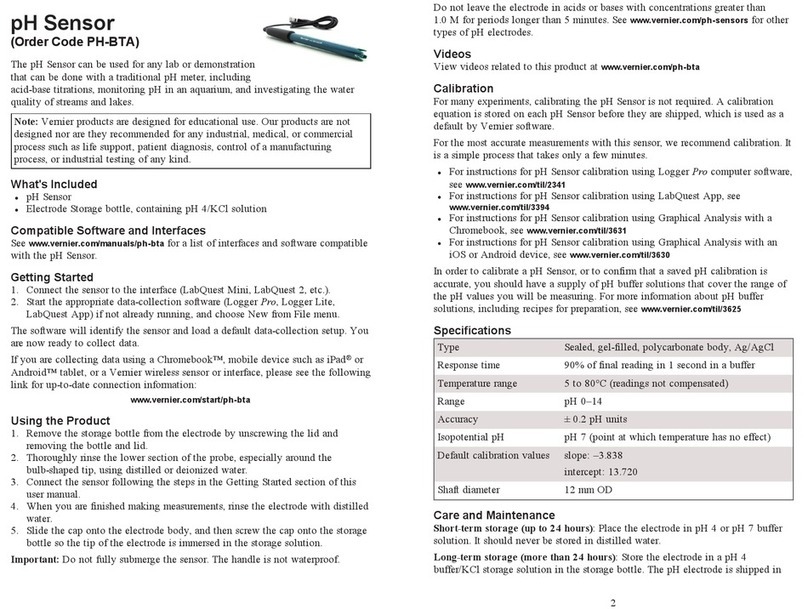

Verner

Verner pH Sensor manual

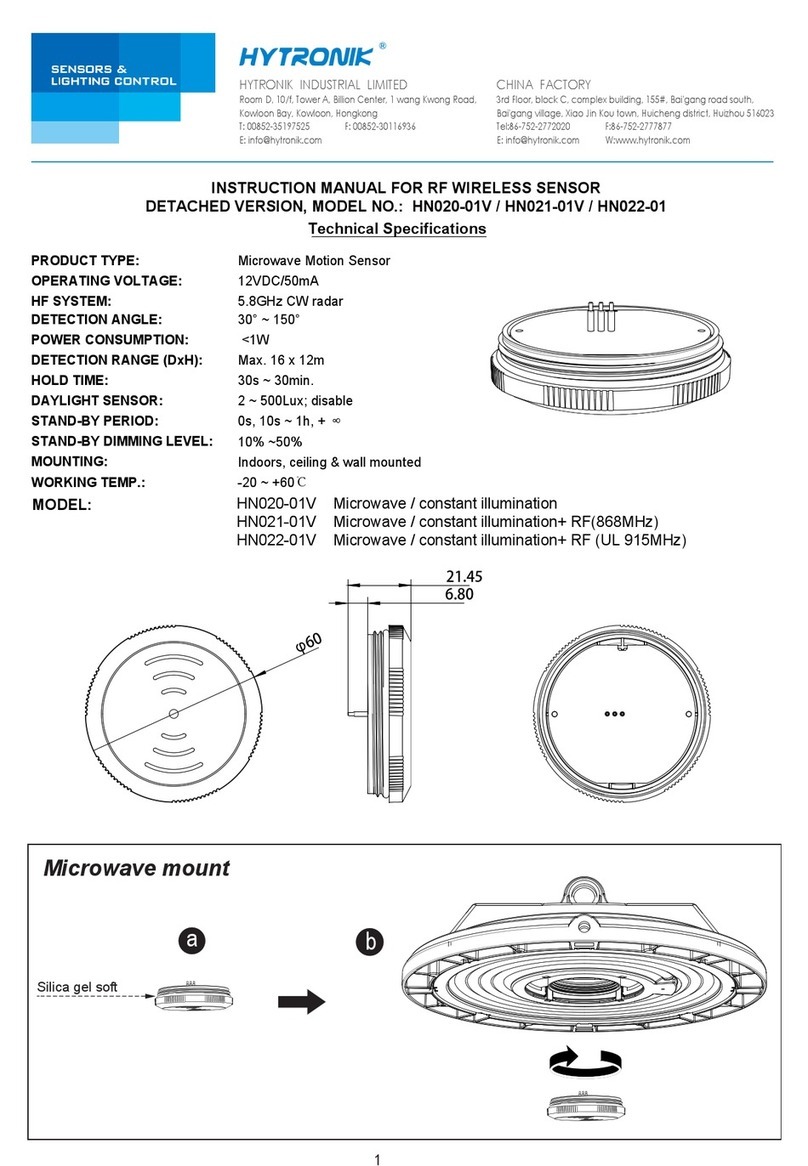

Hytronik

Hytronik HN020-01V instruction manual

CMD

CMD PortHole Information and installation guide