Datamax I-Class User manual

92-xxxx-01 Rev. A

HF and UHF RFID Modules

Installation and Operating Instructions

Datamax International

Herbert House

12 Elizabeth Way, Pinnacles

Harlow, Essex CM19 5FE UK

Phone: +44 1279 772200

Fax: +44 1279 424448

Asia-Pacific

19

Loyang

Way

#01-01 Changi Logistics Centre

Singapore 508724

Phone: +65 542-2611

Fax: +65 542-3611

Corporate Headquarters

4501 Parkway Commerce Blvd.

Orlando, Fl 32808

Phone: 407-578-8007

Fax: 407-578-8377

Printed U.S.A. Copyright 2004

Note: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

CAUTION: This device complies with FCC Radio Frequency exposure limits for an uncontrolled environment.

This equipment should be installed and operated with a minimum distance of 20cm between the

radiator and your body. If 20cm distance cannot be maintained, end users are to be 20cm from

printer extremity.

CAUTION: Any changes or modifications to this RFID module not expressly approved by Datamax Corporation

will void the user’s authority to operate the equipment.

Firmware Required

This option requires Application Version ‘8.04’ or greater to operate.

Preparing the Printer

Start this installation by ensuring that the printer has the correct Application Version as follows:

1. With the printer powered ‘On’ and loaded with media, press the Key.

;

Note: To capture all of the printed information, use 2-inch (51 mm) or wider media, with a Label Width

setting that is matched to the label’s width. See the Operator’s Manual for details.

2. Using the Key, scroll to Print Configuration.

3. Press the Key.

4. Examine the Application Version

printed on the label. Compare that

number with the example, shown right.

Ensure that the Application Version is

at a level of 08.03, or greater.

5. If necessary, update the Application Version by downloading the firmware file for your model printer

from ftp://ftp.datamaxcorp.com/anonymous/temp/rfid/ then follow the “Updating Printer

Firmware” procedure found in the Operator’s Manual.

SYSTEM SETTINGS

INTERNAL MODULE

1024

SCALABEL FONT CACHE

232

SYMBOL SET

DATAMAX

ABSOLUTE COUNTERS

0 inches

DATE NOT SET

RESETTABLE COUNTERS

CONFIGURATION

DATE NOT SET

PRINTER KEY:

4208-PA99-000412-488

APPLICATION VERSION:

83-2368-07ZN1 07.26 CP 09/19/2003

BOOT LOADER:

83-2268-02M 03.04 10/31/2000

Installing the Option

Follow the steps below if installing the RFID module. If the RFID module is already installed proceed to

the next section.

1. Turn off the power switch and unplug the

printer.

2. Open the cover and remove the three Screws

that secure the Front Cover Panel to the

printer.

Screws

Front Cover

Panel

3. Position the RFID Front Cover Panel on the

printer and re-install two of the previously

removed screws, as shown.

Screws

RFID Front

Cover Panel

4. Route the RFID Cable as shown.

5. Connect the RFID Cable to the connector in

the printer’s Centerplate.

This completes the installation. Load Smart

labels and ribbon (if necessary) then close the

printer’s cover.

RFID

Cable

Centerplate

RFID Programming Information

The RFID option uses a programming device with antenna mounted

just after the print head. The device is attached to the cover and thus

the cover should be down for all printing applications. The RFID

module will be auto-detected at power-up.

There are 2 different modules currently supported. The first is the

HF (13.56mhz) by SecuraKey, capable of encoding data into

standard ISO 15693 tags, which have four bytes of data per block

with the number of blocks different for each manufacturer. Texas

Instrument RFID stock contains 64 writable blocks while Philips

contains 28 writable blocks, ST Micro LRI S12 contains 16 writable

blocks.

The second is the UHF (915Mhz) by Alien, capable of encoding data

into Alien Class 1 EPC tags. These contain 64 or 96 bits of user

programmable data.

RFID

Module/Antenna

This section provides details of the Datamax DPL commands necessary to enable, configure, read, write,

and verify RFID tags. It is divided into the following sections: Initialization, Database/Menu, Data Input,

Interfaces, Data Output, and Diagnostics. This document also provides information pertaining to the

scanner option related to the data read and number of valid or defective scans (good or bad barcodes).

Initialization

The initialization interface to the optional RFID module is auto baud detectable. If the option is enabled

or the COM2 interface has the option selected (jumper settings on selective I/O) the firmware will query

the module by sending a unique request for info from the module (i.e. version string/firmware revision

request) on various supported Baud Rates to determine if the module exists.

Database / Menu

Database and Menu Selection will be constructed to support the following system level data.

The following resides on the operator’s front panel menu under “PRINTER OPTIONS” →“RFID”.

Upon selection the display will show “NOT INSTALLED” if the device is not equipped or not

communicating and then proceed to the Mode selection.

RFID

MODE DISABLE, UHF (915mhz), HF(13.56mhz)

POSITION 0.00 - 4.00. Currently if value is 0.00 print

position is used to encode tag. If > 0.00

presented position is used.(Subject to

change.)

HF SETTINGS

AFI VALUE 2 Char Hex Value (Industry Codes)

AFI LOCK E

NABLE or DISABLE

DFSID VALUE 2 Char Hex Value (Industry Codes)

DFSID LOCK E

NABLE or DISABLE

EAS VALUE 2 Char Hex Value (Mfg. Codes)

UHF SETTINGS

LOCK CODE 2 Char Hex Value

LOCK AFTER WRITE E

NABLE or DISABLE

ERASE ON FAULT ENABLE or DISABLE

RETRY ATTEMPTS 0 -> 9

AUTO DETECT TAG Moves label to find tag.

AFI - Application Family Identifier

DFSID - Data Storage Format Identifier

EAS - Electronic Article Surveillance

The following resides on the operator’s front panel menu under “COMMUNICATIONS” →“HOST

SETTINGS” →“OPTION FEEDBACK”.

OPTION FEEDBACK DISABLE, RFID, ASCII, HEX, SCANNER

Data Input

The input data is in the form of new System and Label Formatting commands. The system level commands consist

of Database and Direct User Interface.

Database setup commands <STX>KcRI and response data <STX>KcQQQ support the entries that are shown in the

Operator’s Menu interface.

STX KcRIa

RFID Configuration

RI M, A, D, S,

L, R, W, E, P

See Table Below. Printer Options

(RF) RFID Configuration – This command configures the optional RFID interface module as follows:

Value Range / Interpretation

M, A, D, S, L,

R, W, E, P

Mn - Mode (enables RFID module detection by the printer):

Where n is:

D - disabled (RFID disabled); N is also a valid disabler

U - UHF (915mhz)

H - HF (13.56mhz)

(HF) - Ahhl - Application Family Identifier (AFI); where hh is 2 Char Hex ID & l is Lock after

write (E-Enable /D-Disable)

(HF) - Dhhl - Data Storage Format Identifier (DSFID); where hh is 2 Char Hex ID & l is Lock

after write (E-Enable /D-Disable)

(HF) - Shh - Electronic Article Surveillance (EAS) Set; where hh is 2 Char Hex ID representing

manufacturers code

(UHF) - Lhh – Lock Code; where hh is 2 Char Hex ID

Rn - Number of retries (n = 0 to 9)

Wn – Lock after write; where n is: (E-Enable /D-Disable)

En – Erase (erase tag) on error; where n is: (E-Enable /D-Disable).

Pxxx - Position. Currently if value is 0.00 print position is used to encode tag. If > 0.00

presented position is used.(Subject to change.)

RFID Configuration Set Commands

Example: <STX>KcRIMH;RIA11E;RID22E;RIS04;RIR3;RIWE;RIEE;RIP000<CR>

The above example sets the printer to HF, protect after write AFI 11, protect after write DFSID 22, set EAS Bit

(Mfg. Code 0x04), allow 3 tries for each read or write attempt, lock after write and erase the tag if there is an error

and position of 0.00.

STX KcOFa

Option FeedBack

OF D, Rx, S See Table Below. Printer Options

(OF) Option Feedback Mode – This command configures the printer to output the status of the RFID

operation to the current port. See Data Output section for details of the response.

Value Range / Interpretation

D, Rx, S

D - Disable

R - RFID Enable, where x = A - ASCII Response, x = H - Hexadecimal response

S - Scanner Enable

Interfaces

The printer has two modes of operation for programming the RFID tags: Direct and Label Formatting

Mode.

The Direct Mode allows the User (Host) to control the reading and writing of the RFID Tag directly.

Each RFID tag is individually processed with status and data responses. This mode contains both a

generic Read/Write Interface or High Level Tag HF or UHF specific interface.

The Label Formatting Mode utilizes the current printer configuration to process all the reads, write, and

exception processing, (for exception processing and fault handeling see the Operator’s Manual) for each

tag printed. The specification for the RFID operation is contained in the data fields of a DPL label

format. The label format instructs the printer to write data, read data and update selective fields prior to

printing the label. It supports auto increment and decrement commands (+/-). NOTE: Currently only one

RFID operation per label is allowed.

The RFID Programming Data can be entered in one of two different formats: ASCII and Hexadecimal.

The ASCII format is entered as you would normally see it, i. e 'DATA'. The Hexadecimal format is

entered as the hexadecimal equivalent of the ASCII, i.e DATA becomes '44415441'. When entering byte

counts you must take into account the data format you are entering it in. For ASCII mode 'DATA' has a

byte count of 4. For hexadecimal mode '44415441' has a byte count of 8.

Direct Mode - Generic Read/Write Interface

This interface allows the Host Application to send generic commands for RFID operations. These

commands consist of simple read and write operations requiring no knowledge (except data format) of the

tag types being used. They utilize the printer’s database for specific parameters.

STX KaW Write Data to RFID Tag

This command instructs the RFID device to write data to the tag. It is expected that the tag transponder is

within read/write distance of the RFID programming device otherwise a fault will occur and a warning

message will be displayed.

Syntax: <STX>KaWAaaabbbbcddd…

Where: Aaaa - Optional – for data in ASCII format followed by byte count,

000-999

bbb - HF- Starting block number, (000 -> Max block number)*

UHF – Should be 000.

c - Command 1. Reserved for Future (should be 0)

d - Command 2. Reserved for Future (should be 0)

eee - Data to be encoded on RFID tag. (HF - Last used block will be

null padded if necessary)

Sample: <STX>KaW0000054455354[CR]

This example programs the data “TEST” at block zero

*Dependent on transponder manufacturer.

STX KaR Read Data from RFID Tag

This command instructs the RFID device to read data from the tag and put it in a replaceable field. It is

expected that the tag transponder is within read/write distance of the RFID programming device otherwise

a “Void” will print in the text or barcode label fields.

Syntax: <STX>KaRAaaabbbcdee

Where: A - Optional – for data in ASCII format

aaa - Bytes to read.

bbb - HF - Starting block number, (000 ->Max block number)*

UHF – Should be 000.

c - Command 1. Reserved. Should be 0.

d - Command 2. Reserved. Should be 0.

ee - Field number where to place data. Must be 01, 02, 03, etc…

matching the order of label formatting command U.

Note: a 00 value will send read data to host with no printing.

Sample: <STX>L

1911A1802000010TEXT

U

X

<STX>KaR0000010001

<STX>G

This example creates a replaceable text field, 01, and recalls data from the RFID tag block zero,

reading only one block, and prints the data in the location specified by replaceable field. Since there

are two digits per hex value replaceable fields should be twice as long as if using ASCII data. For

example, the character “A” would be returned as “41”.

*Dependent on transponder manufacturer.

Direct Mode - HF (13.56mhz) ISO15693 Tag Interface

This interface allows the Host Application to perform specific operations pertaining to HF type tags.

These commands override the printer database as they interface directly to the tag module. Knowledge of

HF tags and their operation is required.

STX KtW Write Data to RFID Tag

This command instructs the RFID device to write data to the tag. It is expected that the tag transponder is

within read/write distance of the RFID programming device otherwise a fault will occur and warning

message will be displayed.

Syntax: <STX>KtWBnnnaaabcdeeee…

Where: Bnnn

(Optional)

Where nnn is the data byte count, to allow non-printable

characters, i.e. characters with hex values less than 0x20, to be

encoded. For example, the command

<STX>KtWB004000900<0x00><0x01><0x02><0x03>[CR]

will program the hex values 0x00, 0x01, 0x02, 0x03 in block

zero.

aaa - Starting block number, (000->Max block number)*

b - Number of retry attempts, 0-9

c - Lock block after writing

0 - No Protection

1 – Write Protect

d - Reserved. Should be 0.

eeee - Data to be encoded on RFID tag.

Sample: <STX>KtW000510TEST

This example programs the data “TEST” at block zero, will write protect block zero and will attempt

to write five additional times, if necessary.

*Dependent on transponder manufacturer.

STX KtR Read Data from RFID Tag

This command instructs the RFID device to read data from the tag and put it in a replaceable field. It is

expected that the tag transponder is within read/write distance of the RFID programming device otherwise

a “Void” will print in the text or barcode label fields.

Syntax: <STX>KtRHaaabbbcdee

Where: H

(Optional)

- Hexadecimal Data – An “H” may be added directly after

“R” to return a two character hex value of the data.

Since there are two digits per hex value replaceable

fields should be twice as long as if using ASCII data.

For example, the character “A” would be returned as

“41”.

aaa - Starting block number, (000->Max block number*)

bbb - Number of blocks to read, (001-> Max block number)*

c - Number of retry attempts, 0-9

d - Reserved. Should be 0.

ee - Field name where to place data. Must be 01, 02, 03,

etc… matching the order of label formatting command

U.

Note: a 00 value will send read data to host with no

printing.

Sample: <STX>L

1911A1802000010TEXT

U

X

<STX>KtR0000019001

<STX>G

This example creates a replaceable text field, 01, and recalls data from the RFID tag block zero,

reading only one block, attempting nine times, and prints the data in the location specified by

replaceable field.

*Dependent on transponder manufacturer.

STX KtU Read Unique Serial Number from RFID Tag

This command instructs the RFID device to read the unique serial number data from the tag and put it in a

replaceable field. It is expected that the tag transponder is within read/write distance of the RFID

programming device otherwise a “Void” will print in the text or barcode label fields.

Syntax: <STX>KtUabcc

Where: a - Number of retry attempts, 0-9

b - Reserved. Should be 0.

cc - Field name where to place data. Must be 01, 02, 03, etc…

matching the order of label formatting command U.

Note: a 00 value will send read data to host with no printing.

Note: This is a sixteen character alphanumeric value so the replaceable field should be adequate in

length.

STX KtA Write Application Family Identifier (AFI) to Tag

This commands writes the AFI data to the tag.

Syntax: <STX>KtAabcc

Where: a - Number of retry attempts, 0-9

b -

Lock AFI after writing

0 - No Protection

1 – Write Protect

cc - Two character AFI value representing one byte.

Sample: <STX>KtA91C3[CR]

This example writes 0xC3 AFI byte, locking value, retrying 9 times if necessary.

STX KtD Write Data Storage Format Identifier (DSFID) to Tag

This commands writes the DSFID data to the tag.

Syntax: <STX>KtDabcc

Where: a - Number of retry attempts, 0-9

b -

Lock DSFID after writing

0 - No Protection

1 – Write Protect

cc - Two character DFSID value representing one byte.

Sample: <STX>KtD91C3[CR]

This example writes 0xC3 DSFID byte, locking value, retrying 9 times if necessary.

STX KtE Write Electronic Article Surveillance (EAS) Bit

This commands writes the EAS bit for Philips ISO tags.

Syntax: <STX>KtEabcc

Where: a - Number of retry attempts, 0-9

b -

EAS Option:

0 – SET EAS

1 – RESET EAS

2 – TEST EAS

cc - Two character Mfg Code representing one byte.

Sample: <STX>KtE9004[CR]

This example writes EAS bit for Philips (0x04), retrying 9 times if necessary.

STX KtH Read and Feedback Tag Information to Host

This command returns the tag info to host. This currently works only if the Data Flag for the tag is 0x0F,

i.e. the tag contains DSFID, AFI, VICC and IC data.

Syntax: <STX>KtH

Sample Feedback:

DATA FLAG: 0x0F

TAG ID: E004010000751412

DSFID: 0xE3

AFI: 0x01

NUM BLK: 0x1B

BLK SIZ: 0x03

IC REF: 0x01

Direct Mode- UHF (915mhz) Class 1 Tag Interface

This interface allows the Host Application to perform specific operations pertaining to UHF type tags.

These commands override the printer database as they interface directly to the tag module. Knowledge of

ALIEN CLASS 1Tags and their operation is required.

STX KuW Write Data to RFID Tag

This command instructs the RFID device to write data to the tag. It is expected that the tag transponder is

within read/write distance of the RFID programming device otherwise a fault will occur and warning

message will be displayed.

Syntax: <STX>KuWabcc…

Where: a - Number of attempts to locate tag, erase and program. Valid

values: 1-9.

b - Reserved. Should be 0.

c - Data to be encoded on RFID tag in ASCII format. Must be 16

characters length. Valid characters: 0-9, A-F.

Sample: <STX>KuW30ABCDEF0102030405[CR]

This example programs the data <0xAB><0xCD><0xEF><0x01><0x02><0x03><0x04><0x05> to

the tag and will attempt to write three additional times, if necessary.

STX KuR Read Data from RFID Tag

This command instructs the RFID device to read data from the tag and put it in a replaceable field. It is

expected that the tag transponder is within read/write distance of the RFID programming device otherwise

a “Void” will print in the text or barcode label fields.

Syntax: <STX>KuRaa

Where: aa - Field name where to place data. Must be 01, 02, 03, etc…

matching the order of label formatting command U.

Sample:

<STX>L

D11

1911A1801000100 xxxxxxxx

U

1A31050002000200 xxxxxxxx

U

X

<STX>KuR01

<STX>Kur02

<STX>G

This example creates a replaceable text field 01 and barcode field 02. It recalls the data from the tag

and places it into both fields.

STX KuE Erase RFID Tag

This command erases tag.

Syntax: <STX>KuEa

Where: a - Number of attempts to locate tag and erase. Valid values: 1-9.

STX KuL Lock RFID Tag

This command erases tag.

Syntax: <STX>KuLabb

Where: a - Number of attempts to locate tag and lock. Valid values: 1-9.

b - Two character Lock Code value representing one byte.

Commands to Send Data back to Host

STX KuT Send Tag ID

STX KuV Send Tag ID with Verify

STX KuG Send Tag ID with Global Scroll

STX KuI Send Inventory

Label Formatting Mode

Wx / W1x: RFID

abbbcdeeeffffggggjj….j

Field Valid Inputs Meaning

a Operation to perform (Read/Write/Write Verify) 1-Read1,

2- Write,

3-Write/Verify

bbb Wnx, RFID Hexadecimal Operation. No n is an implied 1. RFID

c Not Used

d Not Used

eee xyy, Lock after write

x = 0 - Use printer setup to determine if lock is performed after write.

x = 1 – Perform lock after write.

yy = Lock Code where yy is a 2 character hex value (UHF only).

ffff Starting Block # (HF only), Valid Entries 0000 – 9998 Starting block #

to write

gggg Not Used

jj…j Valid Hexadecimal character string followed by a termination

character.

Write Data

Note 1: Read function not currently implemented.

Example:

<STX>L

D11<CR>

2W1x0000000010000446174616D61782077726974657320524649442062657374<CR>

E

The example above:

Field 1

“2W1x0000000010000446174616D61782077726974657320524649442062657374<CR>”,

the printer encodes the RFID chip starting at block 001 with “Datamax writes RFID best”.

WX / W1X: RFID with Byte Count Specifier

W1X: RFID

abbbcdeeeffffgggghhhhjj….j

Specified Length – The upper case R identifies a RFID data with a string 4-digit length specifier. This

allows values 0x00 through 0xFF to be included within the data strings without conflicting with the DPL

format record terminators. The four-digit decimal data byte count immediately follows the four-digit

column position field. This value includes all of the data following the byte count field, but does not

include itself.

Field Valid Inputs Meaning

a Operation to perform (Read/Write/Write Verify) 1-Read1,

2-Write,

3-Write/Verify

bbb Wnx, RFID ASCII Operation. No n is an implied 1. RFID

c Not Used

d Not Used

eee xyy, Lock after write

x = 0 - Use printer setup to determine if lock is performed after write.

x = 1 – Perform lock after write.

yy = Lock Code where yy is a 2 character hex value (UHF only).

ffff Starting Block # (HF only), Valid Entries 0000 – 9998 Starting block #

to write

gggg Not Used

hhhh Four-digit decimal data byte count and includes all bytes that follow

until the end of the data.

Note: UHF is restricted to 64 to 96 bits (8 to 12 ASCII Characters).

# of bytes to

follow

jj…j ASCII Character string equal to hhhh characters to write. Write Data

Example:

<STX>L

D11<CR>

2W1X00000000100000024Datamax<CR>

writes RFID best<CR>

E

The example above:

Field 1 “1W1X00000000100000024Datamax<CR>Writes RFID best <CR>”includes a Byte Count

Specifier (the portion in bold), where 0024 equals the four-digit decimal data byte count and includes all

bytes that follow until the end of the data. Field termination is set by the byte count. The printer encodes

the RFID chip starting at block 001 with “Datamax<CR>writes RFID best”.

Data Output

Host response must be enabled for the data to be returned to the host. This is under

COMMUNICATIONS: HOST SETTINGS:OPTION FEEDBACK. Set to SCANNER or RFID.

In summary, the firmware will report information about the operation of the last label printed. This

includes a report of the number of expected scans/reads, the number of actual scans/reads, the printer’s

internal JobID, the printer’s internal SubJobId and the data. One response per label is returned to the

host. This includes each voided and retried label. The format of the printer response message is:

<A; B; C; D; E; F>[CR]

Where,

A is device type – “S” for scanner, “R” for RFID, etc…

B is the resulting status - “F” for Faulted label, “C” for entire label complete, "U" for unknown.

C is the number of expected reads (barcodes/tags). (2 characters)

D is the number of good reads. (barcodes/tags) (2 characters)

E is the printer’s internal JobId:SubJobId. (4 characters each)

F is the data read, delimited with ";" if multiple reads.

An example of a successful label would be:

<S;C;03;03;0002:0001;DATA1;DATA2;DATA3>[CR]

An example of a failed label that was retried successfully:

<S;F;02;01;0002:0001;DATA1>[CR]

<S;C;02;02;0002:0001;DATA1;DATA2>[CR]

For RFID tags write and write/verify the data returned is in the same format as it was written. Write

returns entire tag data. Write/verify returns data written. Read returns data and length requested in

specified format.

Write sample response:

<R;C;00;00;0013:0001>[CR]

Write/Verify hexadecimal sample response:

<R;C;01;01;0012:0001;446174616D61782077726974657320524649442062657374>[CR ]

Read hexadecimal Response:

<R;C;01;01;0013:0001;446174616D61782077726974657320524649442062657374>[CR ]

Write/Verify ASCII sample response:

<R;C;01;01;0012:0001; Datamax writes RFID best >[CR ]

Read ASCII Response:

<R;C;01;01;0013:0001; Datamax writes RFID best >[CR ]

Other manuals for I-Class

5

Table of contents

Popular Control Unit manuals by other brands

LOVATO ELECTRIC

LOVATO ELECTRIC EXM10 00 instruction manual

Hirschmann

Hirschmann PTN-7-SERIAL user manual

Telit Wireless Solutions

Telit Wireless Solutions GL865-QUAD V4 Software user's guide

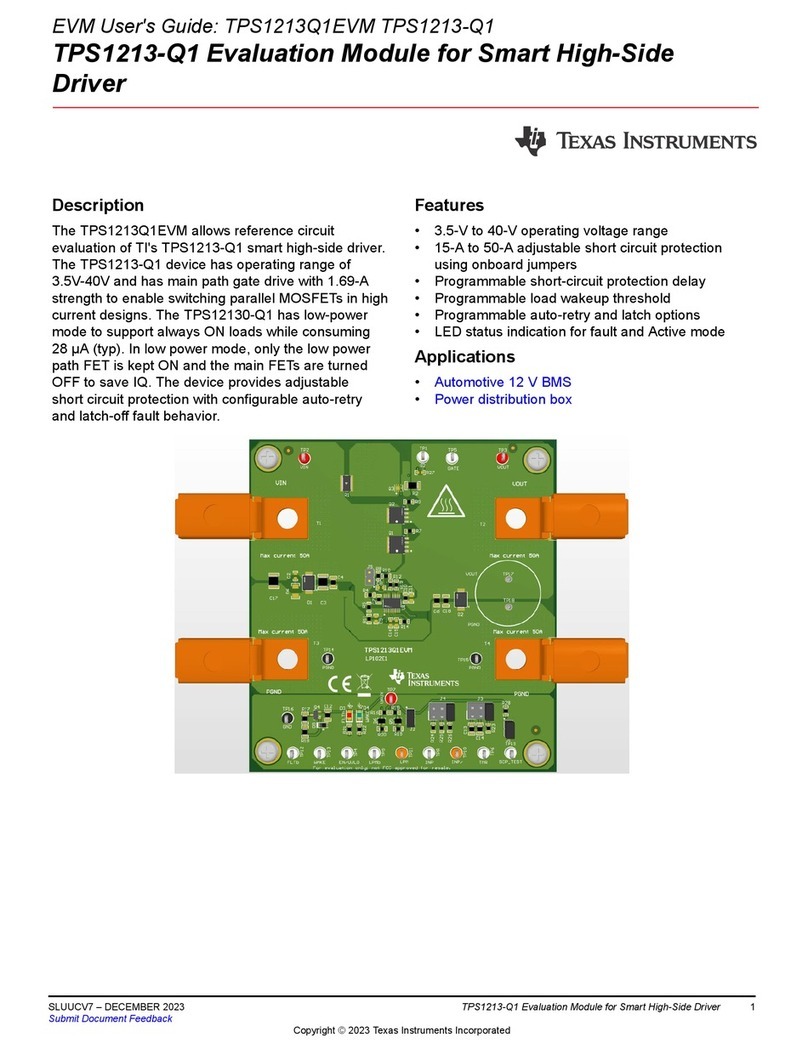

Texas Instruments

Texas Instruments TPS1213Q1EVM user guide

KIESELMANN

KIESELMANN 582x Operating instruction

PVA

PVA JDX owner's manual

Yoshitake

Yoshitake GP-2000 Installation & operation manual

HBC-Radiomatic

HBC-Radiomatic HBC TC693 user manual

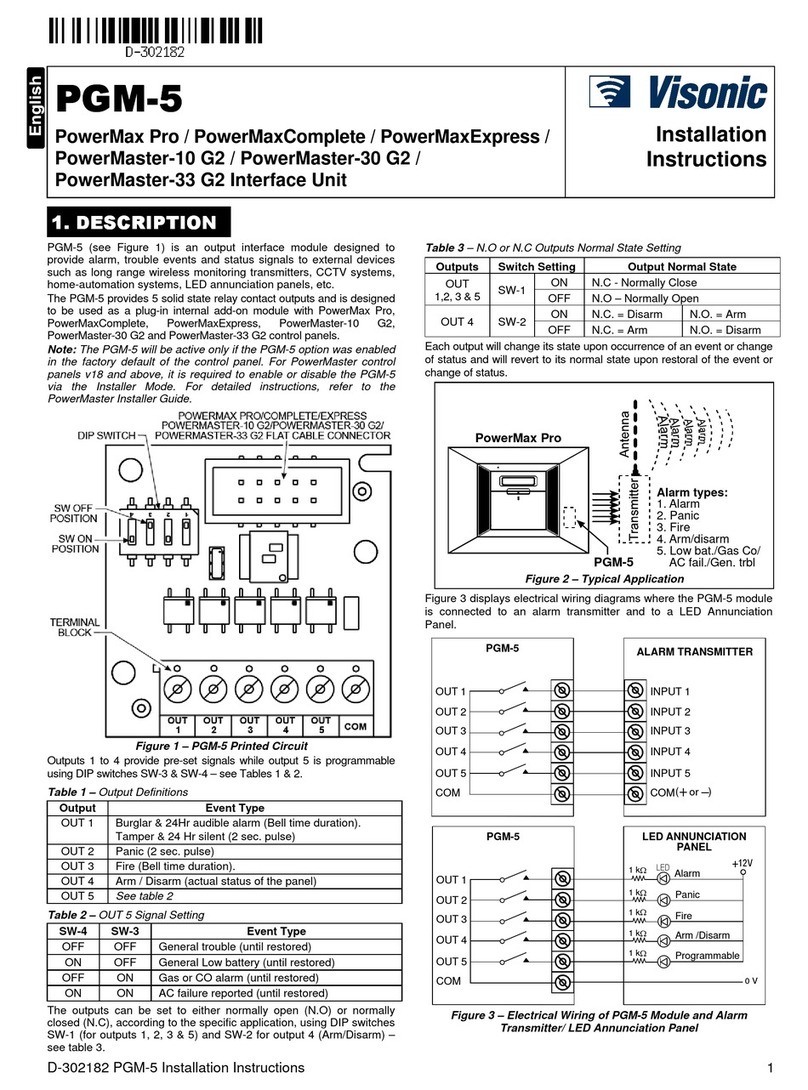

Visonic

Visonic POWERMAX PRO installation instructions

HumanTechnik

HumanTechnik Signolux MV-1 instruction manual

Anybus

Anybus CompactCom 40 Modbus-TCP Network guide

Spirax Sarco

Spirax Sarco 25P Installation and maintenance instructions