Table of Contents

Introduction ............................................................................................. 51.

Document History ............................................................................................... 51.2

Safety .................................................................................................................. 61.3

Theory of Operation............................................................................................71.4

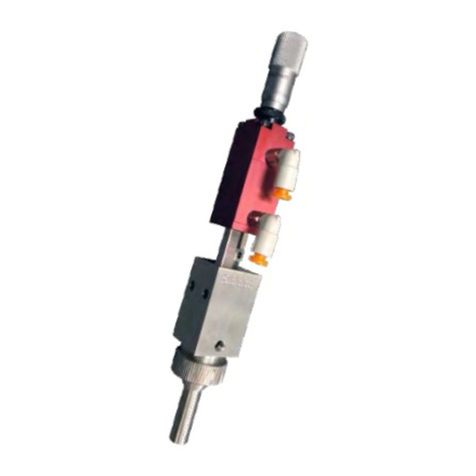

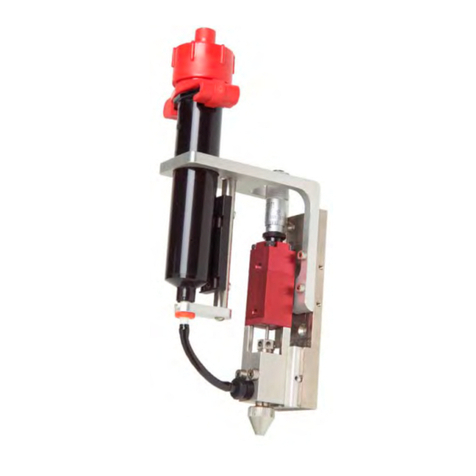

Description of Components ................................................................................ 71.5

Personal Protective Equipment ..........................................................................71.6

Waste Disposal.................................................................................................... 71.7

Necessary Tools ..................................................................................................81.8

Setup........................................................................................................ 82.

Overview .............................................................................................................82.1

Operation................................................................................................. 93.

Install the Diaphragm.......................................................................................... 93.1

Install Nozzle Plate and Feed Tube ...................................................................103.2

Prime the Jet .....................................................................................................123.3

Set the Heater Temperature.............................................................................133.4

Set Fluid Pressure ..............................................................................................133.5

Jet Pressure .......................................................................................................143.6

Jet Shutdown Procedure ...................................................................................143.7

Clean the Wetted Parts.....................................................................................163.8

Replace the Orifice............................................................................................173.9

Maintenance .......................................................................................... 214.

Flush the System ...............................................................................................214.1

How to Use the Valve with Portal ........................................................... 225.

Setup Mode....................................................................................................... 225.1

Select a Recipe ..................................................................................................245.2

Jetter Maintenance...........................................................................................255.3

How to Use the Jet with the PVA JDX Jet Valve Controller ....................... 266.

Jet and Fluid Pressure .......................................................................................286.1

Temperature Controller....................................................................................286.2

To change the SV temperature .................................................................286.2.1