Hirschmann PTN-7-SERIAL User manual

Installation PTN-7-SERIAL Technical support

Release 01 02/2018 https://hirschmann-support.belden.com

User Manual

Installation

Dragon PTN Interface Module

PTN-7-SERIAL

2 Installation PTN-7-SERIAL

Release 01 02/2018

The naming of copyrighted trademarks in this manual, even when not specially indicated, should not

be taken to mean that these names may be considered as free in the sense of the trademark and

tradename protection law and hence that they may be freely used by anyone.

© 2018 Hirschmann Automation and Control GmbH

Manuals and software are protected by copyright. All rights reserved. The copying, reproduction,

translation, conversion into any electronic medium or machine scannable form is not permitted,

either in whole or in part. An exception is the preparation of a backup copy of the software for your

own use.

The performance features described here are binding only if they have been expressly agreed when

the contract was made. This document was produced by Hirschmann Automation and Control GmbH

according to the best of the company's knowledge. Hirschmann reserves the right to change the

contents of this document without prior notice. Hirschmann can give no guarantee in respect of the

correctness or accuracy of the information in this document.

Hirschmann can accept no responsibility for damages, resulting from the use of the network

components or the associated operating software. In addition, we refer to the conditions of use

specified in the license contract.

You can get the latest version of this manual on the Internet at the Hirschmann product site

(www.hirschmann.com).

Hirschmann Automation and Control GmbH

Stuttgarter Str. 45-51

72654 Neckartenzlingen

Germany

Installation PTN-7-SERIAL 3

Release 01 02/2018

Contents

1. INTRODUCTION ......................................................................................................... 5

1.1 General...............................................................................................5

1.2 Manual References .............................................................................6

2. MODULE DESCRIPTION .............................................................................................. 7

2.1 Front Panel And Connection Kits .........................................................7

2.1.1 Handle........................................................................................................7

2.1.2 LEDs............................................................................................................7

2.1.3 RJ.5 Connector...........................................................................................8

2.1.4 RJ.5 Cable...................................................................................................9

2.1.5 Connection Kits..........................................................................................9

2.1.6 Signals per Serial Port ..............................................................................12

2.2 Functional Operation ........................................................................ 13

2.2.1 General ....................................................................................................13

2.2.2 Service Combination Examples per IFM..................................................13

2.2.3 Port Interface Types ................................................................................15

2.2.4 Serial Port Role DTE/DCE .........................................................................15

2.2.5 Synchronization Parameter .....................................................................15

2.2.6 Pin Layout Parameter ..............................................................................16

2.2.7 Services ....................................................................................................16

2.2.8 CES: CESoPSN (Point-to-Point).................................................................17

2.2.9 CES: Hitless Switching ..............................................................................17

2.2.10 CES: Single Path .......................................................................................18

2.2.11 CES: Delay Comparison in CES Features ..................................................19

2.2.12 Serial Ethernet (Point-to-Multipoint) ......................................................20

2.2.13 Serial Ethernet: Master/Slave..................................................................20

2.2.14 Serial Ethernet: Advanced Mode - Bandwidth Optimization..................20

2.2.15 Serial Ethernet: Multidrop Consistency...................................................21

2.2.16 I/O with the Central Switching Module (=CSM) ......................................21

2.2.17 Synchronization / Clock Distribution / Network Timing..........................21

2.2.18 Test and Loopback Selftests ....................................................................24

2.3 Onboard Interfaces ...........................................................................24

2.3.1 Straps .......................................................................................................24

2.3.2 DIP Switches ............................................................................................24

3. TDM FRAMES/PACKET FOR CES................................................................................ 25

3.1 General............................................................................................. 25

3.2 Bandwidth........................................................................................ 25

3.3 Delay ................................................................................................26

3.3.1 General ....................................................................................................26

3.3.2 Delay Parameters ....................................................................................26

3.3.3 Estimated Delay Calculation and Formulas .............................................27

3.3.4 Estimated Delay Examples.......................................................................27

3.4 Tuning CES = Tuning TDM Frames/Packet.......................................... 27

4 Installation PTN-7-SERIAL

Release 01 02/2018

4. MODULE SPECIFICATIONS ........................................................................................ 28

4.1 General Specifications....................................................................... 28

4.2 Other Specifications..........................................................................28

4.3 Ordering Information........................................................................ 28

5. ABBREVIATIONS ...................................................................................................... 28

List of figures

Figure 1 Functional Overview Matrix ............................................................................................ 5

Figure 2 General 7-SERIAL Example .............................................................................................. 6

Figure 3 Front Panel And Connection Kits..................................................................................... 7

Figure 4 RJ.5 Connector................................................................................................................. 9

Figure 5 RJ.5 Cable/Pin Numbering/Color Coding......................................................................... 9

Figure 6 Example1 ....................................................................................................................... 13

Figure 7 Example2 ....................................................................................................................... 14

Figure 8 Example3 ....................................................................................................................... 14

Figure 9 Example4 ....................................................................................................................... 15

Figure 10 Hitless Switching.......................................................................................................... 18

Figure 11 Single Path Enabled ..................................................................................................... 19

Figure 12 Single Path Disabled .................................................................................................... 19

Figure 13 7-SERIAL Clocking/Synchronization Overview............................................................. 22

Figure 14 7-SERIAL: Side View ..................................................................................................... 24

Figure 15 Hardware Edition......................................................................................................... 25

Figure 16 CESoPSN Bandwidth.................................................................................................... 25

Figure 17 Delays .......................................................................................................................... 26

List of Tables

Table 1 Manual References........................................................................................................... 6

Table 2 LED Indications In Boot Operation ................................................................................... 8

Table 3 LED Indications In Normal Operation ............................................................................... 8

Table 4 RJ.5 Cables to Serial Ports Mapping (Basic Kit)............................................................... 10

Table 5 RJ.5 Cables to Serial Ports Mapping (Extension Kit) ....................................................... 11

Table 6 Signals per Serial Port ..................................................................................................... 12

Table 7 Difference Between Hitless and Protection Switching................................................... 18

Table 8 Delay Comparison in CES (Features)............................................................................... 19

Table 9 Clocking Parameters on Port & Service Level................................................................. 23

Table 10 Estimated Delay Formulas ............................................................................................ 27

Table 11 Estimated Delay (µs) Examples..................................................................................... 27

Table 12 Other Specifications...................................................................................................... 28

Installation PTN-7-SERIAL 5

Release 01 02/2018

1. INTRODUCTION

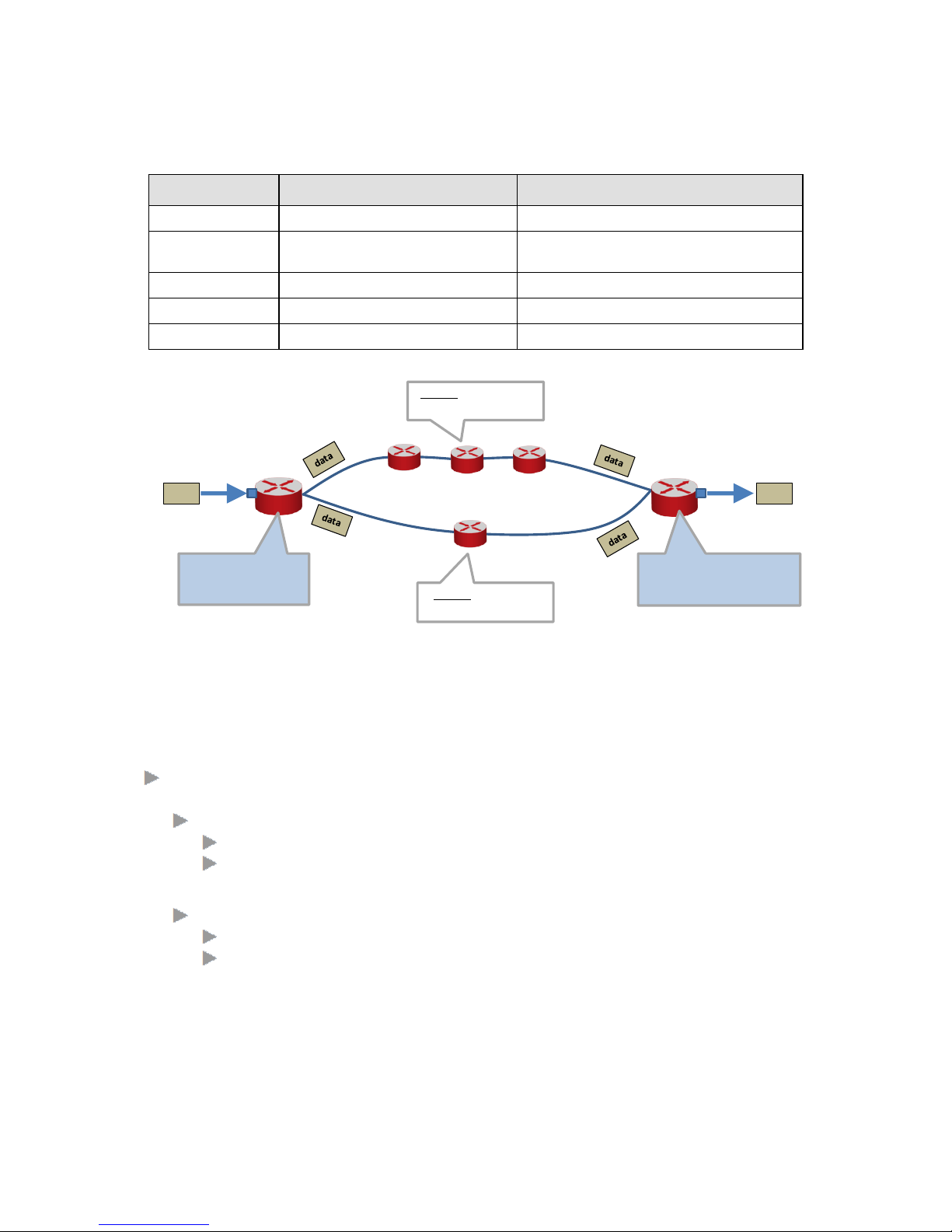

1.1 General

This document is valid as of Dragon PTN Release 3.0DR.

This document describes the 7-SERIAL interface module (=IFM) which provides 7 logical

serial ports.

Depending on how the IFM is used, the amount of available serial ports varies from 4 to 7

per IFM. The matrix figure below indicates how many and which ports (Pn) can be used to

transport the indicated protocol (RS232...) in the indicated mode (Asynchronous,

Synchronous, Optimised, Full) in the indicated service (CES, Serial Ethernet). More

information on all these modes and services can be found further on.

‘CES’: Circuit Emulation Service;

‘X’: this individual port can transport the indicated service;

‘X combi’: these two ports are required to transport the indicated service;

‘spare’: this individual port cannot transport the indicated service, though it can still be

used to transport another service in the matrix, see §2.2.2 for some examples;

A point-to-multipoint service (e.g. SCADA) requires a Serial Ethernet service;

See the figure below for an overview:

Figure 1 Functional Overview Matrix

P1

RS232 RS422 RS485 X.21 V.35

Async

(Serial

Ethernet)

Async

(CES)

Sync

(CES)

Async

(Serial

Ethernet)

Async

(CES)

Sync

(CES)

Async

(Serial

Ethernet)

Async

(CES)

Optimised

(CES)

Full

(CES)

Optimised

(CES)

Full

(CES)

X X X X X spare X X X spare X spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

P2

P3

P4

P5

P6

P7

6 Installation PTN-7-SERIAL

Release 01 02/2018

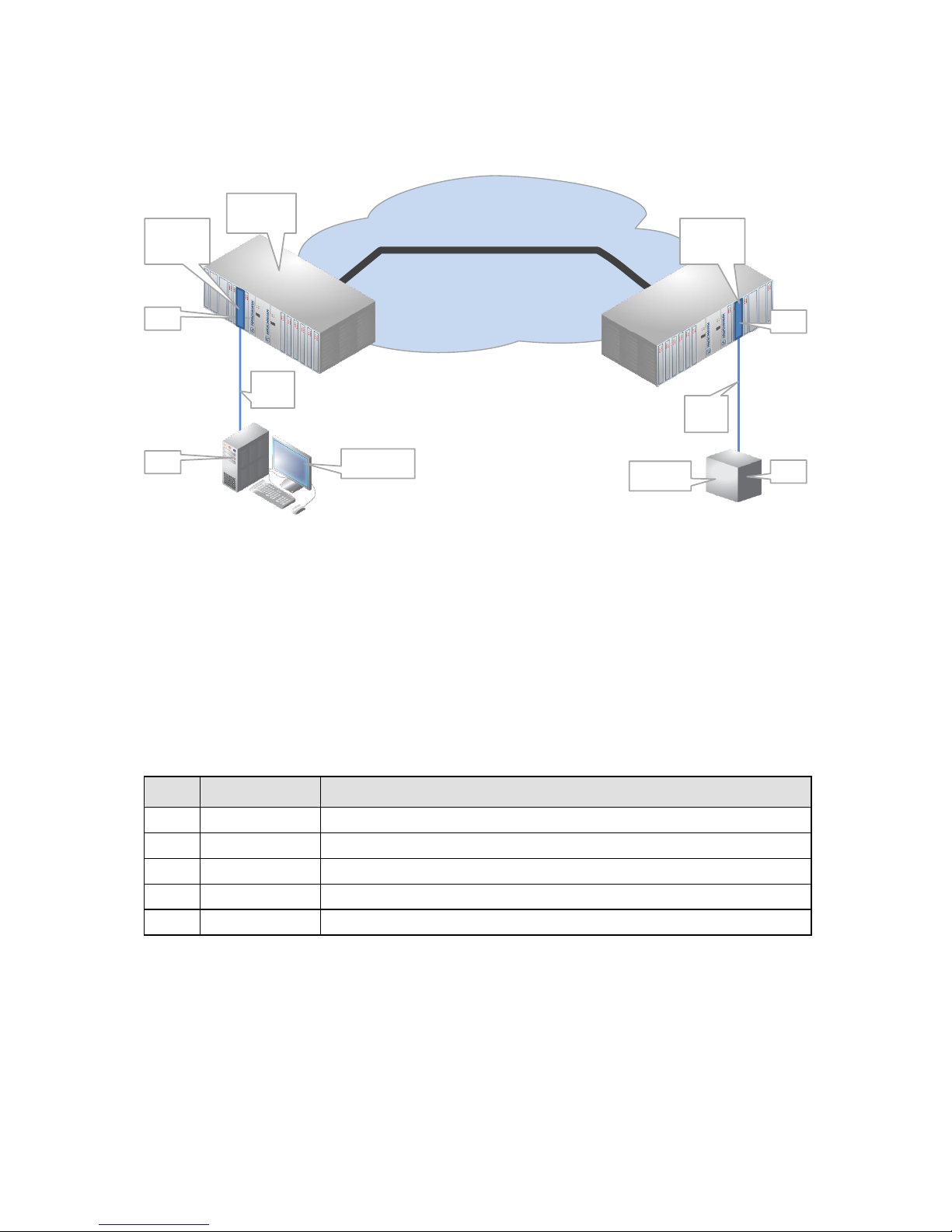

This IFM can be used in any IFM slot of any node. An IFM slot overview can be found in Ref.

[3] in Table 1.

Figure 2 General 7-SERIAL Example

1.2 Manual References

Table 1 is an overview of the manuals referred to in this manual. ‘&’ refers to the language

code, ‘*’ refers to the manual issue. All these manuals can be found in the HiProvision (=

Dragon PTN Management System) Help function.

Table 1 Manual References

Ref.

Number

Title

[1]

DRA-DRM821-&-*

Dragon PTN and HiProvision Operation

[2]

DRA-DRM801-&-*

Dragon PTN Installation and Operation

[3]

DRB-DRM802-&-*

Dragon PTN Nodes: PTN2210, PTN2209, PTN2206, PTN1104

[4]

DRB-DRM803-&-*

Dragon PTN Switching Module: PTN-CSM310-A

[5]

DRA-DRM810-&-*

Dragon PTN General Specifications

MPLS-TP Dragon PTN Network

WAN (via SFP on fiber)

Serial

Link Serial

Link

e.g. SCADA

DTE

e.g. RTU DTE

DCE

Dragon PTN

Node

Module

7-SERIAL

DCE

Module

7-SERIAL

Installation PTN-7-SERIAL 7

Release 01 02/2018

2. MODULE DESCRIPTION

2.1 Front Panel And Connection Kits

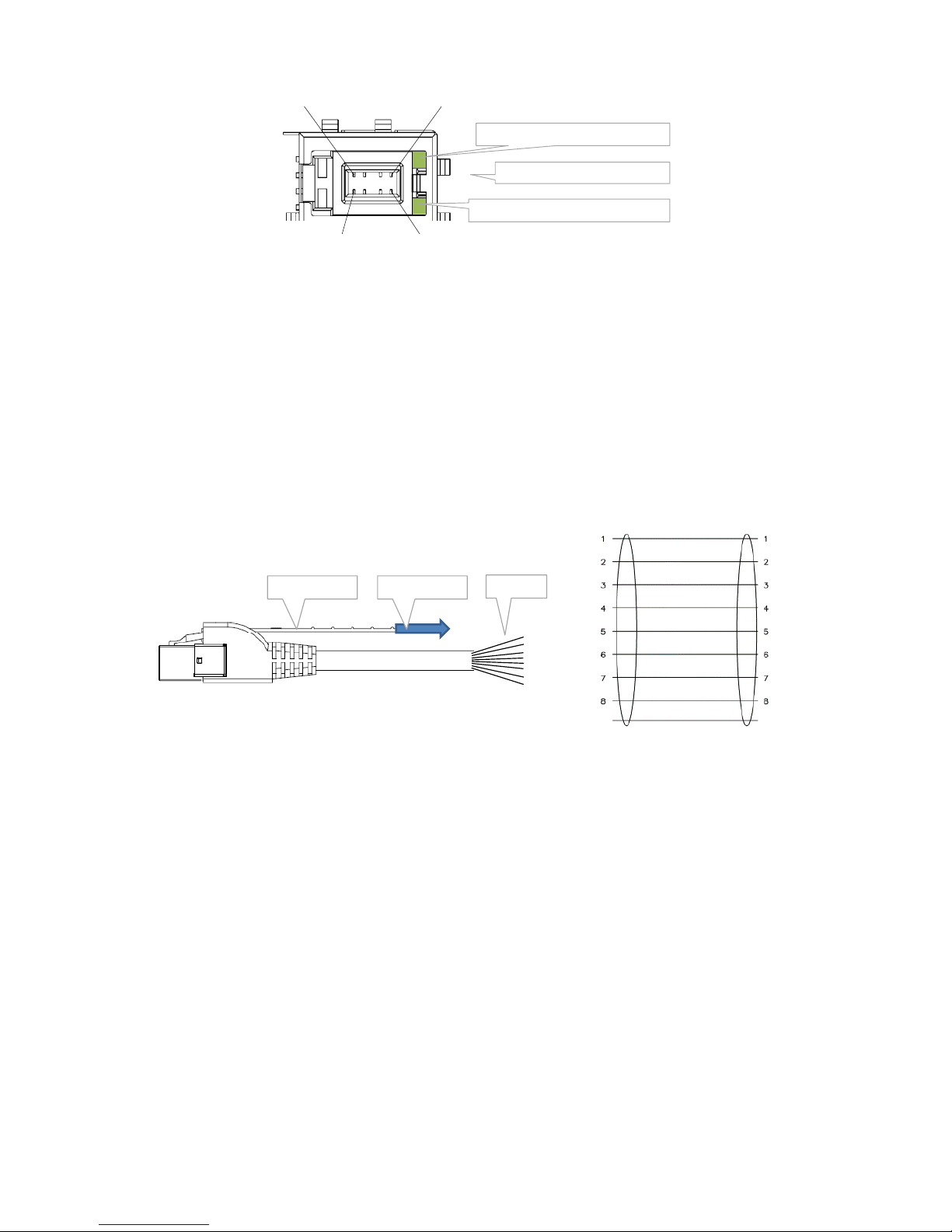

Figure 3 Front Panel And Connection Kits

2.1.1 Handle

a. Insert the Module into the Node

Take the front panel handles to insert or slide the module into the Dragon PTN node. Push

the module thoroughly into the node’s backplane. Next, tighten the two fastening screws in

the front panel corners.

b. Remove the Module from the Node

Untighten the two fastening screws in the front panel corners. Take the front panel handles

to pull out and finally remove the module from the Dragon PTN node.

2.1.2 LEDs

The meaning of the LEDs depends on the mode of operation (= boot or normal) in which the

7-SERIAL module currently is running. After plugging in the module or rebooting it, the

module turns into the boot operation, see Table 2. After the module has gone through all

the cycles in the table below (=rebooted successfully), the module turns into the normal

operation, see LEDs in Table 3.

Handle

Fastening screw

10 RJ.5

connectors

3 Serial ports

CES: port 1,2

Serial Ethernet: port 1,2,3

8

1

Basic

Kit

Extension

Kit

4 Serial ports

CES: port 4,6

Serial Ethernet : port 4,5,6,7

7 Serial ports

CES: port 1,2,4,6

Serial Ethernet : port 1..7

8

1

8

1

8

1

8

1

8

1

8

1

8

1

8

1

8

1

LEDs

LED

Rx Data

LED

Tx Data

8 Installation PTN-7-SERIAL

Release 01 02/2018

Table 2 LED Indications In Boot Operation

Cycle

PI

PF

FLT

Tx Data[1..10]

Rx Data[1..10]

1

x

---

Slow blinking

---

---

2

x

---

Fast blinking

---

---

3

x

---

---

---

---

4

x

---

x

x red

x red

5

x

---

x

x green

x green

x : LED is lit / --- : LED is not lit; The sub cycle times may vary. The entire boot cycle time [1→5] takes

approximately 2 minutes;

Table 3 LED Indications In Normal Operation

LED

Color

Status

PI (=Power Input)

Not lit, dark

+12V power input to the board not OK

Green

+12V power input to the board OK

PF (=Power Failure)

Not lit, dark

power generation on the board itself is OK

Red

power generation on the board itself is erroneous

FLT (=FauLT)

Not lit, dark

no other fault or error situation, different from PF, is active on the module

Red

a fault or error situation, different from PF, is active on the module

Tx Data

RJ.5 Connector ‘x’

Not lit, dark

- No service programmed

- Service programmed: ‘Tx Data’ is not active on serial port ‘x’

Green

Service programmed: ‘Tx Data’ is active on serial port ‘x’

Red

Service programmed but no data receiving from network, e.g. WAN link

interrupted, destination IFM failure....

Rx Data

RJ.5 Connector ‘x’

Not lit, dark

- No service programmed

- Service programmed: ‘Rx Data’ is not active on serial port ‘x’

Green

Service programmed: ‘Rx Data’ is active on serial port ‘x’

Red

Service programmed but no data receiving from network, e.g. WAN link

interrupted, destination IFM failure....

2.1.3 RJ.5 Connector

This connector has 8 pins and 2 bi-color (green/red) LEDs, see figure below. For the meaning

of the LEDs, see Table 3. The LEDs shown on connector ‘x’ show information of serial port ‘x’

although the pins of connector ‘x’ are not necessarily pins of serial port ‘x’ (see Table 4,

Table 5). Example:

RJ.5 connector 1 LEDs show information of serial port 1;

RJ.5 connector 2 LEDs show information of serial port 2; etc.....

RJ.5 connector 8, 9, 10 LEDs are only lit during the self-test in the boot cycle (see Table 2)

but have no further meaning.

Installation PTN-7-SERIAL 9

Release 01 02/2018

Figure 4 RJ.5 Connector

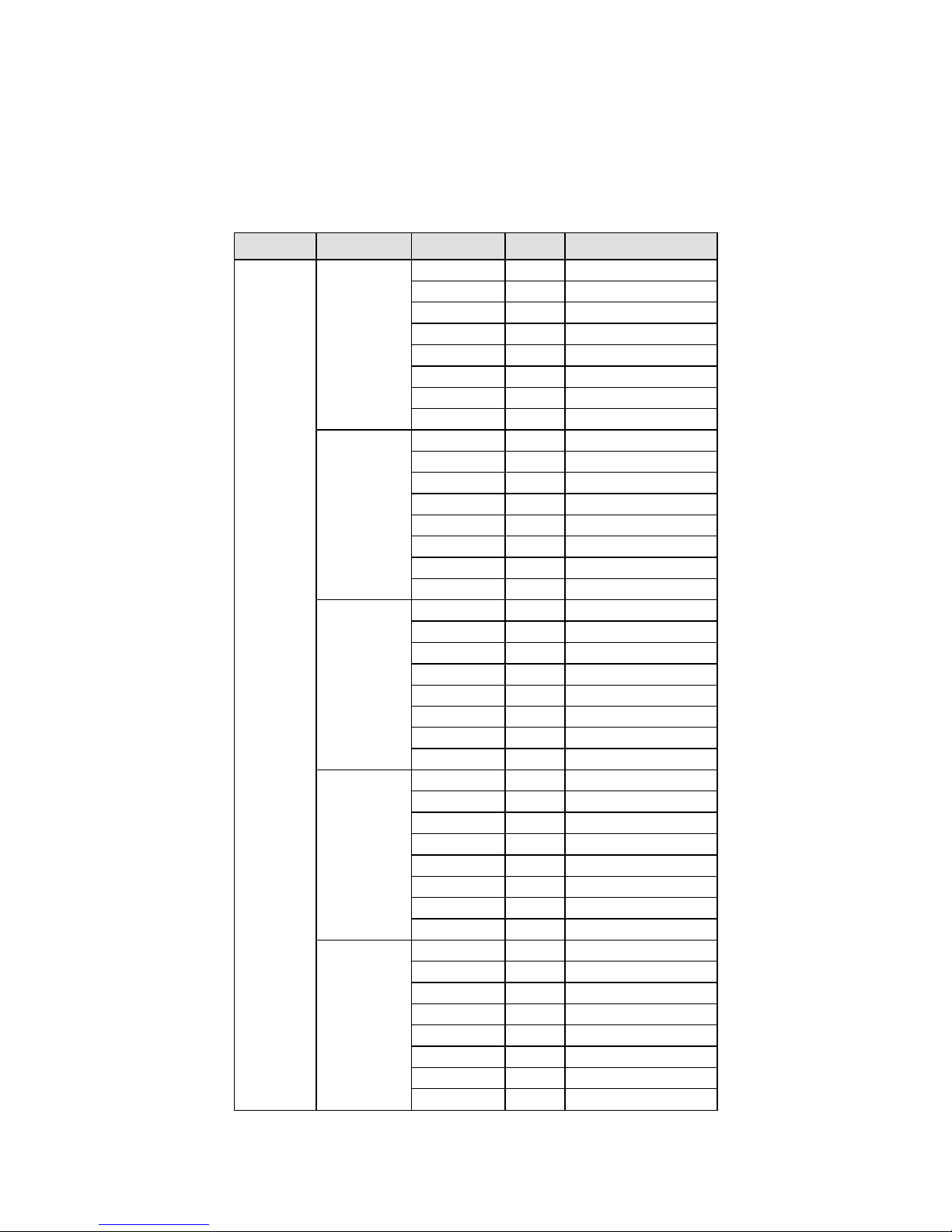

2.1.4 RJ.5 Cable

Each connection kit has five RJ.5 cables. This cable is very suited for high density cabling

compared to traditional RJ45 cables. The RJ.5 cables in the connection kits are open end,

with the color coding of the wires as indicated in the figure below. WH = white; OG =

Orange; GN = Green; BU = Blue; BN = Brown; When a cable is plugged into the RJ.5

connector on the front panel and must be disconnected, remove the connector by pulling

out the unlock handle.

The cable connector has little holes which allow the LED light from the front panel RJ.5

connector to shine through, after the cable has been plugged in.

Figure 5 RJ.5 Cable/Pin Numbering/Color Coding

2.1.5 Connection Kits

The 7-SERIAL module provides 10 RJ.5 connectors on the front with each connector 8 pins.

As a result, a total of 80 pins are used to provide 7 serial ports that are wired out via 2

connection kits. The table below lists a mapping between the front panel connectors and the

7 serial ports; The signals available on the serial port pins depend on the port interface type,

see §2.2.1.

a. Basic Kit

The Basic kit (order n° 942 256-300) must be used to wire out serial port 1, 2 and 3. This kit

includes 5 open end RJ.5 cables of 3 meter marked from 1 to 5. This kit must be connected

to connector [15] on the front panel;

14

85

LED: Tx Data Serial Port ‘x’

1Connector Number = ‘x’

LED: Rx Data Serial Port ‘x’

Open end

WH/OG

OG

WH/GN

GN

BU

WH/BU

WH/BN

BN

SHIELD SHIELD

Unlock handle Pull to unlock

10 Installation PTN-7-SERIAL

Release 01 02/2018

b. Extension Kit

The Extension kit (order n° 942 256-301) must be used to wire out serial port 4, 5, 6 and 7.

This kit includes 5 open end RJ.5 cables of 3 meter marked from 6 to 10. This kit must be

connected to connector [610] on the front panel;

Table 4 RJ.5 Cables to Serial Ports Mapping (Basic Kit)

Cable Kit

RJ.5 Cable

RJ.5 Pin n°

Color

Serial Port –Pin n°

Basic Kit

1

1

WH/OG

1-1

2

OG

1-2

3

WH/GN

1-3

4

GN

1-4

5

BU

1-5

6

WH/BU

1-6

7

WH/BN

1-7

8

BN

1-8

2

1

WH/OG

1-9

2

OG

1-10

3

WH/GN

GND

4

GN

GND

5

BU

GND

6

WH/BU

GND

7

WH/BN

GND

8

BN

GND

3

1

WH/OG

2-1

2

OG

2-2

3

WH/GN

2-3

4

GN

2-4

5

BU

2-5

6

WH/BU

2-6

7

WH/BN

2-7

8

BN

2-8

4

1

WH/OG

2-9

2

OG

2-10

3

WH/GN

3-1

4

GN

3-2

5

BU

3-3

6

WH/BU

3-4

7

WH/BN

3-5

8

BN

3-6

5

1

WH/OG

GND

2

OG

Frame GND

3

WH/GN

Frame GND

4

GN

Frame GND

5

BU

3-7

6

WH/BU

3-8

7

WH/BN

3-9

8

BN

3-10

Installation PTN-7-SERIAL 11

Release 01 02/2018

Table 5 RJ.5 Cables to Serial Ports Mapping (Extension Kit)

Cable Kit

RJ.5 Cable

RJ.5 Pin n°

Color

Serial Port –Pin n°

Extension Kit

6

1

WH/OG

4-1

2

OG

4-2

3

WH/GN

4-3

4

GN

4-4

5

BU

4-5

6

WH/BU

4-6

7

WH/BN

4-7

8

BN

4-8

7

1

WH/OG

4-9

2

OG

4-10

3

WH/GN

5-1

4

GN

5-2

5

BU

5-3

6

WH/BU

5-4

7

WH/BN

5-5

8

BN

5-6

8

1

WH/OG

6-1

2

OG

6-2

3

WH/GN

6-3

4

GN

6-4

5

BU

6-5

6

WH/BU

6-6

7

WH/BN

6-7

8

BN

6-8

9

1

WH/OG

6-9

2

OG

6-10

3

WH/GN

7-1

4

GN

7-2

5

BU

7-3

6

WH/BU

7-4

7

WH/BN

7-5

8

BN

7-6

10

1

WH/OG

5-7

2

OG

5-8

3

WH/GN

5-9

4

GN

5-10

5

BU

7-7

6

WH/BU

7-8

7

WH/BN

7-9

8

BN

7-10

12 Installation PTN-7-SERIAL

Release 01 02/2018

2.1.6 Signals per Serial Port

An individual serial port (‘X’ in Figure 1) has 11 pins whereas a combined serial port (‘X combi’ in Figure 1) has 22 pins. See table below.

In RS232, RS422, X.21, V.35: Pin 9, 10, 20 and 21 are bidirectional pins. If the signal is available, the pin is output in DTE and input in DCE.

Table 4 and Table 5 shows where all these pins are outputted via the basic and extension kit.

Table 6 Signals per Serial Port

Serial

Port

n°

Pin

n°

In/

Out

RS232

RS422

RS485

X.21

V.35

Asynchronous

Synchronous

Asynchronous

Synchronous

Asynchronous

Optimised

Full

Optimised

Full

DTE

DCE

DTE

DCE

DTE

DCE

DTE

DCE

DTE

DCE

DTE

DCE

DTE

DCE

DTE

DCE

n

1

Out1+

TxD

RxD

TxD

RxD

TxDb

RxDb

TxDb

RxDb

Tri-state

TxDb

RxDb

TxDb

RxDb

TxDb

RxDb

TxDb

RxDb

2

Out1-

RTS

CTS

RTS

CTS

TxDa

RxDa

TxDa

RxDa

Tri-state

TxDa

RxDa

TxDa

RxDa

TxDa

RxDa

TxDa

RxDa

3

In1+

RxD

TxD

RxD

TxD

RxDb

TxDb

RxDb

TxDb

---

RxDb

TxDb

RxDb

TxDb

RxDb

TxDb

RxDb

TxDb

4

In1-

CTS

RTS

CTS

RTS

RxDa

TxDa

RxDa

TxDa

---

RxDa

TxDa

RxDa

TxDa

RxDa

TxDa

RxDa

TxDa

5

Out2+

---

---

TTC

RxC

RTSb

CTSb

TTCb

RxCb

Tri-state

Cb

Ib

Cb

Ib

TTCb

RxCb

TTCb

RxCb

6

Out2-

DTR

DSR

DTR

DSR

RTSa

CTSa

TTCa

RxCa

Tri-state

Ca

Ia

Ca

Ia

TTCa

RxCa

TTCa

RxCa

7

In2+

---

---

RxC

TTC

CTSb

RTSb

RxCb

TTCb

---

Ib

Cb

Ib

Cb

RxCb

TTCb

RxCb

TTCb

8

In2-

DSR

DTR

DSR

DTR

CTSa

RTSa

RxCa

TTCa

---

Ia

Ca

Ia

Ca

RxCa

TTCa

RxCa

TTCa

9

In3/Out3+

---

---

TxC(In)

TXC(Out)

DCDb(In)

DCDb(Out)

TxCb(In)

TXCb(Out)

TRxDb

Sb(In)

Sb(Out)

Sb(In)

Sb(Out)

TxCb(In)

TXCb(Out)

TxCb(In)

TXCb(Out)

10

In3/Out3-

DCD(In)

DCD(Out)

DCD(In)

DCD(Out)

DCDa(In)

DCDa(Out)

TxCa(In)

TXCa(Out)

TRxDa

Sa(In)

Sa(Out)

Sa(In)

Sa(Out)

TxCa(In)

TXCa(Out)

TxCa(In)

TXCa(Out)

11

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

n+1

(=combi)

1

Out1+

RTSb

CTSb

Xb

Bb

---

---

2

Out1-

RTSa

CTSa

Xa

Ba

RTS

CTS

3

In1+

CTSb

RTSb

Bb

Xb

---

---

4

In1-

CTSa

RTSa

Ba

Xa

CTS

RTS

5

Out2+

DTRb

DSRb

---

---

---

---

6

Out2-

DTRa

DSRa

---

---

DTR

DSR

7

In2+

DSRb

DTRb

---

---

---

---

8

In2-

DSRa

DTRa

---

---

DSR

DTR

9

In3/Out3+

DCDb(In)

DCDb(Out)

---

---

---

---

10

In3/Out3-

DCDa(In)

DCDa(Out)

---

---

DCD(In)

DCD(Out)

11

GND

GND

GND

GND

GND

GND

GND

Installation PTN-7-SERIAL 13

Release 01 02/2018

2.2 Functional Operation

2.2.1 General

Depending on how the IFM is used, the amount of available serial ports varies from 4 to 7

per IFM. See Figure 1 for an overview matrix. The figure indicates how many and which ports

(Pn) can be used to transport the indicated protocol (RS232...) in the indicated mode

(Asynchronous, Synchronous, Optimised, Full) in the indicated service (CES, Serial Ethernet).

Functional overview matrix, see Figure 1;

Service Combination Examples per IFM: see §2.2.2;

Supported interface types or protocols: see §2.2.3;

Port role DTE/DCE: see §2.2.4;

Synchronization parameter (Asynchronous/Synchronous): see §2.2.5;

Pin Layout parameter (Full/Optimised): see §2.2.6;

Services (CES/Serial Ethernet): see §2.2.7;

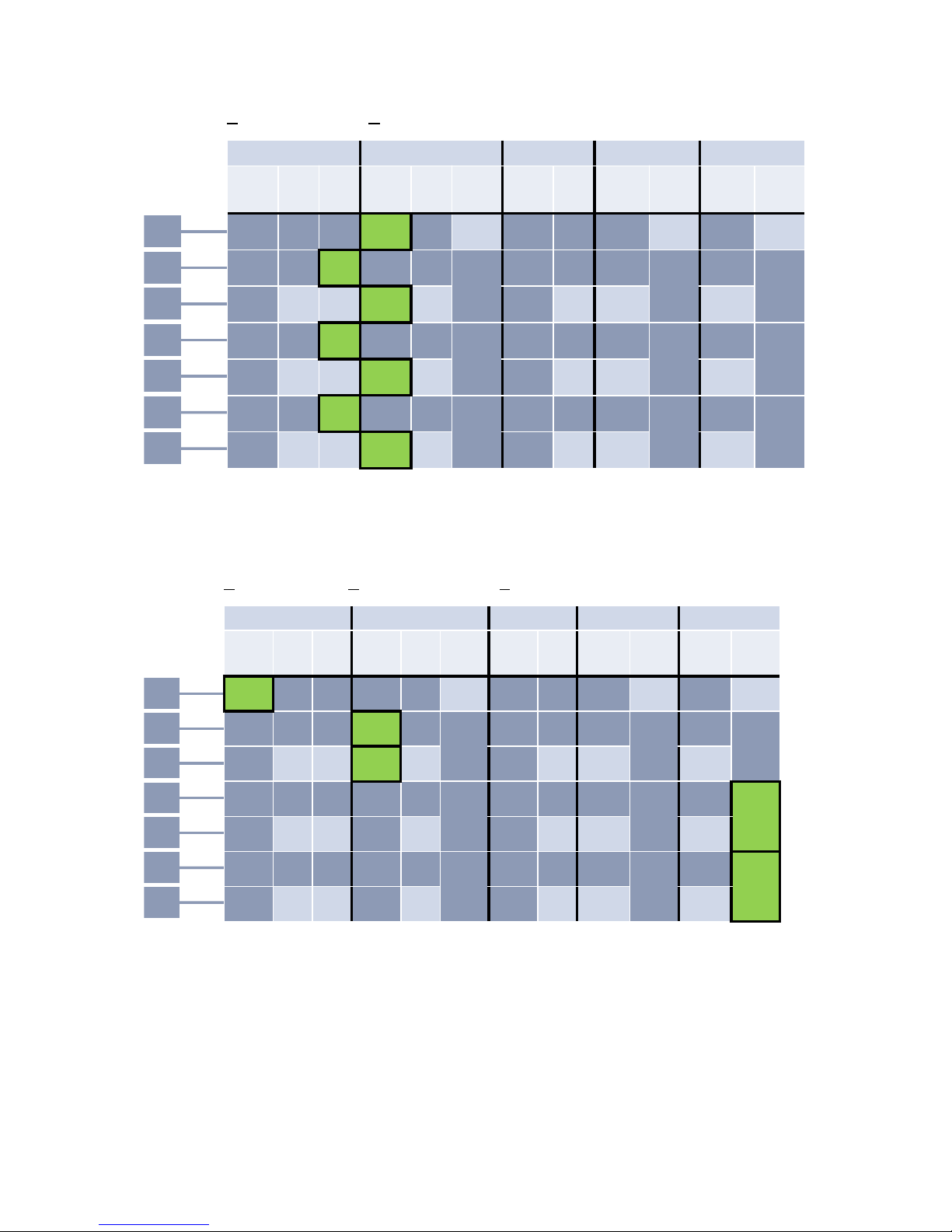

2.2.2 Service Combination Examples per IFM

The figures below some examples how the transport of different serial services can be -

combined on one 7-SERIAL IFM. All the examples below have all the 7 serial ports in use. A

green highlighted box indicates a used port for the indicated service.

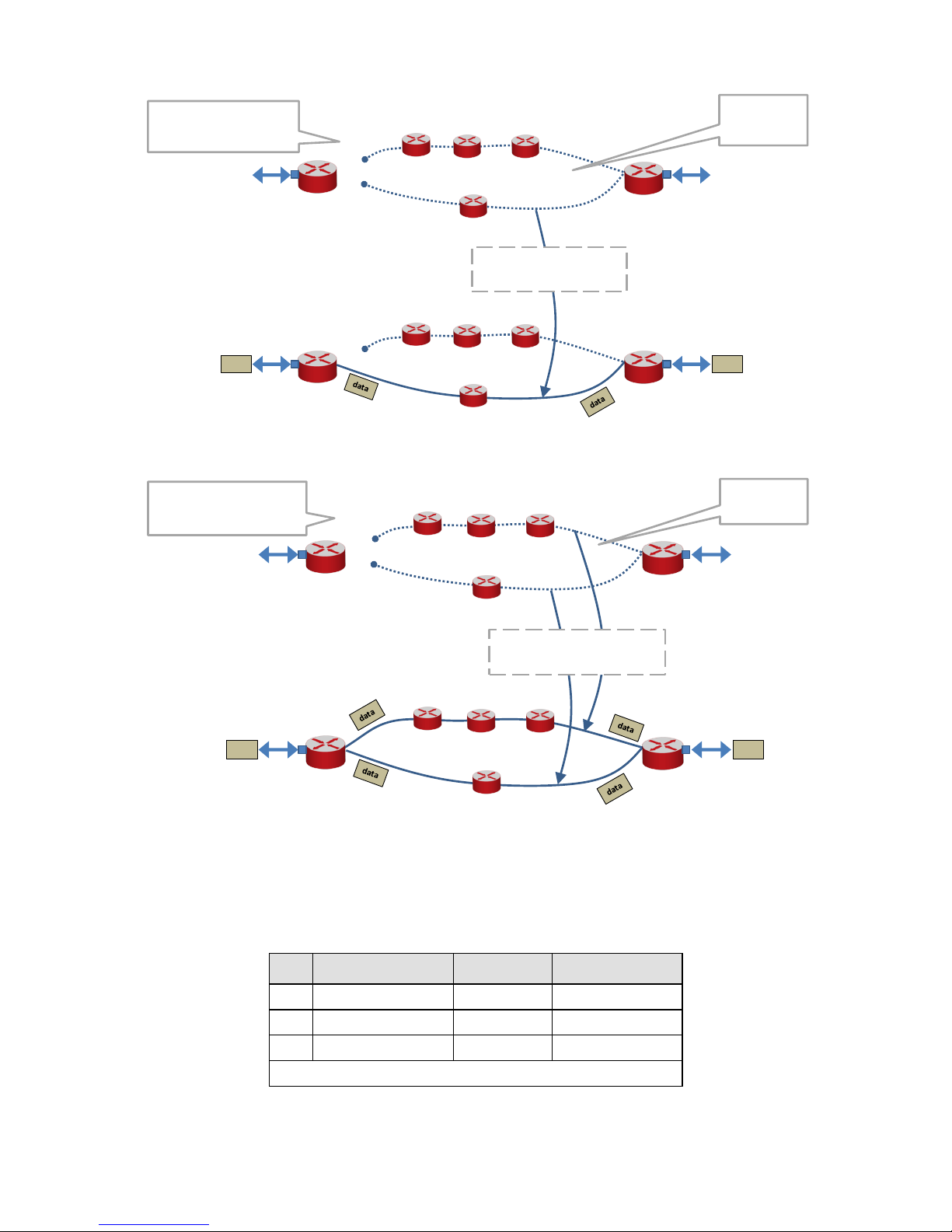

Example1:

Transports 4 services in total;

P1 transports an Asynchronous RS232 protocol via a Serial Ethernet service.

P2+P3 transports a Full V.35 protocol via a CES service;

P4+P5 transports a Full V.35 protocol via a CES service;

P6+P7 transports a Full V.35 protocol via a CES service;

Figure 6 Example1

P1

RS232 RS422 RS485 X.21 V.35

Async

(Serial

Ethernet)

Async

(CES)

Sync

(CES)

Async

(Serial

Ethernet)

Async

(CES)

Sync

(CES)

Async

(Serial

Ethernet)

Async

(CES)

Optimised

(CES)

Full

(CES)

Optimised

(CES)

Full

(CES)

X X X X X spare X X X spare X spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

P2

P3

P4

P5

P6

P7

3*V.35 (Full) + 1*RS232 Async

14 Installation PTN-7-SERIAL

Release 01 02/2018

Figure 7 Example2

Figure 8 Example3

P1

RS232 RS422 RS485 X.21 V.35

Async

(Serial

Ethernet)

Async

(CES)

Sync

(CES)

Async

(Serial

Ethernet)

Async

(CES)

Sync

(CES)

Async

(Serial

Ethernet)

Async

(CES)

Optimised

(CES)

Full

(CES)

Optimised

(CES)

Full

(CES)

X X X X X spare X X X spare X spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

P2

P3

P4

P5

P6

P7

3*RS232 Sync + 4*RS422 Async

P1

RS232 RS422 RS485 X.21 V.35

Async

(Serial

Ethernet)

Async

(CES)

Sync

(CES)

Async

(Serial

Ethernet)

Async

(CES)

Sync

(CES)

Async

(Serial

Ethernet)

Async

(CES)

Optimised

(CES)

Full

(CES)

Optimised

(CES)

Full

(CES)

X X X X X spare X X X spare X spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

P2

P3

P4

P5

P6

P7

2*V.35 (Full) + 1*RS232 Async + 2*RS422 Async

Installation PTN-7-SERIAL 15

Release 01 02/2018

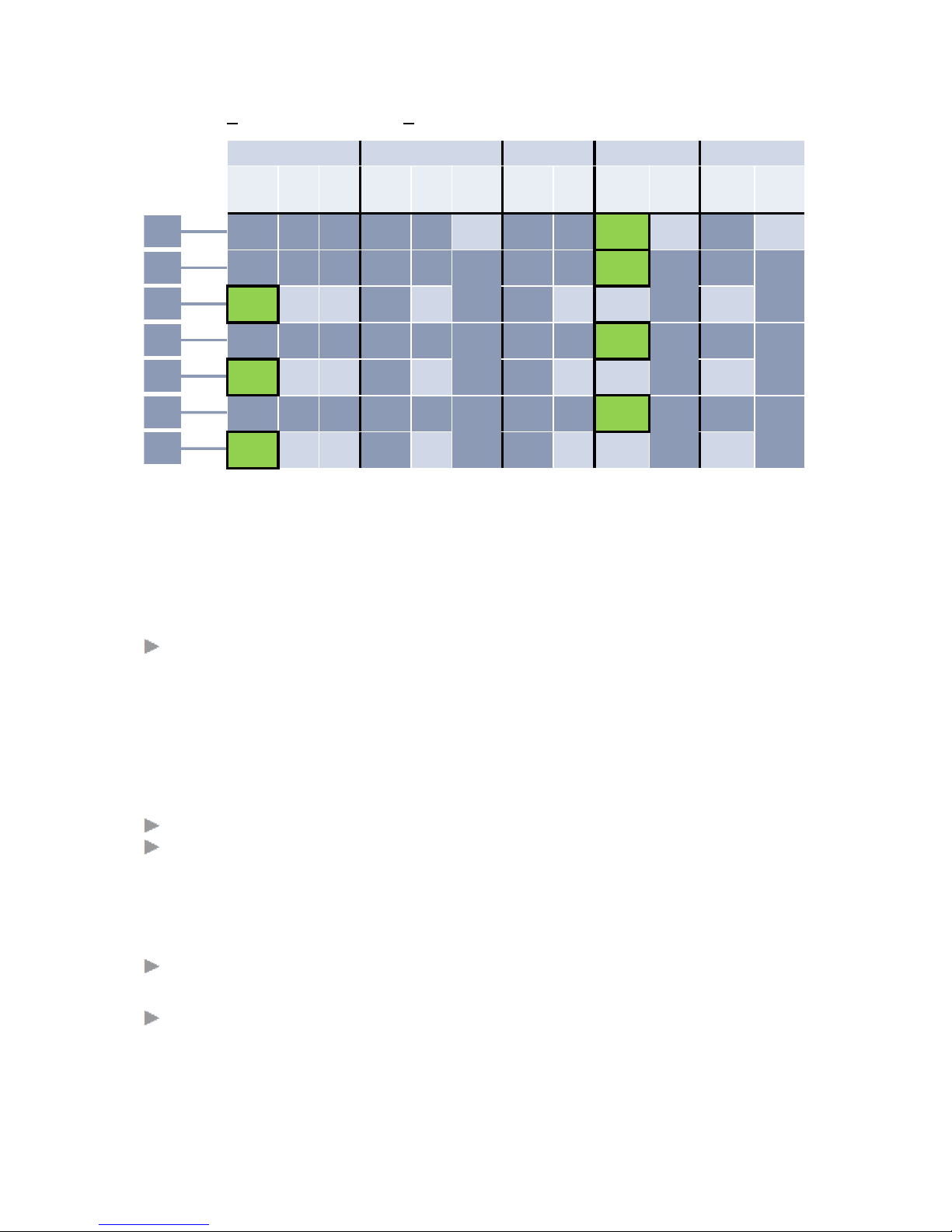

Figure 9 Example4

2.2.3 Port Interface Types

Each serial port can be configured via HiProvision (= Dragon PTN Management System) in

one of the interface types listed below. This setting occurs at service creation. As a result,

both end points or ports will have the same setting after the service creation.

RS232 / RS422 / RS485 / X.21 / V.35;

2.2.4 Serial Port Role DTE/DCE

For the protocols RS232, RS422, X.21, V.35, each serial port can be configured via HiProvision

in the port role DTE or DCE. By default, when a service is configured on a port, its port role is

set automatically to DCE. If it must be changed to DTE, it must be done later on via changing

the port settings in the Network Hardware tab.

DTE (=Data Terminal Equipment): Example: PC, RTU, terminal, printer, etc.

DCE (=Data Communication Equipment): modems etc.

NOTE: Not relevant for RS485;

2.2.5 Synchronization Parameter

Synchronous: both the transmitter and receiver use a clock to exchange data. The clock

is transmitted over the network as well;

Asynchronous: no clock is exchanged between the transmitter and receiver. Only data is

exchanged. Both the transmitter and receiver use start and stop bits to indicate the start

and stop of data;

P1

RS232 RS422 RS485 X.21 V.35

Async

(Serial

Ethernet)

Async

(CES)

Sync

(CES)

Async

(Serial

Ethernet)

Async

(CES)

Sync

(CES)

Async

(Serial

Ethernet)

Async

(CES)

Optimised

(CES)

Full

(CES)

Optimised

(CES)

Full

(CES)

X X X X X spare X X X spare X spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

X X X X X

X combi

X X X

X combi

X

X combi

X spare spare X spare X spare spare spare

P2

P3

P4

P5

P6

P7

4*X.21 Optimised + 3*RS232 Async

16 Installation PTN-7-SERIAL

Release 01 02/2018

2.2.6 Pin Layout Parameter

This parameter is only relevant for X.21 and V.35. See Table 6.

Full: indicates that all protocol signals are fully supported and transported. As a result,

this service requires a combi port ‘X combi’;

Optimised: indicates an optimised pin layout of the available protocol signals. It means

that only the essential signals are transported. As a result, this service only requires one

port ‘X’, which leaves some spare ports to transport other protocols;

X.21: One clock and all control signals are transmitted;

V.35: All three clocks are transmitted, but not the control signals;

2.2.7 Services

Serial communication can be configured in HiProvision via creating a CES or Serial Ethernet

Service.

CES (=Circuit Emulation Service): use this service when Point-to-Point is needed. Serial

data will be encapsulated in TDM packets which will be sent over the Dragon PTN

network as Ethernet packets. CES on the 7-SERIAL IFM is not compatible with CES on the

4-E1-L/4-T1-L/16-E1-L/16-T1-L or C37.94 IFM;

Serial Ethernet: use this service when Point-to-Multipoint (e.g. SCADA) is needed. Serial

data will be encapsulated directly into Ethernet packets and sent over the Dragon PTN

network. All 7 ports can transport such a service. Master(s)/slave(s) must be configured

in this service.

Following parameters are needed per service:

CES: Service Type: Circuit Emulation;

Protocol: Serial;

Usage is always CESoPSN;

optional: Hitless Switching;

optional: Single Path;

Synchronization: Synchronous/Asynchronous;

Interface Type:

Asynchronous: RS232/RS422/RS485;

Synchronous: RS232/RS422/X.21/V.35;

Bitrate;

Pin Layout: Full/Optimised

Serial Ethernet: Service Type: Serial Ethernet;

(Always Asynchronous)

Interface Type: RS232/RS422/RS485;

Bitrate;

Stop Bits;

Data Bits;

Parity;

Master(s)/Slave(s) selection;

Installation PTN-7-SERIAL 17

Release 01 02/2018

2.2.8 CES: CESoPSN (Point-to-Point)

CESoPSN (=Circuit Emulation Service over Packet Switched Network) is a point-to-point

service between two serial ports. One such service can be configured per port. This service

converts the incoming serial data into an amount of timeslots, to transport it over the MPLS-

TP Dragon PTN network. The amount of timeslots over the network just depends on the

selected bit rate.

The destination module will receive the transported timeslots from the Dragon PTN network

and regenerate the serial data from it. As a result, the destination sends out the regenerated

serial data on its serial port.

Each end-point or port must be located in a different node.

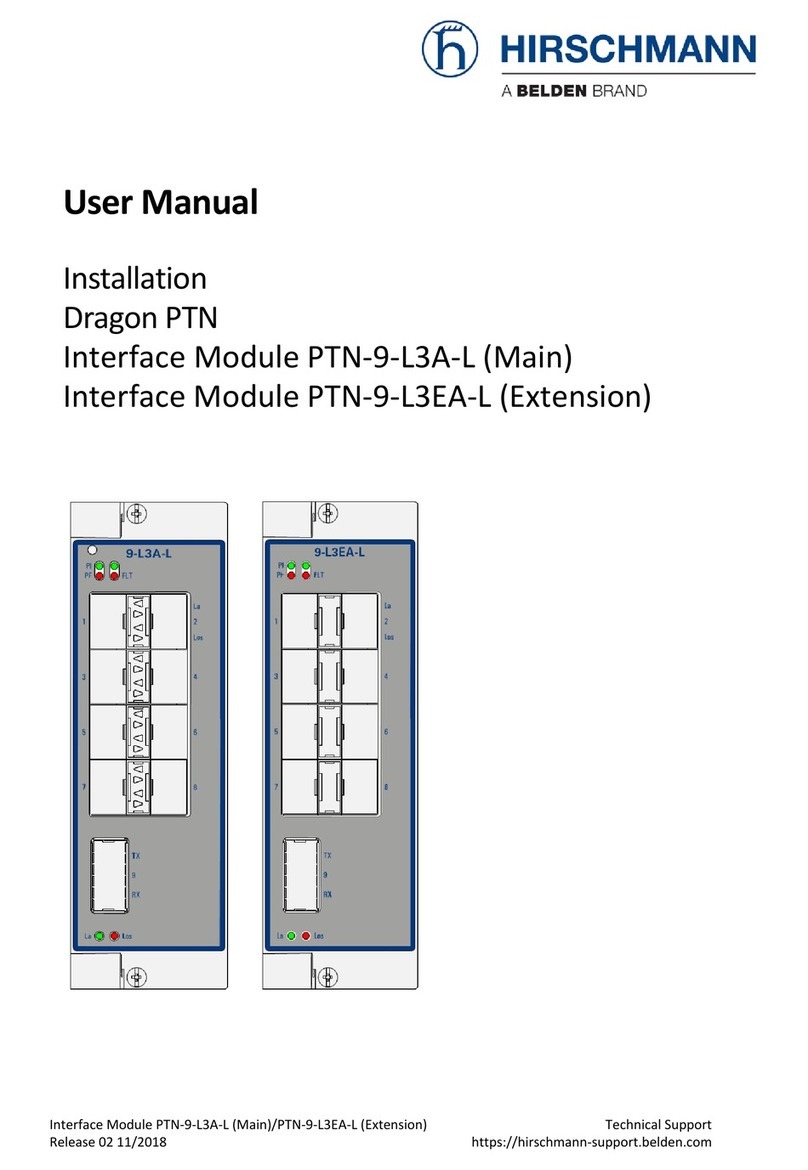

2.2.9 CES: Hitless Switching

Hitless Switching is a feature within CESoPSN that provides a safe redundant connection

where no data or synchronization is lost when switching from the active to the backup path

or vice versa, e.g. because of cable break. The total delay over the network remains nearly

constant during switch-over. Redundancy via Hitless Switching is obtained via completing the

list below:

creating two independent point-to-point tunnels without protection;

setting the Hitless Switching on at service creation time in HiProvision.

NOTE: See Ref.[1] for the creation of tunnels and services;

On the source side, with Hitless Switching enabled, the IFM duplicates each packet on a

second tunnel (e.g. Tunnel y, see figure below). Each packet also contains a 16 bit sequence

number. Different tunnels mean different paths through the network, with each path its

own delay. Different delays result in a slow and a fast path.

On the destination side, with Hitless Switching enabled, the IFM buffers the fastest path and

forwards packets from the slowest path on the serial link. Packets will be processed

according a packet sequence number.

Hitless Switching is a redundant mechanism but differs from Protection Switching, see the

table below for an overview. So if redundancy is needed in the service, either choose Hitless

Switching or Protection Switching, mixing up both mechanisms is not allowed. Depending on

the choice, settings must be done at tunnel creation time and/or service creation time.

When Hitless Switching has been enabled, the CES can only start up with two links up,

coming out of a two-links-down situation (except when Single Path has been enabled, see

§2.2.10).

See §2.2.11 for a delay comparison within CES depending on the enabled sub features, see

also further on.

18 Installation PTN-7-SERIAL

Release 01 02/2018

Table 7 Difference Between Hitless and Protection Switching

Protection Switching

Hitless Switching

required tunnel type

1 point-to-point tunnel

2 point-to-point tunnels

tunnel protection type

1:1;

none; the redundancy is created via two

independent point-to-point tunnels.

service parameter

Hitless Switching = disabled

Hitless Switching = enabled

at switch-over

possible data loss

no data or synchronization loss

total delay

less than hitless switching

more than protection switching

Figure 10 Hitless Switching

2.2.10 CES: Single Path

The Single Path feature is a sub feature of Hitless Switching (see §2.2.9). It influences the

start-up behavior of the Hitless Switching mechanism:

enabled: The CES can already start up with only one link up, coming out of a two-links-

down situation; this setting results in bigger delays because of bigger buffers.

if the fastest path came up first:

the CES starts up according to the fastest path;

possible CES interrupt or minor packet loss when the slowest path comes up

later on;

if the slowest path came up first:

the CES starts up according to the slowest path;

no CES interrupt or packet loss when the fastest path comes up later on;

See §2.2.11 for a delay comparison within CES depending on the enabled sub features, see

also further on.

Serial Data

data

Serial Data

data

Serial WAN:

duplicates and transmits

data twice

WAN Serial:

data buffering = constant delay;

no packet loss at switch-over

MPLS-TP Dragon PTN

Tunnel x has more nodes

= slow path

Tunnel y has less nodes

= fast path

Installation PTN-7-SERIAL 19

Release 01 02/2018

Figure 11 Single Path Enabled

Figure 12 Single Path Disabled

2.2.11 CES: Delay Comparison in CES Features

Table 8 Delay Comparison in CES (Features)

CES

Hitless Switching

Single Path

Resulting Delay

X

---

---

lowest

X

X

---

medium

X

X

X

highest

X = enabled; --- = disabled

data data

Single Path ENABLED:

ONE link required

no links up:

no CES

already with one link up

CES starts

Serial Data Serial Data

MPLS-TP Dragon PTN

MPLS-TP Dragon PTN

data

Serial Data

data

Single Path DISABLED:

BOTH links required

only with both links up

CES starts

no links up:

no CES

Serial Data

MPLS-TP Dragon PTN

MPLS-TP Dragon PTN

20 Installation PTN-7-SERIAL

Release 01 02/2018

2.2.12 Serial Ethernet (Point-to-Multipoint)

Serial Ethernet is a point-to-multipont service between two or more serial ports, e.g. for

SCADA systems. One such service can be configured per port. This service converts the

incoming serial data directly into Ethernet packets, to transport it over the MPLS-TP Dragon

PTN network.

The destination module will receive the Ethernet packets from the Dragon PTN network and

regenerate the serial data from it. As a result, the destination sends out the regenerated

serial data on its serial port.

At least two nodes are required and each node can have multiple end-points of that service.

2.2.13 Serial Ethernet: Master/Slave

A Serial Ethernet Service is typically used for a point-to-multipoint service, e.g. SCADA

systems. In this service, at least one master (maximum two masters) and one or more slaves

(maximum 156 slaves) must be selected.

When two masters are selected, one of them will be the active one and the other one will be

the backup master. Which one is the active/backup master will be decided by the serial

protocol itself.

The (active) master will initiate commands or requests to their slaves. The backup master

and all the slaves will see this request. Only the addressed slave will process the request and

send a response back to the (active) master. The backup master and all the other slaves will

see the slave response.

Only the (active) master will process the slave response. The backup master (if any) will be

synchronized with the active master and will take over when the active master gets out of

service.

2.2.14 Serial Ethernet: Advanced Mode - Bandwidth Optimization

At service creation, fine-tuning the bandwidth and delay through the network is done via the

Advanced Mode parameter. It groups payload data more efficiently in the transmit process

resulting in less overhead. Note that less bandwidth results in more delay and vice versa.

Serial data is collected at the front ports and buffered until one of the events below is

triggered. After the trigger, the payload data is packetized and sent over the Dragon PTN

network.

Amount of payload bytes received at the front (Fixed Block size);

Periodic transmit timer expires (Fixed Transmit Timer);

Detection of a line termination character (Delimiter: Line Termination Character);

Timeout occurs after the last received byte (Delimiter Timeout);

See the HiProvision manual for more info: Ref.[1] in Table 1;

Table of contents

Other Hirschmann Control Unit manuals

Hirschmann

Hirschmann Dragon PTN Series User manual

Hirschmann

Hirschmann Dragon PTN-9-L3A-L User manual

Hirschmann

Hirschmann Dragon PTN Series User manual

Hirschmann

Hirschmann Dragon PTN-6-GE-L User manual

Hirschmann

Hirschmann Rotarus PK 10-16 User manual

Hirschmann

Hirschmann PTN-4-DSL-LW User manual

Hirschmann

Hirschmann GREYHOUND GRM20 User manual

Hirschmann

Hirschmann Dragon PTN Series User manual

Hirschmann

Hirschmann PTN-2-C37.94 User manual

Hirschmann

Hirschmann PRS 80 User manual