Datex-Ohmeda S/5 M-CAiOVX Use and care manual

Datex-Ohmeda Compact Airway modules

S/5TM Compact Airway Module, M-CAiOVX (rev. 01)

S/5TM Compact Airway Module, M-CAiOV (rev. 03)

S/5TM Compact Airway Module, M-CAiO (rev. 02)

S/5TM Compact Airway Module, M-COVX (rev. 02)

S/5TM Compact Airway Module, M-COV (rev. 03)

S/5TM Compact Airway Module, M-CO (rev. 02)

S/5TM Compact Airway Module, M-C (rev. 02)

Technical Reference Manual Slot

All specifications are subject to change without notice.

Document No. 800 1009-1

June 2001

Datex-Ohmeda Inc.

3030 Ohmeda Drive

53707-7550 MADISON, WIS

USA

Tel. +1-608-221 1551, Fax +1-608-222 9147

www.us.datex-ohmeda.com

Datex-Ohmeda Division,

Instrumentarium Corp.

P.O. Box 900, FIN-00031

DATEX-OHMEDA, FINLAND

Tel. +358 10 394 11 Fax +358 9 146 3310

www.datex-ohmeda.com

Instrumentarium Corp. All rights reserved.

Table of contents

Document No. 800 1009-1

i

TABLE OF CONTENTS

S/5 Compact Airway Modules

TABLE OF CONTENTS I

TABLE OF FIGURES III

INTRODUCTION 1

1 SPECIFICATIONS 2

1.1 General specifications ..............................................................................................................................2

1.2 Typical performance .................................................................................................................................2

1.2.1 CO2..................................................................................................................................................2

1.2.2 O2....................................................................................................................................................2

1.2.3 N2O .................................................................................................................................................2

1.2.4 Respiration Rate (RR) .......................................................................................................................3

1.2.5 Anesthetic Agents (AA)......................................................................................................................3

1.2.6 MAC ................................................................................................................................................3

1.3 Gas specifications ....................................................................................................................................3

1.3.1 Normal conditions............................................................................................................................4

1.3.2 Conditions exceeding normal............................................................................................................4

1.4 Patient spirometry specifications...............................................................................................................5

1.4.1 Normal conditions............................................................................................................................5

1.4.2 Conditions exceeding normal............................................................................................................6

1.5 Gas exchange specifications .....................................................................................................................7

1.5.1 VO2and VCO2...................................................................................................................................7

1.5.2 RQ ...................................................................................................................................................7

2 FUNCTIONAL DESCRIPTION 8

2.1 Measurement principle .............................................................................................................................8

2.1.1 CO2, N2O, and agent measurement ...................................................................................................8

2.1.2 O2measurement ............................................................................................................................10

2.1.3 Patient spirometry ..........................................................................................................................10

2.1.4 Gas exchange measurement...........................................................................................................12

2.2 Main components...................................................................................................................................13

2.2.1 Gas sampling system......................................................................................................................13

2.2.2 TPX measuring unit .........................................................................................................................17

2.2.3 OM measuring unit .........................................................................................................................17

2.2.4 PVX measuring unit.........................................................................................................................18

2.2.5 Gas exchange ................................................................................................................................19

2.2.6 CPU board .....................................................................................................................................19

2.2.7 OM board.......................................................................................................................................20

2.2.8 PVX board ......................................................................................................................................20

2.3 Connectors and signals...........................................................................................................................21

3 SERVICE PROCEDURES 22

3.1 General service information.....................................................................................................................22

3.1.1 OM measuring unit .........................................................................................................................22

3.1.2 TPX measuring unit .........................................................................................................................22

3.1.3 OM, TPX, and PVX measuring unit ....................................................................................................22

Datex-Ohmeda S/5 monitors

Document No. 800 1009-1

ii

3.1.4 Serviceable or exchangeable parts..................................................................................................22

3.2 Service check.........................................................................................................................................23

3.2.1 Recommended tools ......................................................................................................................23

3.2.2 Recommended parts......................................................................................................................23

3.3 Disassembly and reassembly..................................................................................................................31

3.3.1 PVX unit .........................................................................................................................................31

3.3.2 Pump unit......................................................................................................................................31

3.3.3 CPU board .....................................................................................................................................31

3.3.4 Software of CPU board ...................................................................................................................32

3.3.5 Instructions after replacing software or CPU board ...........................................................................32

3.4 Adjustments and calibrations..................................................................................................................32

3.4.1 Gas sampling system adjustment ...................................................................................................32

3.4.2 Flow rate measurement ..................................................................................................................32

3.4.3 Flow rate adjustment......................................................................................................................33

3.4.4 Gas calibration...............................................................................................................................33

3.4.5 Flow calibration..............................................................................................................................33

4 TROUBLESHOOTING 34

4.1 Troubleshooting charts ...........................................................................................................................34

4.1.1 CO2measurement..........................................................................................................................35

4.1.2 Patient spirometry..........................................................................................................................36

4.1.3 Gas exchange ................................................................................................................................38

4.2 Gas sampling system troubleshooting .....................................................................................................39

4.2.1 Sampling system leak test..............................................................................................................39

4.2.2 Steam test for the NafionTM tubes....................................................................................................39

4.3 OM measuring unit troubleshooting.........................................................................................................40

4.4 TPX measuring unit troubleshooting.........................................................................................................40

4.5 PVX measuring unit troubleshooting ........................................................................................................40

4.6 CPU board troubleshooting .....................................................................................................................40

4.7 Error messages.......................................................................................................................................41

5SERVICEMENU 42

5.1 General menu ........................................................................................................................................43

5.2 Gases service menu ...............................................................................................................................44

5.3 Spirometry service menu ........................................................................................................................46

6 SPARE PARTS 48

6.1 Spare parts list .......................................................................................................................................48

6.1.1 M-C rev. 00, M-CO rev. 00, M-CAiO rev. 00, M-COV rev. 01, M-CAiOV rev. 01, M-COVX rev. 00 ..........48

6.1.2 M-CAiOVX rev. 00, M-CAiOV rev. 02, M-CAiO rev. 01, M-COVX rev. 01, M-COV rev. 02, M-CO rev. 01, M-

C rev. 01..................................................................................................................................................49

6.1.3 S/5 M-CAiOVX rev. 01, S/5 M-CAiOV rev. 03, S/5 M-CAiO rev. 02, S/5 M-COVX rev. 02, S/5 M-COV

rev. 03, S/5 M-CO rev. 02, S/5 M-C rev. 02 ..............................................................................................49

6.1.4 Front panel stickers........................................................................................................................49

6.1.5 S/5 stickers...................................................................................................................................50

6.1.6 Planned Maintenance (PM) Kits: .....................................................................................................51

7 EARLIER REVISIONS 52

APPENDIX A 53

SERVICE CHECK FORM A-1

Table of contents

Document No. 800 1009-1

iii

TABLE OF FIGURES

Figure 1 TPX sensor principle..............................................................................................................................8

Figure 2 Absorbance of N2O and CO2..................................................................................................................9

Figure 3 Infrared absorbance of AAs ...................................................................................................................9

Figure 4 O2measurement principle ..................................................................................................................10

Figure 5 Absorber ............................................................................................................................................14

Figure 6 Gas sampling system layout, M-C........................................................................................................15

Figure 7 Gas sampling system layout, M-CAiOV, M-CAiOVX, M-CAiO, M-COVX, M-COV, M-CO..............................16

Figure 8 Gas tubing layout ...............................................................................................................................16

Figure 9 TPX measuring unit .............................................................................................................................17

Figure 10 OM measuring unit .........................................................................................................................18

Figure 11 PVX measuring unit.........................................................................................................................18

Figure 12 Signal processing...........................................................................................................................19

Figure 13 Control logic...................................................................................................................................20

Figure 14 Calibration data stored in EEPROM..................................................................................................20

Figure 15 Module bus connector pin layout ....................................................................................................21

Figure 16 Pneumatic unit and reference gas connection block.........................................................................25

Datex-Ohmeda S/5 monitors

Document No. 800 1009-1

iv

Compact Airway modules

Document No. 800 1009-1

1

INTRODUCTION

This section provides information for maintenance and service of the S/5 Compact Airway

modules. The Compact Airway modules are double width plug-in modules. M-C, M-CO, M-COV, M-

COVX, M-CAiO, M-CAiOV, M-CAiOVX and M-CAiOVX/SERVICE are designed for use with the S/5

monitors. The modules provide airway and respiratory measurements.

Letters in the module name stand for:

M = plug-in module, C = CO2and N2O, O = patient O2, V = patient spirometry, X = gas exchange,

A = anesthetic agents, and i = agent identification

About M-CAiOVX/SERVICE module

The M-CAiOVX/SERVICE module is meant for service purposes only. It can be used as a loan

module if the module in the hospital should be sent to the factory for repair. The specifications that

apply to the M-CAiOVX apply also to the M-CAiOVX/SERVICE module. Module differences: the

colour of the front mask is green, the front panel has a “SERVICE” text and there are no front panel

keys equipped.

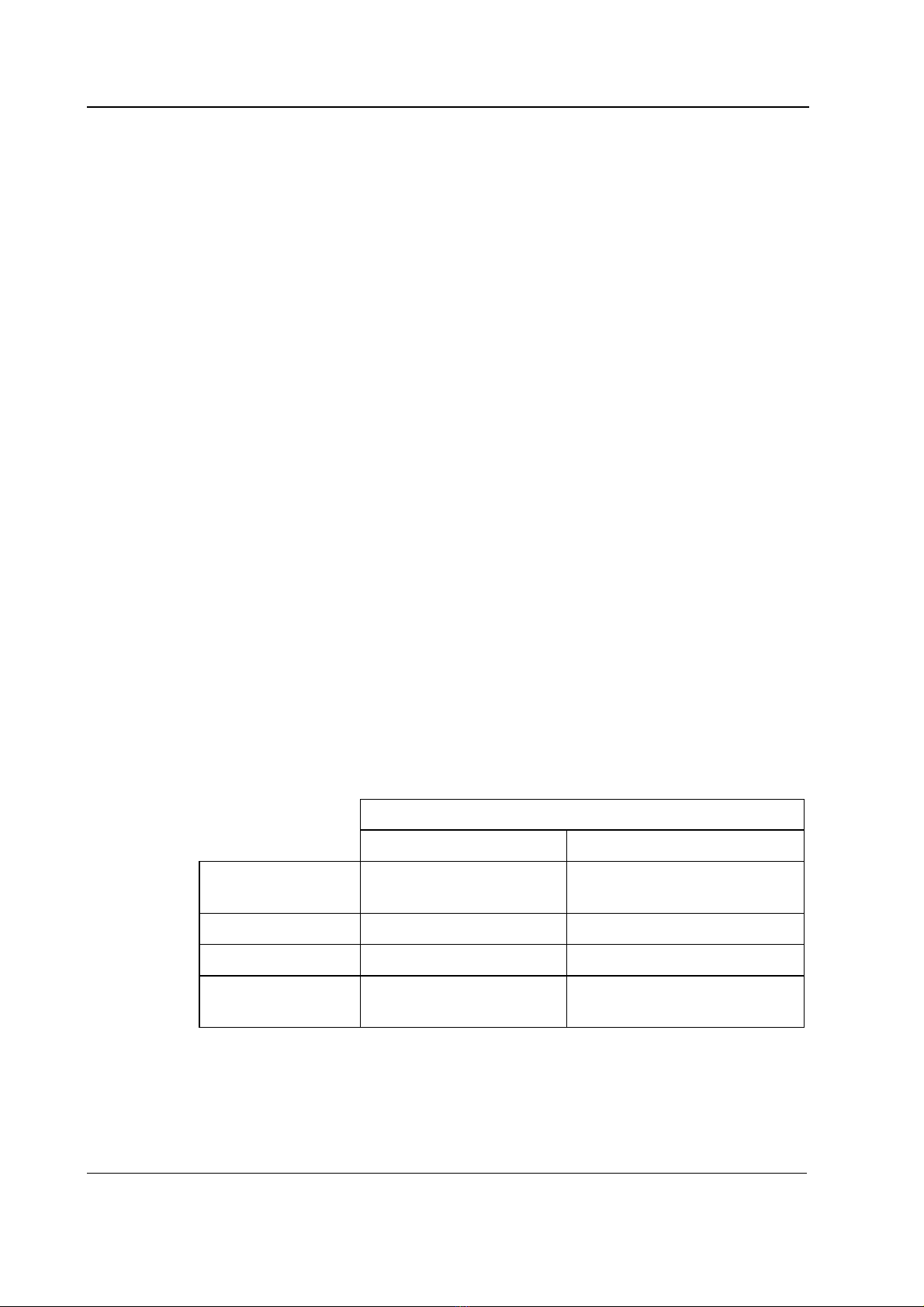

Table 1 Options for Compact Airway modules

Modules Parameters/measurements

CO2N2OO

2Anesthetic

agents

Agent ID Spirometry Gas

exchange

M-CAiOV

X

• • • • • • •

M-CAiO

V

••• • • •

M-CAiO • • • • •

M-CO

V

••• •

M-COV

X

• • • • •

M-CO •••

M-C • •

M-CAiOVX

/

SERVICE ••• • • • •

NOTE: Do not use identical modules in the same monitor simultaneously. The M-C, M-CO, M-COV,

M-COVX, M-CAiO, M-CAiOV, M-CAiOVX and M-CAiOVX/SERVICE are considered identical modules.

NOTE: The Compact Airway Module and Airway Module, G-XXXX, cannot be used simultaneously in

the same monitor.

NOTE: The Compact Airway modules cannot be used in the Extension Frame, F-EXT4.

NOTE: Anesthetic agents and N2O values are not displayed with Critical Care main software, but

when present in the module they are calculated for compensation of CO2and O2.

Datex-Ohmeda S/5 monitors

Document No. 800 1009-1

2

1SPECIFICATIONS

1.1 General specifications

Module size, W ×D ×H 75 ×228 ×112 mm, 2.9 ×9.0 ×4.4 in

Module weight 1.6 kg/3.7 lbs

Operating temperature +10...+40 °C

Storage temperature -25...+70 °C

Atmospheric pressure 666...1060 hPa /

(67...106 kPa)

(500...800 mmHg)

(666...1060 mbar)

Humidity 10...95 % non-condensing (in airway 0...100 %, condensing)

Power consumption 12.6 W Prms, 14.6 W momentary

Protection against electrical shock

Type BF

1.2 Typical performance

1.2.1 CO2

Measurement range 0...15 vol% (0...15 kPa, 0...113 mmHg)

Measurement rise time <400 ms typical

Accuracy ±(0.2 vol% +2 % of reading)

Gas cross effects <0.2 vol% (O2, N2O, anesthetic agents)

If CO2concentration is below 0.1%, 0.0% is displayed.

1.2.2 O2

Measurement range 0 to 100 vol%

Measurement rise time <400 ms typically

Accuracy ±(1 vol% +2% of reading)

Gas cross effects <1 vol%; anesthetic agents

<2 vol%; N2O

O2Fi-Et difference resolution 0.1 vol%

1.2.3 N2O

Measurement range 0 to 100 %; N2O

Measurement rise time <450 ms typically

Accuracy ±(2 vol% +2% of reading)

Gas cross effects <2 vol%; anesthetic agents

Compact Airway modules

Document No. 800 1009-1

3

1.2.4 Respiration Rate (RR)

Measurement range 4...60 breaths/min

Detection criteria 1 % variation in CO2

1.2.5 Anesthetic Agents (AA)

Measuring range

Hal, Enf, Iso 0 to 6 vol%

Sev 0 to 8 vol%

Des 0 to 20 vol%

Measurement rise time <400 ms typically

Accuracy ±(0.15 vol% +5% of reading)

Gas cross effects <0.15 vol% N2O

Resolution is two digits when the AA concentration is below 1.0 vol%.

If AA concentration is below 0.1 vol%, 0.0% is displayed.

Identification threshold 0.15 vol% typically

Identification time <20 s (for pure agents)

Mixture identification threshold for 2. agent:

0.2 vol% +10% of total conc.

1.2.6 MAC

Range 0...9.9 MAC

Equation:

100

OETN

x(AA)

%(ETAA)

=MAC(AA) 2%

+Formula 1

where x(AA): Hal=0.75 %, Enf=1.7 %, Iso=1.15 %, Sev=2.05 %, Des=6.0 %.

1.3 Gas specifications

Airway humidity 0...100 %, condensing

Sampling rate 200 ±20 ml/min. (sampling line 2-3 m, normal conditions)

Sampling delay 2.5 seconds typical with a 3 m sampling line

Total system response time 2.9 seconds typical with a 3 m sampling line, including sampling

delay and rise time

Display update rate breath-by-breath

Automatic compensation for pressure, CO2-N2O and CO2-O2collision broadening effect.

Warm up time 2 min. for operation with CO2, O2, and N2O

5 min. for operation of anesthetic agents

30 min. for full specifications

Autozeroing interval Immediately after ‘calibrating gas sensor’ and 2, 5, 10, 15, 30, 45,

60 minutes after start-up, then every 60 minutes

Datex-Ohmeda S/5 monitors

Document No. 800 1009-1

4

1.3.1 Normal conditions

Accuracy specifications apply in normal conditions (after 30 minutes warm-up period):

Ambient temperature 18...28 °C, within ±5 °C of calibration

Ambient pressure 500...800 mmHg, ±50 mmHg of cal.

Ambient humidity 20...80 % RH, ±20 % RH of cal.

Non-disturbing gases

−Ethanol C2H5OH(<0.3%)

−Acetone (<0.1%)

−Methane CH4(<0.2%)

−Nitrogen N2

−Carbon monoxide CO

−Nitric Oxide NO (<200 ppm)

−water vapor

Maximum effect on readings

−CO2 <0.2 vol%

−O2, N2O <2 vol%

−anesthetic agents <0.15 vol%

Effect of Helium decreases CO2readings <0.6 vol% typically

1.3.2 Conditions exceeding normal

Accuracy specifications under the following conditions; :

Ambient temperature 10...40 °C, within ±5 °C of calibration

Ambient pressure 500...800 mmHg, ±50 mmHg of calibration

Ambient humidity 10...98 % RH, ±20 % RH of calibration

During warm-up 2 to 10 minutes (anesthetic agents 5-10 minutes), under normal conditions

During warm-up 10 to 30 minutes, under normal conditions

Accuracy under different conditions (see above)

Condition and Condition

CO2±(0.3 vol% + 4 % of reading)

(at 5 vol% error ±0.5 vol%)

±(0.4 vol% + 7 % of reading)

(at 5 vol% error ±0.75 vol%)

O2±(2 vol% + 2% of reading) ±(3 vol% + 3% of reading)

N2O±(3 vol% + 3% of reading) ±(3 vol% + 5% of reading)

Agents: Hal, Enf, Iso,

Sev, Des

±(0.2 vol% + 10% of reading) ±(0.3 vol% + 10% of reading)

Compact Airway modules

Document No. 800 1009-1

5

1.4 Patient spirometry specifications

1.4.1 Normal conditions

Accuracy specifications apply in normal conditions (after 10 minutes warm-up period):

Ambient temperature 10...40 °C

Ambient pressure 500...800 mmHg

Ambient humidity 10...98 %RH

Airway humidity 10...100 %RH

Respiration rate 4...35 breaths/min (adults)

4...50 breaths/min (pediatric)

I:E ratio 1:4.5...2:1

Intubation tube 5.5...10 mm (adults), 3...6 mm (pediatric)

Airway pressures (Paw, Ppeak, Pplat, PEEPe, PEEPiStat, PEEPiDyn, Pmean)

Measurement range -20...+100 cmH2O

Resolution 0.5 cmH2O

Accuracy ±1 cmH2O

Airway flow

Measurement range 1.5...100 l/min (adults)

(for both directions) 0.25...25 l/min (pediatric)

Tidal volume

Measurement range 150...2000 ml (adults), 15...300 ml (pediatric)

Resolution 1 ml

Accuracy ±6 % or 30 ml (adult), ±6 % or 4 ml (pediatric)

Minute volume

Measurement range 2...20 l/min (adults), 0.5...5 l/min (pediatric)

Resolution 0.1 l/min

Compliance

Measurement range 4...100 ml/cmH2O (adult), 1...100 ml/cmH2O (pediatric)

Resolution 1 ml/cmH2O (adult), 0.1 ml/cmH2O (pediatric)

Airway resistance

Measurement range 0...40 cmH2O/ l/s

Resolution 1 cmH2O/ l/s

Datex-Ohmeda S/5 monitors

Document No. 800 1009-1

6

Other parameters

Specifications apply in conditions listed in patient spirometry specifications.

Dead space of the sensor

9.5 ml (adult), 2.5 ml (pediatric)

Resistance of the sensor

0.5 cmH2O @ 30 l/min (adult), 1.0 cmH2O @ 10 l/min (pediatric)

1.4.2 Conditions exceeding normal

Accuracy specifications under the following condition (during warm-up 2 to 10 minutes):

Airway Pressure(Paw)

Accuracy ±2 cmH2O

Tidal volume

Accuracy ±10 % or 100 ml (adult), ±10 % or 10 ml (pediatric)

Compact Airway modules

Document No. 800 1009-1

7

1.5 Gas exchange specifications

Mathemathical integration of airway flow and gas concentration for intubated, mechanically

ventilated and/or partly spontaneously breathing patients.

NOTE: These specifications apply only when a 2 meter gas sampling line is used, and a Y-piece

with a physical dead space less than 8 ml.

NOTE: These specifications only apply if the FiO2level delivered to the patient is varing by less than

0.2 % during the inspiratory cycle at the measurement point.

1.5.1 VO2and VCO2

Measurement range 50...1000 ml/min

Resolution 10 ml/min

Accuracy ±10 % or 10 ml; when FiO2<65 %

±15 % or 15 ml; when 65 % <FiO2<85 %

1.5.2 RQ

Measurement range 0.6...1.2

Resolution 0.05

Datex-Ohmeda S/5 monitors

Document No. 800 1009-1

8

2FUNCTIONAL DESCRIPTION

2.1 Measurement principle

2.1.1 CO2, N2O, and agent measurement

TPX is a side stream gas analyzer, measuring real time concentrations of CO2, N2O and anesthetic

agents (Halothane, Enflurane, Isoflurane, Desflurane, and Sevoflurane).

Thermopile

detectors

Temp sensor

Sample

gas in

Sample

gas out

Sample

chamber

Figure 1 TPX sensor principle

Anesthetic agents or mixtures of two anesthetic agents are automatically identified and

concentrations of the identified agents are measured. TPX also detects mixtures of more than two

agents and issues an alarm.

TPX is a nondispersive infrared analyzer, measuring absorption of the gas sample at seven infrared

wavelengths, which are selected using optical narrow band filters.

The infrared radiation detectors are thermopiles.

Concentrations of CO2and N2O are calculated from absorption measured at 3-5 µm.

Compact Airway modules

Document No. 800 1009-1

9

Figure 2 Absorbance of N2O and CO2

Identification of anesthetic agents and calculation of their concentrations is performed by

measuring absorptions at five wavelengths in the 8-9 µm band and solving the concentrations

from a set of five equations.

Figure 3 Infrared absorbance of AAs

The measuring accuracy is achieved utilizing numerous software compensations. The

compensation parameters are determined individually for each TPX during the factory calibration.

Datex-Ohmeda S/5 monitors

Document No. 800 1009-1

10

2.1.2 O2measurement

The differential oxygen measuring unit uses the paramagnetic principle in a pneumatic bridge

configuration. The signal picked up with a differential pressure transducer is generated in a

measuring cell with a strong magnetic field that is switched on and off at a frequency of 165 Hz.

The output signal is a DC voltage proportional to the O2 concentration difference between the two

gases to be measured.

Switched

magnetic

field

Mixture

out

Electromagnet

Microphone

Sample in

Reference in

Figure 4 O2measurement principle

2.1.3 Patient spirometry

In mechanical ventilation breaths are delivered to the patient by a ventilator with a proper tidal

volume (TV), respiration rate (RR), and inspiration / expiration ratio in time (I:E) determined by the

settings of the ventilator.

The Patient Spirometry monitors patient ventilation. The following parameters are displayed:

−Expiratory and inspiratory tidal volume (TV) in ml

−Expiratory and inspiratory minute volume (MV) in l/min

−Expiratory spontaneous minute volume in l/min

−Inspiration/expiration ratio (I:E)

Airway pressure

−Peak pressure (Ppeak)

−Mean airway pressure (Pmean); available only in S/5 Critical Care and Compact Critical Care

monitors

−End inspiratory pressure (Pplat)

−PEEPi, PEEPe; available only in S/5 Critical Care and Compact Critical Care monitors

−Total positive end expiratory pressure (PEEPtot); available only in S/5 Anesthesia and

Compact Anesthesia monitors

−Real time airway pressure waveform (Paw)

−Static Positive end expiratory pressures (Static PEEPiand Static PEEPe); available only in

S/5 Critical Care and Compact Critical Care monitors

Compact Airway modules

Document No. 800 1009-1

11

−Static Plateau pressure (Static Pplat); available only in S/5 Critical Care and Compact

Critical Care monitors

−Static Compliance (Static Compl); available only in S/5 Critical Care and Compact Critical

Care monitors

PEEP, Ppeak, Pmean, and Pplat are measured by pressure transducer on the PVX board. Atmospheric

pressure is used as a reference in measurement. The pressure measurement is made from the

airway part that is closest to the patient between patient circuit and intubation tube.

PEEPi=intrinsic PEEP, PEEPtot-PEEPe

Static pressure measurement maneuvres are automatically identified based on a increased zero

flow period at the end of the inspiration or expiration.

Static Compliance is calculated if Static PEEP and Static Pplat measurements were done within a 2

minutes period.

Airway flow

−Real time flow waveform (V')

−Compliance (Compl)

−Airway resistance (Raw)

−Pressure volume loop

−Flow volume loop

The measurement is based on measuring the kinetic gas pressure and is performed using the Pitot

effect. A pressure transducer is used to measure the Pitot pressure. The obtained pressure signal is

linearized and corrected according to the density of the gas. Speed of the flow is calculated from

these pressure values and TV value is then integrated. MV value is further calculated and averaged

using TV and RR (respiratory rate) values.

Compliance and airway resistance

Compliance is calculated for each breath from the equation

ei

plat PEEPPEEPP

TV

Compl −−

=exp Formula 2

Compliance tells how big a pressure difference is needed to deliver a certain amount of gas into

the patient.

The airway resistance, Raw, is calculated using an equation, that describes the kinetics of the gas

flow between the lungs and the D-lite. The equation states that the pressure at the D-lite can at any

moment of the breath be approximated using the equation

ie PEEPPEEPCompl

tVtVRaw

tp ++

+×

=)()('

)( Formula 3

where p(t), V’(t) and V(t) are the pressure, flow and volume measured at the D-lite at a time t, Raw is

the airway resistance, Compl is the compliance and PEEPe+PEEPiis the total positive end

expiratory pressure (PEEPtot).

Datex-Ohmeda S/5 monitors

Document No. 800 1009-1

12

D-liteTM

Patient Spirometry uses a specific sensor called D-liteTM flow sensor. Different types of the D-lite

sensors are available: adult sensor for measuring adults and pediatric sensor for children. Both are

available as reusable versions and D-lite sensor also for single use.

D-lite adapter is designed to measure kinetic pressure by two-sided Pitot tube. Velocity is

calculated from pressure difference according to Bernoulli's equation. Flow is then determined

using the calculated velocity.

v= 2dP×

ρ

(from Bernoulli's equation) Formula 4

F=v A×,

where:

F = flow (l/min), v = velocity (m/s), A = cross area (m2), dP = pressure difference (cmH2O),

ρ

= density (kg/m3)

Finally the volume information is obtained by integrating the flow signal.

2.1.4 Gas exchange measurement

The gas exchange measurement uses the D-liteTM flow sensor and the gas sampler.

The basic data which is needed to obtain O2consumption and CO2 production are volumes and

concentrations.

Concentrations have been corrected for delay and deformation during the transport of the gas

sample in a sidestream gas measurement sensor.

To obtain the amount of O2consumed in ml/min, the amount which is exhaled is subtracted from

the amount that is inhaled.

To obtain the amount of CO2producted in ml/min, the amount which is inhaled is subtracted from

the amount that is exhaled.

These amounts can be obtained by multiplying each measured volume piece (dv) by the

corresponding gas concentration:

dvfdvf OO ò

−

ò

exp

22

insp

=2

VO Formula 5

and

dvfdvf COCO ò

−

ò

inspexp

=2

VCO 22 Formula 6

Using inspiratory and expiratory minute volumes MViand MVeand volume-weighted inspiratory

concentrations fi and fe these equations can be rewritten as:

eOiO=2 MVfe-MVfiVO 22 ×× [ml/min] Formula 7

Compact Airway modules

Document No. 800 1009-1

13

iCOeCO=2 MVfi-MVfeVCO 22 ×× [ml/min] Formula 8

To obtain results which are less sensitive to errors in volume measurements, so-called Haldane

transformation is used. This means taking advantage of the fact that the patient is not consuming

nor producing nitrogen: the amount of nitrogen inhaled is equal to the amount

exhaled fiN2 ×MVi=feN2×MVe.

VO2and VCO2can then be written as:

iOHaldO2 )MVfef-(fi=VO 22 ×[ml/min] Formula 9

iCOCOHald2 )MVfi-fe(f=VCO 22×[ml/min] Formula 10

with

fHald = (1-fiCO2 – fiO2 – fiN2O - fiAne1 – fiAne2) / (1-feCO2 – feO2 – feN2O - feAne1 – feAne2)

EE=(5.5 ×VCO2) + (1.76 ×VO2) + (1.99 ×Un) [kcal/day] Formula 11

with Un=Urea Nitrogen Excretion = 13 g/day (for adults only).

2.2 Main components

The compact airway modules consist of:

•Gas sampling system

•TPX measuring unit

•OM measuring unit

•PVX measuring unit

•CPU board

•OM board

•PVX board

2.2.1 Gas sampling system

The sampling system takes care of drawing a gas sample to the analyzers at a fixed rate.

The gas sampling system samples the measured air to the module, and removes water and

impurities from it. A sampling line is connected to the water trap. The pump draws gas through the

sampling line to gas measuring units. After the measurements, the gas is exhausted from sample

gas out connector.

The M-COVX and M-CAiOVX modules have a different gas sampling system compared to the other

modules. A number of flow restrictors have been changed to create a bigger pressure difference

with ambient pressure in the gas sensors. The sample flow is however about the same (200

ml/min).

A bigger pressure difference makes the deformations of the gas concentration curves less sensitive

to high variations of the airway pressures thus meeting also the accuracy requirements of gas

exchange for these applications.

Datex-Ohmeda S/5 monitors

Document No. 800 1009-1

14

D-fendTM

The sample is drawn through a sampling line. Then gas enters the monitor through the water trap,

where it is divided into two flows, a main flow and a side flow. The main flow goes into the

analyzers. This flow is separated from the patient side by a hydrophobic filter. The side flow creates

a slight subatmospheric pressure within the D-fend water trap which causes fluid removed by the

hydrophobic filter to collect in the bottle.

Zero valve and absorber

The main flow passes through a magnetic valve before

proceeding to the analyzers. This valve is activated to establish

the zero points for the TPX and OM units. When the valve is

activated, room air is drawn through the absorber into the internal

system and the gas sensors. Paralyme is used as an absorbent.

Figure 5 Absorber

NafionTM tubes 1)

A nafion tube is used between the water trap and the zero valve to balance the sample gas

humidity with that of ambient air. The tube will prevent errors caused by the effect of water vapor on

gas partial pressure when humid gases are measured after calibration with dry gases. Another

nafion tube is used between the absorper and the pneumatic unit to prevent humidity caused by

absorb of CO2.

Gas analyzers

After the zero valve and nafion tube the gas passes through TPX and OM units. The oxygen sensor

has two inputs. One input accepts the main flow and the other draws in room air for reference. Both

gas flows exit from a single port.

Sample flow differential pressure transducer

The sample flow differential pressure transducer measures pressure drop across OM inlet restrictor

and calculates sample flow from the pressure difference.

Working pressure transducer

The working pressure transducer measures absolute working pressure between the TPX unit and

OM unit. It is used for messages: ‘sample line blocked’, ‘check D-fend’, ‘replace D-fend’ and

‘check sample gas outlet’.

1) Nafion is a trademark of Perma Pure Inc.

This manual suits for next models

6

Table of contents