Thermocouple RS485 Converter 4 channel

4 channel Thermocouple to RS485

Converter

DDAAT

T 33016

016

FEATURES

- Field-Bus remote data acquisition

- Modbus Slave device on RS-48

- Modbus RTU/ Modbus ASCII protocol

- 4 channels input

- Input configurable for Tc J, K, R, S, B, E, T, N and voltage up to ± 1V

- Watch-Dog Alarm

- Remotely Configurable

- 2000 Vac 3-ways Galvanic Isolation

- High Accuracy

- UL / CE mark

- DIN rail mounting in compliance with EN- 0022

(1) Referred to input Span (difference between max. and min.

Values)

(2) A pull-up resistor (10MW) is connected to +1V (break sensor)

GENERAL DESCRIPTION

T e DAT 3016 device is able to acquire up to 4 analogue input signals. T e data are transmitted wit MODBUS RTU/MODBUS ASCII protocol on t e RS-485

network (RS-232 interface is available).

It is possible to connect on input t ermocouples or voltage signals up to ± 1V . T e Cold Junction compensation for t ermocouples is internally performed.

T e device guarantees ig accuracy and stable measure versus time and temperature.

To ensure t e plant safety, two Watc -Dog timer alarms are provided.

T e isolation between t e parts of circuit removes eventual ground-loop effects, allowing t e use of t e device even in t e eavy environmental conditions.

T e DAT 3016 is in compliance wit t e Directive UL 61010-1 for US market and wit t e Directive CSA C22.2 No 61010-1 for t e Canadian market.

T e device is oused in a roug self-extinguis ing plastic container w ic , t anks to its t in profile of 17.5mm only, allows a ig density mounting on EN-50022

standard DIN rail.

COMMUNICATION PROTOCOLS

T e DAT3016 is designed to work wit t e MODBUS RTU/MODBUS ASCII protocol: standard protocol in field-bus; allows to directly interface DAT3000 series

devices to t e larger part of PLCs and SCADA applications available on t e market.

For t e protocol instructions, refer to t e User Guide of t e device.

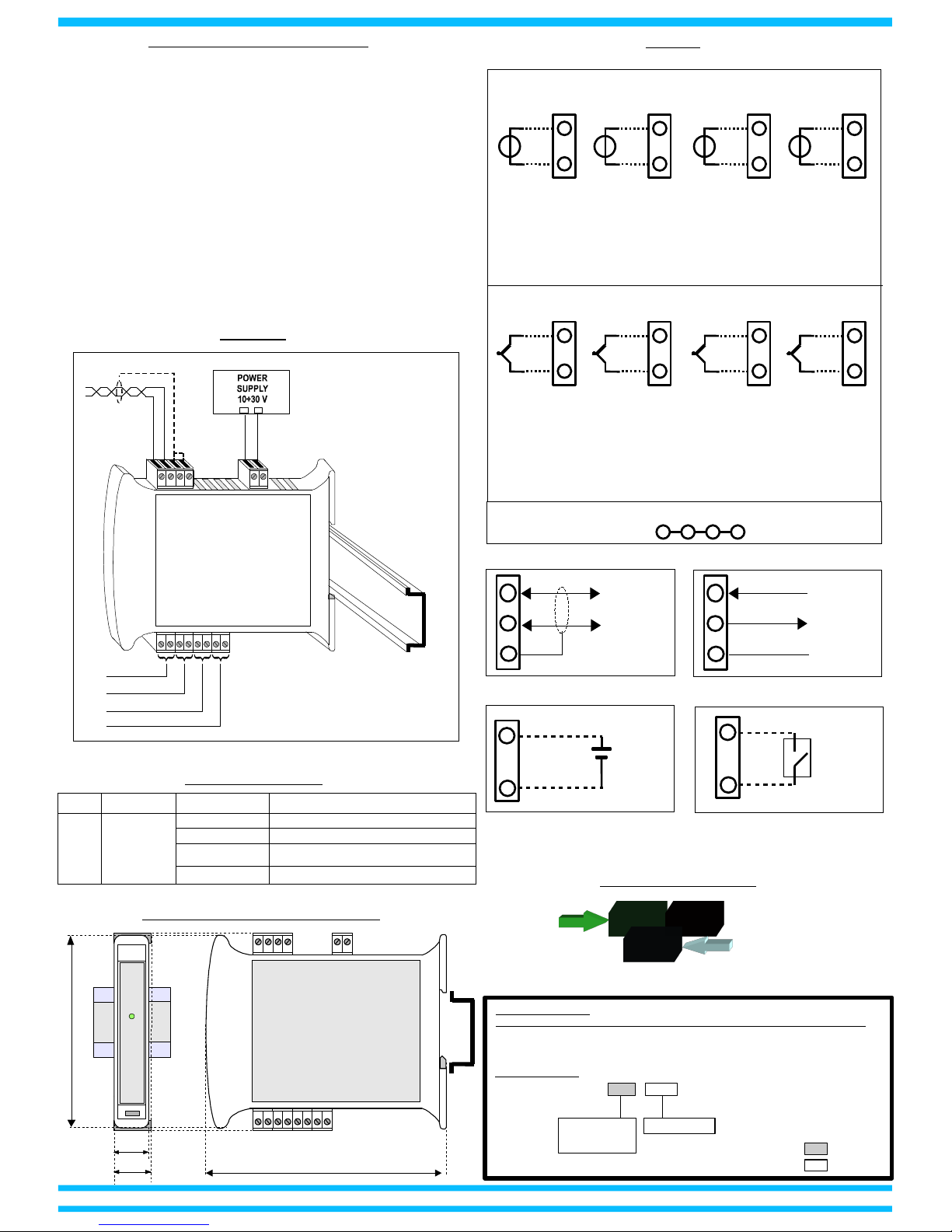

USER INSTRUCTIONS

Before to install t e device, please read t e “Installation Instruction” section.

If t e module configuration is unknown, wit device powered off, connect t e INIT terminal to t e GND terminal (ground), at t e next power on t e device will be

auto-configured in t e default settings (refer to t e User Guide of t e device).

Connect power supply, serial bus and analogue inputs as s own in t e “Wiring” section.

T e “PWR” LED state depends on t e working condition of t e device: see t e "Lig t Signalling" section to verify t e device working state.

To perform configuration and calibration operations, read t e instructions in t e User Guide of t e device.

To simplify andling or replacing of t e device, it is possible to remove t e wired terminals even wit t e device powered.

TECHNICAL SPECIFICATIONS (Typical @ 2 °C and in the nominal conditions)

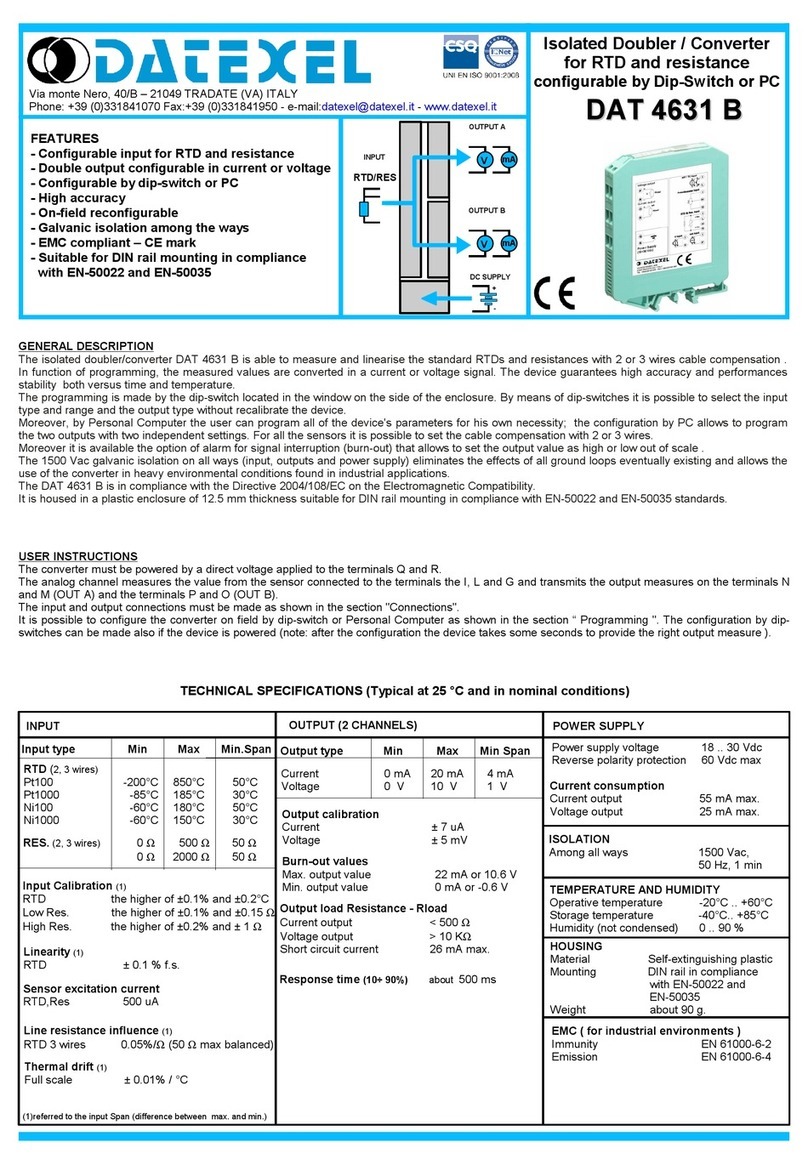

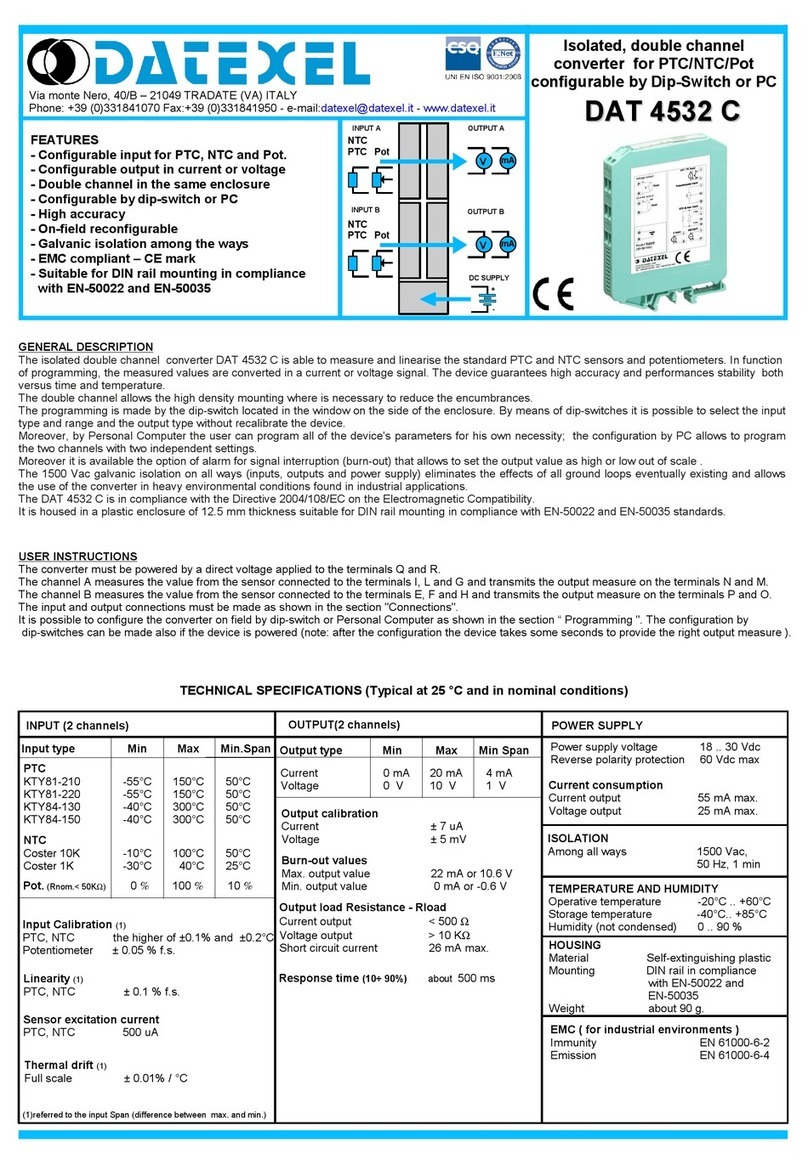

Input Accuracy (1)

mV/Tc t e ig er of

± 0.05% or 5 uV(1)

Linearity (1)

mV ± 0.1% f.s. (1)

Tc ± 0.2% f.s. (1)

Cold Junction Compensation ± 0.5 °C

Input Impedance

mV, Tc >/= 1 MW (2)

Thermal drift

Full Scale ± 0.005 % / °C (1)

CJC Thermal drift

Full Scale ± 0.02 %/ °C

Lead wire resistance influence

mV, Tc < 0.8 uV/O m (1)

Sample time 0.5 ÷ 1 sec.

Data Transmission

Baud Rate 38.4 Kbps

Max. distance 1.2 Km – 4000 ft

Warm-up time 3 min.

Voltage

25 mV -25 mV +25 mV

100 mV -100 mV +100 mV

250 mV -250 mV +250 mV

1000 mV -1000 mV +1000 mV

Thermocouple

J -210 °C +1200 °C

K -210 °C +1372 °C

R -50 °C +1767 °C

S -50 °C +1767 °C

B +400 °C +1825 °C

E -210 °C +1000 °C

T -210 °C +400 °C

N -210 °C +1300 °C

Input type Min Max

INPUT

MECHANICAL SPECIFICATIONS

Material Self-extinguis plastic

IP Code IP20

Wiring wires wit diameter

0.8÷2.1 mm2 /AWG 14-18

Tig tening Torque 0.5 N m

Mounting in compliance wit DIN rail

standard EN-50022

Weig t about 150 g.

ISOLATION

Input – RS485 2000 Vac 50 Hz, 1 min.

Supply – Input 2000 Vac 50 Hz, 1 min.

Supply – RS485 2000 Vac 50 Hz, 1 min.

POWER SUPPLY

Power supply voltage 10 .. 30 Vdc

Reverse polarity protection 60 Vdc max

Current consumption 30 mA max.

ENVIRONMENTAL CONDITIONS

Operative Temperature -10°C .. +60°C

UL Operative Temperature -10°C .. +40°C

Storage Temperature -40°C.. +85°C

Humidity (not condensed) 0 .. 90 %

Maximum Altitude 2000 m

Installation Indoor

Category of installation II

Pollution Degree 2

CERTIFICATIONS

EMC ( for industrial environments)

Immunity EN 61000-6-2

Emission EN 61000-6-4

UL

US Standard UL 61010-1

Canadian Standard CSA C22.2 No 61010-1

CCN NRAQ/NRAQ7

Typology Open Type device

Classification Industrial Control

Equipment

File Number E352854