Datexel DAT 4532 C Operating and maintenance instructions

Via monte Nero, 40/B – 21049 TRADATE (VA) ITALY

DAT 4532 C

DAT 4532 C

Isolated, double channel

converter for PTC/NTC/Pot

configurable b Dip-Switch or PC

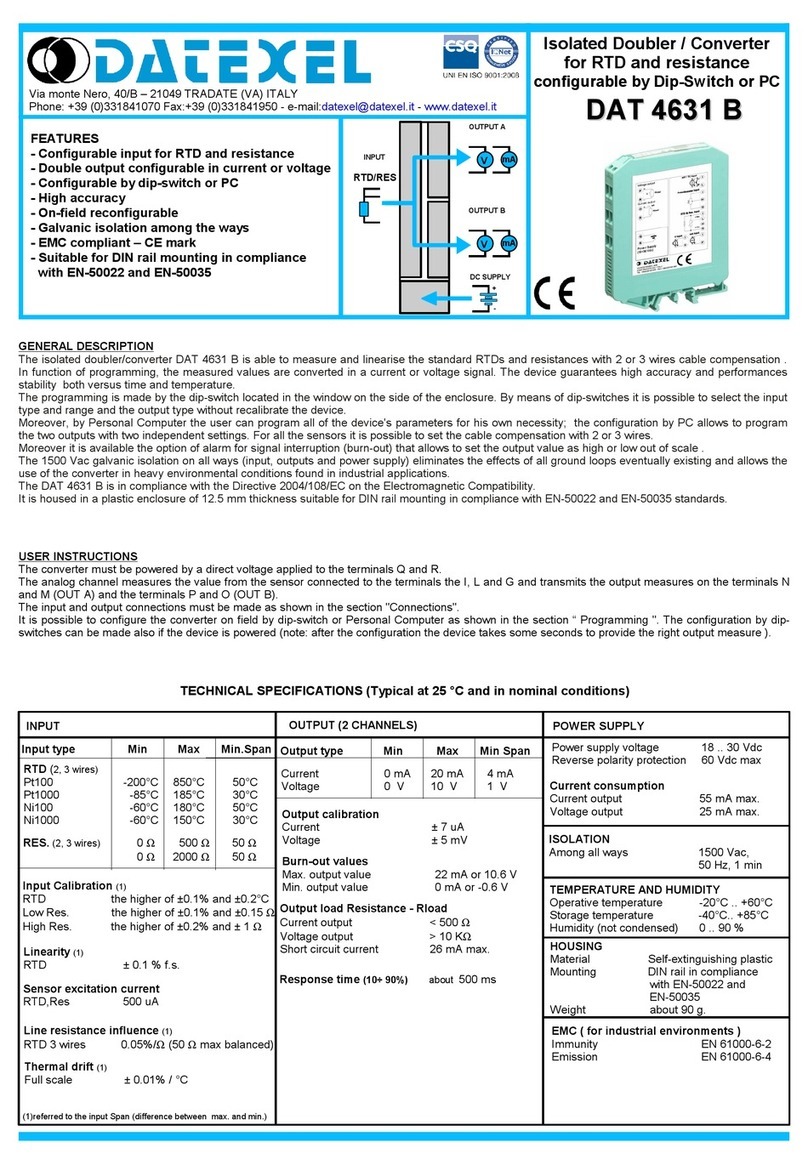

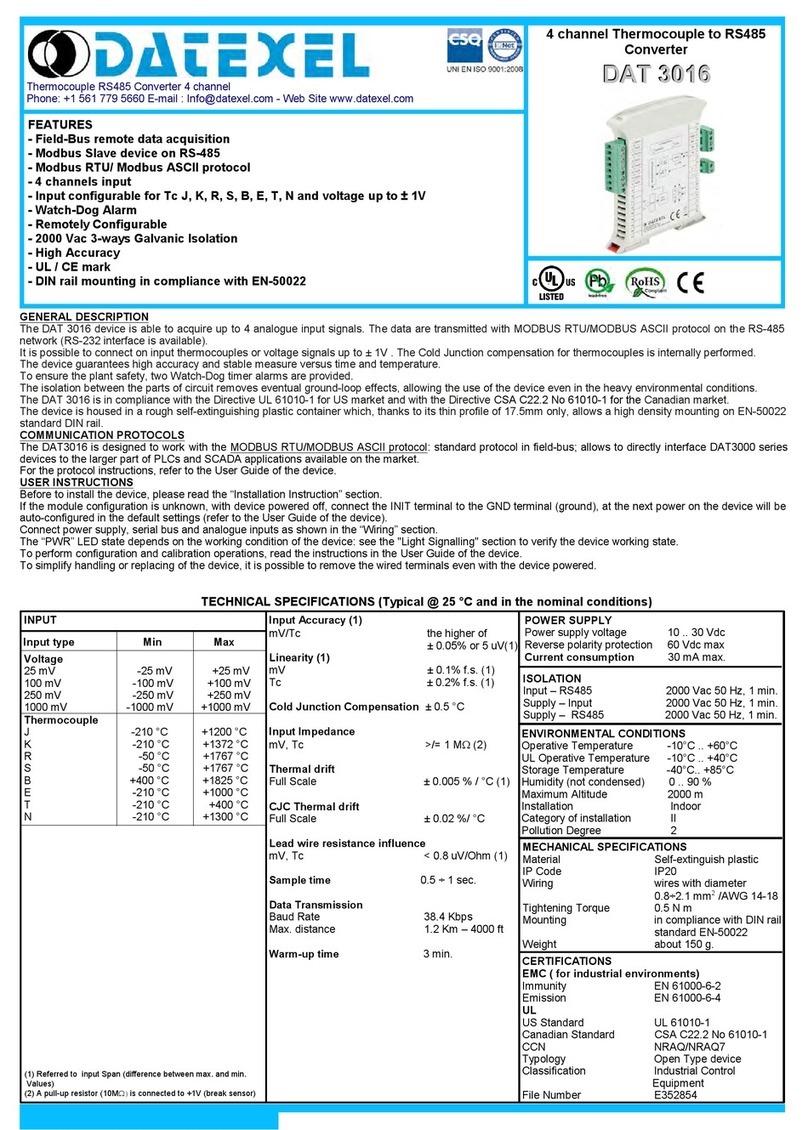

FEATURES

- Configurable input for PTC, NTC and Pot.

- Configurable output in current or voltage

- Double channel in the same enclosure

- Configurable b dip-switch or PC

- High accurac

- On-field reconfigurable

- Galvanic isolation among the wa s

- EMC compliant – CE mark

- Suitable for DIN rail mounting in compliance

with EN-50022 and EN-50035

GENERAL DESCRIPTION

T e isolated double c annel converter DAT 4532 C is able to measure and linearise t e standard PTC and NTC sensors and potentiometers. In function

of programming, t e measured values are converted in a current or voltage signal. T e device guarantees ig accuracy and performances stability bot

versus time and temperature.

T e double c annel allows t e ig density mounting w ere is necessary to reduce t e encumbrances.

T e programming is made by t e dip-switc located in t e window on t e side of t e enclosure. By means of dip-switc es it is possible to select t e input

type and range and t e output type wit out recalibrate t e device.

Moreover, by Personal Computer t e user can program all of t e device's parameters for is own necessity; t e configuration by PC allows to program

t e two c annels wit two independent settings.

Moreover it is available t e option of alarm for signal interruption (burn-out) t at allows to set t e output value as ig or low out of scale .

T e 1500 Vac galvanic isolation on all ways (inputs, outputs and power supply) eliminates t e effects of all ground loops eventually existing and allows

t e use of t e converter in eavy environmental conditions found in industrial applications.

T e DAT 4532 C is in compliance wit t e Directive 2004/108/EC on t e Electromagnetic Compatibility.

It is oused in a plastic enclosure of 12.5 mm t ickness suitable for DIN rail mounting in compliance wit EN-50022 and EN-50035 standards.

USER INSTRUCTIONS

T e converter must be powered by a direct voltage applied to t e terminals Q and R.

T e c annel A measures t e value from t e sensor connected to t e terminals I, L and G and transmits t e output measure on t e terminals N and M.

T e c annel B measures t e value from t e sensor connected to t e terminals E, F and H and transmits t e output measure on t e terminals P and O.

T e input and output connections must be made as s own in t e section "Connections".

It is possible to configure t e converter on field by dip-switc or Personal Computer as s own in t e section “ Programming ". T e configuration by

dip-switc es can be made also if t e device is powered (note: after t e configuration t e device takes some seconds to provide t e rig t output measure ).

TECHNICAL SPECIFICATIONS (T pical at 25 °C and in nominal conditions)

Sensor excitation current

PTC, NTC 500 uA

Linearit (1)

PTC, NTC ± 0.1 % f.s.

Thermal drift (1)

Full scale ± 0.01% / °C

TEMPERATURE AND HUMIDITY

Operative temperature -20°C .. +60°C

Storage temperature -40°C.. +85°C

Humidity (not condensed) 0 .. 90 %

Output t pe Min Max Min Span

HOUSING

Material Self-extinguis ing plastic

Mounting DIN rail in compliance

wit EN-50022 and

EN-50035

Weig t about 90 g.

Output calibration

Current ± 7 uA

Voltage ± 5 mV

Power supply voltage 18 .. 30 Vdc

Reverse polarity protection 60 Vdc max

EMC ( for industrial environments )

Immunity EN 61000-6-2

Emission EN 61000-6-4

Current consumption

Current output 55 mA max.

Voltage output 25 mA max.

Burn-out values

Max. output value 22 mA or 10.6 V

Min. output value 0 mA or -0.6 V

Current 0 mA 20 mA 4 mA

Voltage 0 V 10 V 1 V

(1)referred to t e input Span (difference between max. and min.)

Response time (10÷ 90%) about 500 ms

Output load Resistance - Rload

Current output < 500 Ω

Voltage output > 10 KΩ

S ort circuit current 26 mA max.

ISOLATION

Among all ways 1500 Vac,

50 Hz, 1 min

POWER SUPPLY

INPUT (2 channels) OUTPUT(2 channels)

Input Calibration (1)

PTC, NTC t e ig er of ±0.1% and ±0.2°C

Potentiometer ± 0.05 % f.s.

Input t pe Min Max Min.Span

PTC

KTY81-210 -55°C 150°C 50°C

KTY81-220 -55°C 150°C 50°C

KTY84-130 -40°C 300°C 50°C

KTY84-150 -40°C 300°C 50°C

Pot. (Rnom.< 50KΩ) 0 %100 % 10 %

NTC

Coster 10K -10°C 100°C 50°C

Coster 1K -30°C 40°C 25°C

NTC

PTC Pot

VmA

VmA

DC SUPPLY

INPUT A OUTPUT A

+

-

INPUT B OUTPUT B

NTC

PTC Pot

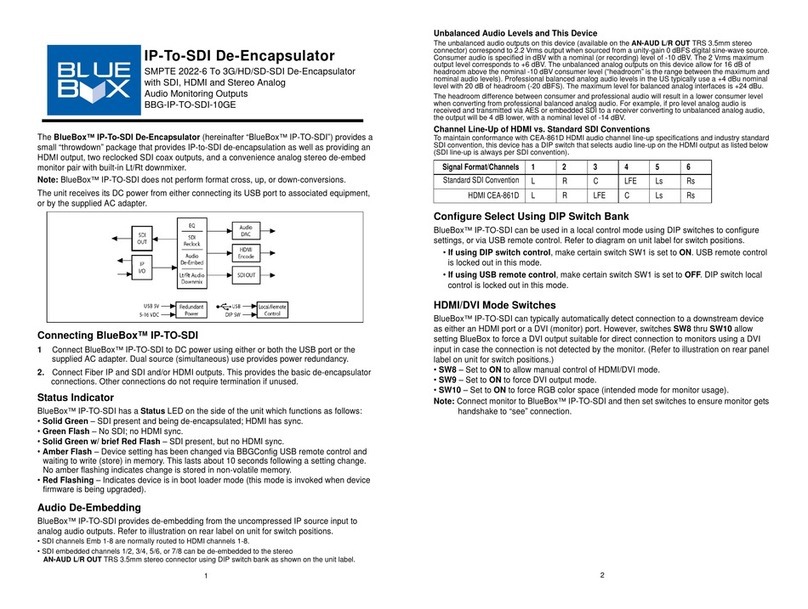

CONFIGURATION BY PC

By software DATESOFT it is possible to:

- set t e default programming of t e device;

- program t e options not available wit t e dip-switc ;

(burn-out level, etc...);

- read, in real time, t e input and output measures;

- follow t e dip-switc es configuration wizard.

To configure t e device follow t e next steps:

1) Power-on t e device.

2) Open t e protection plastic label on t e front of t e device.

3) Connect t e interface PRODAT to t e PC (COM port)

and to t e device (PGRM connector).

4) Open DATESOFT.

5) Select t e COM port in use.

6) Click on “Open COM”.

7) Click on “Program”.

8) Set t e programming data.

9) Click on “Write” to send t e programming data to t e device.

Warning: during these operations the device must always be powered and the TX/RX cable always connected.

For information about D TESOFT refer to the software's user guide.

DIP-SWITCH CONFIGURATION TABLES

PROGRAMMING

J1

TX/RX CABLE

PRODAT

COM PORT

P.C.

V+ V-

QR

PGRM

Plastic label protection

DAT

POWER SUPPLY

UNIT

1) Open t e suitable door on t e side of t e device.

2) Set t e input type by t e dip-switc SW1 [1..4] (see TAB.1)

3) Set t e minimum input scale value (Zero) by t e dip-switc SW1 [5..8] (see TAB.3)

4) Set t e maximum input value (Full scale) by t e dip-switc SW2 [1..6] (see TAB.3)

5) Set t e output type by t e dip-switc SW2 [7..8] (see TAB.2)

NOTE:

- It is also possible to set t e dip-switc es using t e wizard of t e configuration software following t e procedure described in t e section ”Configuration by

PC” until t e step 6 and clicking on “Switc ”.

CONFIGURATION BY DIP-SWITCHES

87654321

87654321

SW1

SW2

Input type

Output

Full scale

Zero

OFF

ON

NOTES:

* To configure t e range for t e input type selected (TAB.1) refer to t e section

of t e TAB.3 on next page relative to it (ex: for Potentiometer use t e table

TAB.3b ).

* If t e dip-switc es SW1 [1..4] are all set in t e position 0 (“EPROM”), t e

device will follow t e configuration programmed by PC ( input type and range,

output type and range and options).

* If t e dip-switc es SW1 [5..8] are all set in t e position 0 (“Default”), t e

device will follow t e input scale programmed by PC for t e input type

selected by t e dip-switc es SW1 [1..4]

* Eventual wrong dip-switc es settings will be signalled by t e blinking of t e

led “PWR”.

0-20 mA

SW2

87

TAB.2

Output type settings

4-20 mA

0-10 V

0-5 V

TAB.1

Input type settings

- Input type KTY84-130

- Zero value 0 °C

- Full scale value 200 °C

- Output type 4-20 mA

Ex of configuration: SW1 =

SW2 =

SW1

321

EPROM *

4

Pot

KTY81-210

KTY81-220

KTY84-130

KTY84-150

Coster 10K

Coster 1K

Zero

SW1

8765

Default

-200

-150

-40

-30

-20

-10

0

5

10

20

30

50

100

°C

Full scale

SW2

4321

Default

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

°C

5 6

SW2

4321

75

80

85

90

95

100

110

120

130

140

150

160

170

180

190

°C

5 6

SW2

4321

220

230

240

250

260

270

280

290

300

310

320

330

340

350

°C

5 6

SW2

4321

380

390

400

°C

5 6

425

450

475

500

525

550

600

800

850

-50

-100

200 360

650

700

750

370210

TAB.3a – Settings for PTC, NTC

Zero

SW1

8765

Default

0

15

30

35

40

45

50

55

60

65

70

75

80

%

Full scale

SW2

4321

Default

5

6

8

10

12

14

16

18

20

22

24

26

28

30

32

%

5 6

SW2

4321

34

36

38

40

42

44

46

48

50

52

54

56

58

60

62

%

5 6

SW2

4321

68

70

72

74

76

78

80

82

84

86

88

90

92

94

%

5 6

SW2

4321

100

100

100

%

5 6

100

100

100

100

100

100

100

100

100

25

20

64 96

100

100

100

9866

TAB.3b –Settings for Potentiometer

Datexel reserves its rig ts to modify totally or in part t e c aracteristics of its products wit out notice at any time .

CONNECTIONS

DAT 4532C / KTY84-130 / 0 ÷ 200 °C / 4 ÷ 20 mA

Input type

Input range

Output range

HOW TO ORDER

T e device is provided as requested on t e Customer's order.

Refer to t e section “Programming” to determine t e input and output ranges.

In case of t e configuration is not specified, t e parameters must be set by t e user.

ORDER CODE EXAMPLE:

INSTALLATION INSTRUCTIONS

T e device is suitable for fitting to DIN rails in t e vertical position.

For optimum operation and long life follow t ese instructions:

When the devices are installed side b side it ma be necessar to

separate them b at least 5 mm in the following cases:

- If panel temperature exceeds 45°C.

- Use of ig power supply value ( > 27 Vdc ).

- Use of output current.

Make sure t at sufficient air flow is provided for t e device avoiding to

place raceways or ot er objects w ic could obstruct t e ventilation slits.

Moreover it is suggested to avoid t at devices are mounted above

appliances generating eat; t eir ideal place s ould be in t e lower part

of t e panel.

Install t e device in a place wit out vibrations.

Moreover it is suggested to avoid routing conductors near power signal

cables (motors, induction ovens, inverters etc...) and to use s ielded

cable for connecting signals.

LIGHT SIGNALLING

LED COLOUR STATE DESCRIPTION

PWR GREEN ON

OFF

Device powered

Device not powered

BLINKING Wrong dip-switc es setting

INPUT

POWER SUPPLY

OUTPUT

ED.03.08-R.06

DIMENSIONS (mm)

90

112

PGRM

12.5

+

-

Vdc

Q

R

Rload

+

N

M

V

+

mA

Vout

Rload

I

G

PTC

NTC

I

L

POT

G

POWER SUPPLY

OUTPUT A

OUTPUT B

INPUT A

INPUT B

CHANNEL B

CHANNEL A

ISOLATION STRUCTURE

Rload

+

O

P

V

+

mA

Vout

Rload

E

H

PTC

NTC

E

F

POT

H

CHANNEL A

CHANNEL B

Other Datexel Media Converter manuals

Popular Media Converter manuals by other brands

Allied Telesis

Allied Telesis AT-MC1005/2 installation guide

MyTek

MyTek Stereo 192-DSD DAC user manual

Easylife

Easylife EL6174 instruction manual

VSpeak

VSpeak ECU Converter manual

Badger Meter

Badger Meter HR-E LCD user manual

Cobalt Digital Inc

Cobalt Digital Inc BlueBox BBG-IP-TO-SDI-10GE quick start guide