Davco fuel pro 382 User manual

TABLE OF CONTENTS

How it Works . . . . . . . . . . . . . . . . 1

“SEEING IS BELIEVING”®. . . . . . . . . . . 2

• Important Safety Precautions . . . . . . . . 3

Fuel Pro 382 Dimensions . . . . . . . . . . . 4

Fluid Heater Installation . . . . . . . . . . . . 7

12 VDC and 24 VDC Electric Pre-heater Installation 8

Water in Fuel Sensor (WIF) Installation . . . . . . 9

Preventive Maintenance. . . . . . . . . . . . 10

Filter Change Procedure . . . . . . . . . . .11

Visual Diagnostics . . . . . . . . . . . . . . 12

Diagnostic Procedures . . . . . . . . . . . . 14

Check Valve Diagnostics . . . . . . . . . . .17

Service Parts . . . . . . . . . . . . . . . . 18

Warranty and Customer Service . . . . . . . .21

Technology, LLC

FUEL PRO ®382

TECHNICAL MANUAL

2012 ©DAVCO Technology, LLC.

Updated 09/05/2012

®

FOR UPDATED INFORMATION, VISIT WWW.DAVCO.COM

®

HOW IT WORKS

Fuel System Diagram

Figure 1

• Fuel from the tank enters the Fuel Processor body (suction side of the fuel system).

• Large contaminants and “free” water are separated from the fuel and remain in the body.

• Fuel rises into the clear cover.

• Contaminants and emulsified water are captured by the filter media.

• Fuel level rises to maintain a fuel path through the clean filter media with low restriction.

• Clean, water-free fuel exits the Fuel Processor and flows to the engine fuel injection system.

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

1

®

• See when NOT to change the fuel filter.

• See the condition of the fuel. Seeing what collects on the filter media or what’s happening inside the clear cover

can help diagnose many fuel and mechanical conditions.

• “Filter on Top” configuration. Water and debris removed from the fuel falls to the lower chamber and stays away

from the filter media resulting in longer filter life.

• Built in protection when priming the fuel filter. Unfiltered fuel is kept on the “dirty” side of the filter media during

priming ensuring only clean fuel reaches the engine.

• Patented media. The “Best in Class” StrataPore™ media removes 98% of free and emulsified water over the life

of the filter. This far exceeds the performance of cellulose media.

“SEEING IS BELIEVING”®

When new, the fuel level in the filter will be very

low with minimal restriction. As the filter is used,

contaminants collect on the filter from the bottom up.

Fuel rises on the filter indicating remaining filter life.

Fuel level increases in clear cover. As contaminants

collect on the filter, the fuel rises to a non-contaminat-

ed section of the filter, providing optimal filtration while

maintaining lowest restriction.

Fuel level at filter wrap level. Even though the fuel

level is now more than half of the filter element, the

fuel is still flowing through clean media at minimal

restriction levels. The filter still has significant life

remaining.

The filter element is now completely covered by

fuel. At this point, all of the media’s surface area is

utilized. Restriction is increasing and the filter element

should be changed at the next scheduled mainte-

nance interval.

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

2

®

• IMPORTANT SAFETY PRECAUTIONS

•General Safety Precautions

• Read all instructions before use to avoid injury

• To avoid serious injury or death, follow the safety information in this document

• Keep this manual

• Read all product safety labels

• Refer to appropriate regulations for environmental and workplace safety rules

•To prevent personal injury

• Scalding hazard: When diesel fuel is circulated through an operating engine, it can become very hot. Do not

allow fuel to come in contact with eyes or unprotected skin. Allow the engine and fuel to cool to ambient tem-

perature before replacing the fuel filter or performing service operations which could result in spillage of fuel

from the fuel system. If this is not possible, protective equipment (face shield, insulated hat, gloves, and apron)

must be worn.

• Fire Prevention: Heated fuel can form combustible vapor mixtures in the area around the fuel source. To

eliminate the potential for fire, keep open flames, sparks or other potential ignition sources away from the work

area. Do not smoke during filter replacement or service operations.

• Inhalation Precaution: Always perform engine or vehicle fuel system maintenance in a well ventilated area

that is kept free of bystanders.

• The ignition key must be in the off position, unless otherwise directed. To avoid unintentional engine startup,

use a lockout key and/or signage to alert personnel that work is being performed.

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

3

®

FUEL PRO 382 DIMENSIONS

16.00 (406.4) MAX

3.46 (88.0)

6.75 (171.5) MAX

5.91 (150.0)

1/2" x 14

NPTF

FUEL INLET

1/2" x 14 NPTF

FUEL OUTLET Ø .43 (11.0)

(2 PLACES)

SERVICE HEIGHT

1.5 (38.1)

6.58 (167.1)

.50 (12.7)

3.9 (99.1)

3.28 (83.3)

FUEL

IN

BOTTOM

RIGHT SIDEFRONT

All dimensions are in inches (millimeters)

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

4

®

INSTALLATION INSTRUCTIONS

Installation Location

The Fuel Pro must be installed between the fuel tank and

the fuel transfer pump. In some cases, the Fuel Pro can be

used as the only fuel filter in the system. This is generally

dependent on the engine model year. Consult the engine

manufacturer for their recommendation. If the Fuel Pro can

be used as a single filter, DAVCO offers a diverter cap to

replace the secondary filter. (See diverter cap installation

section)

Mounting the Fuel Pro

Mount the Fuel Pro keeping the following points in

mind:

• Do not install the Fuel Pro directly on the engine.

• Mount vertically with the cover and element pointing

up.

• Make sure there is enough top and side clearance for

the cover to be conveniently removed for filter replace-

ment.

• The Fuel Pro MUST be installed so that the Filter Ele-

ment is above the "FULL" level of the fuel tank.

•The ignition key must be in the off position, unless

otherwise directed. To avoid unintentional engine

startup, use a lockout key and/or signage to alert

personnel that work is being performed. Chock the

wheels.

Step 1: With the engine shut down and at ambient temper-

ature, close the fuel shutoff valve (if equipped) and place a

suitable container under the fuel filters.

Step 2: Remove the primary fuel filter element assembly,

sedimenter, and/or water separator. Drain the used ele-

ment and dispose of it in an environmentally responsible

manner, according to state and/or federal (EPA) recom-

mendations.

Fuel Line Routing

To minimize fuel system restriction, observe the follow-

ing guidelines when plumbing the fuel system:

• Keep the fuel line routing as smooth as possible with no

low-hanging loops which can trap water.

• Use 90° elbows only when necessary.

• If the fuel hoses are cut to length on the job, be sure that

the inner liner of the fuel hose is not cut by the fitting,

which can cause check valve performance issues. Make

sure hoses are clean and free of debris before installing.

• To avoid damaging the aluminum Fuel Pro body, do not

overtighten fuel lines or fuel line fittings.

Step 1: Route the fuel supply line from the pick up on the

fuel tank to the Fuel Pro inlet (labeled “Fuel In”).

Step 2: Route the fuel outlet line from the Fuel Pro outlet

(labeled “Fuel Out”) to the inlet of the fuel pump.

Priming the Fuel System

Step 1: Check to make sure the drain valve at the base of

the Fuel Pro is closed.

Step 2: Remove the vent cap from the top of the clear

cover. Fill the Fuel Pro full with clean fuel. Reinstall the vent

cap and tighten by hand only.

Step 3: Start the engine. When the lubrication system

reaches its normal operating pressure, increase engine

RPM to high idle for one to two minutes. After the air is

purged loosen the vent cap until the fuel level lowers to

just above the collar. Tighten the vent cap by hand only.

Step 4: Hand tighten the collar again while the engine is

running. To avoid damage, do not use tools to tighten the

collar.

Note: The clear filter cover will not fill completely during

engine operation. It will gradually fill over time and the fuel

level will rise as the filter becomes contaminated.

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

5

®

Diverter Cap Installation

If a single fuel filter system is approved by the engine

manufacturer, the following steps are to be taken to install

a diverter cap properly.

Step 1: Select the required secondary filter head diverter

cap from those listed in Table 1. The required diverter cap

is determined by the size of the spin-on filter stud and the

filter sealing surface diameter.

Step 2: Drain and remove the secondary fuel filter element.

Step 3: Lightly lubricate the seal on the top of the diverter

cap with clean engine oil.

Step 4: Thread the adapter onto the secondary filter stud

and tighten by hand only.

Step 5: Install the “Do Not Remove” label on the diverter

cap.

Diverter Cap

Part Number

Required

Filter Head

Stud Size

Required

Filter Head

Seal ID

Required

Filter Head

Seal OD

101480 1"-14 2.475" 2.895"

101589 1"-14 3.225" 3.435"

101570 M16 x 1.5 2.475" 2.895"

101466 ¾"-16 2.475" 2.895"

101492 7/8" x 14 2.475" 2.895"

Table 1

INSTALLATION INSTRUCTIONS

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

6

®

FLUID HEATER INSTALLATION

Figure 2 Figure 3

The engine return fuel heat and engine coolant heat options apply ONLY to the fluid heater base shown in Figures 2 and

3. If the bottom plate is flat with ½" NPT ports, only the electric pre-heater can be used. Contact DAVCO Customer Ser-

vice to obtain the appropriate bottom plate.

Engine Coolant Heat

To use engine coolant as the Fuel Pro heating fluid, con-

nect a hose (5/8" silicon heater hose) from the high pres-

sure side of the engine coolant system to the Fuel Pro

heater base. Either heater port will work as an inlet. Route

another hose from the heater base to a low pressure port

in the coolant system. DO NOT route into the cab heater

system. (See Figure 2)

Engine Return Fuel Heat

High flow and high temperature return fuel engines can

use the return fuel as the heating fluid for the Fuel Pro.

Route the return fuel line from the engine into the heater

base of the Fuel Pro. Either heater port will work as an in-

let. Connect a second fuel return line from the heater base

to the fuel tank return port.(See Figure 3)

inlet or outlet ports

coolant

transfer pump

fuel tank

Fuel Pro

inlet or outlet ports

return fuel

transfer pump

Fuel Pro

fuel tank

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

7

®

The Fuel Pro 382 12 VDC or 24 VDC electric pre-heater is

installed in the processor base as shown in Figure 4.

Figure 4

Step 1: Drain all the fuel from the Fuel Pro. The fuel can

be reused after the pre-heater is installed. If the fuel is not

reused, dispose of it in an environmentally safe way.

Step 2: Remove the pipe plug in the Fuel Pro base plate.

Step 3: Apply liquid thread sealant to the pre-heater

threads and install into the Fuel Pro base. Tighten to 15-30

ft-lbs.

Step 4: Connect the chassis harness and wire.

• For 12 VDC or 24 VDC without a relay, refer to Figure 5.

• For 12 VDC or 24 VDC with a relay, refer to

Figure6.

• If the keyed circuit will not handle a minimum of 20

amps, use a relay.

• Provide proper (20 amp fuse) electrical protection for

source voltage supplied to the pre-heater.

Step 5: Remove the vent cap from the top of the clear

cover. Pour fuel into the Fuel Pro to one inch below the

top of the filter element. Reinstall the vent cap and hand

tighten.

Step 6: Start the engine. When the lubrication system

reaches its normal operating pressure, increase engine

speed to high idle for one to two minutes. After the air is

purged, loosen the vent cap until the fuel level drops to

just above the collar. Tighten the vent cap by hand only.

Heater element

FUEL PRO

+

20 A Switch

GND GND

Key Controlled Circuit

Fuse*

Battery

Pre-heater Wiring without Relay

*24 VDC pre-heaters require a 15 A fuse.

Figure 5

+

GND

Relay

Key Controlled Circuit

GND

GND

20 A

Fuse*

Battery

FUEL PRO

Heater element

Pre-heater Wiring with Relay

*12 VDC pre-heaters require a 20 AMP fuse. If the keyed circuit will not

handle a minimum of 20 amps, use a relay.

Figure 6

12 VDC AND 24 VDC ELECTRIC PRE-HEATER INSTALLATION

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

8

®

Step 1: Remove the ½"-20 WIF plug in the bottom of the

Fuel Pro.

Step 2: Install the WIF Probe (See Service Parts Page

for P/N) into the bottom of the Fuel Pro. Torque to 20-24

in-lbs.

Step 3: Install the WIF wiring harness (P/N 102600) on

WIF Probe. The harness has the following connections:

black ground lead with a 3/8" diameter ring terminal and

a green WIF wire.

Step 4: Drill ½" hole in the instrument or control panel

where the WIF indicator light is to be located.

Step 5: Connect the black ground wire from the WIF

indicator light to a ground source. Attach additional black

wire as needed.

Step 6: Install the WIF indicator light by pressing firmly

into the drilled hole.

Step 7: Connect the black ground lead with a 3/8" diam-

eter loop end on the WIF wiring harness to the ground

source near the Fuel Pro (if applicable).

Step 8: Connect the green signal wire on WIF wiring

harness to green signal wire on WIF indicator light. Use

additional green wire as needed.

Step 9: Locate 12 VDC or 24 VDC key controlled on

power source. Install a red wire from the power source to

the red wire on WIF indicator light. Add a 1 amp in-line

fuse (not included).

Note: Use appropriate connectors to attach the wires. To

test the WIF indicator light, pour water into the body of

the Fuel Pro until it covers the WIF probe. The WIF indica-

tor light should illuminate.

WATER IN FUEL SENSOR (WIF) INSTALLATION

CHASSIS

GROUND

FUEL

WATER

PROBE

GREEN

CHASSIS

GROUND

BLACK

RED

TO ANY KEYED

12 OR 24 VDC SOURCE

(Recommended fuse: 500ma for 12 VDC. Do not exceed 1 A.)

WATER-IN-FUEL

(WIF)

WARNING LIGHT

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

9

®

PREVENTIVE MAINTENANCE

• Weekly – Drain water

• Turn off the engine and open the vent cap.

• Place a suitable eight ounce, plastic or metal container under the drain valve at the base of the Fuel

Pro and open the valve.

• Water will flow into the container. When fuel begins to flow out the drain, close the drain valve. Drain

the least amount of fuel as possible.

• Hand-tighten the vent cap.

• Start the engine. Raise the RPM for one minute to purge the air from the system.

• Every filter change

• Change the cover and vent cap o-rings (included with the service filter kit).

• Every 12 months

• Check all electrical connections for corrosion. Check all fuel fittings for leaks.

• Seasonal Maintenance:

• Extreme winter or salt corrosion environments may require lubrication of the collar threads with anti-

seize lubricant every 180 days.

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

10

®

FILTER CHANGE PROCEDURE

For filter selection visit www.davco.com/parts.html (Parts

And Cross Reference) for the correct filter for your applica-

tion or call DAVCO Customer Service at 800-328-2611.

Step 1: Remove the vent cap and open the drain valve to

drain the fuel below the collar level.

Step 2: Remove the collar (using the DAVCO collar

wrench) then remove the clear cover.

Step 3: Remove the filter, cover and vent cap seals.

Dispose of the filter and the seals properly.

Step 4: Using a clean shop rag, clean the cover, the collar

and threads on the Fuel Pro body.

Step 5: Install a new filter, cover seal and vent cap seal.

Step 6: Reinstall the clear cover and collar. Hand tighten

the collar.

Step 7: Prime the unit by filling the clear cover with clean

diesel fuel until it reaches the top of the filter.

Step 8: Install the vent cap. Hand tighten only.

Step 9: Start the engine and run for one minute. Slowly

open the vent cap and allow the fuel to drop to about one

inch above the collar.

Step 10: Close the vent cap. Hand tighten only. It is

normal for the fuel level to vary after the initial start-up and

during engine operation. Filter performance is not affected.

Service Wrench Information

• The DAVCO Fuel Pro vent cap and collar are

designed to be removed with a DAVCO wrench.

• Vent caps and/or collars damaged as a result of

not using the DAVCO wrench will not be covered

under warranty. Wrench is for removal ONLY.

Description P/N

Metal Collar/Vent Cap Wrench 380134

Composite Collar/Vent Cap Wrench 382002

Metal Collar/Vent Cap Wrench

Composite Collar/Vent Cap Wrench

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

11

®

Fuel level is not at the top of the fuel

filter.

ÎNormal - Do not change the filter.

Fuel level is at the top of the filter. Low

power.

ÎChange the filter at the first available

opportunity.

Fuel level is at the top of the filter and

appears to be full of wax.

ÎChange the filter - Run the engine for

a minimum of 25 minutes at idle. Do not

run at full RPM.

There is a power complaint and the fuel

level is below the collar.

ÎCheck for a missing grommet at the

lower end of the filter or missing/broken

spring at top of filter.

Bubbles are seen flowing in with the

fuel.

ÎCheck all fittings and lines from the

fuel tank to the fuel processor. Check

lower and upper collar o-rings.

Water is noticed in the cover.

ÎDrain the water. If engine coolant is

visible, follow proper engine pressure

testing procedures to determine root

cause.

Fuel drains back to the fuel tank when

changing the fuel filter or draining sepa-

rator.

ÎRemove the check valve assembly.

Clean or replace and retest. Check air

leaks in the fuel system.

No engine coolant flow to the Fuel Pro

heater.

ÎCheck for closed cutoff valves at

the coolant lines to the fuel processor.

Make sure the cab heater valve is open.

VISUAL DIAGNOSTICS

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

12

®

Air Bubbles (will affect engine performance)

Air bubbles are caused by any air leak on the vacuum (suc-

tion) side of the fuel system from the fuel tank pick-up to,

and including, the lift pump. (See Figure 7)

If there is an air leak in the fuel system, air bubbles will

be present in the clear cover of the Fuel Pro. Follow test

procedures outlined in "Troubleshooting" for air leak diag-

nostics.

If there are no bubbles present in the Fuel Pro cover and

the engine continues to run rough, lopes or has a loss

of power, there may be an air leak between the Fuel Pro

outlet port and lift pump inlet. This type of air bubble can

be seen if a sight tube is installed at the lift pump inlet. Air

bubbles may also be visible in the fuel return (spill) hose

out of the fuel gallery. These leaks are easily eliminated by

checking and torquing the fuel fittings in the area of the

leak.

If there are no air leak symptoms, but bubbles are pres-

ent in a sight tube at the fuel lift pump inlet, they are most

likely vapor bubbles.

Note: A quick procedure to determine if the air leak is

between the fuel tank and the Fuel Pro is to remove the

Fuel Pro inlet hose and route a new hose from the Fuel Pro

inlet into a container of fuel or the fuel tank fill cap opening.

Start the engine and check for bubbles.

Vapor Bubbles (will not affect engine perfor-

mance)

All diesel fuel has some level of entrained air caused by the

natural splashing that occurs in the fuel tank during normal

vehicle or equipment operation. Vapor bubbles develop in

the Fuel Pro because the pressure inside the Fuel Pro is

lower than the atmospheric pressure in the fuel tank. Vapor

bubbles can vary from champagne size up to ¼" in diam-

eter. They may increase in size or volume as engine RPM

increases. The lower pressure draws the entrained air/va-

por out of the fuel and these bubbles will be visible as the

fuel exits the Fuel Pro. (See Figure 8)

As the fuel enters the lift pump, it is pressurized and the

bubbles are compressed back into the fuel. There will be

no bubbles on the fuel return side of the system. (See Fig-

ure 8). These vapor bubbles will not affect the performance

of the engine.

There is no diagnostic or repair procedure required for

vapor bubbles. Vapor bubbles do not cause performance

issues and will not be present after the lift pump.

There are two kinds of bubbles that may be visible at the fuel pump inlet of a diesel fuel system. The bubbles can be

characterized as either air bubbles or vapor bubbles.

VISUAL DIAGNOSTICS

L

Y

FI

FUE PRO

OR OTHER

PRIMAR

LTER

FUE RETURN

ENGINE

LIF PUM

AIR

BUBBLES

L

T P

Figure 7

VAPOR

BUBBLES

L

Y

FI

FUE PRO

OR OTHER

PRIMAR

LTER

FUE RETURN

ENGINE

LIF PUM

L

T P

Figure 8

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

13

®

Air Leaks

Note: Every Fuel Pro is factory tested for leaks and is

identified with a traceable number prior to shipment. Most

field issues associated with leaks are related to loose

fittings. These leaks are easily eliminated by checking

and torquing the fuel fittings in the area of the leak. Some

fittings may also require the application of liquid Teflon

sealer.

Note: All suction side fuel filters experience bubbles. It

is normal to see champagne size bubbles in the Fuel Pro

cover, at the Fuel Pro outlet or at the lift pump.

IN ORDER TO RETURN A FUEL PRO FOR EVALU-

ATION, THE FOLLOWING PROCEDURES/TESTS

MUST BE COMPLETED BEFORE REQUESTING A

DAVCO RGA (RETURN GOODS AUTHORIZATION)

NUMBER.

I. Air Leak: Air bubbles will be visible in the clear cover

of the Fuel Pro if the leak originates between the fuel

tank up and the fuel filter. The following is a quick test

to isolate the air leak source.

A. Bubbles Visible: Remove the Fuel Pro inlet

hose.

i. Install a jumper hose from the Fuel Pro to

the fuel tank (through the fill cap) or to a

container of fuel.

ii. Start the engine. If this eliminates the air

bubbles, the air source is at the fuel tank

fittings or hose connections.

1. Tighten all fittings and connectors

2. Retest

iii. If air bubbles persist, the air source is on

the Fuel Pro side of the system:

1. Tighten all fittings on the Fuel Pro .

2. Hand tighten the top collar.

3. If the drain valve is suspected, install

a plug in place of the drain valve (for

test purposes only).

iv. If air bubbles continue to persist, test as

follows:

1. Remove the Fuel Pro from the chas-

sis.

2. Plug the fuel outlet port. Do not

remove filter, cover/collar, vent cap,

drain valve and/or check valve. If the

Fuel Pro is equipped with a pre-heat-

er, do not remove the pre-heater.

3. Apply 15 PSI of air pressure at the

fuel inlet. Immerse the Fuel Pro in a

tank of water and look for air bub-

bles.

4. Correct the source of the air leak and

retest.

B. Bubbles Not Visible: If there are symptoms of

sucking air (indicated by engine loping/rough

running performance/power loss, etc.) and

there are no bubbles in the clear cover, the air

leak is either at the Fuel Pro outlet fitting, vent

cap o-ring, the lift pump inlet connection, or the

fuel hose/connections to the lift pump. Inspect

and tighten fittings as needed.

II. Excessive Restriction: If the fuel level is at the top

of the filter, replace the fuel filter. The Fuel Pro will

not cause excess system restriction if the fuel level

is below the top of the filter. The only exception is if

the grommet is not installed in the bottom of the filter

element.

III. Loss of Prime: When air is introduced into the fuel

system, (i.e. draining water from the Fuel Pro or when

replacing the fuel filter) a check valve is needed to

keep the fuel system primed from the Fuel Pro back

to the fuel tank. A check valve is standard with every

Fuel Pro

A. To test for proper check valve operation,

remove the fuel inlet hose and open the vent

cap. Fuel should not flow out of the Fuel Pro ,

although a slight seepage of fuel is normal.

B. If fuel drains back to the fuel tank, remove the

check valve assembly at the fuel inlet fitting.

Disassemble the check valve assembly. Clean

and inspect. Replace the assembly if any cuts,

grooves or nicks are evident in the ball or body

seat. Reinstall the check valve assembly.

DIAGNOSTIC PROCEDURES

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

14

®

Fluid Heater Thermovalve Test

Step 1: Drain the Fuel Pro completely.

Step 2: Remove the fluid hoses going to the bottom plate.

These will either be engine coolant hoses or return fuel

hoses. Engine coolant hoses will have to be plugged when

removing them from the Fuel Pro.

Step 3: Remove the bottom plate.

Step 4: While looking into the fluid port of the bottom plate

(see Figure 9) flow cold water over the thermovalve for

30 seconds, then run hot water over the thermovalve and

determine if the thermovalve spool is opening and closing.

Step 5: Replace with a new bottom plate seal and install

the bottom plate onto the Fuel Pro.

Note: There are two styles of bottom plates.

• Torque the collar version to 50 to 60 ft-lbs (the use of

2-3 drops of Loctite 406 is recommended to secure the

bottom collar). Use seal P/N 101994.

• Torque the bolts on the bolt-on version bottom plate to

10 ft-lbs. Use seal P/N 910005.

Step 6: Reconnect the fluid hoses to the bottom of the

Fuel Pro.

Step 7: Fill the Fuel Pro with fuel and restart the engine.

Port to view

thermovalve

spool

Thermovalve

Figure 9

Electric Pre-Heater and Thermoswitch

Tests

Equipment Needed:

• A precision low resistance Ohm Meter capable of mea-

suring 1/10th Ohm or less is recommended.

• Current Flow Meter (Clamp-on type for DC current).

• Ice, dry-ice, CO2or some means of chilling the thermo-

switch.

• A flameless source of heat. Infrared heat lamp, etc. (a

Vortex tube is a good tool to heat and cool for testing).

•DO NOT USE a test light that has a wire probe for

any of these tests. If the insulation of the wiring is

punctured, moisture and road salt can penetrate into

the wires creating a corrosion issue and potential

failure.

There are various configurations of electric pre-heaters and

thermoswitches available for the Fuel Pro. These include

12 VDC pre-heaters, 24 VDC pre-heaters, 120 VAC pre-

heaters, thermoswitch, and combination pre-heater ther-

moswitch. The voltage and wattage ratings are stamped

either on the sheath or the hex of each component for

identification.

If it is necessary to remove the fuel from the fuel/water

separator:

• Shut off the engine and set the parking brake.

• Attach a length of hose to the drain valve and into a

container.

• Loosen the vent cap on top of the clear housing, and

open the drain valve to drain the fuel into the receptacle.

• When the fuel is drained, close the drain valve.

Pre-heater Test

Step 1: Disconnect the pre-heater from the harness.

Step 2: Connect the Ohm meter leads to the pins of the

pre-heater (connect to a pin and the bushing for pre-

heaters with one pin).

Step 3: Using the Table 2, read the value of the resistance

and determine if the pre-heater is within the acceptable

range.

DIAGNOSTIC PROCEDURES

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

15

®

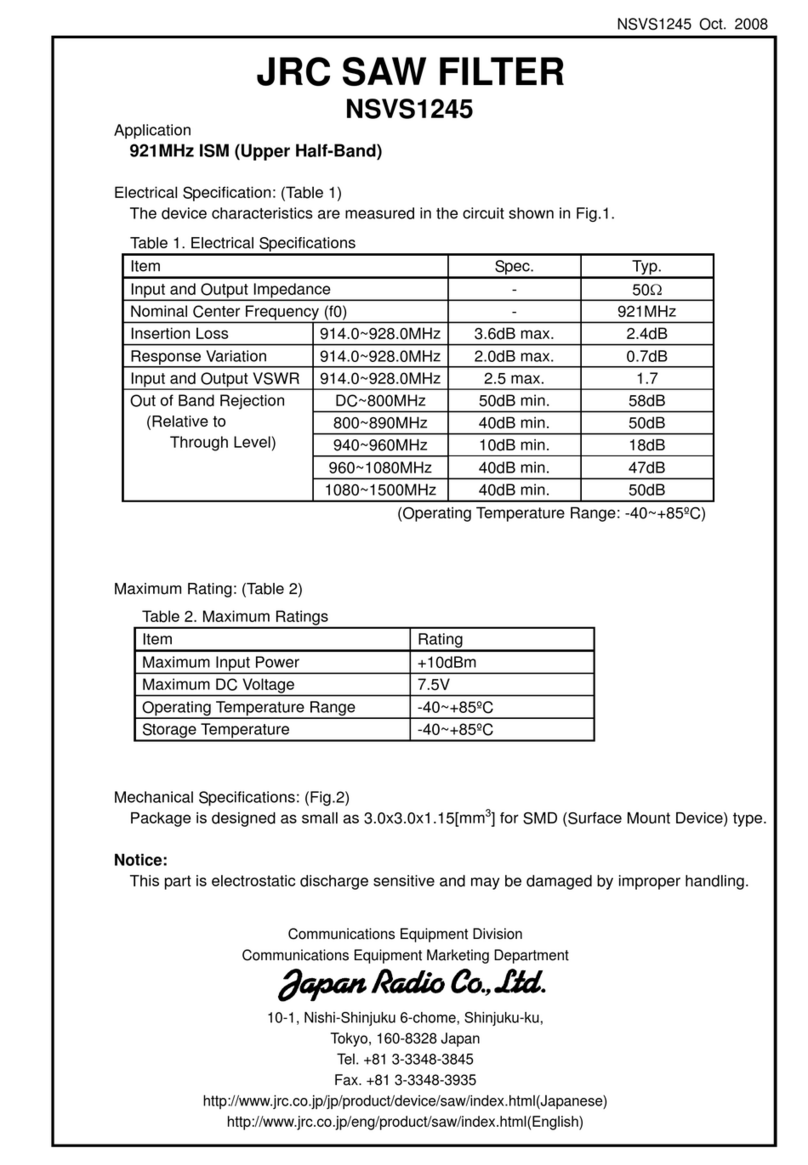

Electric

Pre-heater Watts Resistance Range

in Ohms

12 VDC (two pin) 250 W 0.6 to 0.8

12 VDC (single pin) 250 W 0.6 to 0.8

12 VDC (single pin) 150 W 0.8 to 1.1

12 VDC (two pin) 150 W 0.8 to 1.1

24 VDC (two pin) 250 W 2 to 2.5

24 VDC (single pin) 250 W 1.8 to 2.3

24 VDC (single pin) 150 W 3.6 to 4.1

120 VAC 75 W 173 TO 203

120 VAC 37 W 369 TO 411

Table 2

12 VDC Thermoswitch Test

Step 1: Disconnect the thermoswitch harness (see Figure

10).

Step 2: Connect the Ohm meter leads to the pins of the

thermoswitch.

Figure 10

Note: This test requires the thermoswitch to be below 40°

F. (Use one of the cooling sources listed under "Equipment

Needed".) The resistance should be less than 0.1 Ohm.

Step 3: Using one of the heat sources listed under "Equip-

ment Needed", raise the temperature above 60° F. The

resistance should be more than 10M Ohms.

Step 4: Prime the unit by filling the clear cover with clean

diesel fuel until it reaches the top of the filter.

Step 5: Install the vent cap. Hand tighten only.

Step 6: Start the engine and run for one minute. Slowly

open the vent cap and allow the fuel to drop to about one

inch above the collar. Close the vent cap. Hand tighten

only.

DIAGNOSTIC PROCEDURES

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

16

®

CHECK VALVE DIAGNOSTICS

To test for proper check valve operation, remove the fuel

inlet hose and open the vent cap. Fuel should not flow out

of the Fuel Pro, although a slight seepage of fuel is normal.

If fuel drains back to the fuel tank, remove the check valve

assembly at the fuel inlet fitting.

Step 1: Use a back-up wrench to hold the check valve

body and remove the fuel hose from the inlet of the Fuel

Pro.

Step 2: Remove and disassemble the check valve assem-

bly.

Step 3: Clean and inspect the check valve body. Replace

the check valve body if any cuts, grooves or nicks are

evident or if the ball seat is not smooth.

Step 4: Inspect the check valve spring and spring retainer.

If the spring or spring retainer is broken or if the check ball

has groves, nicks or is out of round, replace with a check

valve service kit. Otherwise, clean and reassemble the

check valve assembly.

Note: The spring retainer snaps into a groove in the check-

valve body.

Step 5: Replace the check valve assembly into the body

and torque to 44-60 ft-lb.

Step 6: . Connect the fuel inlet hose, using liquid or paste

type thread sealant.

Step 7: Prime the fuel system, start the engine and check

for any fuel leaks.

Check Valve Body Check Valve Service Kit

P/N 090037 P/N 101132

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

17

®

SERVICE PARTS

Service Kits

Description Contents Part Number

Vent cap ser-

vice kit

Vent cap and

Vent cap

O-ring

380043

O-ring

service kit

Vent cap and Cover

O-rings 380072

Check valve

service kit

Retainer, spring and

ball (does not include

the check valve body)

101132

Check Valve Service Kit: P/N 101132

Check Valve Body

Service Parts

Description Part Number

Collar 102425

Clear Cover 102420

Spring 380056

Filter Element visit www.davco.com/parts.html

for filter ordering information.

Drain Valve 102008

Electric Pre-heaters visit www.davco.com, Form F1263

WIF See Page 20

Check valve body 090037

Spin-on stud

13/16"-12

(Yellow Zinc)

320620

Heated

Drain Valve

Drain Valve

Check Valve

Service Kit

Check Valve

Service Kit

Check Valve Body

Spin-on Stud

OR

O-Ring Kit

(part no. 380072)

Includes a vent cap seal

and a cover seal.

Vent Cap Kit

(part no. 240023DAV)

Includes Vent Cap

with vent cap seal installed.

Spring

Filter

Collar

DAVCO Wrenches

Description Part Number

Metal Col-

lar/Vent Cap

Wrench

380134

Composite

Collar/Vent

Cap Wrench

382002

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

18

Visit www.davco.com for OEM service part number listing.

®

SERVICE PARTS

Bottom Plate - Service Kits and Parts

Description Part Number

Seal (Bottom Collar) 101994

Seal (Bolt-On) 910005

Unheated Bottom Plate (Bottom

Collar) 382006SVC

Fluid Heated Bottom Plate

(Bottom Collar) 382015SVC

Unheated Bottom Plate (Bolt-On) 382027SVCB

Bottom Plate Upgrade Includes:

Radiator o-rings (2)

Thermo-Valve Assembly

Bottom plate seal (square cut)

Spool assembly

Bottom plate plug w/o-ring

382029SVCB Standard

382029SVCBE With ESOC port

382029-5SDAV With ½-20 WIF port and 3/8" Fluid

Port

382029-14DAV With ½-20 WIF, 3/8" Fluid Ports and

Heater Port

382029NAV Navistar Bottom Plate with 9/16"

Fluid Heat, Heater and WIF ports

FUEL PRO®382

TECHNICAL MANUAL

Technology, LLC

DAVCO Technology, LLC P. O. Box 487 Saline, MI 48176 Call 800-328-2611 www.davco.com F1271 REV C

Updated 09/05/2012

19

Visit www.davco.com for OEM service part number listing.

Other manuals for fuel pro 382

1

Table of contents

Other Davco Water Filtration System manuals