Davey Water Products Torrium 2 User manual

Installation and

Operating Instructions

for Davey CT

Pressure Systems with

DAVEY WATER PRODUCTS GUARANTEE FOR AUSTRALIA & NEW ZEALAND

Davey HP Pressure systems tted with Torrium2 control are guaranteed for a period of two years from the date of original

purchase to be free of material or manufacturing defects. Should any part fail as a result of such defects within this period,

the pressure system will be repaired free of charge.

TERMS AND CONDITIONS

1. This guarantee applies to all states and territories of Australia and New Zealand only and is subject to the provisions of

the Trade Practices Act (Aust.), the Goods and Consumer Protection Legislation of the various Australian states and the

Consumers Guarantee Act 1993 (NZ) as applicable.

2. The guarantee period commences on the date of original purchase of the equipment. Evidence of this date of original

purchase must be provided when claiming repairs under guarantee. It is recommended you retain all receipts in a safe

place.

3. This guarantee covers parts and workshop labour only. Goods should be forwarded, with proof of date of original

purchase, to an Authorised Davey Service Centre freight paid.

4. This guarantee is subject to due compliance by the original purchaser with all directions and conditions set out in the

Installation and Operating Instructions. Failure to comply with these instructions, damage or breakdown caused by

fair wear and tear, negligence, misuse, incorrect installation, chemical or additives in the water, inadequate protection

against freezing, rain or other adverse weather conditions, corrosive or abrasive water, lightning or high voltage spikes

or through unauthorised persons attempting repairs are not covered under guarantee. The product must only be

connected to the voltage shown on the nameplate.

5. Without limiting the original purchaser’s entitlements under the Trade Practices Act (Aust.), the Goods & Consumer

Protection Legislation of the various Australian states, or the Consumers Guarantee Act 1993 (NZ), Davey shall not

be liable for any loss of prots or any consequential, indirect or special loss, damage or injury of any kind whatsoever

arising directly or indirectly from the product or any defect.

6. Where the Trade Practices Act (Aust.), the Goods and Consumer Protection Legislation of the various Australian states

and the Consumers Guarantee Act 1993 (NZ) does not apply, Davey shall not be liable for any loss of prots or any

consequential, indirect or special loss, damage or injury of any kind whatsoever suffered by the purchaser arising

directly or indirectly from the product or any defect and the purchaser shall indemnify Davey against any claim by any

other person whatsoever in respect of any such loss, damage or injury.

7. Nothing in this guarantee is intended to have the effect of contracting out of the provisions of the Trade Practices Act

(Aust.), the Goods and Consumer Protection Legislation of the various Australian states and Consumers Guarantee

Act 1993 (NZ) except to the extent permitted by the various Acts and this guarantee is to be modied to the extent

necessary to give effect to that intention.

8.

Davey may be collecting personal information from you in order to provide you with a service. Davey Water Products Pty

Ltd promises only to use this information in accordance with the Provisions of the Privacy Act 1988 (Cth) and the Privacy

Policy of Davey Water Products Pty Ltd which is available at davey.com.au.

® Davey and Torrium2 are registered trade marks of Davey Water Products Pty Ltd.

© Davey Water Products Pty Ltd 2011.

Please pass these instructions on to the operator of this equipment.

WARNING : The Torrium2®controller, pump and associated pipework

operate under pressure. Under no circumstances should the Torrium2®

controller, pump or associated pipework be disassembled unless the

internal pressure of the unit has been relieved. Failure to observe this

warning will expose persons to the possibility of personal injury and may

also result in damage to the pump, pipework or other property.

WARNING: Failure to follow these instructions and comply with all applicable

codes may cause serious bodily injury and/or property damage.

NOTE: Prior to installation remove the inlet and outlet

pipe transport plugs & associated seals from the

suction and/or discharge ports.

P/N 401958

AUSTRALIA

Head Ofce and Manufacturing

6 Lakeview Drive,

Scoresby, Australia 3179

Ph: +61 3 9730 9222

Fax: +61 3 9753 4100

Website: davey.com.au

Customer Service Centre

Ph: 1300 2 DAVEY

(1300 232 839)

Fax: 1300 369 119

E-mail: sales@davey.com.au

Davey Water Products Pty Ltd

Member of the GUD Group

ABN 18 066 327 517

NEW ZEALAND

7 Rockridge Avenue,

Penrose, Auckland 1061

Ph: +64 9 570 9135

Fax: +64 9 527 7654

E-mail:

Website: daveynz.co.nz

Customer Service Centre

Ph: 0800 654 333

REST OF WORLD

6 Lakeview Drive,

Scoresby, Australia 3179

Ph: +61 3 9730 9121

Fax: +61 3 9753 4248

E-mail:

export@davey.com.au

Website: davey.com.au

Quality

ISO 9001

H/O & MFG SCORESBY

Environment

ISO 14001

H/O & MFG SCORESBY

2 11

Prior to using this pump you must ensure that:

• Thepumpisinstalledinasafeanddryenvironment

• Thepumpenclosurehasadequatedrainageintheeventofleakage

• Anytransportplugsareremoved

• Thepipe-workiscorrectlysealedandsupported

• Thepumpisprimedcorrectly

• Thepowersupplyiscorrectlyconnected

• Allstepshavebeentakenforsafeoperation

AppropriatedetailsforalloftheseitemsarecontainedinthefollowingInstallation

andOperatingInstructions.Readtheseintheirentiretybeforeswitchingonthis

pump.IfyouareuncertainastoanyoftheseInstallationandOperatingInstructions

pleasecontactyourDaveydealerortheappropriateDaveyofceaslistedonthe

backofthisdocument.

Congratulationsonyourpurchaseofahighquality,AustralianbuiltDaveypressure

system.Allcomponentshavebeendesignedandmanufacturedtogivetroublefree,

reliableoperation.

Yournewpressuresystemincorporates‘Torrium2®’,electronicowcontroller–a

Daveydesignedunitthatenablestheuseofahighlyefcientpumpdesignand

offersthefollowingbenets:–

1. Enablesthepumptodeliveraconstantowofwaterparticularlyatlowow

rates–reducingtheinconvenienceofpressurevariationinshowersetc.

2. Providesautomatic“cut-out”protectionshouldthepumprunoutofwateror

overheat*,shouldthepumpfailtostartduetolowvoltageorablockageinthepump.

3.

Providesaneasytounderstandvisualrepresentationofthesystemstatus.

4. Hasadaptivepressurecut-inwhichallowsthepumptostartatapproximately

80%ofthemaximumpressureatlastshut-down.Thisallowsthecontrollerto

accommodatevaryinginletpressuresandpumpperformance.

5. Automaticretryfunctionsintheeventofacriticalsystemfault.

6. Pressureindicatorsoyoucaneasilytellwhatthepressureinyourwatersupply

systemisdoing.

7. Easyvisualguidetothestatusoftheinbuiltsurgearrestor.

8. Choiceofbothverticalandhorizontaloutlets.

*Motoroverload/overheatprotectionincluded.Motorhasitsownoverload/

overheatprotection.

NOTES

Before installing your new pump, please read all instructions carefully as failures

caused by incorrect installation or operation are not covered by the guarantee. Your

Davey pressure system is designed to handle clean water. The system should not be

used for any other purpose without specic referral to Davey. The use of the system to

pump ammable, corrosive and other materials of a hazardous nature is specically

excluded.

NOTE:Priortoinstallationremovetheredtransportplugsfromthesuctionand/ordischarge.

1.Torrium2®(optionalverticaloutlet)

2.Torrium2®ControlModule

(TT45)orTT70

3.DischargeOutlet(1”BSPM)

4.SuctionInlet(11/4”BSPF)

5.PumpBody

6.Motor

7.PrimingPlug

1

2

3

4

5

6

7

3

NOTE: The Torrium2® controller tted to this pump is adaptive. If your

pump draws air or is subject to blockage, the Torrium2 adapts to its new

maximum pressure. This may result in your system pressure not dropping

below the new cut-in pressure and your pump not starting. Should this

occur, re-prime your pump units as detailed above. Should this not prove

successful, it is likely you have a blockage in the pump. You should

contact your Davey dealer for assistance.

Rotary Coupling Inlet

1” Male

Horizontal Outlet

1” Male

Priming Cap which covers the 1” Male Vertical Outlet

and access to the internal check valve.

Status Indicator

Lights

Prime Button Pressure

Indicator

Window

Fitting the Torrium2®directly to the Pump

TheTorrium2®isttedwitharotarycoupling.This

couplingallowsthepumpcontrollertobetted

simplyandeasilytothepumpdischarge.

Thecouplinghasanoringseal.Thecontroller

adaptornutisabletorotateindependentofthe

Torrium2®andthecompletepump,thisallowsit

tobetightenedontothepumpeasily.Forease

ofinstallationatighteningtoolisincludedwith

Torrium2®totightenthecontrollernuttoensurea

rmconnectiontoyourcontroller.

Theabilitytorotatetheadaptornutalsomeansthatthecompletecontroller,once

ttedtothepump,canberotatedafull360ointhehorizontalplane,withoutcausing

thecouplingtounscrewfromthepumpoutlet.

With Torrium2®you can connect the discharge pipework to the

discharge port and/or the vertical priming port. The priming port is

able to be used as a discharge port.

WARNING: When servicing or attending pump, always ensure power

is switched off and lead unplugged. Electrical connections should be

serviced only by qualied persons. If the electrical supply lead of this

pressure system is damaged, it must be replaced.

After Sales Service

ForprofessionalaftersalesserviceorrepaircontactyourDaveyDealer.For

assistanceinlocatingyournearestdealercontacttheDaveyCustomerService

Centreon13002DAVEY(1300232839)ortheappropriatebranchaslistedonthe

backofthisdocument.

NOTE:

a) For protection, the Davey® pump motor is tted with an automatic

“over temperature” cut-out. Constant tripping of this overload device

indicates a problem e.g. low voltage at pump, excessive ambient

temperature (above 50°C) in pump enclosure.

b) The Torrium2®control device may have to be reset after rectifying any

of the above operating troubles. This is done by pushing in the “prime”

button and releasing it after 2 seconds, or switching the power supply

off then on.

Care should also be taken when servicing or disassembling pump to avoid

possible injury from pressurised water. Unplug pump, relieve pressure by

opening a tap on the discharge side of the pump and allow any hot water in

the pump to cool before attempting to dismantle.

During servicing, use only approved, non-petrochemical based oring and

gasket lubrication. If unsure, consult your Davey Dealer for advice.

WARNING: Do not use hydrocarbon based or hydrocarbon propelled

sprays around the electrical components of this pump.

In accordance with AS/NZS 60335.2.41 we are obliged to inform you that

this pump is not to be used by children or inrm persons and must not be

used as a toy by children.

NOTE: The Torrium2®controller is adaptive. If your pump draws air or is subject to

blockage, the Torrium2®adapts to its new maximum pressure. This may result in

your system pressure not dropping below the new cut-in pressure and your pump

not starting. This is more likely to occur when boosting mains pressure. Should this

occur, re-prime your pump unit. Should this not prove successful, it is likely you have

a blockage in the pump. You should contact your Davey dealer for assistance.

10

4 9

Trouble Shooting Check List

a) PUMP HAS STOPPED OR MOTOR RUNS FOR SHORT PERIOD ONLY

WHEN SWITCHED ON OR PRIME BUTTON PUSHED, BUT DOES

NOT PUMP - YELLOW STATUS INDICATOR LIGHT ILLUMINATED.

1. Suctionlineandpumpbodynotlledwithwater.

2. Airleaksinsuctionlinesorsuctionpipenotunderwater.

3. Airtrappedinsuctionlines(alsopossiblewithoodedsuctionduetouneven

riseinpiping;eliminatehumpsandhollows).

4. Nowateratsourceorwaterleveltoolow.

5. Valveonsuctionlinesclosed.Openvalve&pumpwillrestartautomatically

orpress“Prime”button.

b) PUMP SWITCHES ON AND OFF FREQUENTLY (CYCLING)

1. Cyclingmayoccasionallybecausedbyoatvalvesllingtanks.

2. Leakingtaps,oatvalvesetc.checkplumbing.

3. Leakingcheckvalve/footvalve.

c) MOTOR DOESN’T START WHEN SWITCHED ON - INDICATOR LIGHTS NOT

ILLUMINATED

1. Powernotconnectedornopoweravailablefromsupplyoutlet.

d) MOTOR STOPS - YELLOW STATUS INDICATOR LIGHT IS ILLUMINATED.

1. Motor”overtemperature”cut-outtripped.ConsultDaveydealer.

2. Motornotfreetoturn-e.g.ajammedimpeller.ConsultDaveydealer.

3. Primebuttonhasbeenheldinfortoolong.Releaseprimebuttonand

switchoffpowerfor1minutetoallowunittoreset.

4. YourTorrium2®hasdetectedhighwatertemperatureinthepump.Oncethe

waterhascooledtheTorrium2®willautomaticallyrestartthepump.

e) PUMP WILL NOT STOP

1. Waterleaksondischargesideofpump.

f) PUMP WILL OPERATE NORMALLY INITIALLY BUT WILL NOT RESTART

ON WATER DEMAND - STATUS INDICATOR LIGHT NOT ILLUMINATED

1. Powersupplyproblem-seec)1.

g) PUMP WILL OPERATE NORMALLY INITIALLY BUT WILL NOT RESTART ON

WATER DEMAND - YELLOW STATUS INDICATOR LIGHT IS ILLUMINATED.

1. Suctionairleak-pumphaspartiallylostprime.

2. Blockedimpellersorsuction.

3. Dischargevalveclosed-openvalve.

WARNING: Automatic reset thermal overloads may allow the pump to restart

without warning. Always disconnect the pump motor from the electrical

supply before maintenance or repairs.

WARNING: When servicing or attending pump and/or controllers, always

ensure power is switched off and lead unplugged. Electrical connections

should be serviced only by qualied persons.

Choosing a Site

Chooseasitewitharmbaseandasclosetothewatersourceaspossiblewith

correctpowersupply.Makesureyourpressuresystemisalwaysconnectedtoan

adequate,reliablesourceofcleanwater.

Housing your Davey Pressure System

Toprotectyourpressuresystemfromtheweather,makesurethe

pumphouseisbothwaterproof,frostfreeandhasadequate

ventilation.Thepumpshouldbehorizontallymountedona

rmbaseallowingfordrainage,toavoiddamagetoooring

etc.,thatovertimemayoccurfromleakingpipejointsor

pumpseals.Donotmountthepumpvertically.

Discharge Connections

TheTorrrium2®offerstheoptionofusingoneorbothoutletoptions.

Useofthehorizontaloutletonlyallowsforeither:

1. Easyaccesstoprimethepumpand/ortheremovaloftheinbuiltTorriumcheck

valve

2. Fitmentofapressuretank(upto20litrecapacity)ontotheprimingport/vertical

dischargeport

Ifyouusetheverticaloutletinsteadoraswell,youneedtoconsideraccesstothe

inbuiltcheckvalveintheTorrium.Daveysuggestyouuseaexibleconnectionand/

orunionconnectiontoallowforeaseofaccesstothecheckvalve.

Pressure Indicator Window

Torriumhasaneasytoreadpressureindicatorwindowonthesideoftheinbuilt

pressurevessel–seeFigure1onpage3.

Ifthepressureislowthewindowwillshowmainlyred.Ifthepressureisat

maximum(i.e.450kPaforTT45and700kPaforTT70models)thewindowwillshow

mainlygreen.

Thewindowcanalsohelpanalysetheoccurrenceofunwantedleaks.Ifthecolour

bandinthewindowismovingtowardsred,thisshowsthatpressureisdecreasing.

Ifthecolourbandinthewindowismovingtowardsgreen,thisshowsthatpressure

isincreasing.

WARNING: Some insects, such as small ants, nd electrical devices

attractive for various reasons. If your pump enclosure is susceptible to

insect infestation you should implement a suitable pest control plan.

Maintenance

Theonlyregularattentionyournewpressuresystemmayrequirewillbeifyou

haveusedanadditionalpressuretank.Dependingonthetankusedyoumayneed

tocheckthepressuretank’sairchargeevery6months.Followtheinstructions

applicabletoeachtank.

WARNING : Under no circumstances should Torrium2®controller be

disassembled. Failure to observe this warning will expose persons to the

possibility of personal injury and may also result in damage to other property.

Do not dismantle, no user serviceable parts, spring under pressure.

8 5

Auto-retry and Water Return Modes

ShouldyourTorrium2®detectalossofprime,afterstoppingthepump,itwillwait

veminutesbeforeactivatingAuto-retryandWaterReturnmodes.Auto-retry

automaticallystartsthepumptoseeifthepumpisnowprimed.Itdoesthisafter5

mins,30mins,1hr,2hrs,8hrs,16hrsand32hrs.Waterreturnmodewillrestart

thepumpautomaticallyiftheTorrium2®detectswaterowthroughit.

Electrical Power Surge Protection

Anelectricalpowersurgeorspikecantravelonthesupplylinesandcauseserious

damagetoyourelectricalequipment.TheTorrium2®ttedtothispumphasametal

oxidevaristor(MOV)ttedtohelpprotectit’scircuit.ThisMOVisa“sacricial”

device,meaningthatiteffectivelyisgraduallydamagedeverytimeittakesasurge.

TheMOVisnotalightningarrestorandmaynotprotecttheTorrium2®iflightningor

averypowerfulsurgehitsthepumpunit.

Iftheinstallationissubjecttoelectricalpowersurgesorlightningwestrongly

recommendtheuseofsuitableadditionalsurgeprotectiondevicesonALLelectrical

equipment.

Surge Protector Status Window

ToallowyoutocheckthestatusoftheinbuiltMOVintheTorrium2®there is a

viewingwindowatthebackoftheTorrium2®abovethepowerleadentry/exit

grommet.TheMOVisthebluediscshapedcomponent.Shoulditbeconsumed

duetopowerspikesitwillalmostalwaysblackentheviewingport.Thiswillindicate

anon-warrantablefailure.

InaccordancewithAS/NZS60335.2.41weareobligedtoinformyouthatthispumpis

nottobeusedbychildrenorinrmpersonsandmustnotbeusedasatoybychildren.

Pipe Connections

ForbestperformanceuseP.V.C.or

polythenepipesatleastthesame

diameterasthepump’sinletanddelivery

outletopenings.Largerdiameterpipe

maybeusedtominimiseresistanceto

owwhenpumpinglongerdistances.

NOTE: For protection, the Davey pump motors are tted with an automatic

reset thermal overload, constant tripping of this overload indicates a

problem e.g. low voltage at pump, excessive temperature (above 50°C) in

pump enclosure.

Power Connection

Connectleadtopowersupplydesignatedonpumplabel.Donotuselong

extensionleadsastheycausesubstantialvoltagedrop,poorpumpperformance

andmaycausemotoroverload.

The Davey Torrium2® tted to this pump has status indicator light mounted

on its front panel. These lights will only work when unit is connected to an

electrical supply.

The electrical connections and checks must be made by a qualied

electrician and comply with applicable local standards.

For Automatic Pressure Pumps Installed with a

Mains Pressure Hot Water System

Toprotectyoursystemfromdamagecausedbyback

pressurefromhotwatersystems.Youshouldalways

haveinstalledonthehotwaterinletanapprovednon-

returnvalve.

Connection of Mains Scheme or Town Water

Supply to either Suction or Discharge of Pumps &

Pressure Systems

MostWaterSupplyAuthoritieshavestrictregulationsregardingdirectconnectionof

pumpstomainswatersupplies.Inmostcasesanisolatingtankisrequiredbetween

mainssupplyandpump.Daveyalsorecommendthismethod.Directlyapplied

mainspressurecanexceedpumpoperatingpressureanddamagepump.

Davey Water Products Pty Ltd can not

accept responsibility for loss or damage

resulting from incorrect or unauthorised

installations.

NOTE: Always ensure hot water

systems are installed in compliance with

manufacturers recommendations and in

accordance with all local regulations.

Priming and Operation

TheTorrium2®modulettedtoyourCTsystemisprovidedwithapushbutton

“Prime”button.Thisbuttonisusedduringinitialprimingofthepumpandalsoacts

asaresetbuttoniftheTorrium2®switchesoutinpumpprotectionmode.

1. Removeprimingplugandll

casingandsuctionline(onooded

suction,simplyopengatevalveto

pump).Whenfull,replacepriming

plug.

2. Ensureoutletnearest

topumpisopen.

3. Ensureallvalvesinsuctionline

areopen.

4.Switchonpower-The

statusindicatorlight

willbeilluminated

greenandthepump

willrun.Afullow

ofwatershouldbe

dischargedfromthe

opentap.

5.Ifthepumpstopswiththetapopen

seetroubleshootingchecklist.

6. Closetheopenoutletortapand

thepumpshouldstopafterafew

seconds(thestatusindicatorlight

shouldbeilluminatedred(constant).

Ifnot,consultthetroubleshooting

checklist.

To Reset if Pump switches out in

Pump Protection Mode

1. Makesurepumpisprimed.

2. Opentap,pushprimebutton.

3. Closetapandpumpwillstop.

6 7

Where to use Check Valves and Foot Valves

TheTorrium2®controllerttedtoCTmodelshasaninbuiltnon-return(check)valve

tted.Inoodedsuctioninstallationsthereisnoneedtohaveasuctionnon-return

valve.

Insuctionliftinstallationsafootvalvewillnormallyberequiredforthepumpto

retainprime.

Insomesuctionliftinstallationstheremaybegoodreasontoremovetheinbuilt

checkvalvetoensurethatthedischargepressureisalsoappliedtothesuctionline

andfootvalve.Thiscouldbewherethesuctionlinewasverylongorwherethere

wasconcernregardingaleakingfootvalve.Thismaynotalwaysbeapplicableand

itisacceptabletoretaintheinbuiltcheckvalveintheTorrium2onsuctionliftswith

goodsuctionplumbing.

Shouldtheinbuiltcheckvalveberemovedthough,anadditionalaccumulator

shouldbettedtotheTorrium2,ordischargepipeworkasapplicable,toensurethe

pumpisnotcycledonshutdown.Thesizeofthisaccumulatorwilldependonthe

size,lengthandtypeofpipeusedonthesuction.

Torrium2 Check Valve Removal

Useunionsatpipeconnectionstoenableeasyremoval

andservicing.Usesufcienttapetoensureairtightseal

andhandtightenonly.Topreventstrainonpumpthreads

alwayssupportheavyinletandoutletpipes.Ifthereisa

likelihoodthewatersupplymaycontainsolidparticlessuch

aspiecesofplantorvegetablematter,altershouldbe

installedbeforethepumptoavoidblockingofwaterways.

Laysuctionpipeataconstantgradienttoavoidairpocketswhichmayreduce

pumpefciency.

NOTE: Suction leaks are the largest cause of poor pump performance and

are difcult to detect. Ensure all connections are completely sealed using

thread tape only.

Flexible pipe should be considered to allow for movement between

building, pump and/or water supply. Braided hose, reinforced hose or

polythene pipe are suitable.

Do not use pipe thread sealing compounds on any part of this pump. ONLY

use Teon sealing tape.

Removeprimingcapand

turnovercap.Lugson

capwillengagecheck

valvetounscrew.

Extra Draw-off Capacity

TheTorrium2®controllerhasanin-builtaccumulatorwhichwillaccommodatesmall

leaks.Insomeapplicationsitmaybeappropriatetoinstalladditionalaccumulator

(Supercellpressuretank)capacity.Theseapplicationsincludes:

• Longsuctionlines(seeSuctionLines/Lift)

• Lowowappliancesconnectedtothepump,suchasevaporativeair

conditioners,slowllingtoiletcisterns,etc.

Anyadditionalaccumulatorscanbeinstalledeitherinplaceofthepriming

plug(seeFigure1)fortanksupto20litrestotalcapacity,orforlargertanks,

downstreamofthecontroller(ie.betweenthecontrollerandtherstoutlet).

Whereextradraw-offcapacityisutilisedtheadditionalpressuretankshouldhavea

pre-chargeof70%ofthemaximumsystem(shut-off)pressure.

Evaporative coolers, RO lters and extra draw-off

capacity

WhereaTorrium2®equippedpumpisrequiredtosupplywatertoanevaporative

cooler,reverseosmosis(R.O.)lterorsimilarlowowdevice,theTorrium2®willdetect

thelimiteddemand.ThiswillresultintheTorrium2®adaptingtotheslowdemand.The

pumpstartpressurewillbeallowedtodroptoalowercutinpressureeachtimelow

owsaredetected.Toprovidethemaximumdraw-offfromtheadditionalpressuretank,

thetank’spre-chargeshouldbesetat45%ofthepumpshut-offpressure.

Ifnormalowisrequiredfromyoursystem,Torrium2®willinitiateinstantstart.

FittheSupercellpressuretank(upto20litrestotalcapacity)tothetankconnection/

priming port with thread tape and pipe socket.Firmlyhand tighten.Forlargertanks,

theseshouldbeinstalleddownstreamofthecontroller.

NOTE: If tting a tank to the priming port, you may require a 1”

BSP socket, since both Torrium2®prime port and tank are 1” male

threads.

DO NOT USE THREAD SEALING COMPOUNDS, HEMP OR PIPE DOPE!

Installationswithoodedsuctionrequireagate

orisolatingvalvesowatersupplycanbeturned

offforpumpremovalandservicing.

Abrasive Materials

The pumping of abrasive materials will cause damage to the pressure

system which will then not be covered by the guarantee.

Table of contents

Popular Controllers manuals by other brands

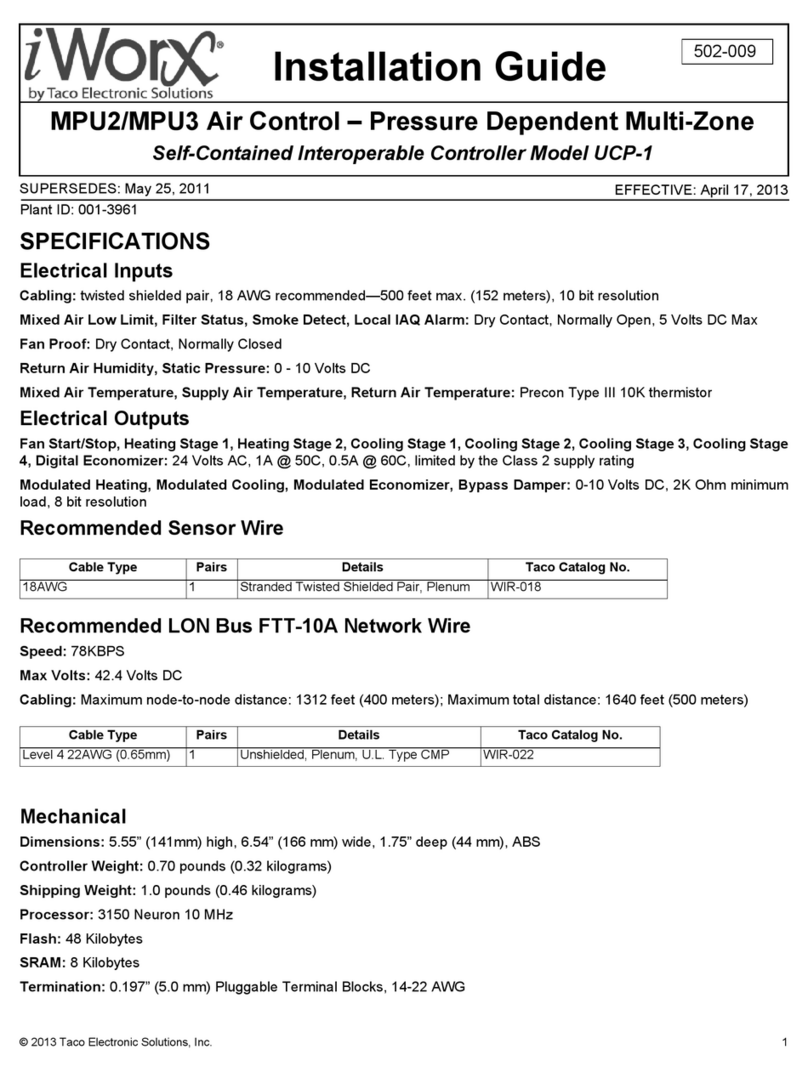

Taco Electronic Solutions

Taco Electronic Solutions iWorx MPU2 installation guide

Kockum Sonics

Kockum Sonics TYFON Ti98 OPERATING AND INSTALLATION Manual

OmniCell

OmniCell OmniTrack installation guide

SANYU

SANYU SSXA Series user manual

Samson

Samson 3372 Mounting and operating instructions

ICP DAS USA

ICP DAS USA TPD-433-H quick start