4

3.

P

LANNING

Y

OUR

I

NSTALLATION

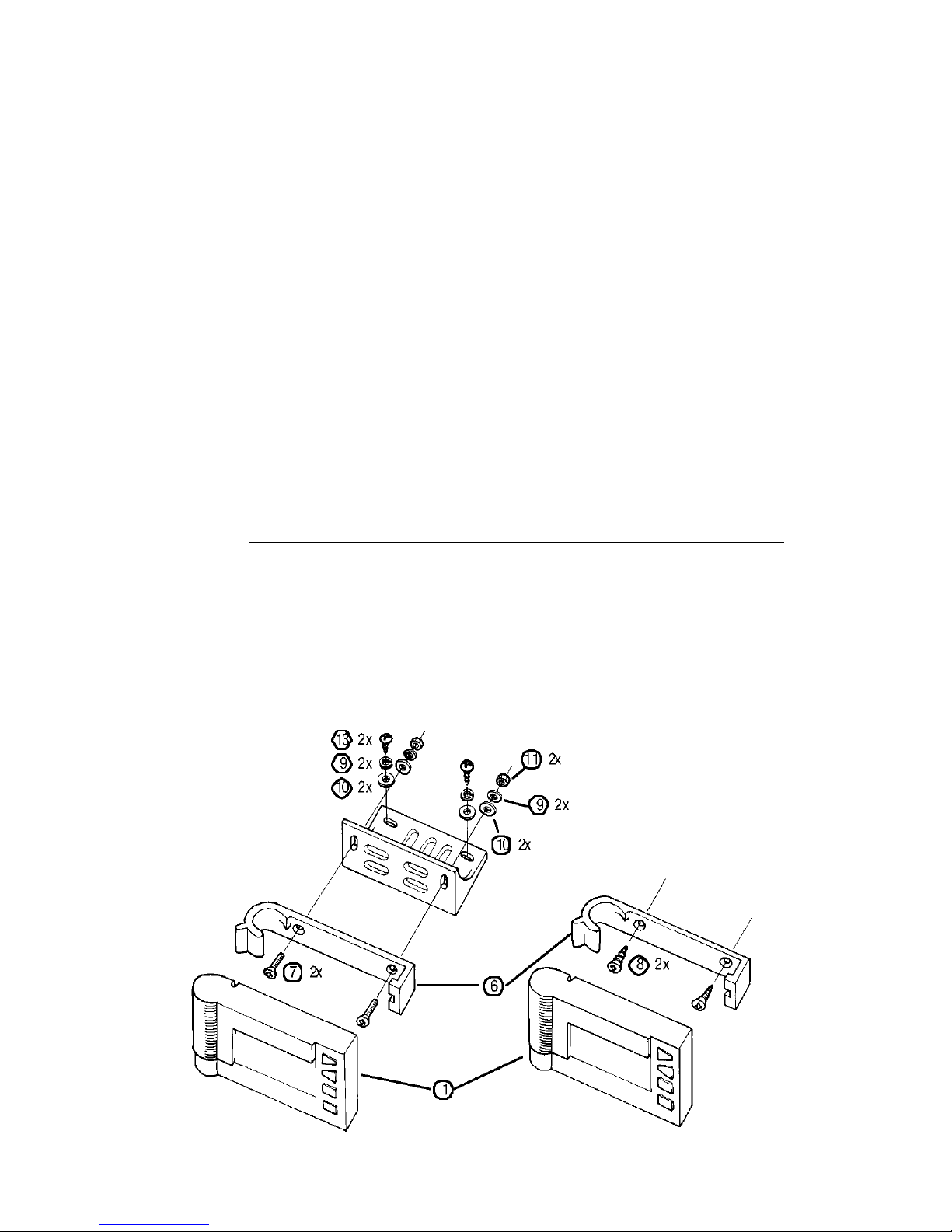

Figure 2 illustrates the installation of the DriveRight. The sensor, sensor magnet

and associated brackets mount underneath your vehicle. Figure 12 on page 11 is a

sketch of a typical rear wheel drive sensor installation while Figure 17 on page 13 is

a sketch of a typical front wheel drive sensor installation. The sensor leads run

under the vehicle and into the vehicle cabin where they connect to the DriveRight

display. The DriveRight display also requires unswitched +12V and ground connec-

tions to your vehicle’s electrical system.

Before you begin the actual hands-on installation of your DriveRight, please plan

out your installation by thinking through the following points. This will save you

time, frustration, and parts.

• Determine how and where you want to mount the DriveRight display within the

vehicle cabin.

NOTE:

Safe driving requires that the driver’s attention be focused on the road. Please install

your DriveRight in a location which minimizes distractions to the driver.

• Find a single point in the vehicle cabin where you can bring together the leads

of the harness cable, the sensor leads, and the +12V and ground wires.

• Determine how you will route the harness cable to the DriveRight display.

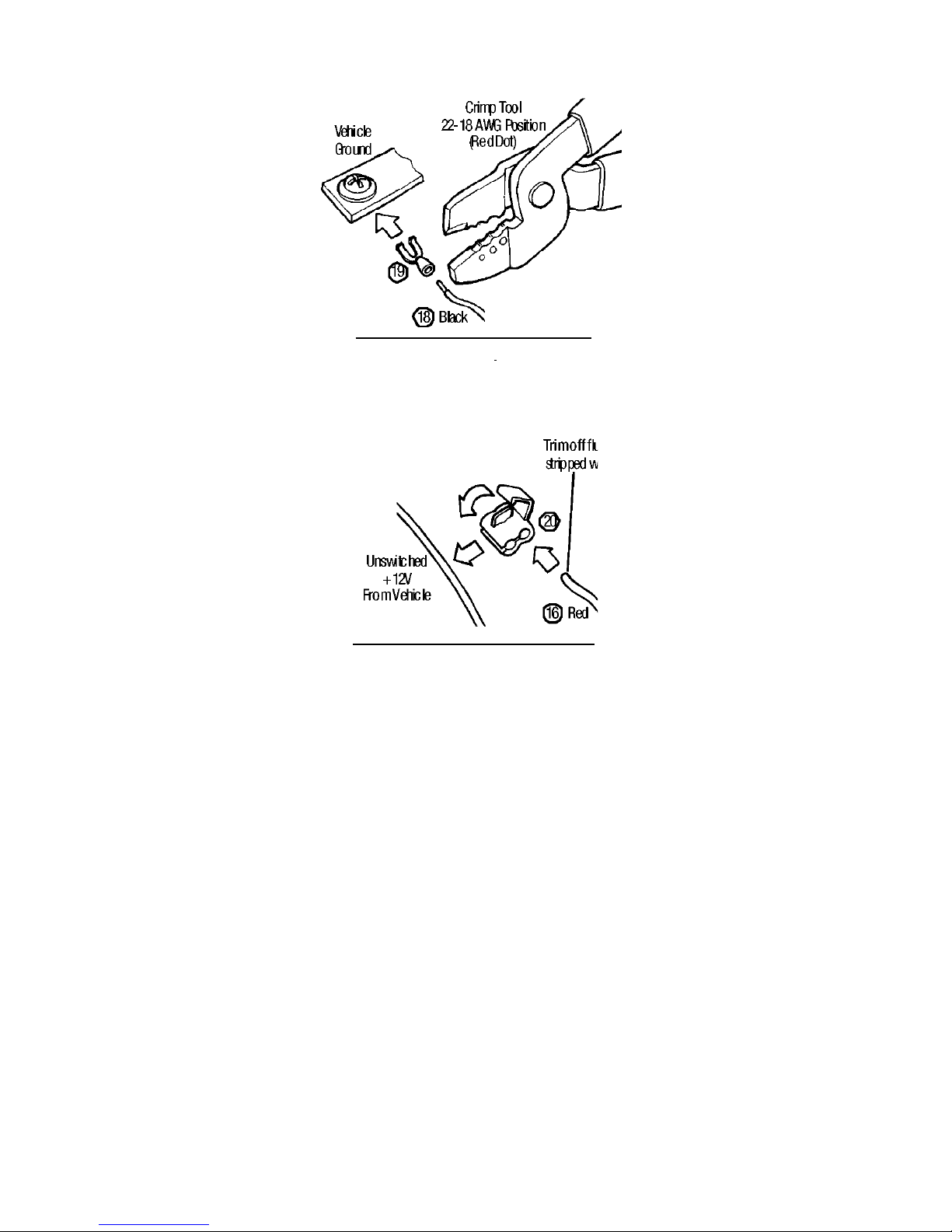

• Locate your fusebox and find a source of UNSWITCHED +12V NOT USED FOR

SAFETY RELATED EQUIPMENT.

NOTE:

“Unswitched +12V” means +12V not switched off by the ignition key. The

DriveRight consumes negligible power (nominally, 5mA) and will not run down

your vehicle’s battery. The lithium 3.0V battery inside the DriveRight is not

rechargeable and is not charged by the vehicle’s battery.

• Locate a ground point to attach a ground wire spade terminal.

• Locate a feedthrough into the vehicle cabin through which you can bring the

two sensor leads and the +12V and ground wires if your fusebox is in your

engine compartment.

• IF YOU HAVE A FRONT WHEEL DRIVE VEHICLE, decide whether you will place the

sensor magnet on either the left or right side in-board constant velocity (CV)

joint hub.

• IF YOU HAVE A REAR WHEEL DRIVE VEHICLE, decide where on the driveshaft

within 12” (30cm) of the transmission you will place the sensor magnet.

• Decide how you will attach the brackets so that the sensor is within 3/8” - 5/8”

(10-16mm) of the magnet. How will you form the brackets to fit? What holes

will you use or drill to mount the bracket? Do these holes pierce the vehicle

floor? Where? (DO NOT USE FLUID RETAINING BOLTS AS MOUNTING POINTS.)

• Decide how you will route the wires from the sensor to a feedthru into the

vehicle cabin.

• THE WIRES SHOULD BE ROUTED AT LEAST 12” (30CM) AWAY FROM SPARKPLUG

WIRES, THE COIL, AND THE ALTERNATOR. AVOID LOOPS, COILS, AND FOLDS

SHOULD TO PREVENT UNWANTED INTERFERENCE THAT MIGHT RESULT IN

ERRONEOUS READINGS.