C O N T E N T S

0.0 EC Declaration of Conformity

1.0 Introduction

1.1 Basic Safety Points

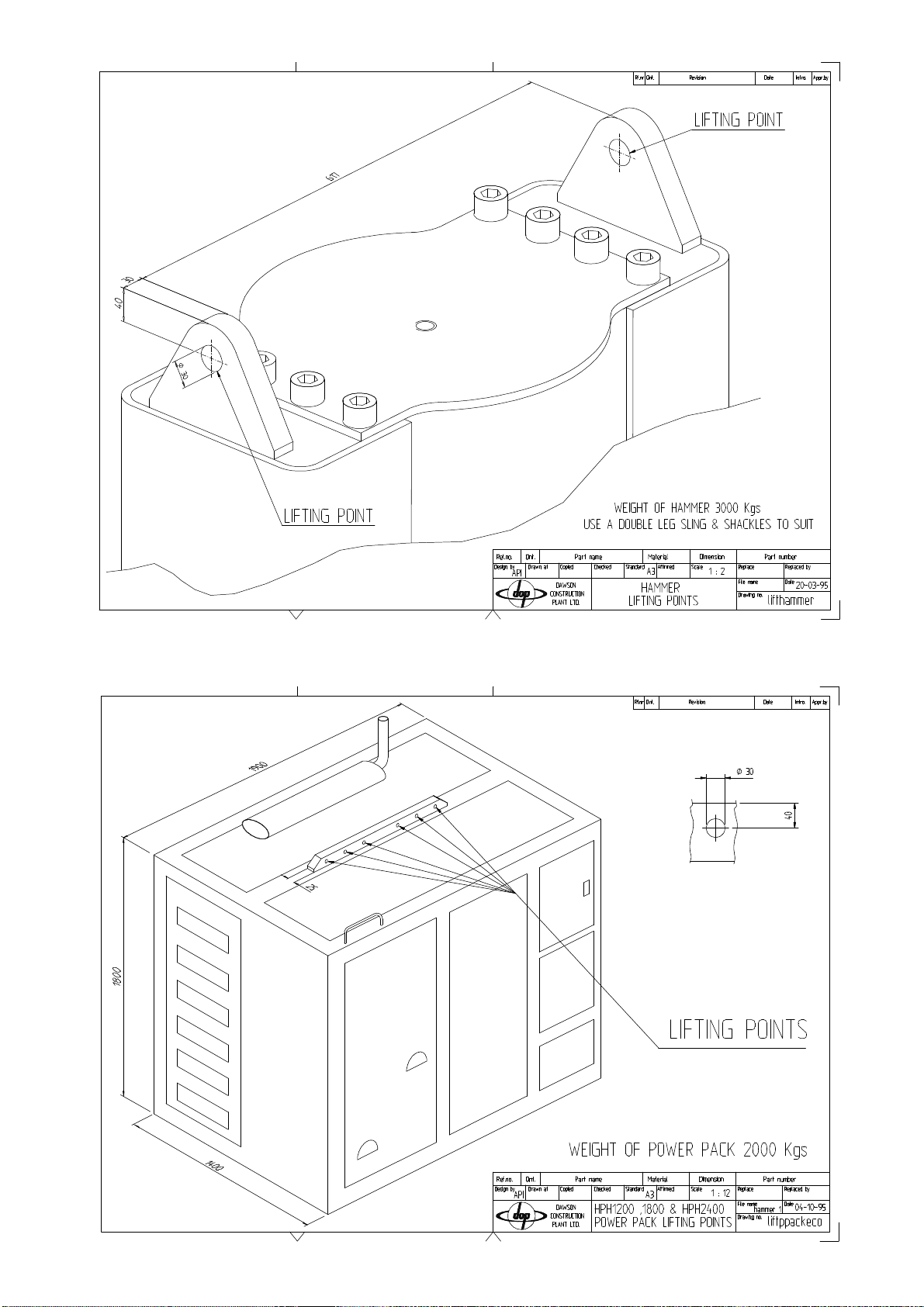

- Basic Specification of HPH 1200 - Drawing

- Lifting the HPH 1200 & Power Pack -

Drawing

1.2 Transportation and laying hammer down

2.0 How does the Hammer Work?

Figure 1

3.0 Power Pack and Hammer Operation

3.1 Connecting the hydraulic hoses and

control pendant

3.2 Checking the power pack

3.3 Starting the power pack

3.3.1 Hydraulic oil warm-up procedure

3.4 Using the hammer

3.4.1 Installing hammer on the pile

3.4.2 Bleeding air from the hammer

hydraulic system

3.4.3 Pile driving with the hammer

3.4.4 Cold running/overtravel

3.4.5 Refusal

Figure 2

3.5 Using the hammer underwater

3.6 Wider or special pile sections

Figure 3

Figure 4

3.7 Preventive Maintenance Guideline Chart

4.0 Hammer Maintenance

4.1 Daily maintenance

4.2 Planned 125 hour maintenance checks

4.3 Planned 250 hour maintenance checks

4.4 Planned 500 hour maintenance checks

4.4.1 Changing Resilient Washers

4.4.2 Other items

Figure 5

4.5 Planned 1000 hour maintenance checks

5.0 Power Pack Maintenance

5.1 Power pack specifications

5.1.1 Basic specification

5.1.2 Lubrication specification

5.2 Daily maintenance checks

Figure 6 Dolly wear

5.3 Planned maintenance checks

5.3.1 Every 125 hours

5.3.2 Every 250 hours

5.3.3 Every 500 hours

5.3.4 Every 1000 hours

5.4 Maintenance procedures

5.5 Setting procedures

6.0 Troubleshooting

6.1 Power pack engine will not start

6.2 Engine cuts out during running

6.3 Power pack does not generate any pressure

6.4 Power pack generates pressure but hammer

does not run

6.5 Hammer will lift but not drop

6.6 Hammer runs erratically

6.7 Excessive hose 'jumping'

6.8 Hammer 'jumping' excessively on pile top

6.9 Stroke height indicator will not move

6.10 Smoke from bottom end of hammer

7.0 Appendices

7.1 Hammer parts list

7.2 Accumulator parts list and instructions

7.3 See Cummins service manual

7.4 Power pack parts list

7.4.1 Hydraulic circuit schematic

7.4.2 Electrical circuit schematic

7.4.3 General assembly drawing - 3 off

7.5 Tool kit parts list