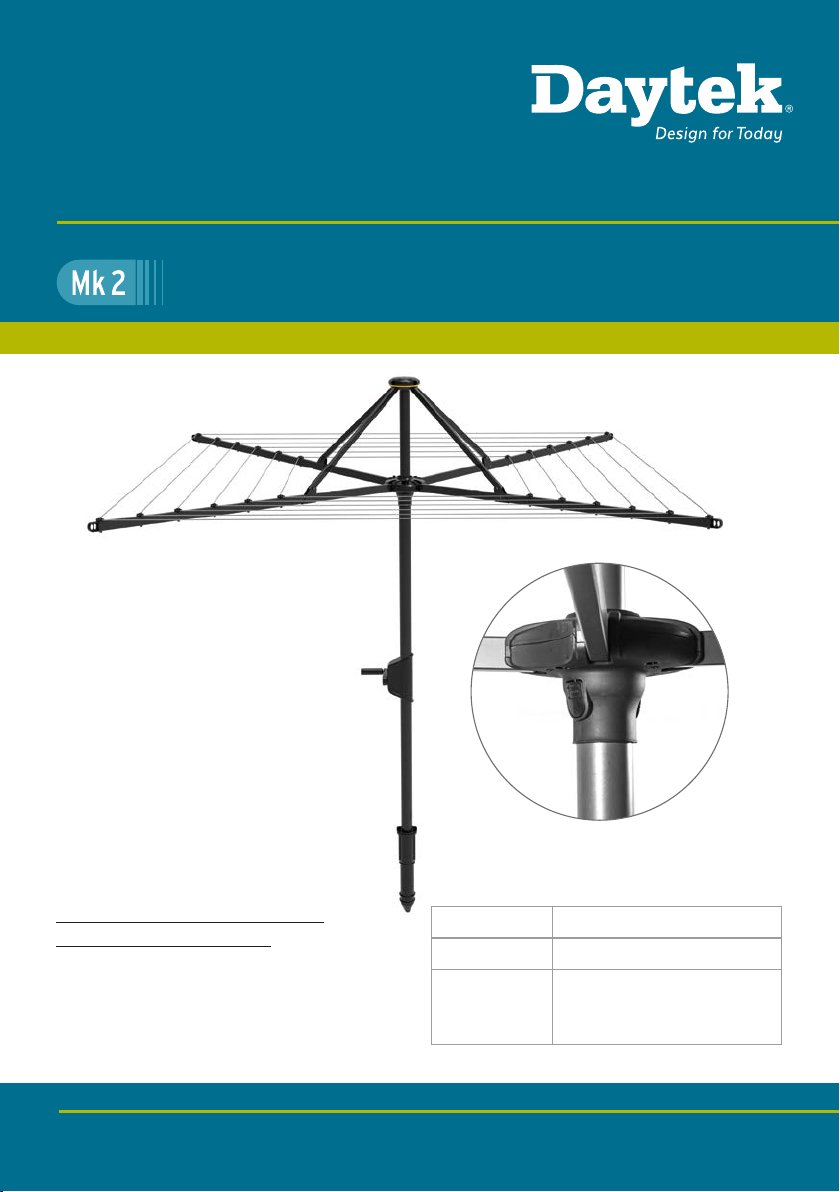

DAYTEK M32 User manual

Rotary Clotheslines

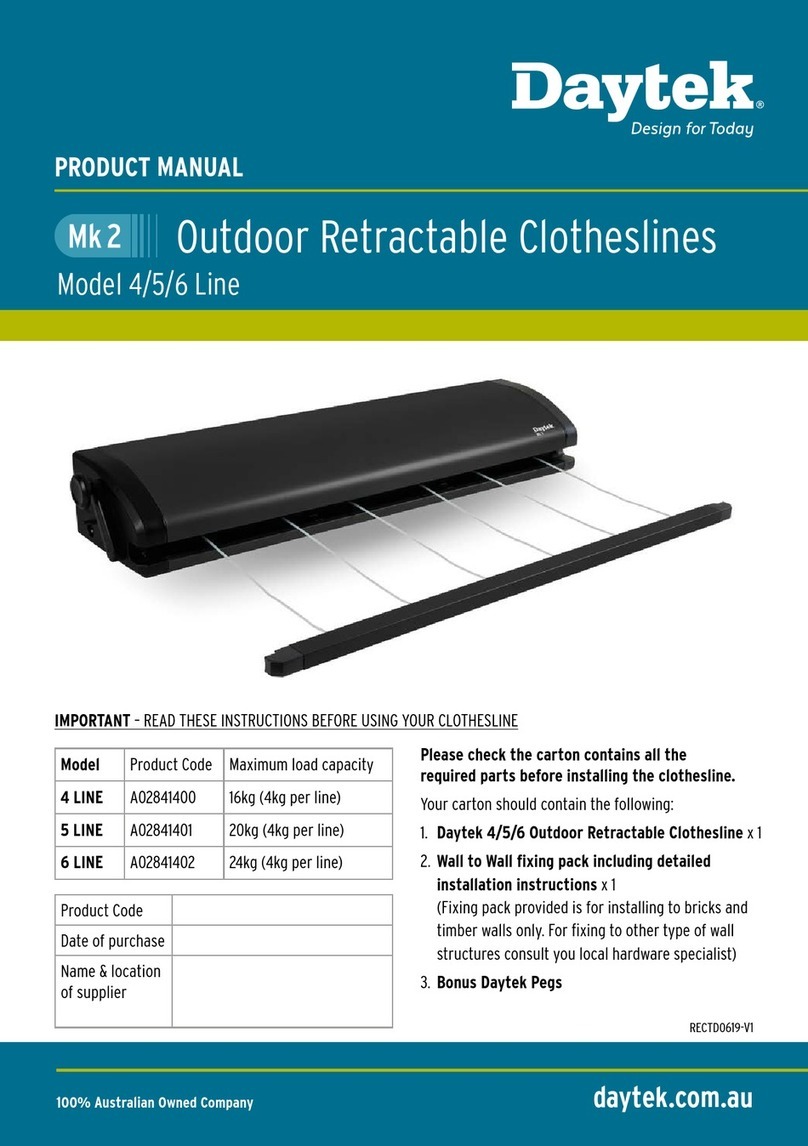

PRODUCT MANUAL

100% Australian Owned Since 1954 daytek.com.au

Product Code

Date of purchase

Name & location

of supplier

R0619-V1

IMPORTANT – READ THESE INSTRUCTIONS

BEFORE USING YOUR CLOTHESLINE

Suitable for models

M32 / M38 / M42 / M48 / M52 / M58

2

BEFORE YOU BEGIN

Please check that the carton contains all the

required parts before assembly.

Your carton should contain the following:

A – Main Tube Assembly

B – Hoist Tube Assembly

C – Ground Socket and Cap

D – Bonus Peg Bag

E – Bonus Pegs (12 pcs)

F – Bonus Rotary Storage Bag

G – Bonus Sock Holder

Note: We recommend two persons to install this product

Tools and materials required for installation:

• Medium aggregate screenings (crushed rock)

• 20kg bags of pre-mix concrete x 2

• Wooden or metal stakes 400mm long x 3

• Length of rope approximately 2 meters long x 3

• Spirit Level

B

C

D

E

F

G

A

3

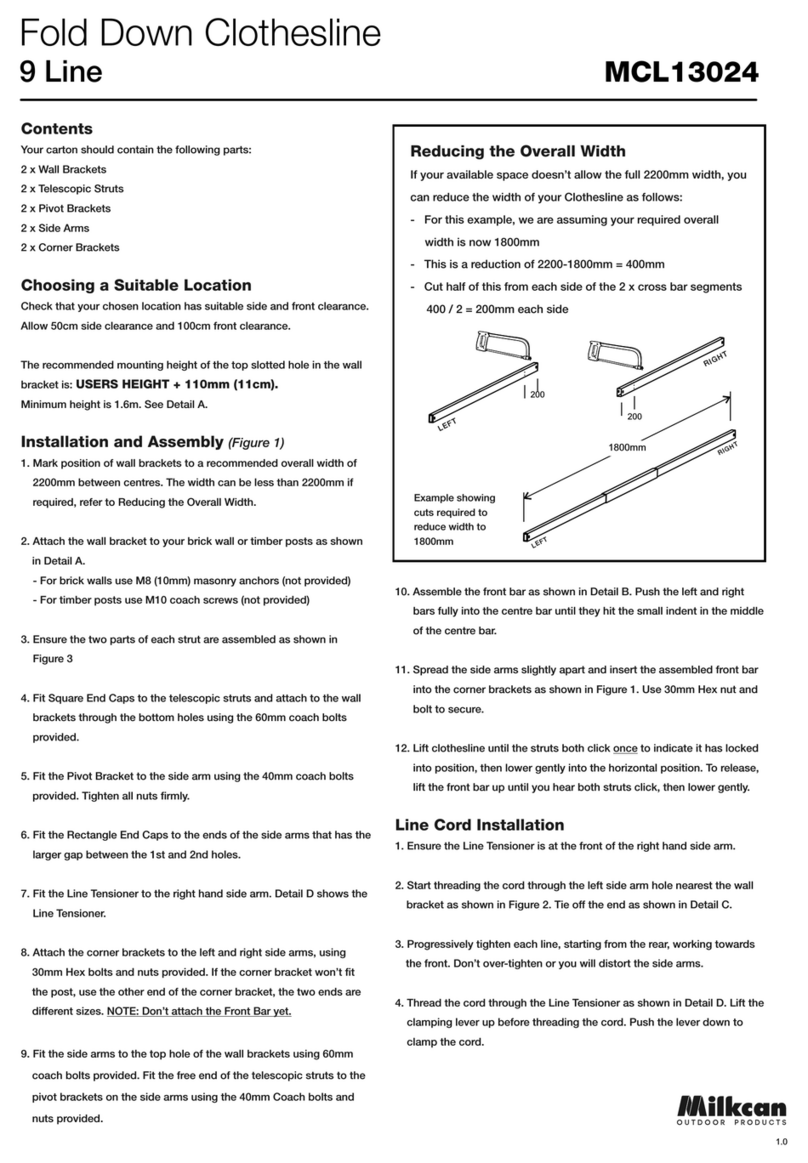

600 450

3.0

METRES

MINIMUM

250

DIAM

425

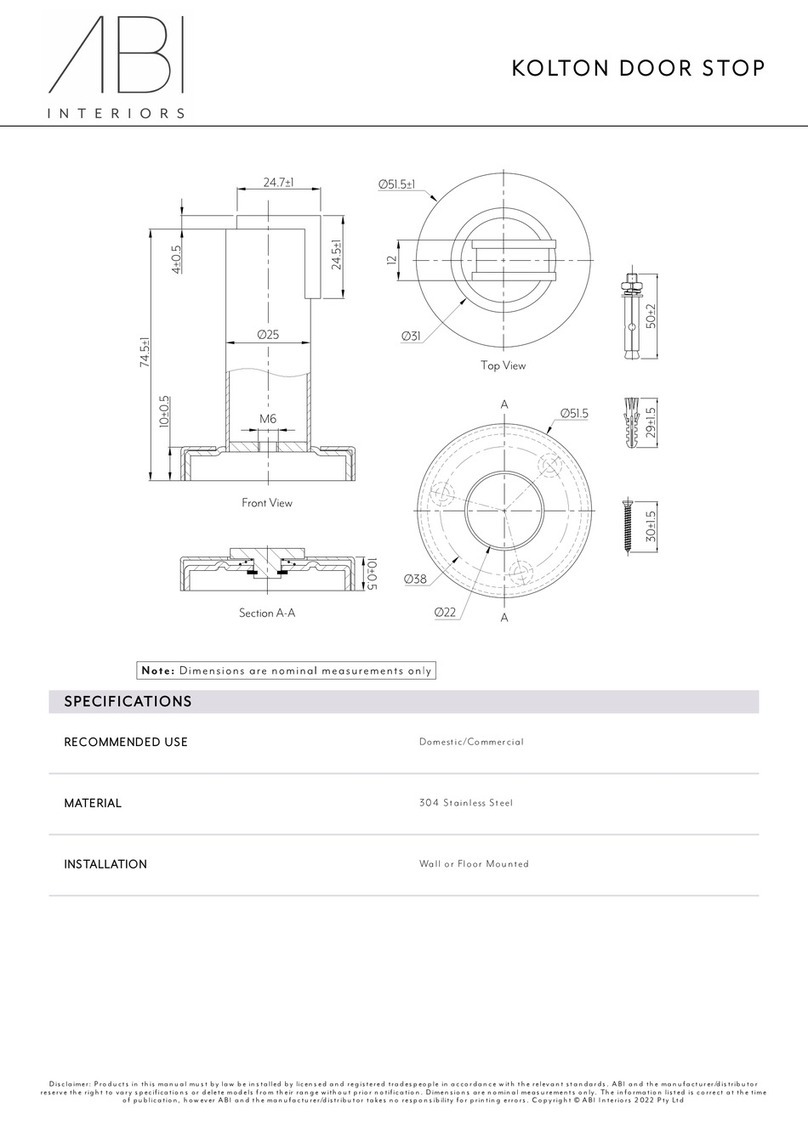

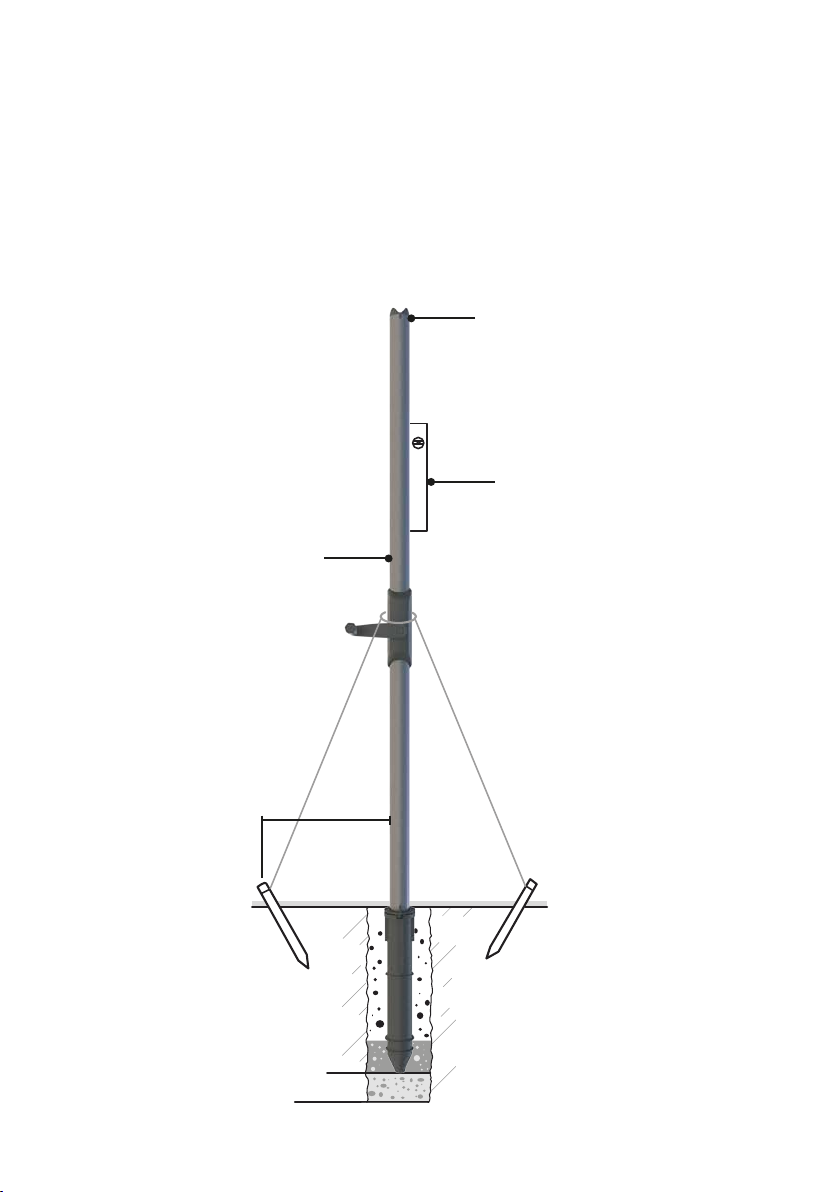

PREPARING THE SITE FOR YOUR ROTARY CLOTHESLINE

Preparing the ground socket

1. Make sure the selected installation position has a

minimum of 3 meters clearance on all sides from the

central location.

2. Excavate a hole 250mm in diameter x 600mm deep.

3. Back fill the hole with screenings (small crushed

rock) to 450mm from ground level. This is necessary

to drain rain water that enters via the socket.

4. Position the the ground socket inside the hole so

that it sits centrally and vertically. The bottom end of

the ground socket will rest on the screenings while the

top of the ground socket should reach the ground level.

Adjust the depth of the screenings as needed.

5. To retain the ground socket in the central position,

backfill with screenings to 425mm from ground level.

Ensure no rocks are inside the socket.

Positioning the main tube assembly

PIN

SLOT

6. Position 3 stakes spaced at an

equal distance around the hole

approximately 1 meter out. Insert

the stakes at at angle approximatly

300mm into the ground.

7. Insert the main tube assembly

into the ground socket making

sure the pin is positioned into

one of the slots. Secure by

engaging the locking ring.

(See Fig. 1 – 4)

SCREENINGS

1

3 4

2

4

10. Ensure the concrete is underneath the top

lip of the ground socket.

11. Re-check that the main tube assembly is

still vertical. Leave for 24 hours to set concrete

before assembling the hoist tube.

Securing the main tube assembly

8. Tie a length of rope from each stake to the main

tube assembly to secure it vertically. Check that

the tube is sitting vertically using a spirit level.

9. Prepare the pre-mix concrete and backfill the

hole with the concrete mix. Gently compact

the concrete.

MAIN TUBE

ASSEMBLY

WIND BRAKE

LOWER

SPIRIT LEVEL

1 METRE

5

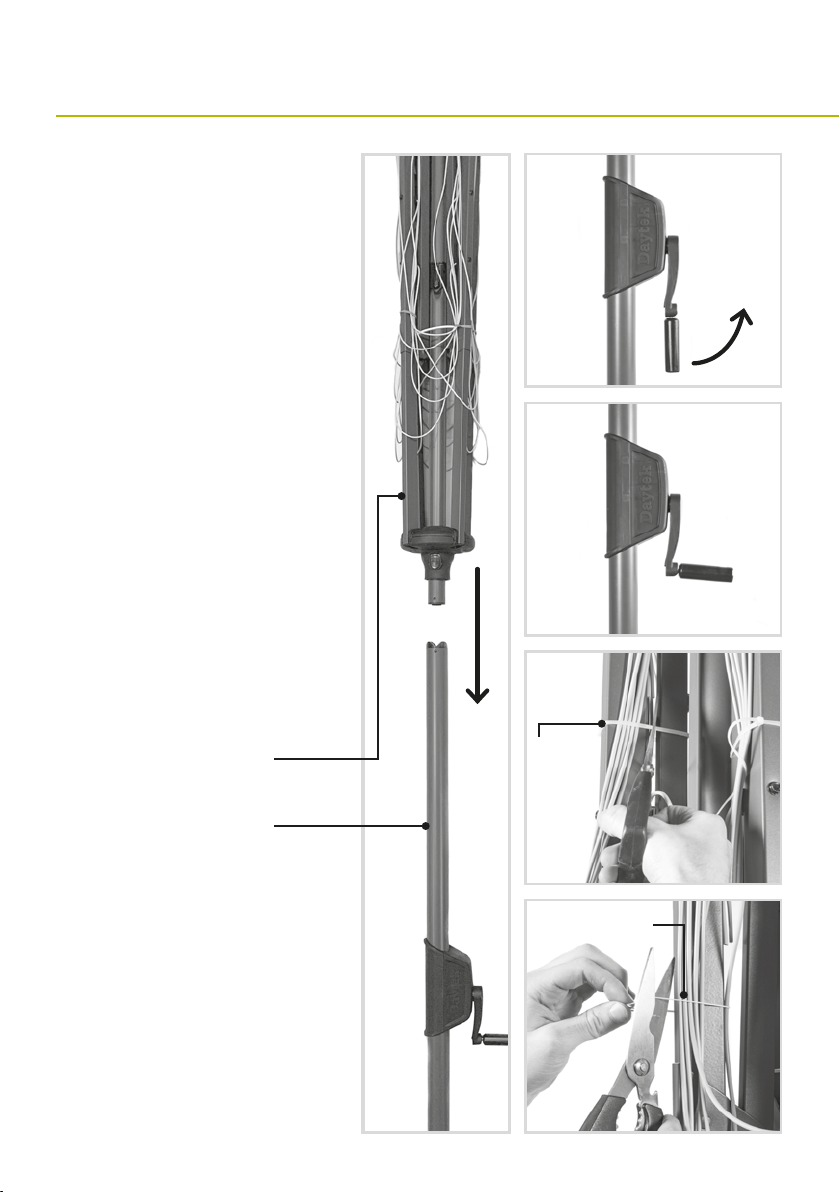

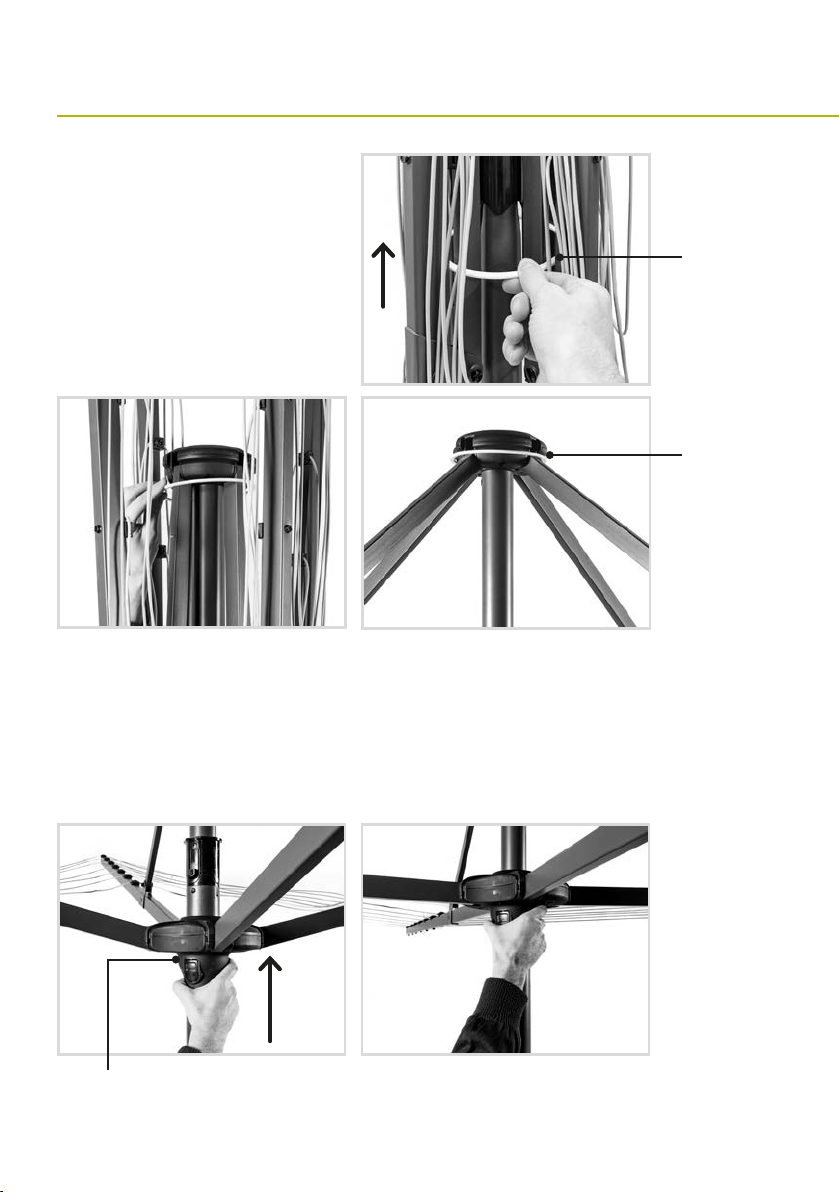

ASSEMBLING YOUR ROTARY CLOTHESLINE

1. Once the concrete is dry, remove

the cord and stabilising stakes.

2. Gently slide the hoist tube

assembly into the main tube

assembly until the units engage

together. The tube assemblies are

engaged when both the upper and

lower wind brake face meet.

(See Fig. 1)

3. Lock handle into final position by

pulling upwards on the handle grip.

(See Fig. 2 – 3)

4. Each clothesline arm is secured

with a plastic cable tie. Carefully

cut and remove each one making sure

not to cut or damage the clothesline

cord. (See. Fig. 4)

5. The clothesline cords are secured

to each arm with a rubber band.

Cut and remove these bands making

sure not to damage the clothesline

cord. (See. Fig. 5)

HOIST TUBE

ASSEMBLY

PLASTIC

CABLE

TIE

RUBBER

BAND

MAIN TUBE

ASSEMBLY

21

3

4

5

6

OPERATING YOUR ROTARY CLOTHESLINE

1. Slide the yellow ring upwards, this

allows the arms to be folded out to

horizontal position where the dual

latches will lock the arms in place.

(See Fig. 1 – 3)

2. Push the clothlesline hoist up into the open position. To do this,

hold the Slide and push upwards until the hoist “clicks” into the open

position. (See Fig. 4 – 5)

1

2

45

3

YELLOW

RING

YELLOW

RING

SLIDE

7

Note: There is a safety clutch within the gear

box. When the clothesline is in maximum lowest

or highest position the handle will rotate freely

(clicking sound), which prevents damage to the

gear box.

3. To raise the hoist for ‘free spinning’ wind

drying, simply rotate the handle in a

clockwise direction to disengage the wind

break. (See Fig. 6 – 7)

To activate the wind brake, turn the

handle anti-clockwise until the two

serrated plastic faces meet. This will lock

the clothesline head and prevent the hoist

from freely spinning.(See Fig. 8 – 9)

6

WIND BRAKE DISENGAGED

WIND BRAKE ENGAGED

7

8 9

8

FOLDING AWAY YOUR ROTARY CLOTHESLINE

1. Wind down the clothesline to the wind

break position.

2. Use one hand to push the release buttons

on the Slide whilst pulling down on the

Central Hub with your other hand. Once

the catch disengages you can move the Slide

downwards until all four arms are folded

vertically. (See Fig. 1 – 3)

3. Allow the yellow ring to drop down,

securing the arms into the folded position.

4. If the clothesline will be left unused for

an extended period of time you can utilise

the Rotary Storage Bag.

1

RELEASE

BUTTON

PULL DOWN LIGHTLY ON HUB

PRESS BUTTONS EACH SIDE OF HUB

2

3

9

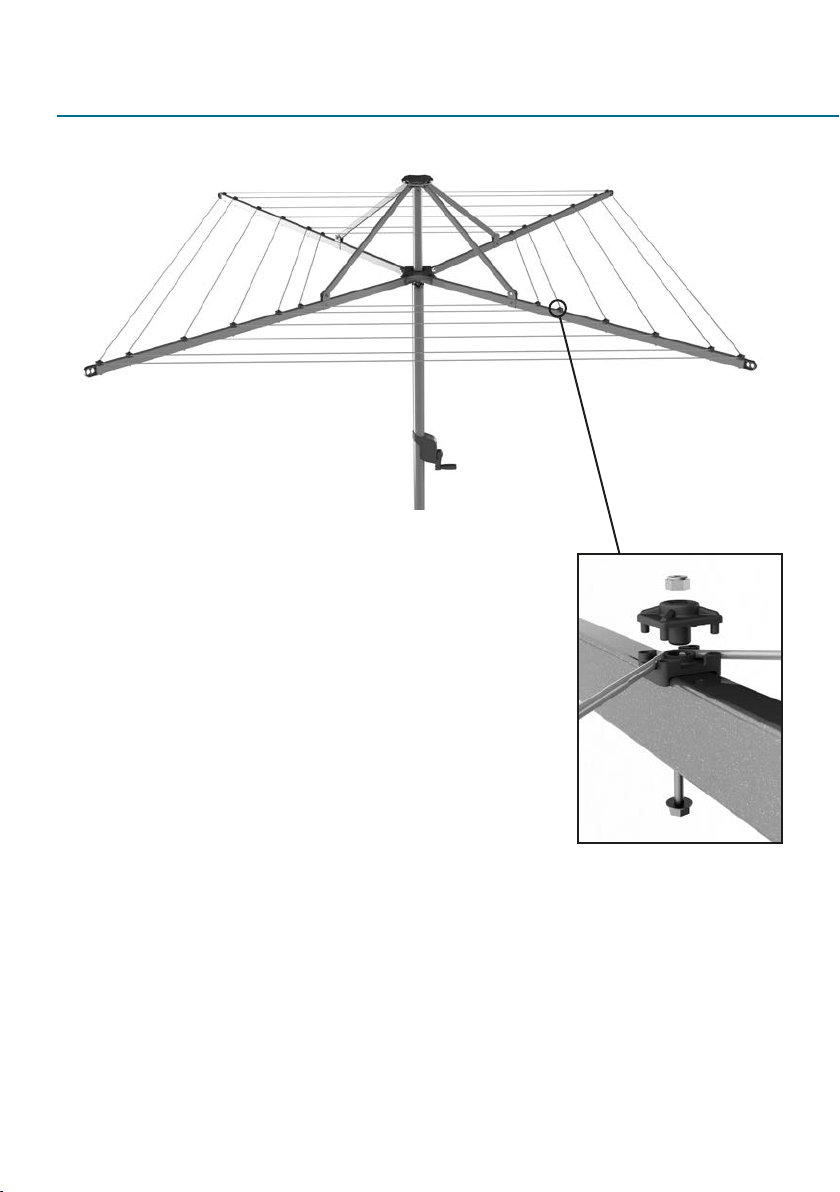

ADJUSTING THE HEIGHT OF YOUR ROTARY CLOTHESLINE

HELPFUL HINTS

IMPORTANT

The ideal height of the clothesline should be

approximately 50mm from the users head to

the underside of the horizontal arms.

To adjust the clothesline to higher position

simply remove the support ring from the

ground socket, lift the clothesline and rotate

to either slot 1, 2 or 3. Each position will

increase your clothesline height by 75mm.

With the slothesline at the required height

replace the support ring into the ground

socket to secure the clothesline.

• Engage the wind brake mechanism while hanging laundry. By pulling sideways on

the horizontal arms the clothesline will rotate to the next loading position.

• Hang washing starting from the inside line with small garments.

• Distribute the weight of the washing evenly on each line around the four quadrants

• After hanging the washing it is important to wind the line up off the wind brake for spin air drying.

• Located at the end of each horizontal arm is a clothes hanger loop.

Please ensure your clothesline is not used as a playing item by children swinging

on lines and main arms. Any damage from misuse will void the warranty.

1

3

2

HIGHEST

MEDIUM

LOWEST

1

2

2

1

33

10

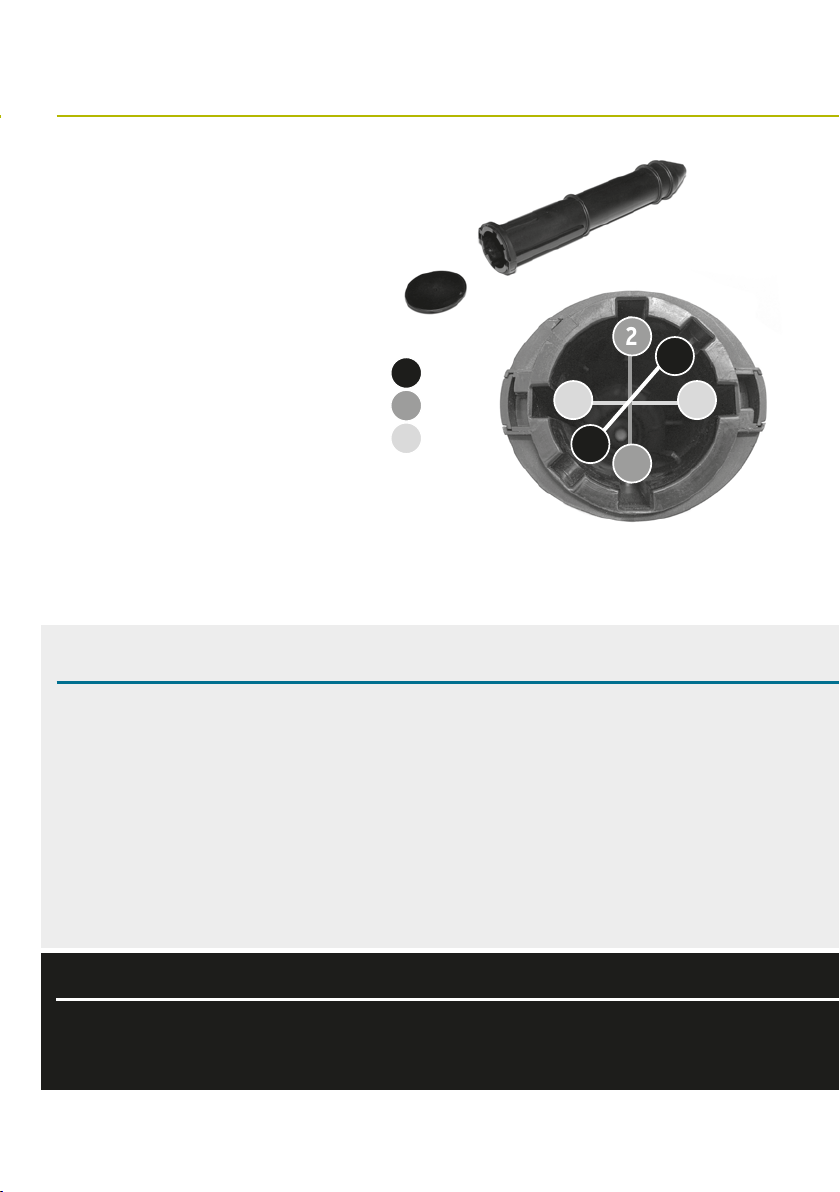

HOW TO RESTRING/REPLACE THE LINE ON YOUR DAYTEK ROTARY CLOTHESLINE

ARM 3

ARM 2 ARM 1 – LINE END

ARM 4

D

B

A

C

A. Tensioner Block Bottom –

recessed into the arm of the

clothesline.

B. Tensioner Block Top –

positioned on top of the

bottom block.

TO REPLACE A LINE ON YOUR DAYTEK ROTARY

CLOTHESLINE, YOU MUST REMOVE THE TENSIONER

BLOCK TOPS OFF THE AFFECTED LINE.

C. Bolt – head of bolt under

the arm of the clothesline.

D. Nut – seated in the top of

the line tensioner.

To remove the Tensioner Block Tops

3. Remove the line from the Tensioner Block.

4. Work your way around the clothesline

removing all four Terminal Blocks Tops

and the line.

1. Place your index finger on top of the Tensioner

Block and over the Nut to ensure that the Nut is

held in position.

2. Undo and loosen the bolt from under the arm of

the clothesline. Once the bolt is fully loose, you can

carefully remove the Tensioner Block Top & Nut.

11

HOW TO TENSION THE LINE ON YOUR DAYTEK ROTARY CLOTHESLINE

To attach a new line

1. Start by clamping one end of the new line into

ARM 1 as shown below (ARM 1 can be any arm

you choose).

2. Work your way around the clothesline

attaching the line at ARM 2, 3 & 4 as shown

below. Ensure line is pulled tight and clamped

in Tensioner Block before moving on to

next arm.

3. When you arrive back at ARM 1, remove the

Tensioner Block Top and clamp both line ends

into line tensioner as shown below, making

sure the lines are pulled tight.

4. Trim line ends leaving approximately 5cm.

1. At the required tensioning point, place your index

finger on top of the Tensioner Block Top and over

the Nut to ensure that the Nut is held in position.

2. Loosen the bolt from under the arm of the

clothesline.

3. Pull the line through the Tensioner Block to

required tension and re-tighten the bolt.

4. Repeat this process around the clothesline

working the slack cord towards the end of

the line.

ARM 1

STRING BOTH ENDS TERMINAL BLOCK TOP AFFIXEDSTRING ONE END

ARM 2, 3 & 4

TERMINAL BLOCK TOP AFFIXEDSTRING LINE

25 YEAR PRODUCT WARRANTY

directly. You must bear the cost of claiming the

warranty. This warranty is in addition to other rights

and remedies of the customer under law.

Where it is deemed necessary, Daytek Australia will

arrange for the inspection of your product.

Warranty exclusions

Defects caused by incorrect installation (including

poor drainage from ground socket), adjustment,

modification or misuse. Paint deterioration caused

by exposure to sea air where the product is installed

in coastal areas. Product damage or deterioration

due to abnormal environmental conditions including

storm damage, fire, wind, humidity and similar.

Damage to frame or line through accident or

negligence. Warranty does not cover bonus items.

The warranty covers domestic use only and does not

apply to commercial applications.

Our goods come with guarantees that cannot be

excluded under the Australian Consumer Law.

You are entitled to a replacement or refund for

a major failure and for compensation for any

loss or damage. You are also entitled to have the

goods repaired or replaced if the goods fail to be

acceptable quality and the failure does not amount

to a major failure.

If any part of this clothesline fails to operate

correctly due to faulty workmanship or defective

material Daytek Australia will repair or replace

free of cost within 25 years from the original date

of purchase (receipt of purchase required). The

PVC line cord is covered by a 2 year warranty from

the date of purchase. Any evidence of misuse or

incorrect adjustment will void the warranty. To claim

a product warranty, please contact Daytek Australia

Manufactured/Supplied by Daytek Australia Pty. Ltd.

77-81 Gower Street, Preston

Victoria 3072 Australia

T +61 3 9470 1755

F +61 3 9470 5381

E [email protected]om.au

daytek.com.au

CARE AND MAINTENANCE

If you are living within close proximity to a seaside

location, salt in the air will build up a thin layer on

your clothesline over time. To ensure longevity it is

important to regularly wipe down the surface of your

clothesline with a damp cloth.

Regularly check your clothesline for damage or

wear and tear. Any damaged part should be replaced

or repaired before using again. A full range of

spares are available through Daytek. Wipe away dust

and dirt regularly to prevent build up and ensure

smooth operation.

CONTACT DAYTEK

enquiry@daytek.com.au

daytek.com.au

facebook.com/daytekAU

www.productreview.com.au/listings/daytek

This manual suits for next models

5

Table of contents

Other DAYTEK Household Appliance manuals