DCA Intertel MP2005 User manual

1DCA IntertelDCA Intertel

V1.1 V1.1

User Manual

MP2005

Mobile Impact Printer

80 Column Dot Matrix

www.dca-group.com

2DCA IntertelDCA Intertel

V1.1

3DCA IntertelDCA Intertel

V1.1 V1.1

Table of Contans

1.Customer Care And Service 4

1.1 Warranty And Repair Service 4

1.2 Application Support 4

1.3 Notice 4

1.4 Warning 5

1.5 Limited Warranty 5

2. Description 6

2.1 Printer Overview 6

2.2 Printer Layout 7

3. Technical Specications 8

4. Installation 9

4.1 Unpacking 9

4.2 Procedure for Installation 9

4.2.1 Mechanical installation 9

4.2.2 Driver installation 9

4.3 Printer Setup 10

4.4 Caution! 12

4.5 Self Test 13

4.6 Indicators 14

4.7 Alarm and Indicator Functions 14

5. Printer Operation 15

5.1 Control Keys 15

5.2 Power Source 16

5.3 Paper Loading 17

5.4 Sensors 18

5.5 Maintenance 19

5.6 Inked Ribbon Cartridge Installation and

Replacement 20

6. Interfaces 21

6.1 Appendix A: 21

6.2 Appendix B: 22

6.3 Appendix C: 23

4DCA IntertelDCA Intertel

V1.1

5DCA IntertelDCA Intertel

V1.1 V1.1

1.Customer Care And Service

1.1 Warranty And Repair Service

To obtain warranty or repair service please contact DCA

Intertel at Phone: +31(0)172-604963 or

Fax: +31(0)172-605237 for a RMA number and shipping

instructions.

1.2 Application Support

If you have any questions on operating the MP-2005 or

require

information on specic applications, please contact DCA

Intertel.

Phone: +31(0)172-604963 or Fax: +31(0)172-605237.

1.3 Notice

The information contained in this document is subject to

changewithout notice. DCA Intertel makes no waranty

of any kind with regard to this material and shall not be

liable for errors contained herein or for consequential da-

mages in connection with the furnishing, performance, or

use of this material.

1.4 Warning

This equipment generates, uses, and can radiate radio

frequency energy, and may cause interference to radio

communications. It has been found to comply with the li-

mits for a Class A computing device, pursuant to Subpart

J of Part 15 of FCC rules, which are designed to provide

reasonable protection against such interference when

operated in a commercial environment. Operation of this

equipment in a residential area may cause such interfe-

rence that the user may be required to take measures to

correct.

1.5 Limited Warranty

The MP-2005 is warranted against manufacturing defects

in material for a period of one year from shipment to the

purchaser. Within this period DCA Intertel will repair or

replace the product without charge for material or la-

bor. Extended warranty is available. This warranty does

not cover damage or failure caused by abuse, improper

maintenance, or any repairs or modications other than

those provided by DCA Intertel. DCA Intertel makes no

other warranty, either expressed or implied, with respect

to this product and specically disclaims the implied war-

ranties of merchantaility and tness for a particular pur-

pose and shall not be responsible for any damages arising

out of or in connection with the use of this product.

6DCA IntertelDCA Intertel

V1.1

7DCA IntertelDCA Intertel

V1.1 V1.1

2. Description

2.1 Printer Overview

The MP- 2005 Mobile Printer is a ruggedized dot matrix

printer designed specically for mobile and portable ap-

plications. It can print in graphics mode along with diffe-

rent character fonts, both in draft ( 150 cps ) and NLQ (

25 cps ) mode. It has both tractor and friction feed me-

chanisms and can print on multi-copy paper

( 1 original and up to 3 copies ).

MP- 2005 is particularly suited for in vehicle applications,

due to its compact size and reduced weight. Power re-

quirements have been kept to a minimum bij means of

two DC motors with integrated optical encoders, and an

integrated driver board for precise positioning rather than

stepping motors.

MP- 2005 has a 2 Kbytes input buffer and comes with

an RS-232 serial interface. The MP 2000 driver software

supports DOS, Windows NT, Windows ‘95 and is compa-

tible to the commandset of EPSON LX 400/800.

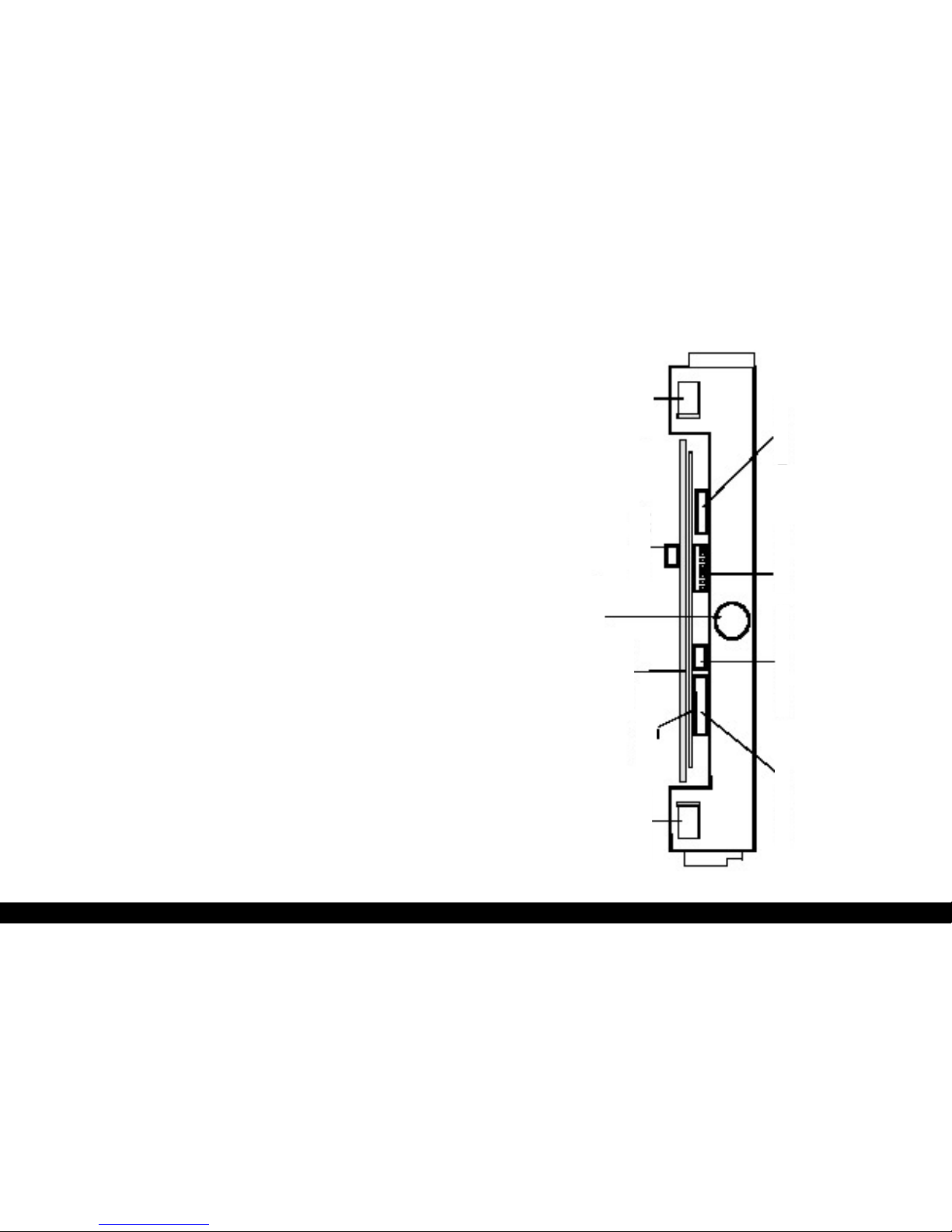

2.2 Printer Layout

Servermotor

Dip Switches

TTL Serial Interface Control Panel

TTL Parallel Interface

PRINTER HEAD

Power Supply

Power Board

Logic Board

HOT

Servermotor

8DCA IntertelDCA Intertel

V1.1

9DCA IntertelDCA Intertel

V1.1 V1.1

3. Technical Specications

Weight: 7 kg.

Power: 11-14,0 Volts DC

85 mA Standby

2.5 A at medium print density

Print: Impact Dot Matrix, 9 pins

Bi-directional with logic seeking

Paper Feed: Bi-directional, Sprocket and

friction

Copies: 1 original, 3 copies

Speed: 150 cps Draft

Paper Speed: 7 lines/second at 1/6”

13 lines/second continuous

Print Width: 8.25”

Paper Width: 8.93” pin to pin (sprocket)

3.5-8.5” tickets

Dots/Line: 1920 Max

Char. Set: IBM graphic bit image

Ribbon Life: Black 1.2 x 106 characters

Interface: RS - 232

Operating temp: + 5 C.....+ 40 C

Non operating: -15 C ..... +70 C

MIL SPEC: 810 D/E Shock and Vibration

Printer Operation

4. Installation

4.1 Unpacking

Take the printer out of its shipping box and remove any

packing material. It is advisable to keep the shipping box

in case the printer needs to be reshipped or stored

elsewhere.

4.2 Procedure for Installation

4.2.1Mechanical installation

The MP-2005 can print in any position

4.2.2 Driver installation

MP-2005 driver software supports DOS, Windows NT,

Windows ‘95 and is EPSON LX 400/LX 800 compatible

and it can therefore be congured as such in the majority

of the software packages.

Table of contents

Other DCA Intertel Printer manuals