UNPACKING AND HANDLING

6

STEP 1:

MOVING AND PLACING THE COOKTOP

NOTE: If a solid side cabinet wall exists on one or both sides, you will need to notch the

front corner of the cabinet to match the counter top notch and to provide clearance

for the cooktop front (see page 8).

CAUTION:

Proper equipment and adequate manpower must be used in moving the

cooktop to avoid personal injury or damage to the unit

ANCHORING THE COOKTOP

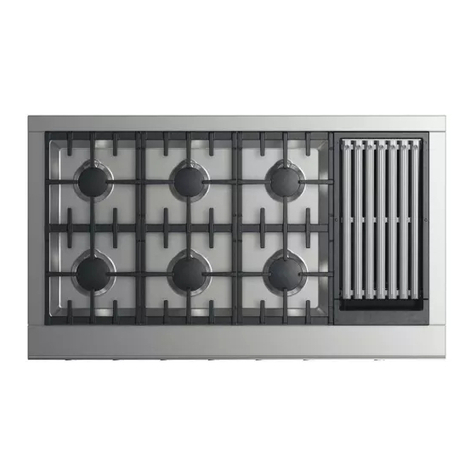

The cooktops have a shipping weight of approximately 228 pounds (36" models) and 324 pounds (48"

models). After removal of packing materials, it is recommended that the grates and drip pan (below

knobs) be removed to facilitate handling. This will reduce the weight to about 150 pounds.

DO NOT REMOVE THE GRILL OR GRIDDLE ASSEMBLIES.

It may be necessary to remove the cooktop knobs to pass through some doorways. With the knobs

removed a 29-3/8" wide opening is required. Remove the outer carton and packing material from the

shipping base. The cooktop is held to the skid by four straps. After removing the straps, the cooktop

must be lifted and removed from the skid.

The professional cooktop should be moved close to its final location. Electric and gas connections

should be made (steps 5 & 6 pgs. 12 & 13) and the backguard installed (as required, step 4 pg. 11)

before the cooktop is placed in its final position. The grill and griddle sections are fastened in place at

the front with screws.They are designed to be stationary and not meant to be removed for cleaning.

The griddle has two leveling screws beneath the rear flue cover which can be used to adjust the

griddle to the desired slope.The center screw is for shipping and should be removed.

Due to the weight of the cooktop, along with a built-in side frame gasket that is meant to rest and

create a seal on the counter top once installed, it is not necessary to anchor the unit to the counter.