Important!

SAVE THESE INSTRUCTIONS

The models shown in this document may not be available in all markets and are subject to change at any time. For current details about model and specification availability in your country, please go to our

website www.dcsappliances.com or contact your local DCS Customer Care Representative.

SAFETY AND WARNINGS

1

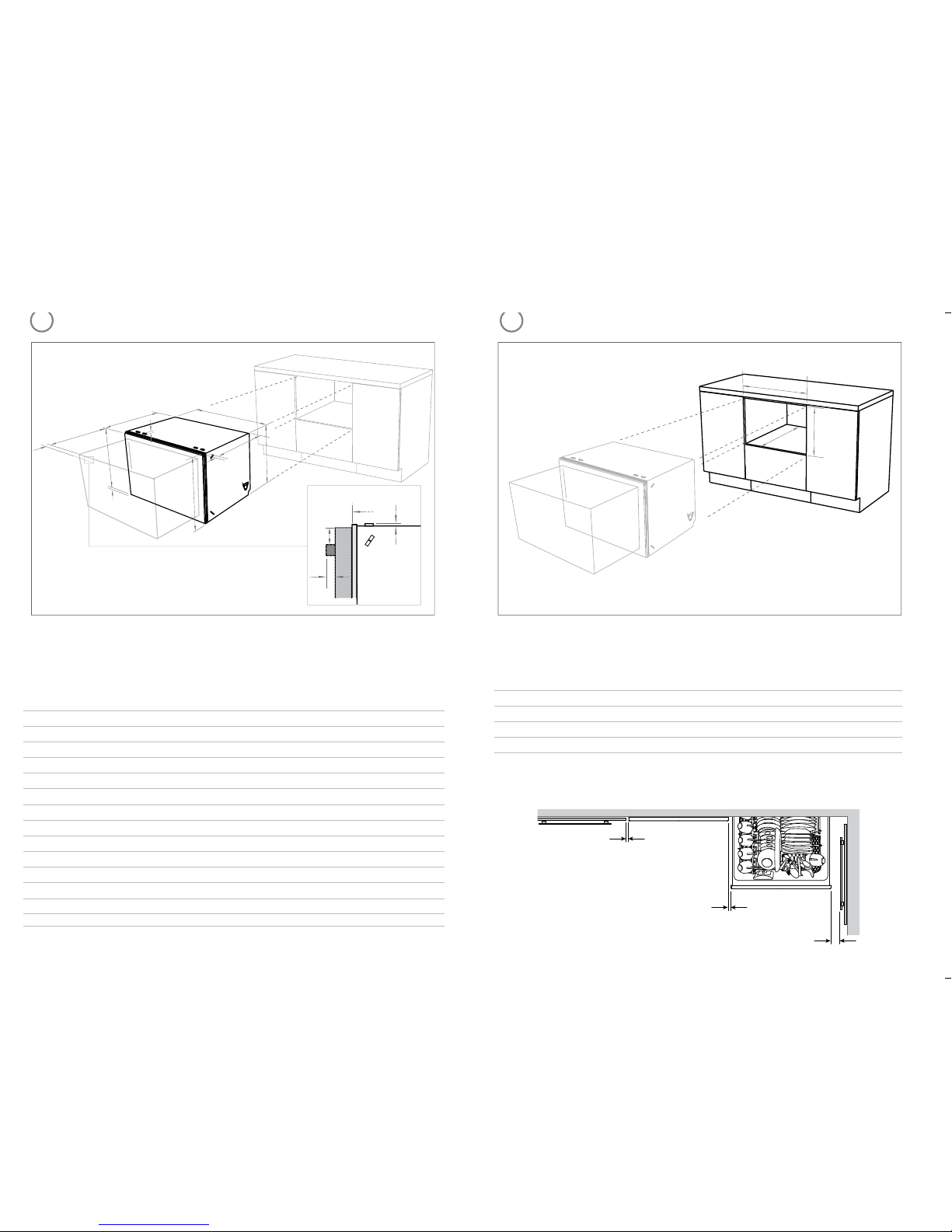

DishDrawer®

Installation instructions

US CA

DD24SUT models

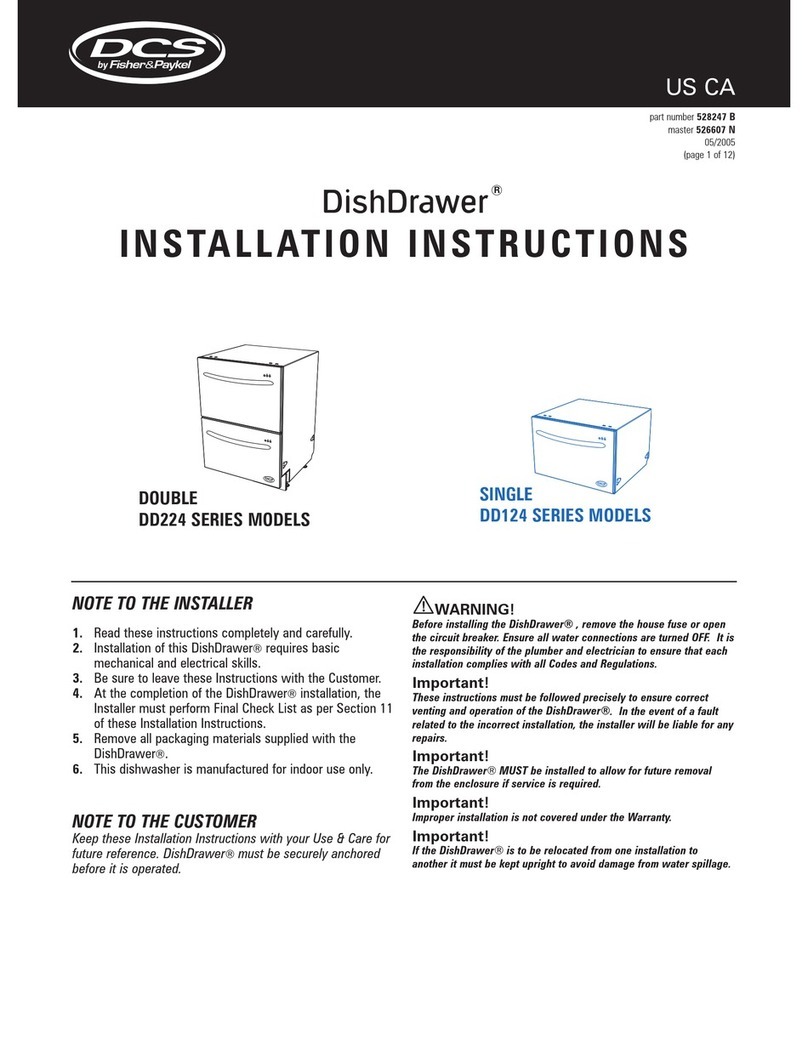

Important safety instructions!

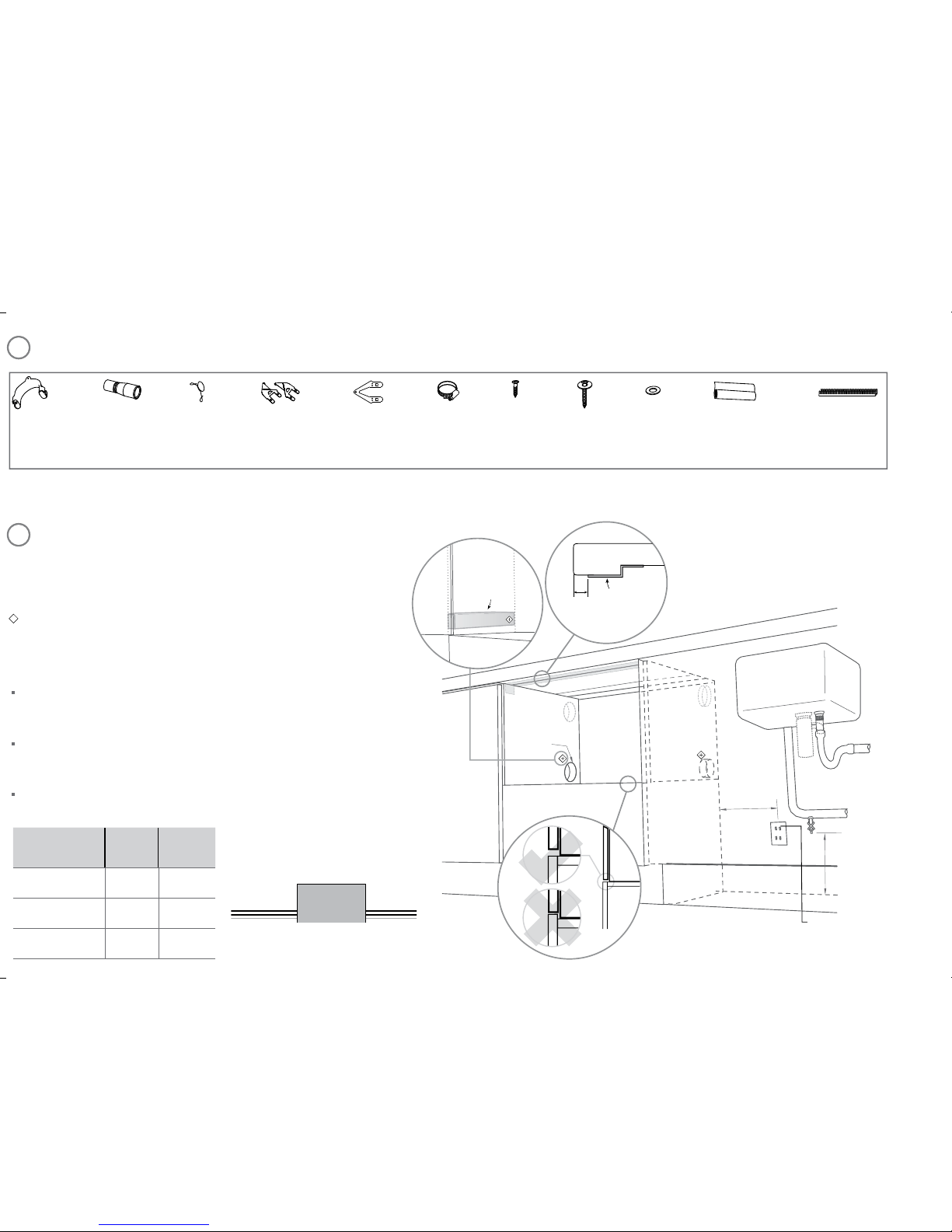

Installation of this DishDrawer® requires basic mechanical and electrical skills.

Be sure to leave these Instructions with the Customer.

Installation must comply with your local building and electricity regulations.

At the completion of the DishDrawer® installation, the Installer must perform

Final Check List.

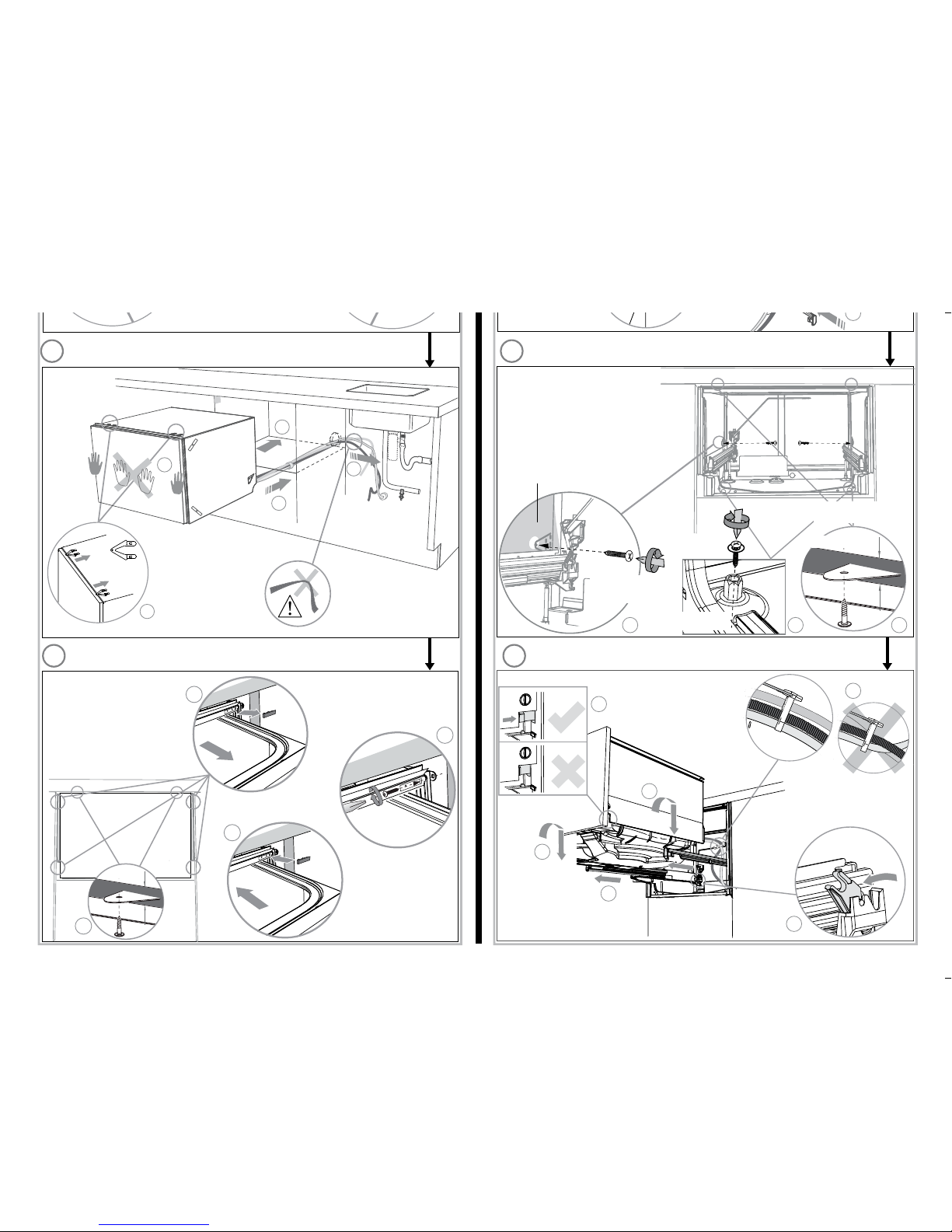

Remove all packaging materials supplied with the DishDrawer®.

This DishDrawer® is manufactured for indoor use only.

Ensure all water connections are turned OFF. It is the responsibility of the plumber and

electrician to ensure that each installation complies with all Codes and Regulations.

The DishDrawer® MUST be installed to allow for future removal from the enclosure if service is required.

The switched power outlet must be outside the DishDrawer® cavity so that it is accessible after

installation.

Care should be taken when the appliance is installed or removed to reduce the likelihood of damage to

the power supply cord.

If the DishDrawer® is to be relocated from one installation to another it must be kept upright to avoid

damage from water spillage.

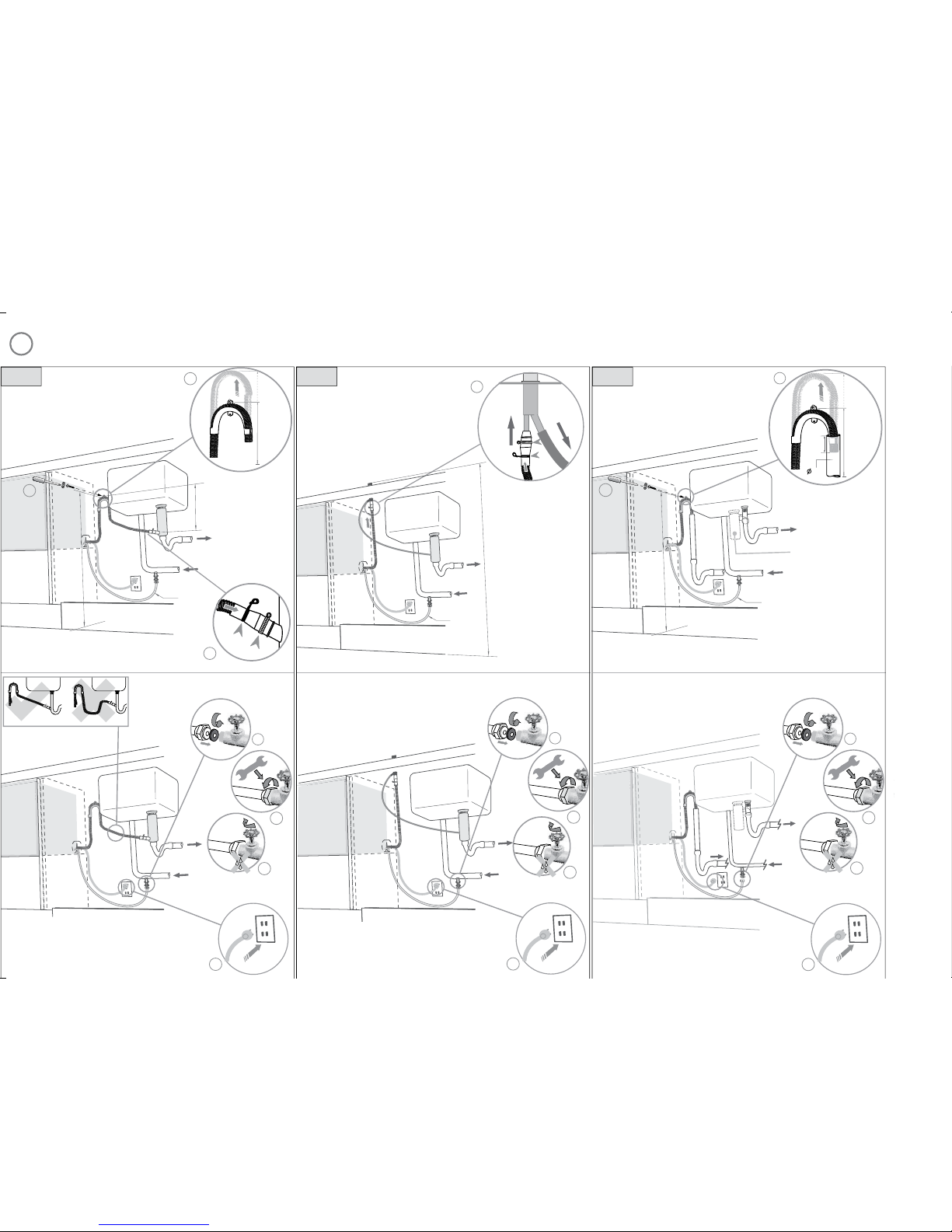

Make sure only new hoses are used for connection (supplied with DishDrawer®). Old hoses should not

be reused.

Failure to install the DishDrawer® correctly could invalidate any warranty or liability claims.

If the product is installed in a motor vehicle, boat or similar mobile facility, you must bring the vehicle,

boat or mobile facility containing the product to the service shop at your expense or pay the service

technician’s travel to the location of the product.

WARNING!

Electrical hazard

Before installing the DishDrawer®, remove the house fuse or open the circuit

breaker.

If permanently connecting the DishDrawer®, be sure the power is isolated and

the DishDrawer® unplugged.

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of a malfunction or breakdown,

grounding will reduce the risk of electric shock by providing a path of least

resistance for electric current. This appliance is equipped with a cord having

an equipment-grounding conductor and a grounding plug. The plug must be

plugged into an appropriate outlet that is installed and grounded in accordance

with all local codes and ordinances. WARNING - Improper connection of the

equipment-grounding conductor can result in a risk of electric shock. Check with

a qualified electrician or service representative if you are in doubt as to whether

the appliance is properly grounded.

If the DishDrawer is installed as a permanently connected appliance:

GROUNDING INSTRUCTIONS - This appliance must be connected to a grounded

metal, permanent wiring system, or an equipment-groounding conductor must

be run with the circuit conductors and connected to the equipment-grounding

terminal or lead on the appliance.

Do not modify the power supply plug provided with the appliance - if it will not

fit the outlet, have a proper outlet installed by a qualified electrician. Do not use

an extension cord, adapter plug or multiple outlet box.

Failure to follow this advice may result in electrical shock or death.

WARNING!

Cut hazard

Take care - panel edges are sharp.

Failure to use caution could result in injury or cuts.

(1,1) -1- 590116A DCS DD24SU TALL installA2 USCA.indd 17/8/10 8:49:55 AM

(1,1) -1- 590116A DCS DD24SU TALL installA2 USCA.indd 17/8/10 8:49:55 AM