De Agostini Model Space Robi Pack 05 User manual

Build your own

Stages 15-18:

Begin building

Robi’s left arm

05

Pack

All rights reserved © 2015

Published in the UK by De Agostini UK Ltd,

Battersea Studios 2, 82 Silverthorne Road,

London SW8 3HE

Published in the USA by

De Agostini Publishing USA Inc.,

915 Broadway, Suite 609, New York, NY 10010

Packaged by Continuo Creative,

39-41 North Road, London N7 9DP

Printed in EU

The names and likenesses of all Robi characters,

artwork and distinctive lettering are protected

under the copyright and trademark laws of the

United States and all foreign countries.

Assembly Guide p78

Stage 15: Assembling Robi’s left forearm p78

Stage 16: Set the ID of Robi’s left forearm servo p81

Stage 17: Completing Robi’s left forearm p86

Stage 18: Building up Robi’s left upper arm p90

CONTENTS

™

www.model-space.com

NOT SUITABLE FOR CHILDREN UNDER THE AGE OF 14.

THIS PRODUCT IS NOT A TOY AND IS NOT DESIGNED FOR USE

IN PLAY. ITEMS MAY VARY FROM THOSE SHOWN. THERE MAY BE

COLOUR VARIATIONS OWING TO THE MATERIALS USED.

Build your own

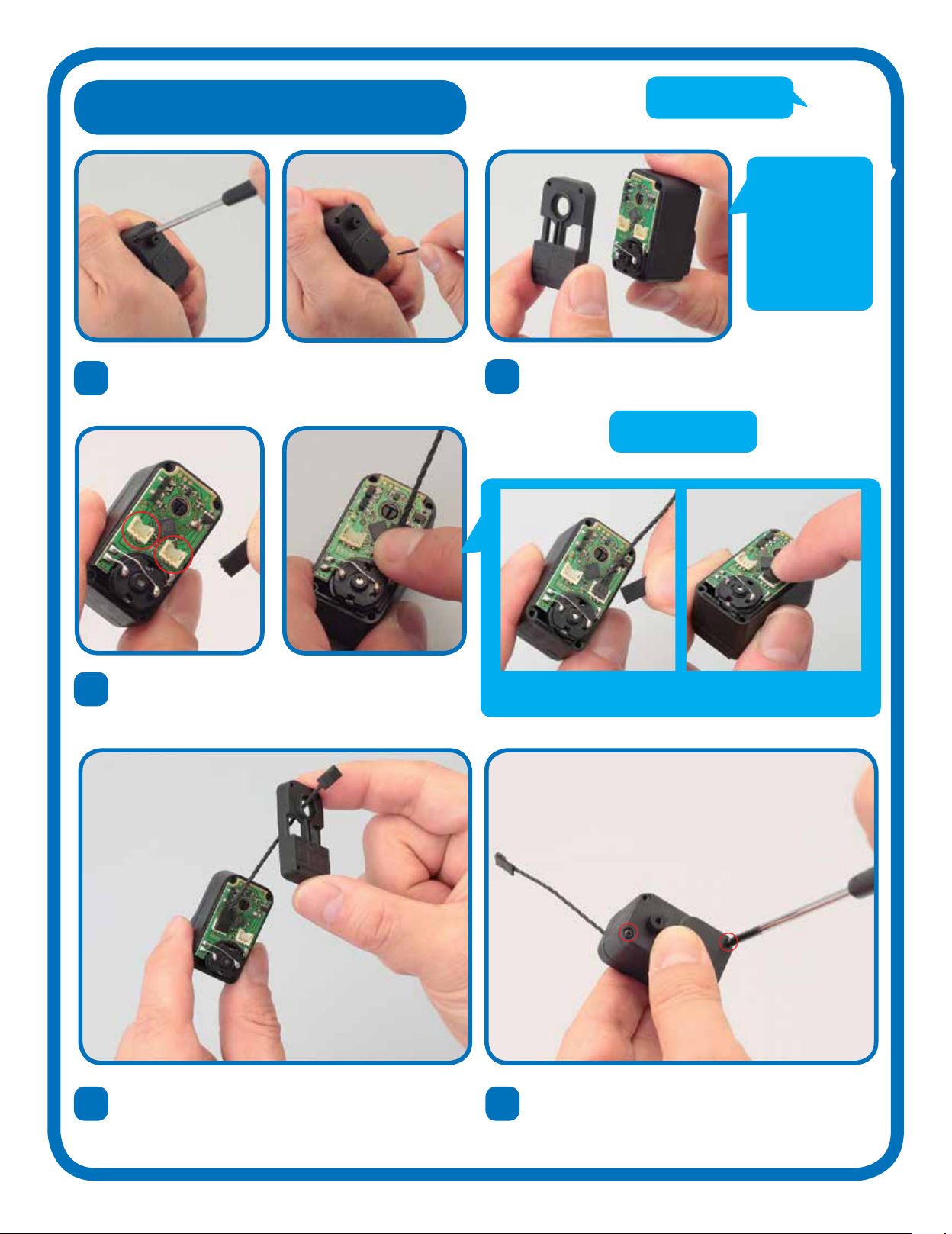

STAGE 15: ASSEMBLING

ROBI’S LEFT FOREARM

In this stae you will start assemblin Robi’s left arm, beinnin

by fittin the thumb to the forearm frame. You will then prepare

another servo cable by fittin it with protective pads.

Robi’s left arm is symmetrical to his

riht, so the assembly process is

nearly identical. Aain, the servos that

operate his arm’s movement will be

fitted onto a framework, the forearm

section of which is supplied with this

stae. After startin the physical

assembly, you will o on to prepare the

servo cable that will carry power to

Robi’s forearm servo on completion.

As always, care must be taken when

handlin delicate electronic parts.

ASSEMBLY GUIDE

1

2

3

45

6

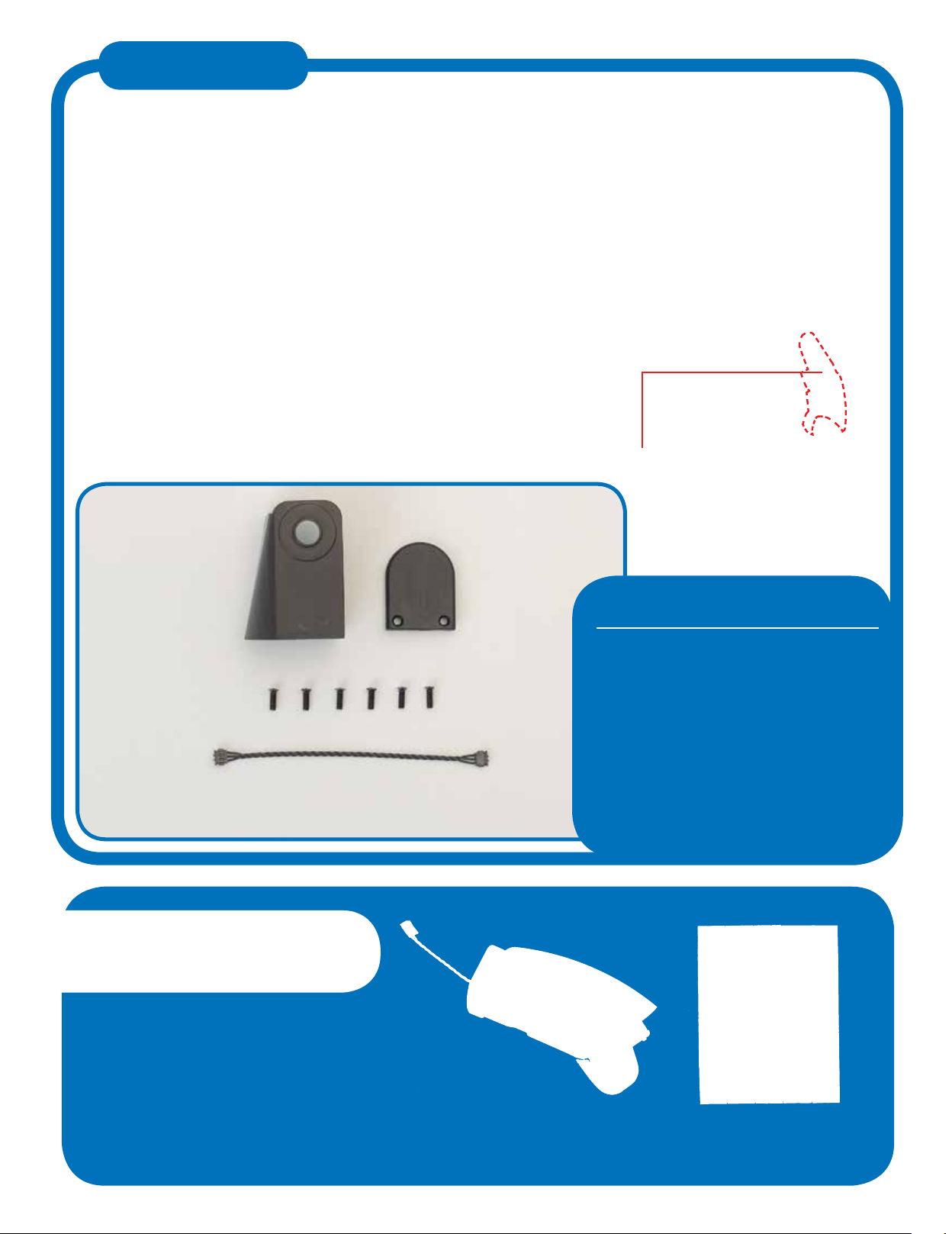

1 Left forearm frame

2 Left thumb

3 Left finger mount

4 M2 x 5mm pan-head screws (x 2)

5 M2 x 10mm pan-head screws (x 3)

6 Servo cable (70mm long)

You will be usin the protective pads

supplied with Stae 3, so be sure to

have these to hand before beinnin.

SAVED PARTS

YOUR PARTS

PARTS TO BE

ASSEMBLED

Protective pads (Stage 3)

78

THE FINGER MOUNT

THE THUMB

3

1

5

Turn the forearm frame over to check that the holes in

the finer mount are in line with the two screw holes in

the forearm frame.

Alin the left forearm frame and finer mount as

shown. The mount can be fitted either way up.

Line up the thumb and the forearm frame, notin the

position of the square tab on the thumb and the

matchin hole in the frame, circled in red.

4Fit two M2 x 10mm pan-head screws throuh the holes

and carefully tihten them to secure the finer mount.

2Press the tonue of the finer mount into the lon slot

in the end of the forearm frame.

6Press the parts toether so that the tab locks into the

hole and the thumb fits flush aainst the frame.

79

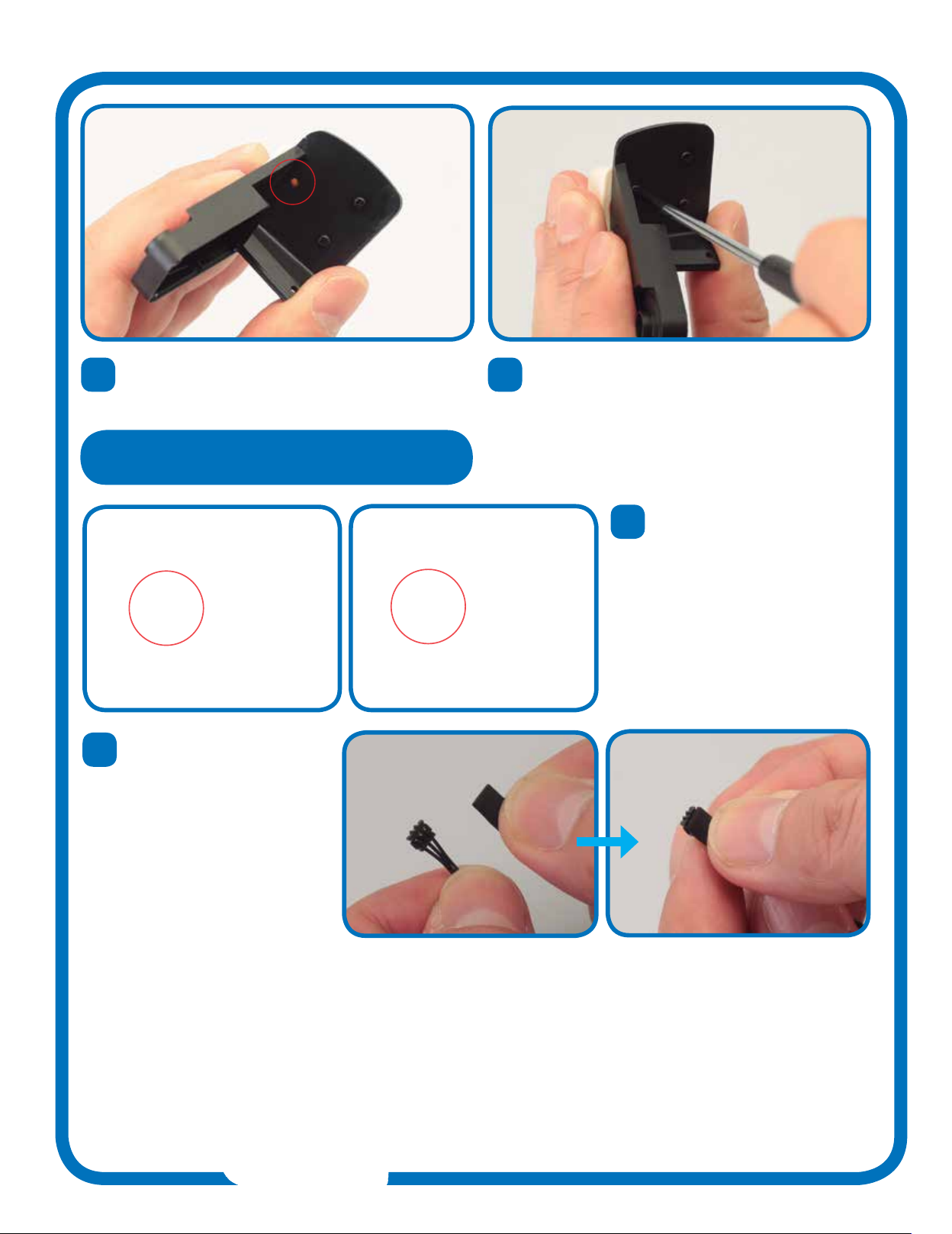

9

10

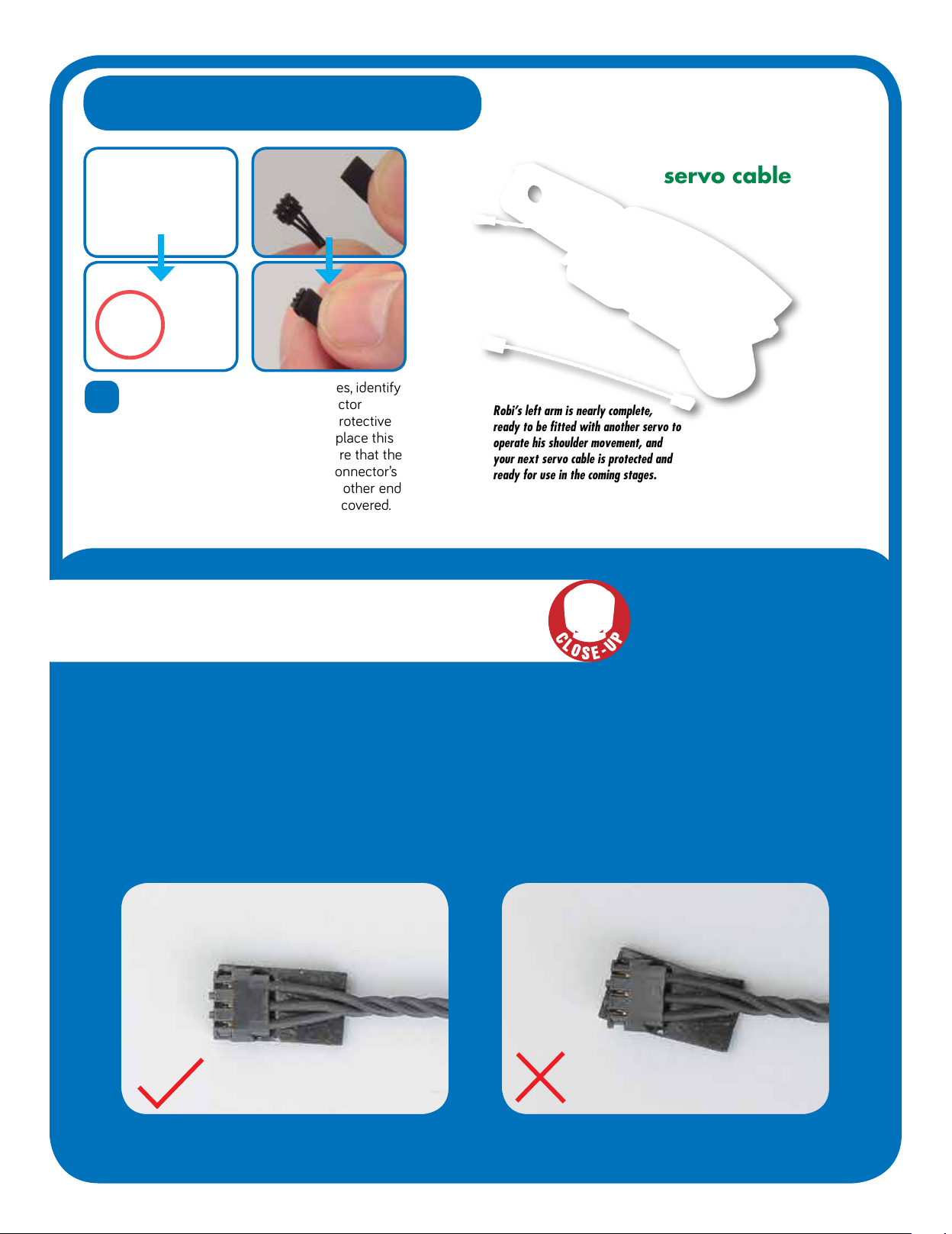

Next, prepare the servo

cable supplied with this stae.

As you have done with previous

cables, identify the side of the

connector with PUSH printed

on it. The protective pad will be

fitted to this side.

Remove a protective pad from

the sheet saved from Stae 3,

and press it into place as shown

onto the servo cable’s connector.

Repeat for the connector at the

other end of the cable.

7Turn the forearm frame over and check that the hole in

the thumb is in line with the remainin screw hole in

the forearm frame.

8Fit an M2 x 5mm pan-head screw in the hole and

carefully tihten it, to secure the mount.

Assembled

left forearm

frame

The rst parts of Robi’s left arm

have been assembled, and another

servo cable is ready for use in the

coming assemblies.

THE SERVO CABLE

80

STAGE 16: SET THE

ID NUMBER OF ROBI’S

LEFT FOREARM SERVO

In this stae, you will set the ID number of the servo that acts

as an elbow joint to move Robi’s left forearm, before fittin the

part onto the left forearm frame, ready for use.

The work in this assembly will be

similar to that of Stae 8, when you

wired and set the ID number of the

correspondin servo for Robi’s riht

arm. Even so, make sure you follow

the assembly steps closely, as it can

be dicult and, for the electronic parts

such as the servo cables, even

damain, to re-open the assembly

should you need to o back and

perform the steps aain.

Similarly, when settin the servo’s ID,

be absolutely sure you choose the

correct number, as Robi may not work

properly if the part is set to the wron

number when operated.

ASSEMBLY GUIDE

1

1 Servo motor

(for left elbow)

You will be usin parts from the

previous staes, so be sure to have

these to hand before beinnin.

SAVED PARTS

YOUR PARTS

PARTS TO BE

ASSEMBLED

Servo cable and left forearm

frame (Stage 15) Neck stand (Stage 8)

81

CONNECTING THE SERVO CABLE

3Take either end of the connector cable saved from the

previous stae and carefully fit it in one of the two

sockets circled in red. It does not matter which one.

Gently push it until it locks in place.

1Use a screwdriver to undo the four screws securin the

cover of the servo, and take each one out.

4Carefully feed the free end of the cable up throuh the

circular hole in the servo cover. Make sure that the cover

is the riht way up.

5Fit the cover onto the servo casin, then turn the servo

over and insert two of the screws you removed in Step 1.

Tihten them lihtly, as you will be removin them aain

in this assembly.

2Carefully lift the cover away from

the other side of the servo.

BE CAREFUL!

Try to avoid

touching the

circuit board

or electronic

components

when you remove

the cover from

the servo.

TIP!

If you chose not to fit the protective pad in Stae 15, you can fit it

now, which will help to secure the connector in place.

82

6Take the neck stand and unplu the black servo cable

from the socket on the left of the test board. Plu the

cable leadin to this stae’s servo in its place.

HELP!

If the LEDs flash rapidly when

you run the test at Step 14, you

have a faulty connection.

Double-check the servo cable’s

connection to the socket on the

test board, TURNING THE

POWER PACK OFF BEFORE

YOU DO. If the liht still flashes,

carefully unscrew the servo

housin and check that the

internal connector plu is in

place. If you pressed the wron

button, reset the board by

holdin down the TEST/SET

switch for several seconds.

9The shaft at the top of the servo casin should rotate 45 derees to the left,

stop, then move back across to 45 derees to the riht. After you have run

the test, turn o the power switch on the battery pack.

TESTING THE SERVO

7Turn the test board to ON. All the LEDs should blink

twice, then turn o to leave only number 1 lit.

8Now press the TEST/SET switch

briefly to run the servo test.

Units

Tens

10 Re-familiarise yourself with the lihts and switches on the test board, which you

have used to set the servos’ ID numbers. Each time you press the UP switch, the ID

number increases by one, and the result is displayed by the two banks of LED

lihts. The top row reads in tens and the bottom in units. For example, to set the ID

to 21, press UP 20 times. This will liht up the 20 LED and the 1 LED. (If you

overshoot, press the DOWN switch to take it down one step at a time.) When the

ID number is correct, you set it by pressin and holdin the TEST/SET switch.

83

15 Once all is well, switch the power pack OFF, then carefully

unplu the servo from the test board. It will retain its settin,

ready to be fitted to Robi’s left arm.

11 To set the ID number of the servo to

21, press the UP button 20 times. The

20 and 1 LEDs should remain lit once

you have done this.

13 It is vital that each of Robi’s servos is prorammed to the correct ID number,

or his operation may malfunction on completion. To bein checkin the ID

number, leave the servo connected, switch the power OFF and then back ON.

Only the 1 LED should liht up.

14 To check the ID number, press

TEST/SET. Now the 20 and 1

LEDs should liht up.

12 Confirm the settin by pressin the

TEST/SET button. The 20 and 1 lihts

should flash, then o out.

SETTING THE ID NUMBER

CHECKING THE ID NUMBER

It is normal for the 1 LED to

light up when you switch on. It

will only change to give you the

ID number of the servo when

you press TEST/SET. If you

made a mistake and set the

wrong ID number, you can reset

it by going through the setting

procedure again.

ID=21

TIP!

84

16 Remove the two screws fitted temporarily in Step 5 and

discard the cover as you will not be usin it aain. Keep

the screws.

17 Now line up the open servo with the left forearm frame.

The servo cable will fit throuh the circular hole at the

top of the frame (circled).

18 19

Carefully feed the servo cable throuh the hole in the

forearm frame.

Press the servo into place at the top of the forearm

frame. Make sure the servo cable is not bent or cauht

in any way as you do this.

20 Usin the four screws you removed in Step 1, secure

the servo to the forearm frame.

The next of Robi’s servos is in place,

ready to be joined to the rest of his

body in future stages.

Assembled

forearm

ATTACHING THE SERVO

85

STAGE 17: COMPLETING

ROBI’S LEFT FOREARM

In this stae, you finalise the parts that make up Robi’s

left forearm, from his elbow joint and forearm cover

down to his hand.

In this session, you continue to

assemble Robi’s left forearm, carryin

on from settin the ID number of the

forearm servo in the last stae. This

time, you will fit the elbow joint and

forearm cover, before closin the

assembly with the servo front panel. At

the end of this session, the left forearm

will be ready to be joined to the upper

arm servo in comin staes.

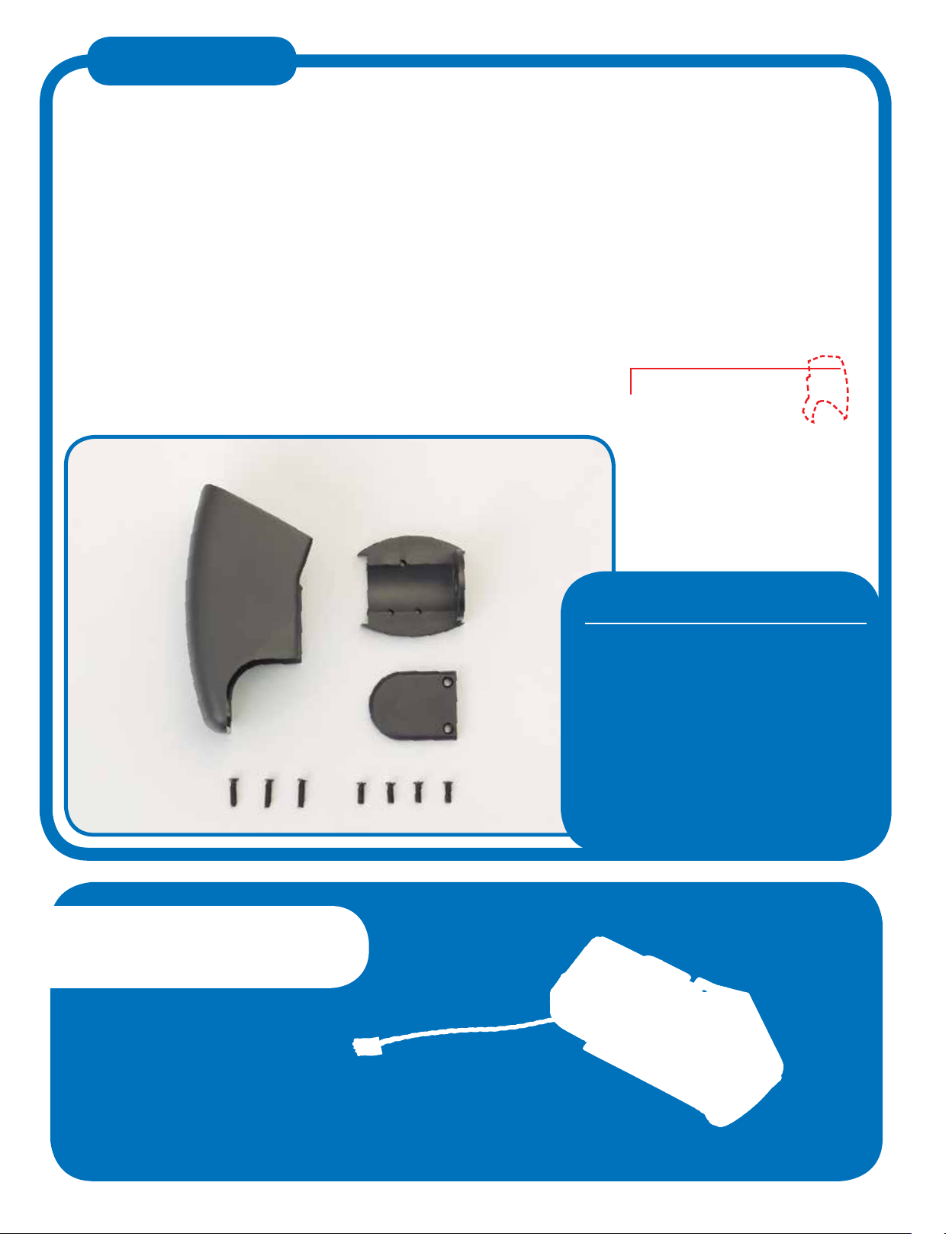

ASSEMBLY GUIDE

1 2

3

4 5

1 Left forearm cover

2 Left elbow joint

3 Servo front panel

4 M2 x 8mm countersunk screws x 3

5 M2 x 6mm countersunk screws x 4

You will be usin parts from the

previous staes, so be sure to have

these to hand before beinnin.

SAVED PARTS

YOUR PARTS

PARTS TO BE

ASSEMBLED

Left forearm assembly

(Stage 16)

86

The round shafts of Robi’s servos are moulded with a small flat

ede on one side – seen end-on, they are shaped like the letter

‘D’ – that fits into a correspondinly shaped recess on the part

that the servo will drive. This ensures that the parts can be set

correctly when in the neutral position.

THE D-CUT

Restorin to the neutral position

If somethin oes wron when you are testin one of

Robi’s servos – for example, if the power is accidentally

disconnected and the servo’s shaft stops turnin and

remains at an anle – you will need to reset the servo to

its neutral position. To do this, identify the flat on the

servo shaft (left photo) and place the part it will operate

over it at the same anle (riht photo). Then, very ently,

rotate the part back to the neutral position, with the servo

shaft’s flat facin downwards.

A ‘D-cut' shaft

Left photo: The servo’s shaft is termed ‘D-cut’ because, viewed

end-on, it isn’t completely circular but has a D-shaped outline.

Riht photo: The hole into which the D-cut servo shaft will fit has

a similarly shaped outline.

Neutral position

The advantae of usin a D-cut shaft and joint set-up is

that it makes it very easy to assemble Robi’s servos and their

accompanyin parts correctly. When a servo and a part are

alined correctly, as in the far left photo, they will fit toether

easily, but if they are not lined up as they should be, they will

strule to fit toether and result in an o-centred neutral

position (near left). If this happens, do not force the part.

Instead, realin it with the servo shaft

until it fits easily.

Warning: applying too much force when

tting a part over the servo’s shaft

can result in damage to both items!

ASSEMBLY GUIDE

87

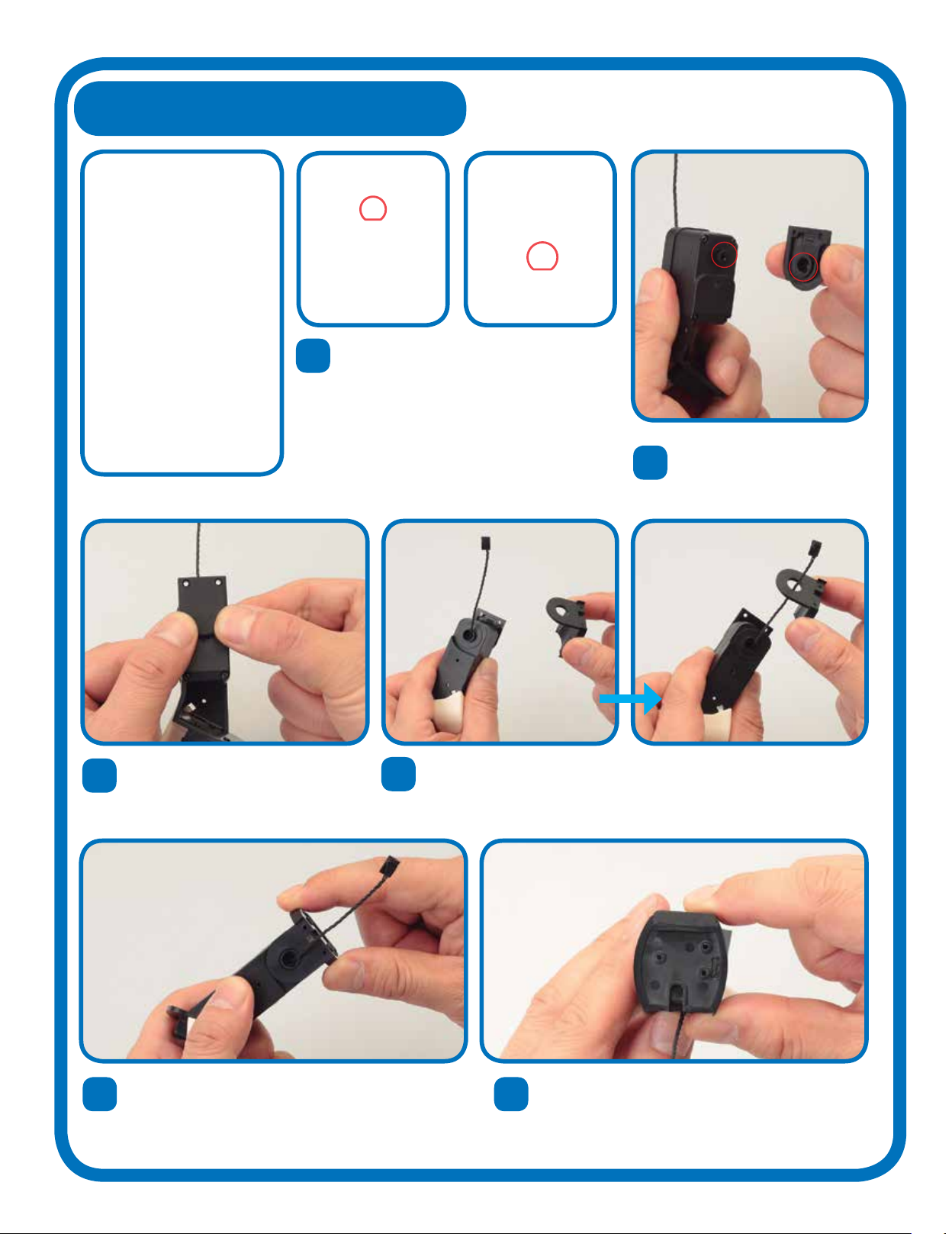

COMPLETING THE LEFT FOREARM

1Take the left forearm assembly and the

servo front panel supplied with this stae,

and line up the D-shaped servo shaft with

the correspondinly shaped socket on the

underside of the servo cover. Be absolutely

sure that the parts are set correctly toether

to avoid damae to either part – for more

information, see the box about D-cuts on

the previous pae.

5Run the left elbow joint alon the whole of the servo

cable, then fit it onto the top of the left elbow frame,

as shown.

6The top ede of the elbow joint is moulded to

accommodate the upper tip of the servo cover fitted

in Step 2, so ently press these toether.

2Join the parts so that they fit

snuly toether. Do not force

the parts as you combine them.

3When you are certain that the parts

are set straiht to one another, press

evenly on the panel to secure it to the

servo shaft.

4Turn the assembly around so that the side from which the servo cable

emeres is facin you. Then, with the left elbow joint positioned as

shown, lower the part over the cable, which should run throuh the hole

in its centre.

88

11 Finally, locate the circled hole on the left forearm frame,

and insert and tihten another M2 x 6mm countersunk

screw into it.

87 Hold the parts toether, then insert and tihten two of

the loner, M2 x 8mm countersunk screws into the two

holes shown above.

Now prepare to add the left forearm cover to the

assembly, linin up the holes circled above.

9Join the parts, makin sure that the circled holes are

properly lined up with one another, ready to take the two

M2 x 6mm countersunk screws.

10 Insert and tihten both M2 x 6mm countersunk screws

into the holes to secure the forearm cover.

Robi’s left forearm is now complete,

and ready to be joined to his upper

arm in future stages.

Assembled

forearm

89

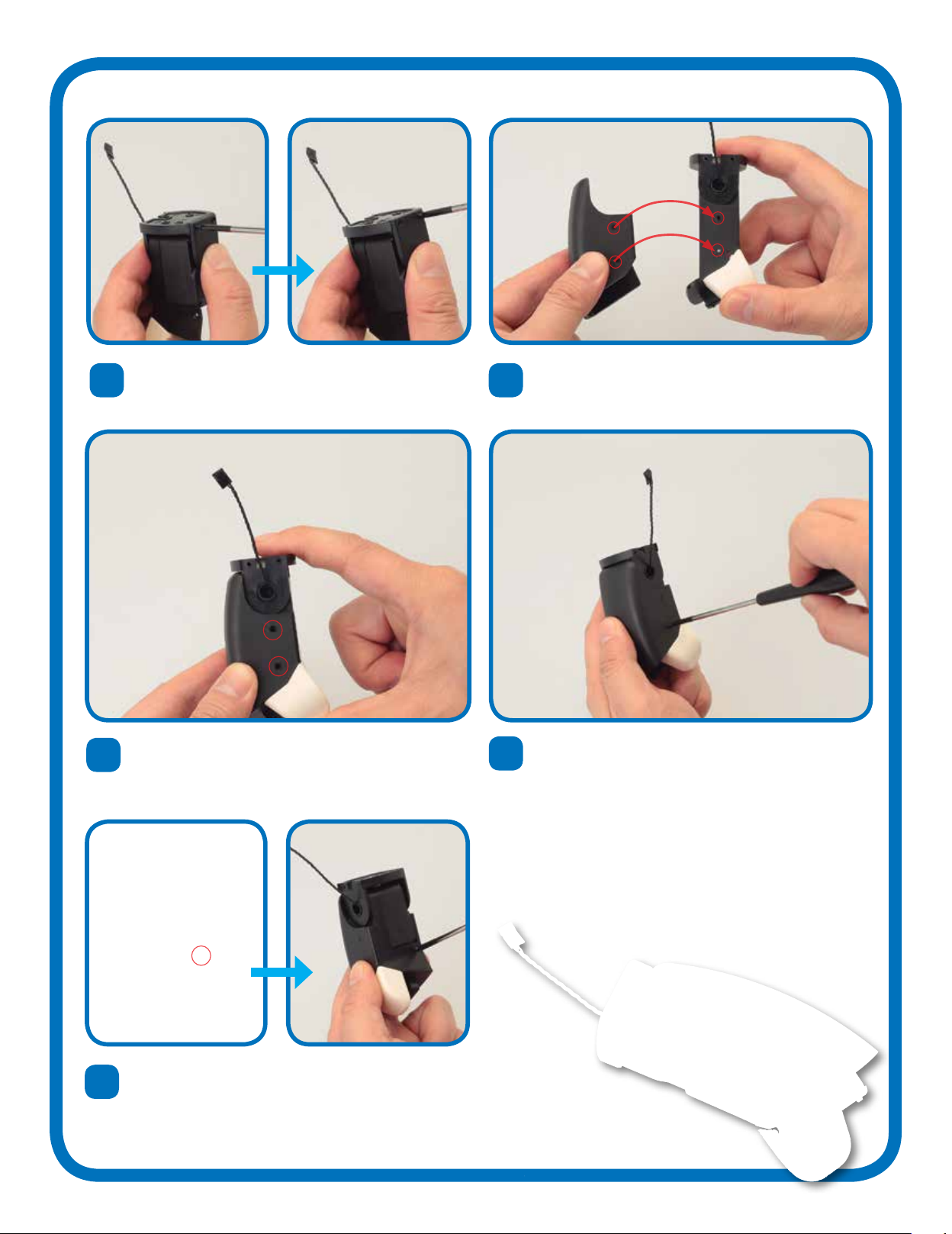

STAGE 18: BUILDING UP

ROBI’S LEFT UPPER ARM

In this stae, you start buildin up Robi’s left upper arm, beinnin

by sealin in his elbow before fixin the left upper arm frame itself.

The upper arm frame will join to the

forearm assembly at the elbow, which

you will seal o from the rear with the

elbow back panel also supplied with

this stae. As you do this, you will feed

the forearm’s servo cable throuh a

small trouh set into the side of the

back panel and frame. It is very

important that the cable fits throuh

this recess freely, without ettin

trapped or cauht between either part,

as this may damae the cable and

later aect the operation of Robi’s arm.

Lastly, you will prepare this stae’s

servo cable for safe use, as you have

done in previous staes.

ASSEMBLY GUIDE

1 2

3

4

1 Left upper arm frame

2 Left elbow back panel

3 M2 x 6mm countersunk

screws x 6

4 Servo cable (70mm)

You will be usin parts from the

previous staes, so be sure to have

these to hand before beinnin.

SAVED PARTS

YOUR PARTS

PARTS TO BE

ASSEMBLED

Left forearm assembly

(Stage 17)

Protective pads (Stage 3)

90

FITTING THE LEFT ELBOW BACK PANEL

BE CAREFUL!

1Take the left forearm assembly (built over previous

staes). Fold the servo cable back and into the

recess at the elbow, as shown.

2Holdin the cable in the recess, place the left elbow

panel onto the correspondinly shaped space on the

forearm frame.

3

5

Press the elbow panel into position,

so that its curved ede fits into the

frame neatly.

When you are happy that the elbow panel is fitted correctly and the servo cable is

not cauht in any way, use two M2 x 6mm countersunk screws to secure it.

4Press the part firmly into place,

makin sure the cable isn’t trapped

in any way.

Make absolutely sure that the servo

cable is sittin neatly in the recess

circled in the photo, and not trapped

between the parts (as shown below). If

the cable is crushed between the frame

and panel, there is a risk that it may

short-circuit when in operation, and

cause Robi to malfunction. Check that

your cable is safe before proceedin.

91

6

10

8

Line up the left forearm assembly and the left upper

arm frame, notin the position of the rectanular

hole (circled).

Still holdin the parts in one hand, tihten three more of the M2 x 6mm countersunk screws into the holes lined up

in the previous step.

With the parts held at a 45° anle to one another, line

up the three circled screw holes with those of the

forearm beneath.

7

9

Carefully pass the tip of the servo cable throuh the

rectanular hole, as shown.

Once you have the screw holes lined up, hold the parts

toether in one hand, makin sure that they do not slip

out of position.

ADDING THE LEFT UPPER ARM FRAME

45°

45°

92

PREPARING THE SERVO CABLE

11 As you have done in previous staes, identify

the side of the servo cable’s connector

marked ‘PUSH’. Then, separate a protective

pad from the sheet (Stae 3) and place this

on top of the connector, makin sure that the

pad does not extend beyond the connector’s

tip. Repeat for the connector at the other end

of the servo cable so that both are covered.

Assembled

left arm and

servo cable

Robi’s left arm is nearly complete,

ready to be tted with another servo to

operate his shoulder movement, and

your next servo cable is protected and

ready for use in the coming stages.

By now you will be familiar with the servo cables that connect Robi’s servo

motors, but take a moment to revisit the process of applyin the protective pads

to these. It is important that the pads are fitted neatly and in line with the shape

of the cables’ rectanular connectors, because if fitted incorrectly they can

obstruct the other cables and components of the servos. For some steps, it will

be easier to fit the protective pad after the servo connector is in position – when

this is the case, a Tip box will appear next to the step.

SERVO CABLES

The pad is fitted neatly, in line with the connector. The pad is fitted incorrectly, at an anle to the connector.

93

COMING IN PACK 6

PARTS PROVIDED

The servo that will operate

Robi’s left upper arm.

Stage 19

Add another servo

to Robi’s left arm

PARTS PROVIDED

Components to build up Robi’s shoulder joint,

along with another servo cable.

Stage 20

Build up Robi’s

left shoulder joint

Stage 21

Test Robi’s left

shoulder servo

PARTS PROVIDED

The servo that will perform

the role of Robi’s shoulder.

Stage 22

Continue building

up Robi’s body

PARTS PROVIDED

The next parts of Robi’s body, including

the left body cover and servo horn.

Your next FOUR complete

Stages, as Robi starts to

come to life!

Other De Agostini Robotics manuals

Popular Robotics manuals by other brands

Eddyfi Technologies

Eddyfi Technologies Inuktun VT150 Vertical Crawler user manual

SunFounder

SunFounder PiSloth manual

adept technology

adept technology 550 Instruction handbook

Lynxmotion

Lynxmotion AL5D-PLTW Guide

Segway Robotics

Segway Robotics RMP 440 Omni V3 user manual

HEBI Robotics

HEBI Robotics 7-DoF Assembly instructions