De Agostini MODEL SPACE Robi User manual

Build your own

16

Pack

Stages 59-62:

Begin working

on the inside of

Robi’s head

All rights reserved © 2016

Published in the UK by De Agostini UK Ltd,

Battersea Studios 2, 82 Silverthorne Road,

London SW8 3HE

Published in the USA by De Agostini Publishing

USA, Inc., 121 E. Calhoun Street

Woodstock, IL 60098

Packaged by Continuo Creative,

39-41 North Road, London N7 9DP

Printed in EU

The names and likenesses of all Robi characters,

artwork and distinctive lettering are protected

under the copyright and trademark laws of the

United States and all foreign countries.

CONTENTS

Build your own

Assembly Guide p320

Stage 59: Test Robi’s neck, back and arms p320

Stage 60: Prepare and fit Robi’s head servos p328

Stage 61: Build up Robi’s head p338

Stage 62: Fit Robi’s first infrared eye sensor p342

™

www.model-space.com

NOT SUITABLE FOR CHILDREN UNDER THE AGE OF 14.

THIS PRODUCT IS NOT A TOY AND IS NOT DESIGNED FOR USE IN

PLAY. ITEMS MAY VARY FROM THOSE SHOWN. THERE MAY BE

COLOUR VARIATIONS OWING TO THE MATERIALS USED.

STAGE 59:

TEST ROBI’S NECK,

BACK AND ARMS

Use the CPU board to test Robi’s neck, body and arms,

before fittin the velvet pads supplied in this stae to his feet.

This stae beins with you testin all the

servos of Robi’s neck, back and arms

toether, to ensure they all work before

you seal them inside Robi’s body. You will

then start buildin up the frame that will

hold both of Robi’s head servos, by

securin this to the neck base and servo

assembly via the servo itself. Finally, you

will attach the velvet pads supplied in

this stae to the soles of Robi’s feet.

Unlike the double-sided adhesive pads

used in Pack 9, these pads come in a left

and riht shape, so make sure you use

the correct one!

ASSEMBLY GUIDE

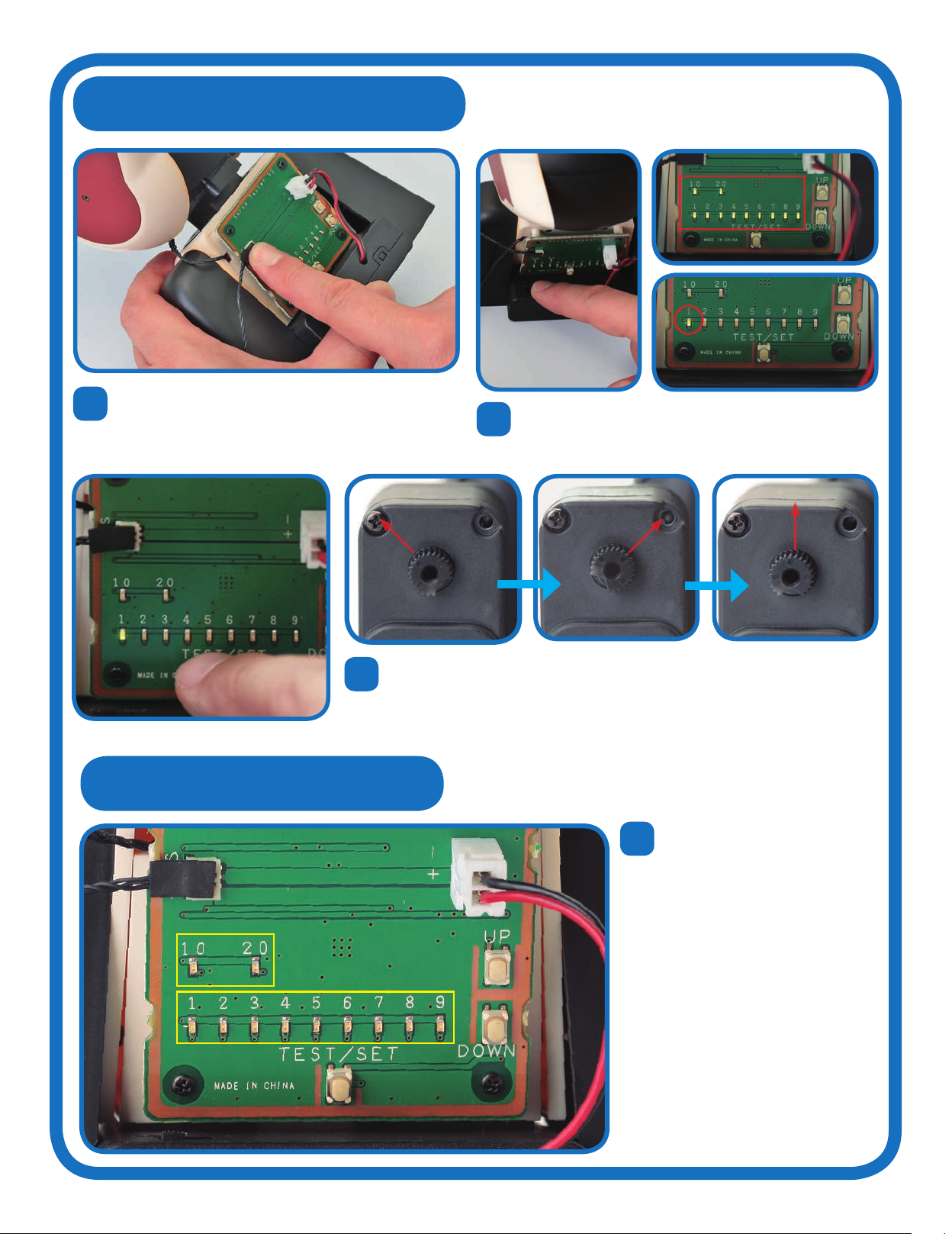

1

2

3

4

56 7 8

9

You will be usin parts from previous staes,

so be sure to have these to hand before beinnin.

1 Head servo frame

2 Head lever

3 Lever ring nut

4 Velvet foot pads

5 M1.7 x 24mm pan-head screws x 3

6 M3 x 8mm pan-head screws x 2

7 M2 x 6mm pan-head screws x 2

8 M2 x 6.2mm pan-head screws x 2

(one of each screw is a spare)

9 Servo cable 70mm

YOUR PARTS

PARTS TO BE

ASSEMBLED

Power distribution board

(Stage 40)

Neck stand

(Stage 53)

Body

(Stage 58) Legs and hip base

(Stage 52)

Protective pads

(Stage 3)

Battery

(Stage 38)

SAVED PARTS

320

FASTEN THE NECK PLATE

TEST THE SERVOS

Use an M2 x 6.2mm pan-head screw to secure the part,

but do not tighten it too much, as the plate needs to be

able to move. You received a number of screws with this

stage, so make sure you use the correct one – this one

was part number 8 in the list.

Hold the body as shown, then push the switch

to the ON position.

Connect the battery’s connector to the socket

marked CN1 on the power distribution board. Make

sure the battery is charged (see box, above).

Now take the free connector on the body’s power/switch cable

and fit this into CN3.

12

3

45

Position the circled end of the neck plate fitted in the

previous stae over the hole in the scarf beneath.

To rechare Robi’s

battery, connect

the battery and

power cord to the

power distribution

board, in sockets

CN1 and CN3

respectively, then

plu the mains

charer into the

back of the rear

hip panel.

RECHARGING

THE BATTERY

POWER DISTRIBUTION

BOARD SOCKETS CN1

AND CN3 CHARGER

CABLE

321

Still holding the battery in place,

turn the switch ON. Note: Robi’s

arms will move as soon as the

power is switched on!

Slide the battery into the space next to the back servo, making sure all the

connectors stay in their sockets. Hold the battery in place.

When the power is connected, Robi will perform a movement test of his arms, by setting them to their starting, or neutral,

position, stretching them outwards from the elbows, then bringing them back to the neutral position.

Next, Robi’s upper arms will lift outwards – and while this

happens, his neck servo will pan to the right and back.

Finally, Robi’s shoulders will extend his arms forward

over his chest – and the shaft of his back servo will

rotate to the left.

76

8

910

STARTING

POSITION ELBOWS

STRAIGHTENED STARTING

POSITION

UPPER ARMS

RAISED

NECK ROTATES

BACK SERVO ROTATES

SHOULDERS LIFT

ARMS FORWARD

322

When the tests described on the previous pages are

complete, Robi will return to his neutral position and you

will hear him say ‘OK!’ This is to test his speaker. Turn the

switch back to OFF, and disconnect the switch cable and

battery from the power distribution board.

Line up the head servo frame to the neck

servo, as shown.

Set the frame on top of the neck servo, so that the circled holes align

with the free ones on the neck servo. Then insert and tighten two

M1.7 x 24mm pan-head screws into these holes.

Now locate the circled hole in the top of the frame. Insert an M2 x 6mm pan-head screw into this hole to

secure the part.

11

OK!

STARTING

POSITION Each of the white plastic

connectors has a small barb

on one side, which holds the

connector securely in its

socket. To unplug a connector

easily and safely, press the

barb inwards – never pull on a

connector without doing this!

ATTENTION! !

Both arms were tested in

Stages 43 and 44, so if they

do not work now it is most

likely a problem with the

connection to the CPU, so

check/reset this.

Remove the back servo’s

cable from the CPU and

check to see if the arms start

working.

Consult the troubleshooting

guide of this stage.

IF THE ARMS DO NOT

MOVE

IF NO SERVOS MOVE

IF THE BACK AND NECK

DO NOT MOVE

Robi saying ‘OK!’ is only to test his speaker, not to affirm that the movement

test went as planned. If the movement tests do not go as described, see the

box above right, or the troubleshooting guide later in this stage.

12 13

14 15

ATTACH THE HEAD SERVO FRAME

323

FIT THE HEAD LEVER

Take the head lever and fit the ring nut into the hole in its longer arm,

from the angle shown. The ring nut should fit perfectly.

Take an M3 x 8mm pan-head screw and insert it through the circled

hole in the inside of the head servo frame, entering from the left. Turn

the screw through this hole so that it travels through the ring nut in the

lever and out to the other side.

With the ring nut still in position, slide the

lever into the space in the middle of the

head servo frame. Its shorter arm should

be at the rear of the assembly, pointing

out towards Robi’s right arm.

Holding the ring nut in its hole, line up the

lever to the head servo frame, oriented as

shown above.

16

19

18

17

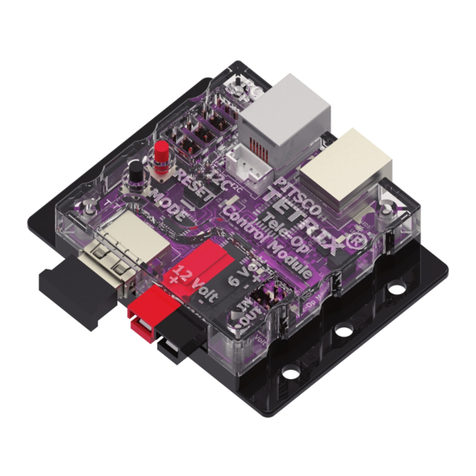

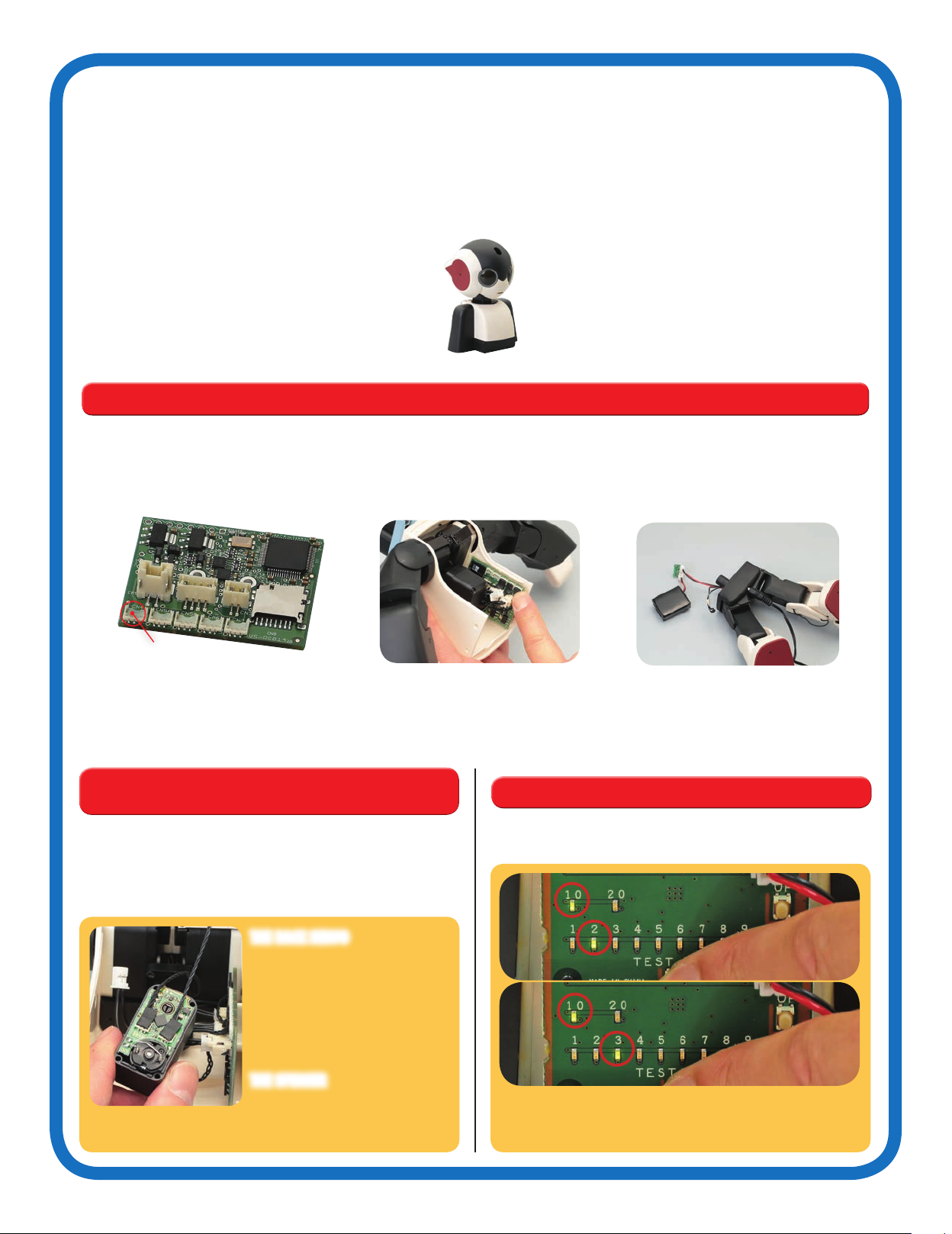

TEST AND FIT SERVO ID=15

20 21

Make sure the test board is switched OFF, then

connect its own servo cable to it.

Turn the board ON. The LEDs should flash, and then leave the

1 LED lit alone.

324

22

23 24

Press the TEST/SET switch: Robi’s head should rotate 45° to the left, stop, then

move back across to 45° to the riht, before returnin to its oriinal position. The

next step is to set the servo’s ID number, so keep the power on. If the test does not

run, or if the LEDs flash rapidly, refer to the HELP box in Stae 8.

Althouh this servo has been used for Robi’s

neck durin the testin process, it will be his

forward-tiltin head servo when fitted, with

the ID number 15. To set this, press UP 14

times, so that the 10 and 5 LEDs liht up.

Press and hold down the TEST/SET button

for a few seconds. The 10 and 5 LEDs

should flash, then remain lit. The ID number

is now set.

If the test does not

run, check the servo

cable’s connector,

and ensure that the

battery is charged.

ID=15

25 It is vital that Robi’s servos are set correctly,

so it is always a ood idea to check that you

have set the intended ID number afterwards.

To do this, leave the servo connected, then

switch the power OFF, then back ON. Only

the 1 LED should liht up.

26 To check the ID number, press TEST/SET briefly. Now the 10 and 5

LEDs should liht up and the servo shaft should repeat the rotations

seen in the test. Note: if anythin is amiss, you can bein the settin

process aain from Step 23.

CHECKING THE ID NUMBER

It is normal for the 1 LED to

light up when you switch on.

It will only change to give you

the ID number of the servo

when you press TEST/SET. If

you made a mistake, or set the

wrong ID number, you can reset

it by going through the setting

procedure again.

As you will have seen in the previous few packs, the process of

checking and resetting a servo’s ID number once fitted can be

fiddly and time-consuming, so be sure to get it correct now!

!

325

FITTING THE FOOT PADS

PREPARING THE SERVO CABLE

27 28

Match the riht foot pad to the sole of Robi’s riht foot, then,

when you are sure that they alin, peel the backin away to

the middle. Press the heel of the pad onto the back of the

sole, then smooth it down from the back to the front, peelin

the rest of the backin away as you do.

Make sure that the pad fits exactly: if it doesn’t, peel it away

and reset it. Once you are happy with it, repeat the process

for the left foot and pad.

29 30

As you have done previously, identify the side of this

stae’s servo cable connector that has PUSH marked

on it (circled).

Apply a pad to the connector on this side. Repeat for the

other end of the cable.

If you want to delay fitting

the pads until the cable is

used in the build, you may

do so.

Remember, to see all of Robi’s assembly

stages, including this one, visit the

ModelSpace web page at:

www.model-space.com

Assembled

body and feet

326

TROUBLESHOOTING

In this section, we look aain at what to do if the movement test carried out in this stae does

not o as described. As the arms have been tested previously, we will focus on the operation

of the neck and back servos, as well as the speaker, from which Robi says ‘OK!’

Before dismantlin the assembly to check its individual servos, check the other electrical components used in the test.

HEAD/NECK/BACK SOCKET

CHECK THAT THE CABLE IS CONNECTED TO

THE CORRECT SOCKET ON THE CPU

CHECK THAT THE SERVO CABLE IS

SECURELY CONNECTED TO THE CPU

CHECK THAT THE

BATTERY IS CHARGED

Ensure that the back servo

cable’s connector is sittin

securely within its socket.

Remove and replace it carefully

if need be.

The socket farthest from

the micro SD card slot on

the CPU board will hold the

servo cable runnin from

the back servo.

The test will only run if sucient

power is received from the

battery, so make sure the battery

is fully chared (see the Close-

Up box earlier in this stae).

INITIAL CHECKS

Neck stand (Stage 53)

Alon with the Phillips screwdriver

supplied with Stae 2, you will need

the followin:

IF NEITHER THE NECK NOR BACK SERVOS MOVE,

OR IF ROBI DOES NOT SAY ‘OK!’

If neither the neck nor the back servo moves when you start

the test, it is probable that there is a misplaced connection,

so o back and check these. Similarly, if Robi does not say

‘OK!’ at the end of the test, you should check the connection

between the speaker cable and CPU board.

THE BACK SERVO

THE SPEAKER

Follow the assembly of Steps

14-19 of Stae 58 in reverse, and

check the back servo’s connections

carefully. If both were sound,

disconnect it from the neck servo

and check the servo’s ID number

(ID=12), resettin it if necessary.

If Robi does not say ‘OK!’ at the

end of the test, check the connection of the speaker cable to

the CPU – done in Step 15 of Stae 57.

IF ONLY ONE SERVO MOVES

If one servo moves but the other does not, it is likely that one

of the ID numbers has been set incorrectly.

Should you need to disassemble and reset Robi’s neck or back

servos, see Stae 58 (for the back servo, ID=12) and/or Stae

54 (for the neck servo, ID=13).

327

You will be usin parts from the

previous staes, so be sure to have

these to hand before beinnin.

STAGE 60: PREPARE

AND FIT ROBI’S

HEAD SERVOS

Prepare Robi’s second head servo then fit it, alon with the

one from the previous stae, to his head servo frame.

There are two servos inside the upper

part of Robi’s head, ID=14 and ID=15.

Both are set onto the head servo

frame that you fitted and wired over

the previous staes, and they will work

in tandem with the internal lever and

head base to make Robi’s head tilt

forward and back (in the case of

ID=15) and side to side (ID=14). As

ever, take care when handlin open

servos, and make sure you set the

correct ID number.

ASSEMBLY GUIDE

1

PARTS TO BE

ASSEMBLED

1 Servo motor (ID=14)

YOUR PARTS

SAVED PARTS

Neck stand

(Stage 53)

Battery

(Stage 38)

Power distribution board

(Stage 40) Body and neck assembly, and

servo cable (Stage 59)

328

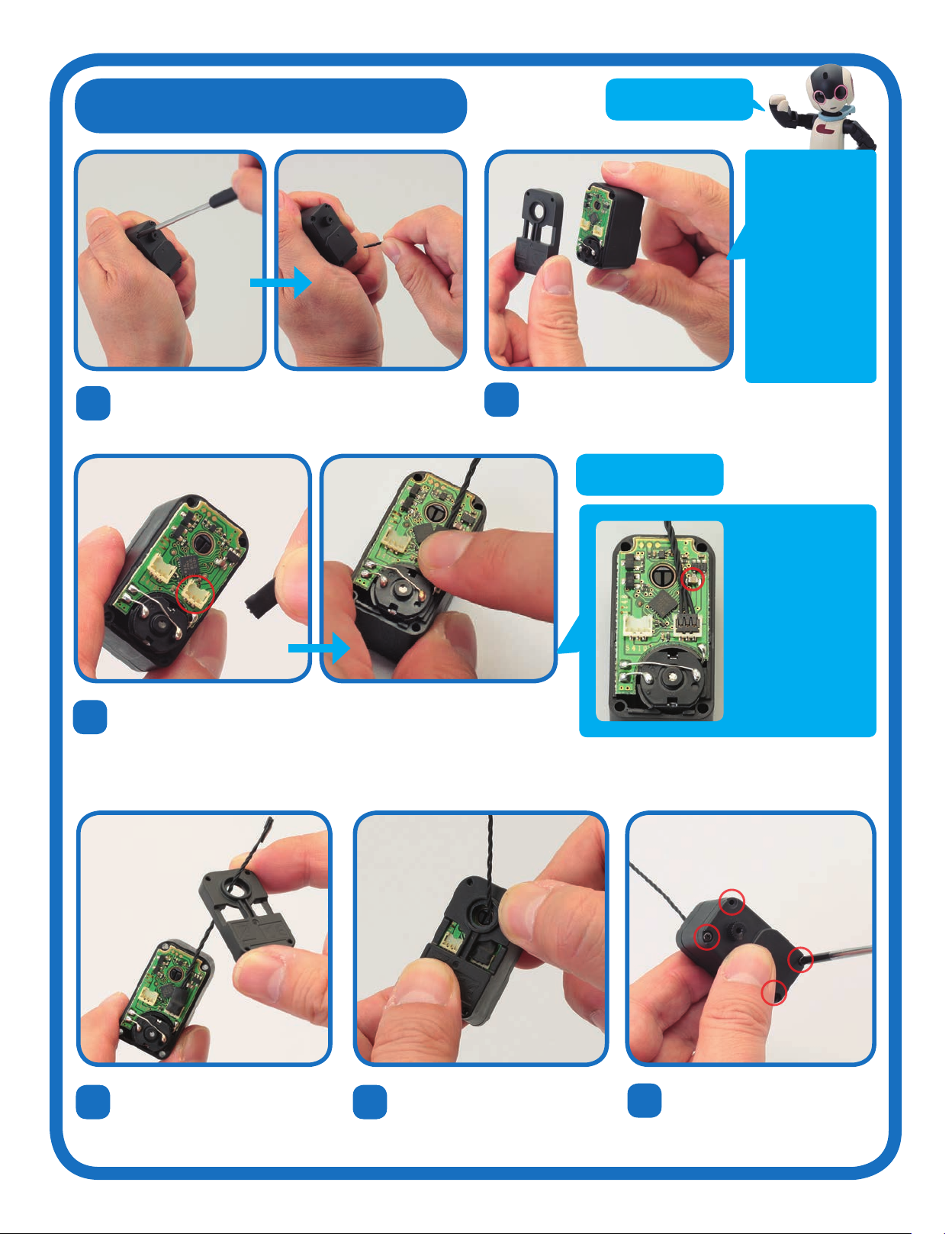

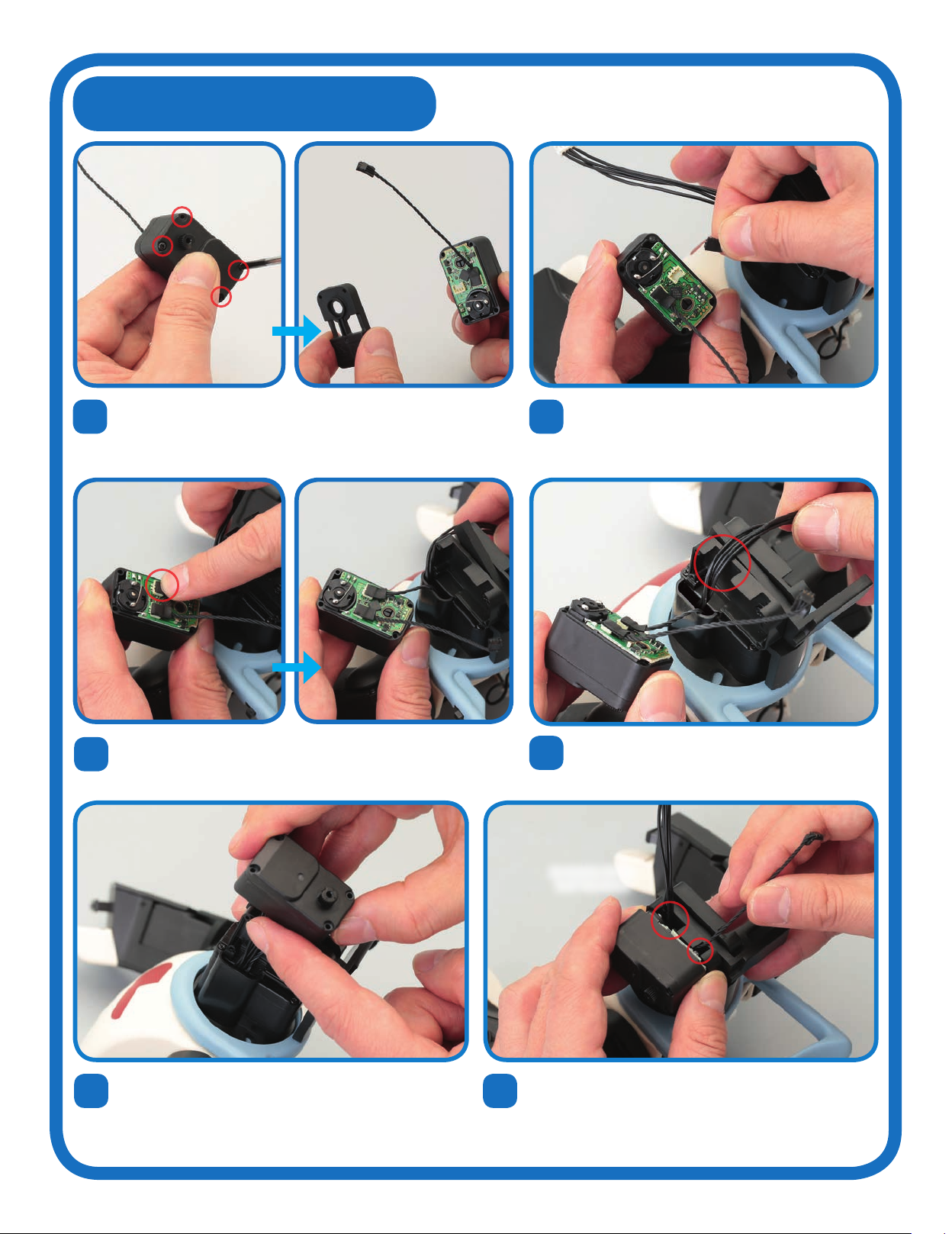

THE SERVO AND CABLE

2

3Hold the open servo with the circuit board facing upwards. Fetch the

servo cable fitted with protective pads in the previous stage, and press

one of its connectors into the socket circled in red, as you have done

before. It does not matter which end of the servo cable you use.

Gently lift the cover away, takin

care not to force it or damae

the circuit board underneath.

1Take out the four screws holdin the servo’s removable

cover in place, and keep these safely to one side.

As ever, it is very

important that the

electronic parts

exposed by removin

the servo’s cover are

not touched in any

way. Make sure to hold

the open servo by its

sides, and if you put it

down on your work

surface durin the

assembly, do this with

the open side facin

upwards.

4Pass the free end of the servo

cable throuh the circular hole in

the removable cover, as shown.

56

Press the cover back into place

on the servo’s main housin.

Fasten the cover back into place

with all four screws, but only

lihtly, as you will be removin

them aain at a later stae.

TIP!

TIP!

This servo cable had

protective pads fitted

to its connectors in the

previous stage, but if you

find it difficult to attach

with a pad in place, it is

possible to fit the pad

afterwards. If you choose

to do the assembly this

way, be especially careful

not to press down on the

circled projection, next to

the cable, as you do so.

329

TESTING THE SERVO

8

7Take the neck stand and make sure the power pack is

turned OFF. Carefully unplu the black servo cable from

the socket on the left of the test board, and attach the

servo cable connected to the servo in Step 3.

With the servo connected, switch the power to ON. After

the LEDs blink twice, only the 1 LED should liht up.

9To test the servo, press the TEST/SET switch: the servo’s shaft should rotate 45°

to the left, stop, then move back across to 45° to the riht. The next step is to set

the servo’s ID number, so keep the power on. If the test does not run, or if the LEDs

flash rapidly, refer to the HELP box in Stae 8.

SETTING THE ID NUMBER

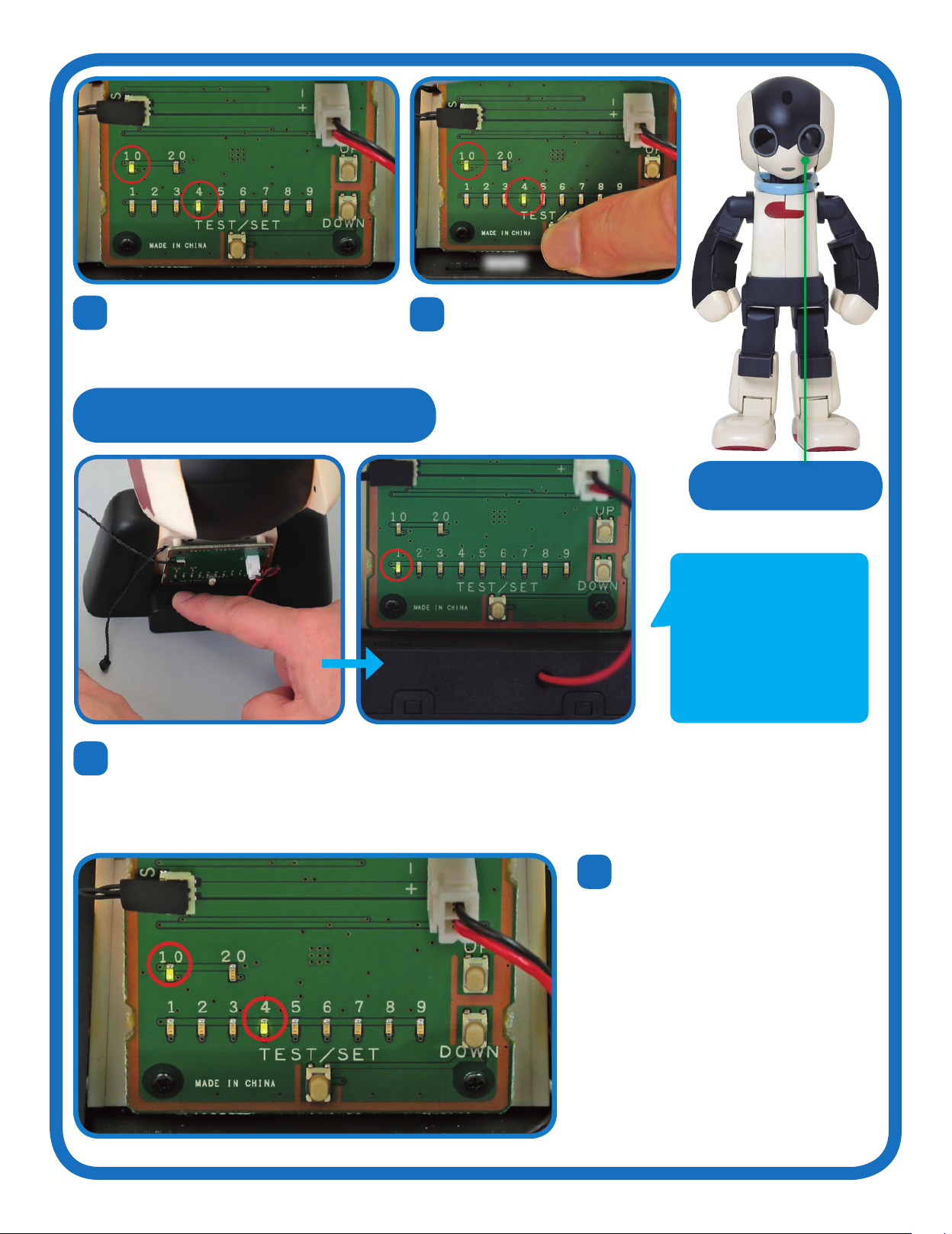

10 Next, you will set the ID number

of the servo usin the test board,

as you have done before. Each

time you press the UP switch, the

ID number increases by one, and

the result is displayed by the two

banks of LED lihts. The top row

reads in tens and the bottom in

units. For example, to set the ID to

14 as you will do in this stae, you

press UP 13 times. This will liht

up the 10 and 4 LEDs. (If you

overshoot, press the DOWN switch

to take it down one step at a time.)

When the ID number is correct,

you set it by pressin and holdin

the TEST/SET switch.

9

Units

Tens

330

TEST/SET

ID=14

11 12

To set the head servo to ID=14, press UP 13

times, so that the 10 and 4 LEDs are lit.

Pressin DOWN will adjust this if you

overshoot while doin this.

Once the numbers are correct,

press and hold TEST/SET for a few

seconds. The LEDs will blink, then

stay lit, confirmin that the ID is set.

13 It is vital that Robi’s servos are set correctly, so it is always a ood idea to check

that you have set the intended ID number afterwards. To do this, leave the servo

connected, then switch the power OFF and back ON aain. After blinkin, only the

1 LED should liht up.

14 To check the ID number, press TEST/SET

briefly. Now the 10 and 4 LEDs should

liht up and the servo shaft should repeat

the rotations seen in the test. Note: if you

find that a servo has the wron number

assined to it, o back and repeat the

settin process in full.

CHECKING THE ID NUMBER

It is normal for the 1 LED to

light up when you switch on.

It will only change to give you

the ID number of the servo

when you press TEST/SET. If

you made a mistake, or set the

wrong ID number, you can reset

it by going through the setting

procedure again.

331

BE CAREFUL NOT TO

TRAP THE CABLES

ATTACH THE FIRST HEAD SERVO

15

17

19 20

16

18

Remove all four screws aain from the servo prepared in this stae

(ID=14) and remove its cover. You will not be usin the cover aain.

Set the neck servo’s cable connector into the free socket on the

head servo ID=14.

With the VR cable still in the larer cutaway, brin the open

face of the servo towards the head frame, with the servo

shaft at the rear of the assembly, closest to Robi’s scarf.

Make sure the VR cable is still in the larer cutaway,

then run the servo cable into the smaller cutaway in the

frame. Be careful not to disturb the connectors on the

servo’s face as you do this, or to trap or pinch any of the

cables themselves.

Line up the servo to the left-hand side of Robi’s

neck base. Take the servo cable leadin from the

neck base in your hand.

Run the four-strand VR cable, also leadin from the

neck base, into the larer, circled cutaway in the left

side of the head servo frame.

332

21

22

24

26

23

25

Join the servo to the frame – checkin aain as

you do so that none of the cables are trapped, and

that the connectors stay in place. Use all four screws removed in Step 15 to secure the servo to the

head frame.

Remove all four screws holdin the neck servo in place. Keep

these, as you will be usin them aain.

Now unhook the servo cable by hand to free servo ID=15.

Carefully remove Robi’s head from the neck stand.

Gently lift the servo away from its base, but do not

move it far enouh to disconnect the servo cable.

REMOVING SERVO ID=15

333

27

29

31

30

28

Position servo ID=15 next to the free side of the head

frame, on the riht side of Robi’s neck base. Line up the

servo cable leadin to servo ID=14, fitted in this stae, to its

open face.

Brin the servo to the frame, and pass the servo cable

connected in the previous step throuh the circled cutaway.

Use all four screws removed in Step 24 to secure the servo to the head frame.

Join the servo to the frame, makin sure the servo cable

is not trapped and remains neatly in the cutaway. Pullin

ently upwards as you combine the parts will achieve this.

Connect this servo cable to one of the sockets. The other

will not be used.

MAKE SURE THE CABLE

IS NOT TRAPPED

ATTACH THE SECOND HEAD SERVO

334

ROBI’S HEAD, NECK STAND AND TEST BOARD

Robi’s head contains a number of his most vital electronic components, which you will

bein to add in the comin staes. The first components you will fit, in Stae 62, are the

infrared sensors that identify movement and are set into the centre of his eyes. Then, later

on, you will add the LEDs that illuminate his eyes and liht up his mouth to ive him his

expressive character. The head will also hold key parts used for his voice-reconition

capabilities, and more!

Robi’s head

Althouh you have disassembled the neck stand in recent

staes, you will be usin it and the test board that it holds

aain, so keep it safely until then!

USING THE NECK STAND AND TEST BOARD

Althouh you have removed the scarf, neck servo and head, you will continue usin the neck stand, and the test board it

holds, to check or reset servos’ ID numbers. The process for doin this will be the same as before, thouh is actually a

little more straihtforward, as you can now use the neck stand’s existin servo cable (previously used to connect the

neck servo) to connect to the servo in question. The steps for performin a servo test this way are found below.

1Ensure the neck stand’s servo

cable is connected securely to

the test board, then set the

other end to the servo you wish

to check/reset.

2Bein the process of testin/

resettin the chosen servo in

the usual way.

3To complete the test, simply turn

the test board OFF and carefully

disconnect the servo.

335

TEST THE NECK AND HEAD SERVOS

32

35 36

37

33 34

Push the switch on the scarf

to the OFF position.

Turn Robi’s switch ON.

The test will bein as

soon as power is turned

on, so be prepared!

As well as the servos

focused on in these steps,

the arms will also move,

so hold Robi in a way that

will not interfere with this.

The test will bein once the power is turned on.

First, observe the left-hand head servo, ID=14,

which will return to its neutral position, then

rotate a small way clockwise, raisin the D-cut

section upwards. Look very closely, as the

movement will be minimal (inset). Robi’s neck

servo, ID=13, will then rotate. Once that is done,

Robi will say ‘OK!’

While the neck servo is performin its

rotation, Robi’s second head servo,

ID=15, will also run its test, this time

rotatin anticlockwise a little to

aain raise its D-cut upwards

(inset). Once you are happy

with the test, disconnect

the power.

Connect the battery to the power

distribution board, in socket CN1.

Now connect the power/switch cable to

socket CN3.

STARTING

POSITION

STARTING

POSITION

Remember, to see all of Robi’s assembly

stages, including this one, visit the

ModelSpace web page at:

www.model-space.com

Assembled

body and

head servos

Each of the white plastic

connectors has a small barb

on one side, which holds the

connector securely in its

socket. To unplu a connector

easily and safely, press the

barb inwards – never pull on a

connector without doin this!

ATTENTION! !

Robi sayin ‘OK!’ is only to test his speaker, not to arm that the

movement test went as planned. If the movement tests do not o

as described, see the box in Stae 59, or the troubleshootin uide

later in this stae.

336

TROUBLESHOOTING

In this section, we look aain at what to do if the movement test carried out in this stae does

not o as described. As the arms have been tested previously, we will focus on the operation

of the neck and back servos, as well as the speaker, from which Robi says ‘OK!’

Before dismantlin the assembly to check its individual servos, check the other electrical components used in the test.

HEAD/NECK/BACK SOCKET

CHECK THAT THE CABLE IS CONNECTED TO

THE CORRECT SOCKET ON THE CPU

CHECK THAT THE SERVO CABLE IS

SECURELY CONNECTED TO THE CPU

CHECK THAT THE

BATTERY IS CHARGED

Ensure that the back servo

cable’s connector is sittin

securely within its socket.

Remove and replace it carefully

if need be.

The socket farthest from

the micro SD card slot on

the CPU board will hold the

servo cable runnin from

the back servo.

The test will only run if sucient

power is received from the

battery, so make sure the battery

is fully chared (see the Close-

Up box in Stae 59).

INITIAL CHECKS

Neck stand (Stage 53)

Alon with the Phillips screwdriver

supplied with Stae 2, you will need

the followin:

IF NEITHER HEAD SERVOS MOVES

If neither head servo moves when you start the test, it is

probable that there is a misplaced connection, so o back

and check these. If this does not resolve the issue, you will

need to check/reset their ID numbers.

DISASSEMBLY

Follow the assembly of Steps 15-31 of this stae in reverse, and

carefully check the connections made in the steps before. If

both were sound, you will need to check the servos’ ID numbers,

resettin them if necessary.

IF ONLY ONE SERVO MOVES

If one servo moves but the other does not, it is likely that one

of the ID numbers has been set incorrectly.

If you need to reset Robi’s head servos, they are ID=14 (left-

hand side of head servo frame, prorammed in this stae) and

ID=15 (riht-hand side of frame, prorammed in Stae 59).

337

Other De Agostini Robotics manuals