DEC VR315 User manual

VR315andVR325MonochromeMonitors

ServiceGuide

Order Number EK-VR315-SV-002

Digital Equipment Corporation

Second Edition, February 1991

The information in this document is subject to change without notice and should not

be construed as a commitment by Digital Equipment Corporation. Digital Equipment

Corporation assumes no responsibility for any errors that may appear in this document.

The software described in this document is furnished under a license and may be used or

copied only in accordance with the terms of such license.

No responsibility is assumed for the use or reliability of software on equipment that is not

supplied by Digital Equipment Corporation or its affiliated companies.

Restricted Rights: Use, duplication, or disclosure by the U. S. Government is subject to

restrictions as set forth in subparagraph (c) (1) (ii) of the Rights in Technical Data and

Computer Software clause at DFARS 252.227–7013.

Copyright © Digital Equipment Corporation 1991

All Rights Reserved.

Printed in U.S.A.

The following are trademarks of Digital Equipment Corporation:

DEC DIBOL UNIBUS

DEC/CMS EduSystem VAX

DEC/MMS IAS VAXcluster

DECnet MASSBUS VMS

DECsystem–10 PDP VT

DECSYSTEM–20 PDT

DECUS RSTS

DECwriter RSX

dt

This document was prepared and published by Educational Services Development and

Publishing, Digital Equipment Corporation.

Contents

About This Manual vii

1 Overview

1.1 Product Description ................................ 1–1

1.1.1 Model Variations ................................ 1–2

1.2 Tools and Equipment ............................... 1–2

1.3 Recommended Spare Parts List ....................... 1–3

2 Troubleshooting

2.1 Before You Start. . . ................................ 2–1

2.2 Troubleshooting Procedures . . ........................ 2–2

2.3 Troubleshooting Tables.............................. 2–2

3 Removing and Replacing FRUs

3.1 Introduction ...................................... 3–1

3.1.1 Removing the External Cables ...................... 3–2

3.1.2 Removing the Rear Cover . ........................ 3–3

3.1.3 Removing the Top Cover . . ........................ 3–4

3.2 Field Replaceable Units (FRUs)....................... 3–5

3.2.1 Interconnect Cable ............................... 3–6

3.2.2 Power Supply Module ............................ 3–8

3.2.3 Discharging the CRT and Removing the Anode Cap ..... 3–10

3.2.4 Deflection Module ............................... 3–12

3.2.5 Video Casting Assembly . . . ........................ 3–16

3.2.6 CRT/Chassis Assembly............................ 3–20

3.3 CRT Disposal (Trained Service Personnel Only) . . . ....... 3–21

3.4 Tilt-Swivel Base . . ................................ 3–24

iii

iv Contents

4 Aligning the Video Monitor

4.1 Introduction ...................................... 4–1

4.1.1 Before You Start. ................................ 4–1

4.1.2 Check LEDs and Heater Filament................... 4–4

4.1.3 Displaying Screen Tests . . . ........................ 4–4

4.2 Monitor Adjustments ............................... 4–5

4.3 Deflection Adjustments ............................. 4–6

4.3.1 Raster Adjustment ............................... 4–6

4.3.2 Anode Voltage Adjustment . ........................ 4–6

4.3.3 Height and Width Adjustments ..................... 4–6

4.4 Using the Radiance Meter . . . ........................ 4–8

4.5 Cutoff Adjustment . ................................ 4–10

4.6 GAIN Adjustment . ................................ 4–11

A VR315 and VR325 Documentation

Figures

1–1 Monochrome Monitor ............................... 1–1

3–1 Removing Cables from the Monitor .................... 3–2

3–2 Rear Cover Removal ............................... 3–3

3–3 Top Cover Removal ................................ 3–4

3–4 Field Replaceable Units ............................. 3–5

3–5 Disconnecting the Interconnect Cable . . . ............... 3–7

3–6 Removing the On/Off Switch Cable from the Power Supply . . 3–8

3–7 Removing the Power Supply . ........................ 3–9

3–8 Discharging the CRT and Removing the Anode Cap ....... 3–11

3–9 Loosening the Captive Screw . ........................ 3–13

3–10 Disconnecting Cables from the Deflection Module . . ....... 3–14

3–11 Removing the Deflection Module ...................... 3–15

3–12 Removing Cables from the Video Casting ............... 3–17

3–13 Removing the CRT Socket Connector ................... 3–18

3–14 Removing the Video Casting . ........................ 3–19

3–15 Crushing the Evacuation Point ....................... 3–23

3–16 Tilt-Swivel Base . . ................................ 3–25

4–1 User Controls and Indicator . . ........................ 4–3

Contents v

4–2 Circle-Crosshatch Pattern . . . ........................ 4–4

4–3 Using the Metric Measuring Tape ..................... 4–5

4–4 Internal Controls . . ................................ 4–7

4–5 Radiance Meter . . . ................................ 4–9

4–6 Using the Radiance Meter . . . ........................ 4–10

4–7 GAIN, G2, and FOCUS (G4) Adjustments .............. 4–11

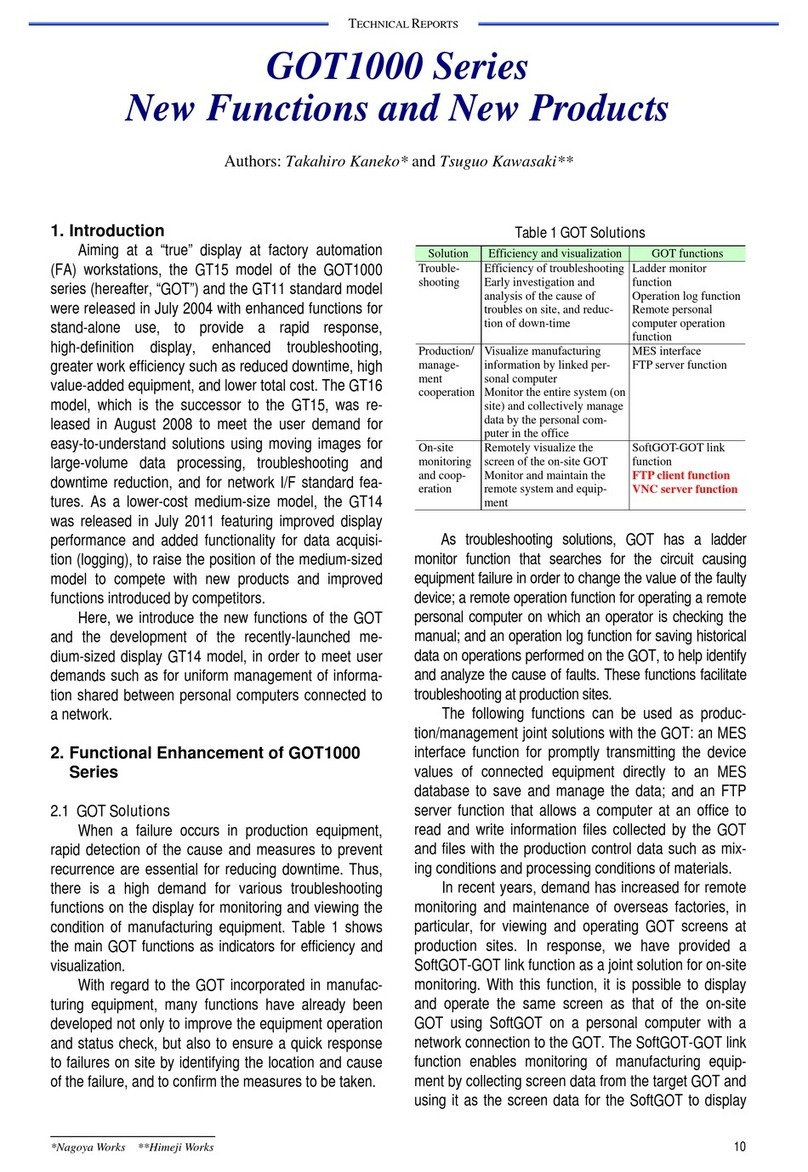

Tables

1–1 Tools and Equipment ............................... 1–2

1–2 Recommended Spare Parts. . . ........................ 1–3

2–1 Blank Screen, No Video or Raster ..................... 2–3

2–2 Blank Screen, No Video, but Raster is Present ........... 2–5

2–3 Poor Display Quality ............................... 2–6

4–1 Monitor Controls and Indicators ...................... 4–2

AboutThisManual

VR315 and VR325 Video Monitors

This guide describes how to service the VR315 and VR325 monochrome

monitors in the field.

Manual Organization

This manual is organized as follows:

• Chapter 1 provides a general overview of the product and includes a

list of spare parts.

• Chapter 2 describes the troubleshooting procedures.

• Chapter 3 provides the removing and replacing procedures for the

Field Replaceable Units (FRUs).

• Chapter 4 describes the alignment procedures.

• Appendix A describes related documentation.

Conventions

Convention Meaning

Caution Provides information to prevent damage to the equipment.

Warning Provides information that relates to personal safety.

Note Provides general information.

PN Refers to a part number.

!

This type of number in text refers to an item in an illustration.

monitor Refers to the VR315 and VR325 monochrome monitors.

vii

1

Overview

1.1 Product Description

The monochrome monitor (Figure 1–1) has a direct viewed antiglare

screen with an auto-ranging power supply for worldwide operation. Its

built-in tilt-swivel base lets the user adjust the screen for viewing comfort.

When connected to a host system, the monitor displays information sent

by the host.

MA-0299-90.DG

Figure 1–1 Monochrome Monitor

1–1

1–2 Overview

1.1.1 Model Variations

The monitor is available in the following models:

Model Applicable Area

VR315-DA Northern hemisphere

VR315-D4 Southern hemisphere

VR325-DA Northern hemisphere

VR325-D4 Southern hemisphere

1.2 Tools and Equipment

Table 1–1 lists the tools and equipment you will need to service the

monitor:

Table 1–1 Tools and Equipment

Tools and Equipment Part Number

Terminal technician tool kit 29-27340-01

Static protection kit 29-26246-00

Anode discharge tool 29-24717-00

Metric measuring tape 29-25342-00

Safety goggles 29-16141-00

Gloves 29-16146-00

Overview 1–3

1.3 Recommended Spare Parts List

Table 1–2 lists the recommended spare parts for the monitor.

Table 1–2 Recommended Spare Parts

Spare Part VR315 Part

Number VR325 Part

Number

Power supply 54-19629-02 54-19629-03

Deflection module 54-19826-01 54-19826-02

Video casting assembly 70-27073-01 70-27073-01

Module interconnect cable 70-27000-02 70-27000-02

CRT/chassis assembly

Northern Hemisphere 70-27477-01 70-27481-03

Southern Hemisphere 70-27477-02 70-27481-04

2

Troubleshooting

This chapter describes how to troubleshoot a monitor problem through

fault isolation.

2.1 Before You Start

The following information will help you troubleshoot the monitor easily

and effectively:

WARNING

If you smell burning components, press the monitor power switch

off and disconnect the power cord.

• If you are going to service a display quality type of problem, tell the

customer to warm the monitor up for at least 20 minutes, if possible,

before you arrive and begin the troubleshooting procedures.

• Magnetic fields affect monitor performance and can give a false

indication of a monitor failure. Place the monitor away from any

electromagnetic devices such as printers and terminals, or away from

large magnetized objects such as filing cabinets and steel beams in

walls.

NOTE

Any time you replace a video casting assembly, deflection module,

or power supply module, perform all the necessary adjustments.

Refer to Chapter 3.

2–1

2–2 Troubleshooting

2.2 Troubleshooting Procedures

These procedures assume that only one assembly has failed or only one

problem exists. Always troubleshoot the most obvious symptom first;

however, one symptom may indicate multiple failures. Problems may

come from either the host system or the monitor.

Troubleshoot the monitor as follows:

1. Ask the operator to describe the problem. The operator often is the

most knowledgeable.

2. Identify the problem. The screen display often indicates which

problem is occurring.

3. Isolate the problem. Refer to the troubleshooting tables (Section 2.3)

to find the suggested solutions.

4. Display the host system alignment test patterns to make sure that

no other problem exists. Refer to the host system service guide for

displaying test patterns.

2.3 Troubleshooting Tables

The troubleshooting tables list the possible cause in order of probability.

This troubleshooting information applies to three types of video problems

that the monitor may exhibit:

• A blank screen, without video or raster (Table 2–1)

• A blank screen, without video, but raster present (Table 2–2)

• Poor display quality (Table 2–3)

Use the troubleshooting tables as follows:

1. Note the symptom of the problem.

2. Check the Symptom column for a match.

3. Check the conditions in the Possible Cause column in the order given.

4. Perform the action in the Suggested Solution column in the order

given.

Troubleshooting 2–3

Table 2–1 Blank Screen, No Video or Raster

Symptom Possible Cause Suggested Solution

Blank screen, no video

or raster. Power to

the monitor is on (the

power switch is in) but

the power indicator

light is off.

The power cord is

not connected to

the power source or

monitor.

Connect the power cord to the

power source or monitor.

Low or no power at

wall outlet. Use another wall outlet. If

the problem continues, call the

facilities person.

Power supply

module is faulty. Replace the power supply

module (Section 3.2.2).

Deflection module

is faulty. Replace the deflection module

(Section 3.2.4).

Video module is

faulty. Replace the video casting

assembly (Section 3.2.5).

No video or raster, but

the power indicator is

on.

Brightness or

contrast is set

incorrectly.

Adjust the brightness and

contrast controls.

Power to the host

system is not on. Turn power to the host system

on.

Host signal cable is

disconnected. Connect the signal cable to the

monitor and host.

2–4 Troubleshooting

Table 2–1 (Cont.) Blank Screen, No Video or Raster

Symptom Possible Cause Suggested Solution

Deflection module

is faulty. Replace the deflection module

(Section 3.2.4).

Video casting

assembly is faulty. Replace the video casting

assembly (Section 3.2.5).

CRT/chassis

assembly is faulty. Replace the CRT/chassis

assembly (Section 3.2.6)

only after trying the previous

solutions.

No video or raster, but

the power indicator

and LED on the

deflection module are

on.

Internal cabling is

loose or faulty. Check all cabling going to

the deflection module and

the video casting assembly,

including the CRT socket

connector. If necessary, secure

the cables.

G2 Bias is set

incorrectly. Correct the G2 adjustment.

(Section 4.5).

Signal cable is

faulty. Replace the signal cable.

Refer to the host system

documentation.

Deflection module

is faulty. Replace the deflection module

(Section 3.2.4).

No video or raster, but

the power indicator

LED is on; the

deflection module

LED is off.

Deflection module

is faulty. Replace the deflection module

(Section 3.2.4).

Troubleshooting 2–5

Table 2–2 Blank Screen, No Video, but Raster is Present

Symptom Possible Cause Suggested Solution

Raster can be

displayed by

adjusting the

brightness control,

but no video or

cursor can be seen

even when the

contrast control is

at maximum.

The Host system

CRT screen saver

feature is activated.

Press any key to reactivate the

display.

Internal cabling is

loose or faulty. Check all the cables to the

deflection module and the

video casting assembly.

The host system

is not supplying

video signals to the

monitor.

Connect the monitor to a

known working host system (if

available) to verify the problem

before replacing any monitor

modules.

Host system is

faulty. Repair the host system.

Video casting

assembly is faulty. Replace the video casting

assembly (Section 3.2.5).

Deflection module is

faulty. Replace the deflection module

(Section 3.2.4).

Faulty CRT/chassis

assembly Replace the CRT/chassis

assembly (Section 3.2.6)

only after trying the previous

solutions.

2–6 Troubleshooting

NOTE

Make sure the monitor has warmed up for at least 20 minutes

before you use Table 2–3.

Table 2–3 Poor Display Quality

Symptom Possible Cause Suggested Solution

Poor geometry,

centering, height,

width, and/or

linearity.

Controls on top of the

monitor are out of

adjustment.

See section 4.1.

Local magnetic fields. Remove any electro-

mechanical devices from

the vicinity of the monitor, or

move the monitor to another

location.

Monitor is out of

adjustment. Perform the alignment

procedure. Refer to Chapter

4.

Deflection module is

faulty. Replace the deflection module

(Section 3.2.4).

CRT/chassis assembly

is faulty. Replace the CRT/chassis

assembly (Section 3.2.6) only

after trying the previous

solutions.

Poor light output

(using the all-white

diagnostic pattern).

The Display is not

bright enough.

The brightness or

contrast control is set

incorrectly.

Adjust the brightness and

contrast controls.

Host system is not

supplying correct

signal levels.

Repair the host system.

GAIN and Cutoff

adjustments may be

incorrect.

Perform the GAIN

adjustment (Section 4.6)

and the Cutoff adjustment

(Section 4.5).

Video casting

assembly is faulty. Replace the video casting

assembly (Section 3.2.5).

Deflection module is

faulty. Replace the deflection module

(Section 3.2.4).

Troubleshooting 2–7

Table 2–3 (Cont.) Poor Display Quality

Symptom Possible Cause Suggested Solution

CRT is worn out. Replace the CRT/chassis

assembly (Section 3.2.6) only

after trying the previous

solutions.

Display is too bright. Brightness control is

set incorrectly. Set the brightness control to

the optimum range.

Video casting

assembly is faulty. Replace the video casting

assembly (Section 3.2.5).

Deflection module is

faulty. Replace the deflection module

(Section 3.2.4).

Vertical lines are not

straight. Local magnetic fields

are present. Remove any electro-

mechanical devices from

the vicinity of the monitor, or

move the monitor.

Deflection module is

faulty. Replace the deflection module

(Section 3.2.4).

Faulty CRT/chassis

assembly Replace the CRT/chassis

assembly (Section 3.2.6) only

after trying the previous

solutions.

Video noise (Display

has intermittent

flashing or changes

in brightness.)

The signal cable is

loose or faulty. Reseat the connectors or

replace the signal cable.

Video casting

assembly is faulty. Replace the video casting

assembly (Section 3.2.5).

Deflection module is

faulty. Replace the deflection module

(Section 3.2.4).

Power supply module

is faulty. Replace the power supply

module (Section 3.2.2).

Host system is faulty. Repair the host system.

Focus is not sharp. Adjustment is

incorrect. Perform the FOCUS

adjustment (Section 4.5).

Deflection module is

faulty. Replace the deflection module

(Section 3.2.4).

2–8 Troubleshooting

Table 2–3 (Cont.) Poor Display Quality

Symptom Possible Cause Suggested Solution

Video casting

assembly is faulty. Replace the video casting

assembly (Section 3.2.5).

CRT/chassis assembly

is faulty. Replace the CRT/chassis

assembly (Section 3.2.6) only

after trying the previous

solutions.

This manual suits for next models

1

Table of contents

Other DEC Monitor manuals