deconta decontamination mobile D 3000 Manual

Guide book

mobile lock

decontamination mobile

D 3000 / 4000 / 5000

Manufacturer: deconta GmbH

Im Geer 20, 46419 Isselburg, Germany

Denomination: decontamination mobile D 3000 / 4000 / 5000

Type-No. : 484

Serial-No. : ………………

Guide book

D 3000 / 4000 / 5000

Seite 2

Table of contents

on Page

1 Operation on road traffic 3

1.1 General trailer description 3

1.2 Controls before each journey 4

1.3 Regular control and maintenance 5

1.4 Wheels, tyres and wheel replacement 6

1.5 Transport / towing, coupling and axle load 7

1.6 Connection 7

1.7 Uncoupling 8

1.8 Reverse track 8

2 Technical description 9

3 Initial operation 10

3.1 Electric-Version 10

3.1.1 Energy supply 10

3.1.2 Tank filling 10

3.1.3 Room heating 11

3.1.4 Negative pressure plant 12

3.1.5 Shower 13

3.1.6 Sewage water filtering plant 13

3.1.7 Filter change 15

3.1.8 Light 15

3.2 Electric-Version with forced locking 16

3.2.1 Activation forced locking 16

3.2.2 Lock system procedure 16

3.3 Diesel-Version 18

3.3.1 Energy supply 18

3.3.2 Tank filling 18

3.3.3 Room heating 20

3.3.4 Negative pressure plant 20

3.3.5 Shower 21

3.3.6 Sewage water filtering plant 21

3.3.7 Filter change 23

3.3.8 Light 23

3.4 Gas-Version 24

3.4.1 Energy supply 24

3.4.2 Water supply with tap water 24

3.4.3 Water supply autarkic (Option) 25

3.4.4 Gas fired heating 25

3.4.5 Negative pressure plant 26

3.4.6 Shower 27

3.4.7 Sewage water filtering plant 27

3.4.8 Filter change 29

3.4.9 Light 29

4 Equipment and options 30

5 Spare parts 32

6 Technical data 38

6.1 Dimensions 38

6.2 Circuit vehicle lightning 39

6.3 Connection diagram plug 40

6.4 Circuits vehicle technology Electro-Version 41

6.5 Circuit s vehicle technology Electro-Version with forced locking 43

6.6 Circuits vehicle technology Diesel-Version 46

6.7 Circuits vehicle technology Gas-Version 48

6.8 Efficiency of the sewage water filtration 50

7 Operation time on battery 51

8 Declaration of conformity 52

Guide book

D 3000 / 4000 / 5000

Seite 3

1 Operation on road traffic

1.1 General trailer description

Vehicle class:

Trailer of the vehicle class O1 0 kg to 750 kg gross vehicle weight.

Trailer of the vehicle class O2 750 kg to 3500 kg gross vehicle weight.

Coupling system

Tow ball coupling Ø 50 mm according to 9420/EG

Electrical connections of the towing vehicle

Plug connection, 13-pin, according to ISO 11446

Box construction

Floor, extern and intern wall material in Sandwich – structure.

Frame construction in Aluminium.

Operation limits

Dimension, type and equipment determine the gross vehicle weight and the coupling load

of a trailer at delivery ex works. Loading and unloading done by the user change the

coupling load the weight. Following operation limits must not be exceeded or undercut.

Permissible maximum speed 80 km/h

Permissible total weight see name plate

Permissible coupling load min. 40 kg max. 100 kg

Permissible floor load 100 kg/m², equally distributed (only within

approved limits)

Permissible ceiling load none

Driving during storm or squalls is prohibited.

National laws for the operation of the trailer for the road traffic take precedence

over the statements listed in this guide book.

Guide book

D 3000 / 4000 / 5000

Seite 4

1.2 Controls before each journey

Has the trailer been controlled in regard to completeness, loose parts and

intactness?

Have the support stands been fully pulled in?

Has the spherical head been locked audibly and visibly (see 1.6)?

Has the breakaway cable been wrapped around the coupling?

Has the jockey wheel been raised and secured?

Have all electrical connections been established?

Has the hand-brake been unlocked?

Have all wheel-chocks been removed?

Have the lights been checked?

Has the tyre and air pressure been controlled?

Have all doors been closed and secured?

Is the roof free of snow and ice?

Before starting each journey you have to test, if:

the overrunning brake works,

the brakes react steadily,

the vehicle stays on track during braking.

Please adapt yourself to a changed driveability when towing a trailer: bigger vehicle

width, lower acceleration power and prolonged braking distance!

Faults in the braking system must at once be repaired by an authorized specialist

workshop.

Guide book

D 3000 / 4000 / 5000

Seite 5

1.3 Regular controls and maintenance

Axle

After 1500 km or 6 months

Have the axial play of the hub bearing checked and

adjusted, if necessary.

Every 10000 km or every 12 months

Check wheel brake linings of wear via the inspection

hole (see adjacent picture). Adjust if necessary. Where

continuous travel in hilly regions or high mileage is

experienced, earlier inspection and adjustment may be

necessary.

Check quantity and quality of grease of the tapered

roller bearing, renew if necessary.

N.B. All necessary service work should be carried out by

trained personnel in specialist workshops or service stations.

Please also obey the corresponding guide book of company AL-KO Fahrzeugtechnik

GmbH.

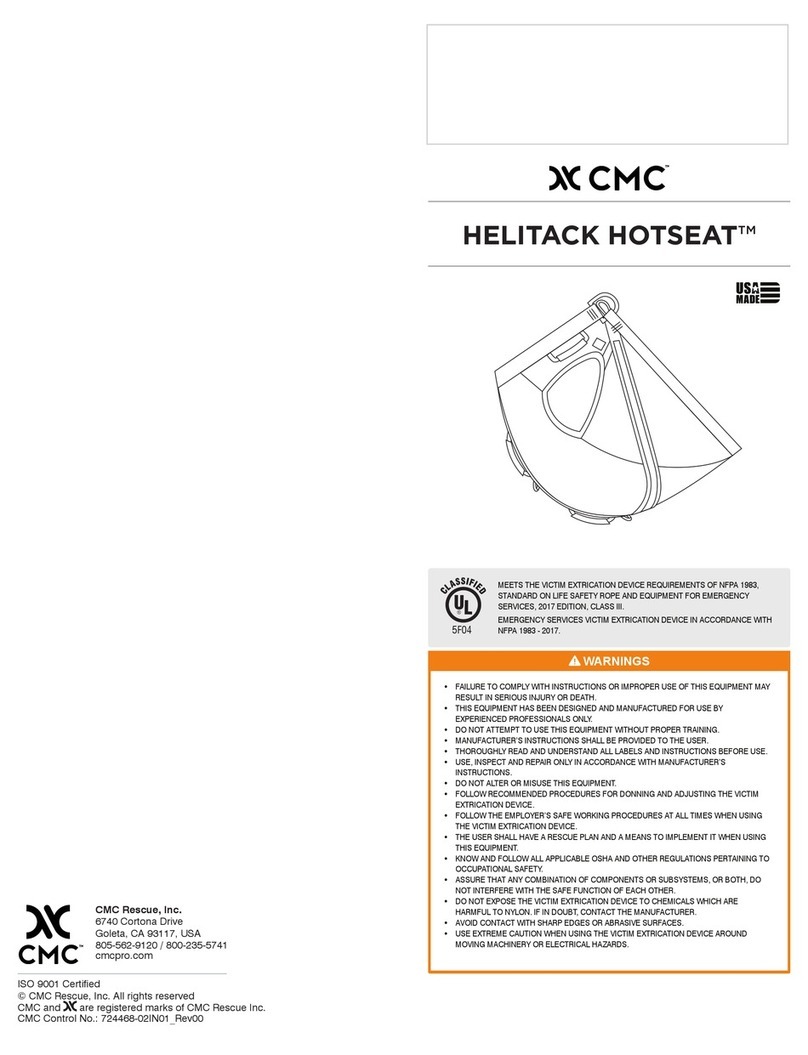

Overrun device

Every 10000 – 15000 km or every 12 months

Lubricate/grease all sliding and moving parts

of the overrun device as shown in the

adjacent picture.

Please also obey the corresponding guide book of

company AL-KO Fahrzeugtechnik GmbH.

Coupling head

Weekly or when obviously dirty

Control the coupling head and clean if necessary.

Lubricate/grease the ball cup, joints and bearings.

Lubrication points see adjacent picture.

Please also obey the

corresponding guide book of

company AL-KO Fahrzeugtechnik GmbH.

Guide book

D 3000 / 4000 / 5000

Seite 6

1.4 Wheels, tyres and wheel replacement

Check regularly the steady wear tread, the tread depth and the external damages

of the tyres. Please observe the minimal tread depth officially required.

Use only authorized tyres in accordance with the wheel rim type (see registration

certificate).

Use always tyres of the same construction, the same make and same version

(Summer- or winter tyres).

Tighten the wheel nut cross wise,

Tightening torsional moment 90 – 110 Nm.

Check again after first journey (after approx. 100 km).

Check the pressure of the cold trailer tyres regularly before the journey.

Tyres Pressure in bar

195 / 50 B 10 6,0

The statement of the value of the tyre pressure applies to the cold tyres. The trailer is steadily adapted to the newest

technical standard. It is possible that new tyres sizes are not considered in this chart. In this case, deconta provides

you the newest values.

Wheel change:

The trailer must stay on an even, firm and slip-free soil.

For the wheel change, please use the supplied car jack.

Before lifting the trailer, the hand brake has to be applied tightly.

Ensure that the trailer cannot roll away using wheel chocks placed on the opposite

side.

Do not ever lift the vehicle with the attached landing gear

Fix the car jack only in the provided and marked place.

Do not lay down under the lifted trailer

If you use wheel rims or tyres which are not allowed for the trailer, the road traffic

security can be affected.

Guide book

D 3000 / 4000 / 5000

Seite 7

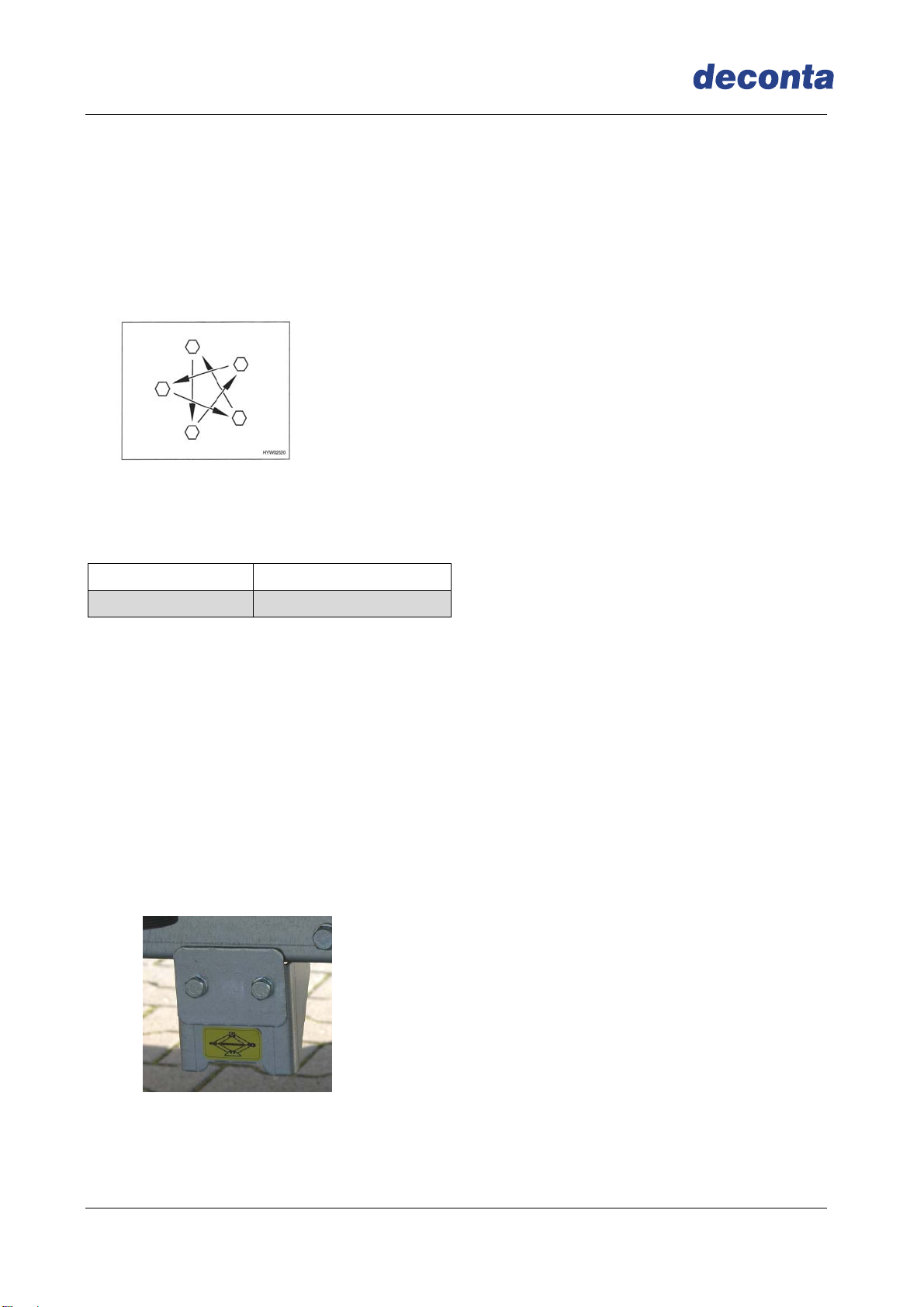

1. 5 Transport/ towing, coupling and axle load

The important for the choice of the towing vehicle

and trailer are statements which are listed in the

registration certificate and defined in the operation

limits.

The quoted trailer load of the towing vehicle gives

information about which maximal weight the towing

vehicle is allowed to tow.

The coupling load indicates with which power the

drawbar of the trailer is allowed to press on the on

the tow-bar of the towing vehicle. The maximal

permitted coupling load may not be exceeded and

the minimal coupling load may not be undercut

The Transport of the trailer is only permitted with

vehicles which can prove the coupling load listed in

the operation limits for their tow-bar.

The axle load accounts for the permitted peak load

for the front and back axle of the towing vehicle and

may not be exceeded by the trailer.

1.6 Coupling

Manoeuvre towing vehicle and trailer to the coupling point

Do not couple the trailer with overrunning brake

Manoeuvre the trailer with help of the drawbar jockey wheel onto the towball of the

towing vehicle

Put the open coupling (coupling head handle pulled upwards) and wind down the

jockey wheel on the tow-bar of the towing vehicle

The coupling head handle locks independently and audibly (if necessary press

downward additionally with the hand); locking and securing happen automatically

Wrap the breakaway cable with a loop around the towball of the tow-bar of the towing

vehicle.

Wind the jockey wheel up fully and clamp securely in the direction of travel

Connect trailer electric plug of the trailer in the socket of the towing vehicle and take

care that the connection cables do not drag on the road

Check the lights

Remove all wheel chocks

Slacken the handbrake

1 Trailer load

2 Coupling load

3 Axle load

Guide book

D 3000 / 4000 / 5000

Seite 8

Caution:

It is only coupled correctly when the green cylinder of the locking display becomes

visible. Please mind that the inside of the coupling is not dirty and that the

movable parts are smooth-running.

1.7 Uncoupling

Apply hand-brake of the trailer fully

Secure trailer by chocking both wheels an

Remove the breakaway cable of the towing vehicle

Unplug the light plug and fix it in the holder on the drawbar

Wind down the jockey wheel until it has firmly reached the soil

Push firmly the coupling handle upwards and slacken

Raise the drawbar with help of the jockey wheel as far as one can drive away without

danger

After the uncoupling respect following:

Place the trailer on a straight and even surface

Secure the trailer against rolling backwards even by slopes or descents

1. by applying the fixing brake of the drawbar

2. by placing the chocks under the wheels

Lower the landing gear in order to give the trailer a safe position.

1.8 Reverse track

With a reverse automatic the backing up of the trailer is possible without problems. In

addition to a rolling resistance, a remaining brake force has to be overcome.

Locking display

Guide book

D 3000 / 4000 / 5000

Seite 9

2 Technical description

The mobile lock is a multi-chambers system which enables the gradual entry in a

contaminated area as well as the leaving in various phases, without the spreading of

fibres.

In this mobile lock system, a negative pressure is produced in order to prevent the entry

in other rooms or outdoors of the asbestos fibres, whether through an air exchange or

spreading through e.g. the working suits.

Lock in and out process according to the country-specific laws.

Floor-, extern and intern walls in Sandwich construction.

Electric- Water heating

by 3 kW heating rod, 220 Liter stainless steel - fresh water tank, 230 Volt power

supply necessary for operation

Diesel- Water heating and room heating

Warm water heating through 4 kW WEBASTO - Diesel warm water producer,

220 Liter stainless steel - fresh water tank. An integrated battery enables the use

of all consumers without external current connection. (Autarkic operation, with a

connection of 230 Volt the batteries are loaded automatically)

Gas- Water heating

continuous flow heater with 11 kW, power supply of 230 Volt only necessary for

use of extra consumers, water connection necessary

Gas- Water heating autarkic

continuous flow heater with 11 kW, 4 x 30 Liter fresh water canister. An integrated

battery enables the use of all consumers without external current connection.

(Autarkic operation, with a connection of 230 Volt the batteries are loaded

automatically

Guide book

D 3000 / 4000 / 5000

Seite 10

3 Initial operation

3.1 Electric-Version

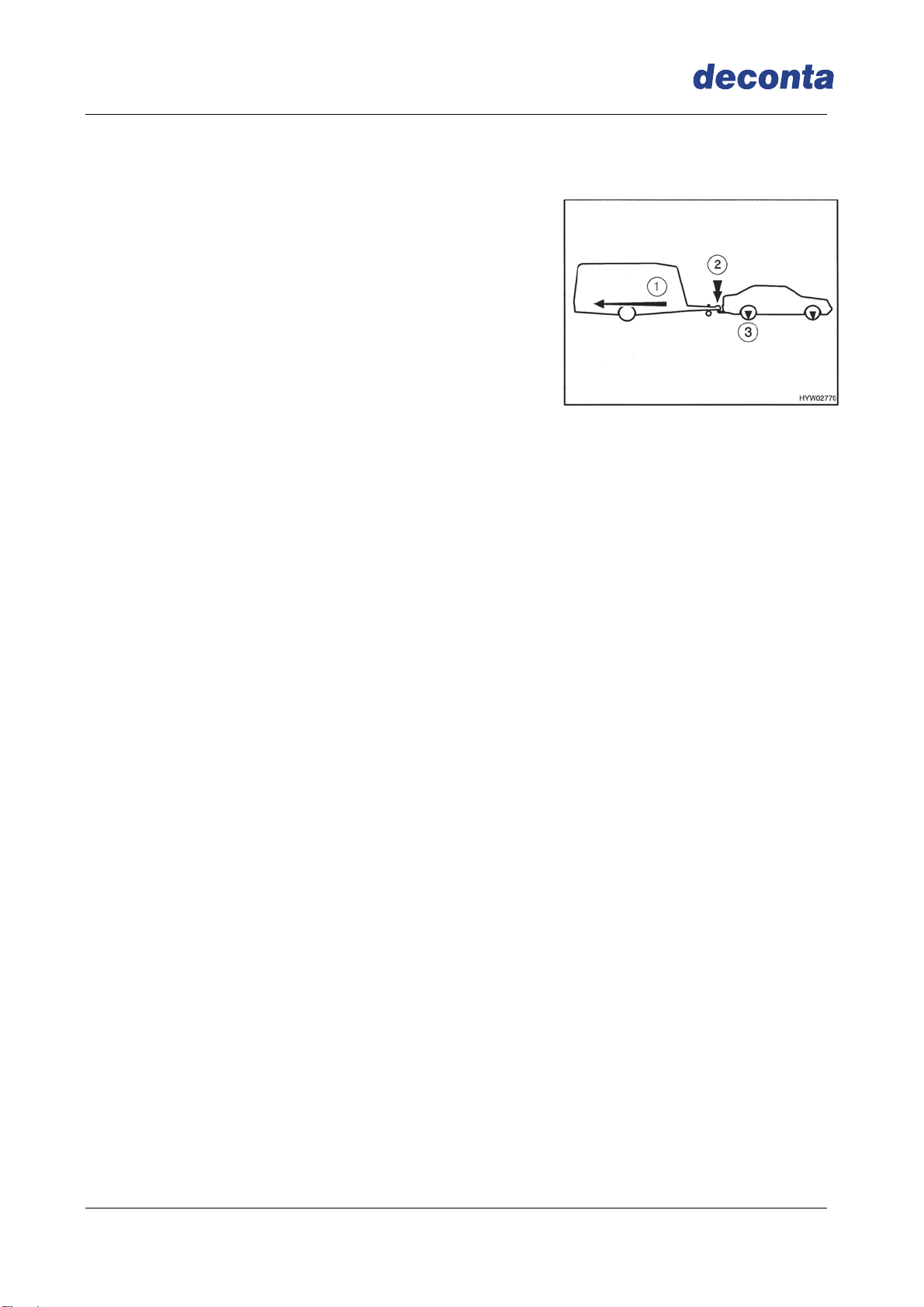

3.1.1 Energy supply

The electric supply takes place from the outside at the connection "Supply" (230 Volt). If

the supply has occurred, the socket inside the vehicle is activated.

3.1.2 Tank filling

In the vehicle, there is 220 litres fresh water tank.

The filling occurs from the outside via the GEKA connection at the connection fresh

water.

Connect the fresh water hose and open the conduct

Switch on the main plug (if power supply is connected correctly the control lamps

basic function and heating are illuminated)

Tank fills up to minimal mark

To reach desired shower temperature move red hand in thermostat

(usually onto 36-37°C)

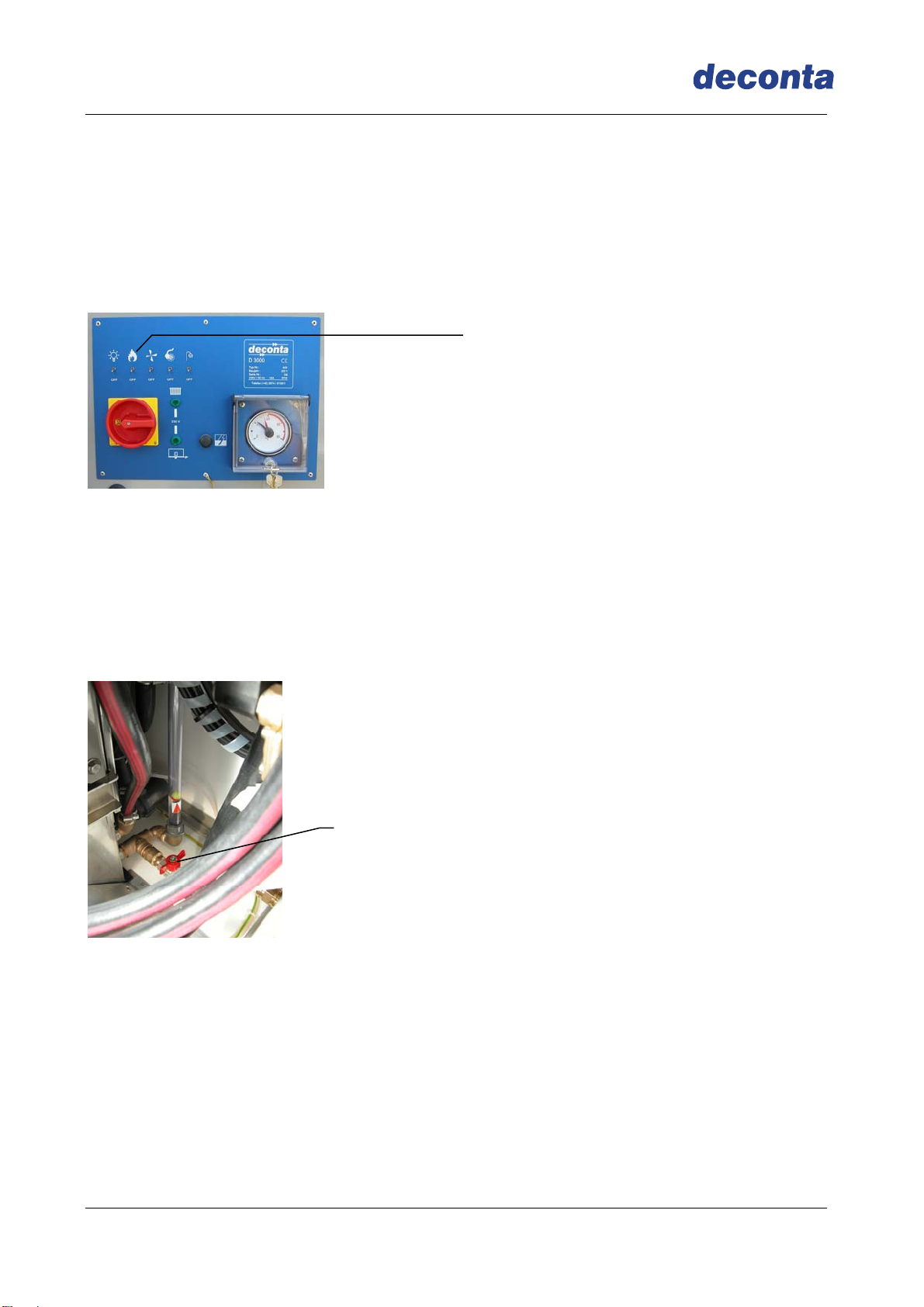

Connector fresh water

Connector sewage water

Main plug

Thermostat

Power supply – basic function

Power supply – room heating

Control lamp heating

Control lamp basic function

Guide book

D 3000 / 4000 / 5000

Seite 11

Switch on the water heating. The water in the tank is heated up to the chosen

temperature.

When the water in the tank has reached the required temperature, fresh water is

automatically added.

If the temperature in the tank drops about 2°C, the fresh water supply will be

stopped and the water will be heated again.

This procedure is repeated until the tank has been fully filled.

Thanks to this way of filling (Step by Step) you have after a short time tempered shower

water at your disposal.

ATTENTION: Never drive the trailer with a full tank!

For the emptying of the tank, there is a ball valve placed in the technical room. If you

open it, all the water runs out under the vehicle

3.1.3 Room heating (optional equipment)

Room heating through 2000 Watt Wall heater. A thermostat at the wall heater regulates

the desired room temperature.

Water heating

Ball valve for draining of

tank

Guide book

D 3000 / 4000 / 5000

Seite 12

3.1.4 Negative pressure plant (optional equipment)

To avoid the danger of the spreading of dust out of the dirty area to the clean area, all

rooms are ventilated. In the dirty area, the air is sucked in and blown out through P3

filters.

Through the fresh air openings, the shower and the clean area are also ventilated. The

fresh air openings have been scaled in such a way that a pressure drop prevails going

from the dirty area to the clean area.

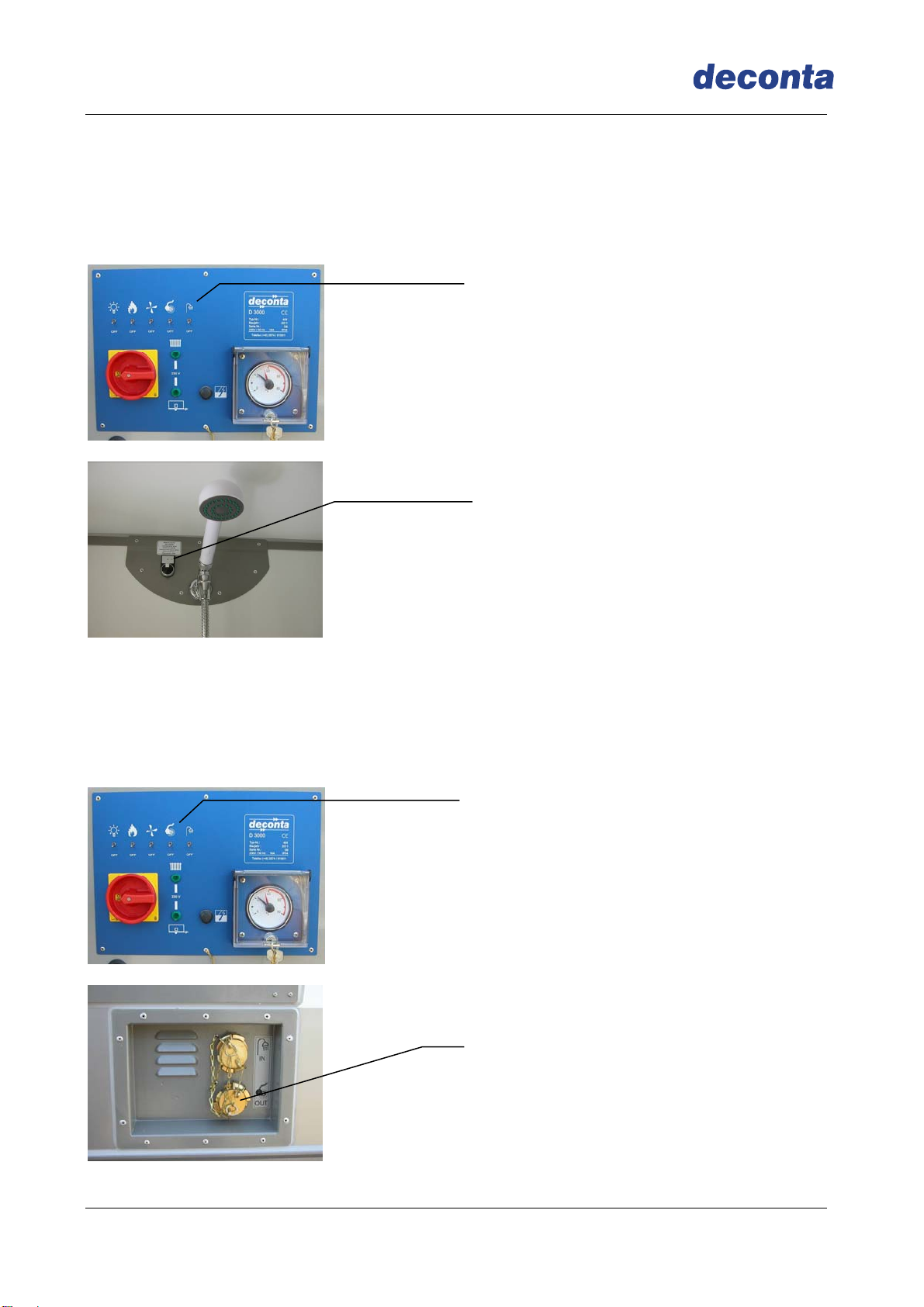

Negative pressure plant

Negative pressure plant

Guide book

D 3000 / 4000 / 5000

Seite 13

3.1.5 Shower

The switch shower in the technical room switches the shower water pump ready for use.

The shower procedure can only be started and stopped via the switch „Shower procedure

Start“.

3.1.6 Sewage water filtering plant (optional equipment)

If the switch „Sewage water filtering plant“ is switched on in the technical room, the

sewage pump starts automatically if you switch the switch „shower water start“ and

pumps the dirty shower water via 2 steps filtering plant. The filtered sewage water comes

out at the connection „filtered sewage water“.

Shower procedure Start

Shower

Sewage water filtering plant

filtered sewage water

Guide book

D 3000 / 4000 / 5000

Seite 14

Filter sizes:

Prefilter 10“ :220

Finefilter 10“ : 1(other sizes on demand)

max. medium temperature : 50°C at 4bar

Please note:

If the switch sewage water filtering plant is not activated, no sewage water filtering

takes place during the shower procedure. The consumed shower water comes out

from the connection „non filtered sewage water.

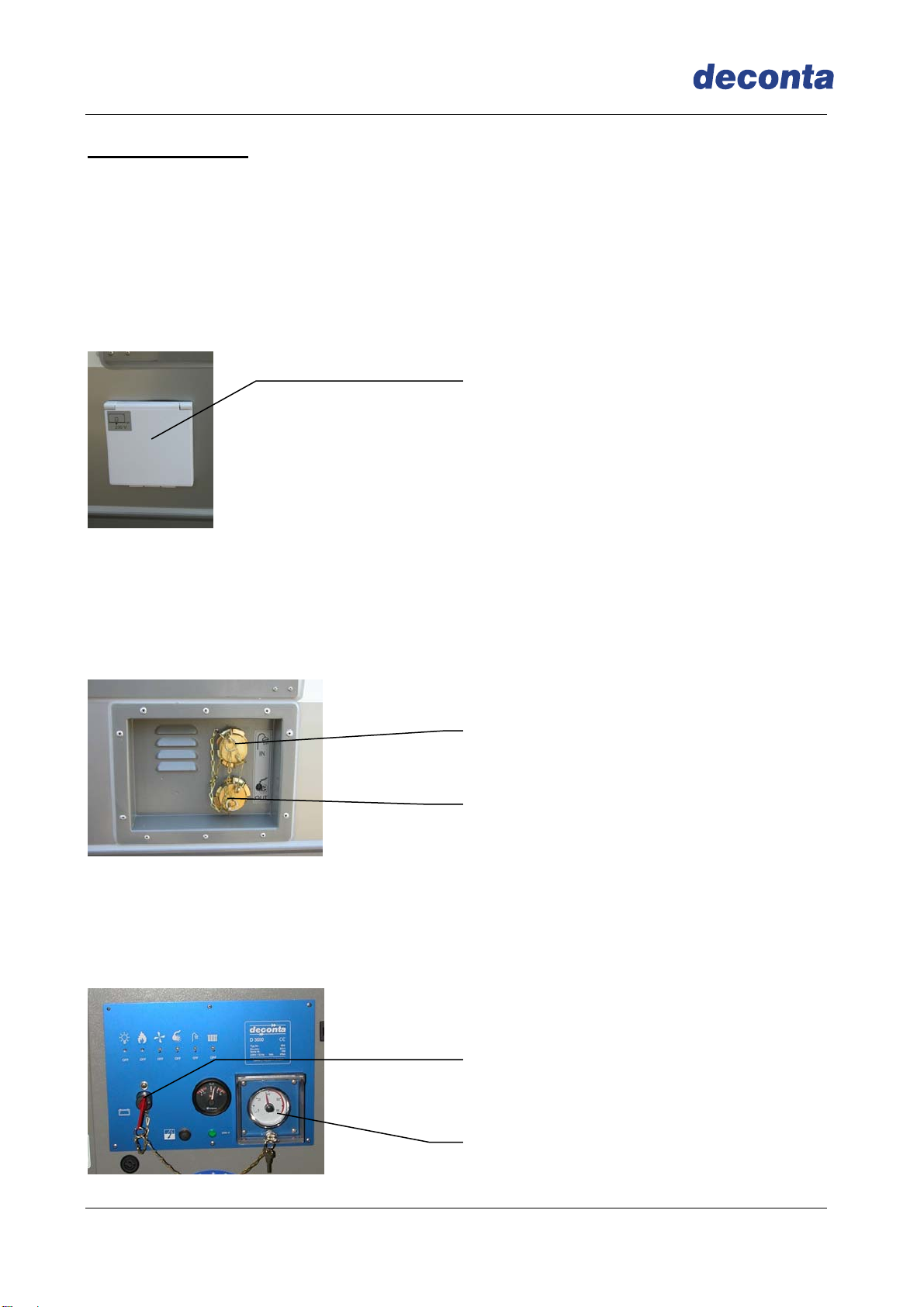

Prefilter

Finefilter

unfiltered sewage water

Guide book

D 3000 / 4000 / 5000

Seite 15

3.1.7 Filter change

filter change only when device is deactivated

dismount the dirty filters in a wet state in order to avoid the release of filter dust

only use authorized filters

damaged filter candle may not be used

The sewage water filters have to be changed if the power of the sewage water

pump decreases. We recommend by normal consumption of dirty water a weekly

change, by stronger strain a daily change.

Slacken cap nut

Take out the filter and dispose of it

Keep filter glas and sealing face clean

Insert new filter candles

Screw on cap nut with key carefully

Suction hoses, pumps, filter housings and filter are already contaminated by the

first use. Repairs and maintenance works are only allowed to be undertaken in

observing the security measures.

All mentioned filters must be disposed of according to the regulations required by

law.

3.1.8 Light

Through the activation of the switch light, the LED-lighting in the vehicle is switched on.

Light

Key

Guide book

D 3000 / 4000 / 5000

Seite 16

3.2 Electric-Version with forced locking

The general start-up is done as described in item 3.1.

3.2.1 Activation of the forced locking

The control of the forced locking is to be found in the clean area.

Make sure both doors to the shower room are closed.

Position key switch on „Test“, the green keys of the door case illuminate. After 5 Sec. s,

switch to „Automatic“, the forced locking is now activated and the green keys are still

glow.

3.2.2 Lock system procedure

Step into shower cabin from clean area. The forced locking is not yet activated.

Press green key on door case to shower cabin, door can be opened.

Step into shower cabin

Close the door

Press green key on door case to the dirty area, door can be opened.

Close the door.

Key switch

Guide book

D 3000 / 4000 / 5000

Seite 17

When entering the shower cabin from the dirty area the forced locking is activated.

Press green key on door case to shower cabin, door can be opened.

Enter shower cabin

Close the door

Shower is activated for a default time of 90 sec.

After finishing the showering procedure press green key on door case to clean

area, door can be opened.

Leave the shower cabin and close the door.

All door cases have an emergency off-key (red key) to enable an early exit out of the

shower cabin with forced locking.

By pressing the red key all doors open and an acoustic signal is heard.

Guide book

D 3000 / 4000 / 5000

Seite 18

3.3 Diesel-Version

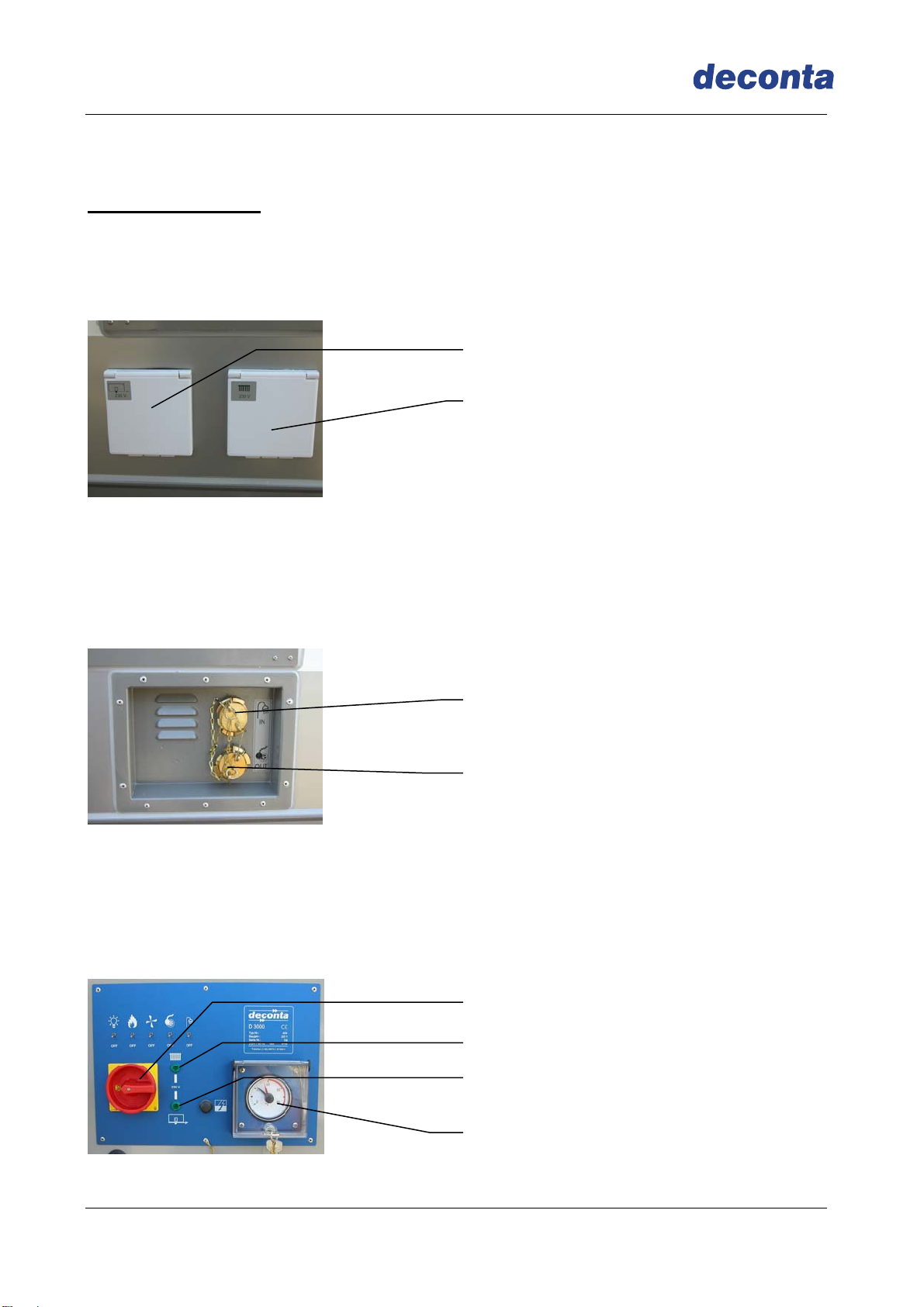

3.3.1 Energy supply

The electric supply takes place from the outside at the connection "Supply" (230 Volt). If

the supply has occurred, the sockets inside the vehicle are activated.

The autarkic version enables an integrated on-board battery to make use of all

consumers without external power supply. When connecting to 230V the battery is

automatically reloaded.

IMPORTANT! The battery loads only when main switch is turned on!

3.3.2 Tank filling

In the vehicle, there is 220 litres fresh water tank.

The filling occurs from the outside via the GEKA connection at the connection fresh

water.

Connect the fresh water hose and open the conduct

Switch on the main plug (if power supply is connected correctly the control lamps

basic function and heating are illuminated)

Tank fills up to minimal mark

To reach desired shower temperature move red hand in thermostat

(usually onto 36-37°C)

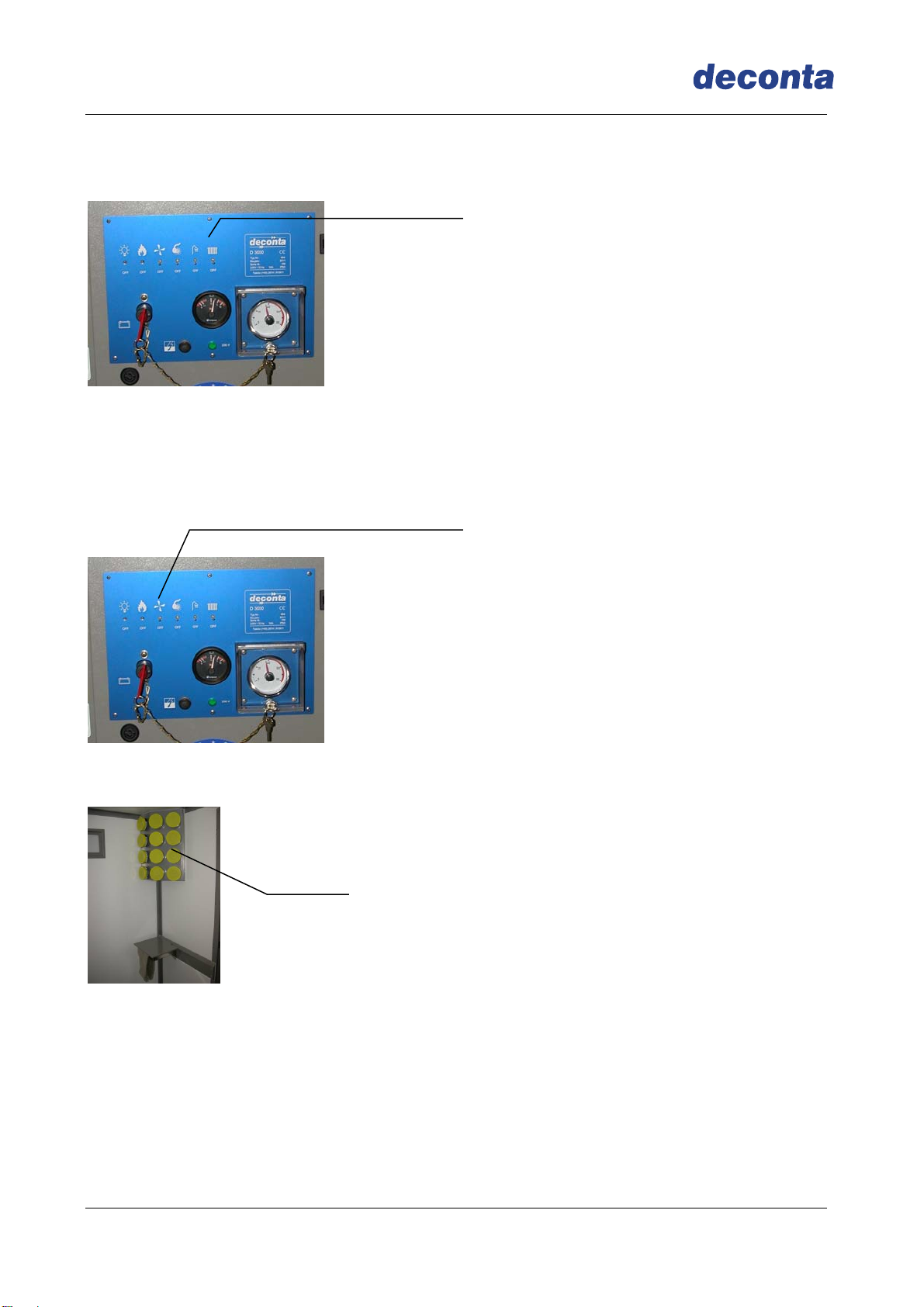

Connector fresh water

Connector sewage water

Battery-Main switch

Thermostat

Power supply basic function

Guide book

D 3000 / 4000 / 5000

Seite 19

Switch on the water heating. Make sure the Diesel jerry can is sufficiently filled.

The Diesel-Water heater starts. Due to the length of the hose from canister to

the warm water heater, it might happen that not enough diesel reaches the

burner. The warm water heater switches off (pay attention to running

noises). In this case switch off the water heating and switch on again after

about 1 min. Repeat this procedure 2 -3 times, if necessary.

The water in the tank is heated up to the chosen temperature. When the water in

the tank has reached the required temperature, fresh water is automatically

added.

If the temperature in the tank drops about 2°C, the fresh water supply will be

stopped and the water will be heated again.

This procedure is repeated until the tank has been fully filled.

Thanks to this way of filling (Step by Step) you have after a short time tempered shower

water at your disposal.

ATTENTION: Never drive the trailer with a full tank!

For the emptying of the tank, there is a ball valve placed in the technical room. If you

open it, all the water runs out under the vehicle.

Water heating

Ball valve for draining of

tank

Guide book

D 3000 / 4000 / 5000

Seite 20

3.3.3 Room heating

The space heater can be switched on/off in the plant room.

3.3.4 Negative pressure plant (optional equipment)

To avoid the danger of the spreading of dust out of the dirty area to the clean area, all

rooms are ventilated. In the dirty area, the air is sucked in and blown out through P3

filters.

Through the fresh air openings, the shower and the clean area are also ventilated. The

fresh air openings have been scaled in such a way that a pressure drop prevails going

from the dirty area to the clean area.

Negative pressure plant

Negative pressure plant

Space heater

This manual suits for next models

2

Table of contents

Other deconta Safety Equipment manuals

Popular Safety Equipment manuals by other brands

safemax

safemax LEVEL 2 PROTEKTOR 2.0 User information

Milwaukee

Milwaukee BOLT User instructions

babcockdavis

babcockdavis Lume-A-Lite BEM-DSH1-10 Installation, operation and maintenance manual

ABS Safety

ABS Safety UniGlide PRO manual

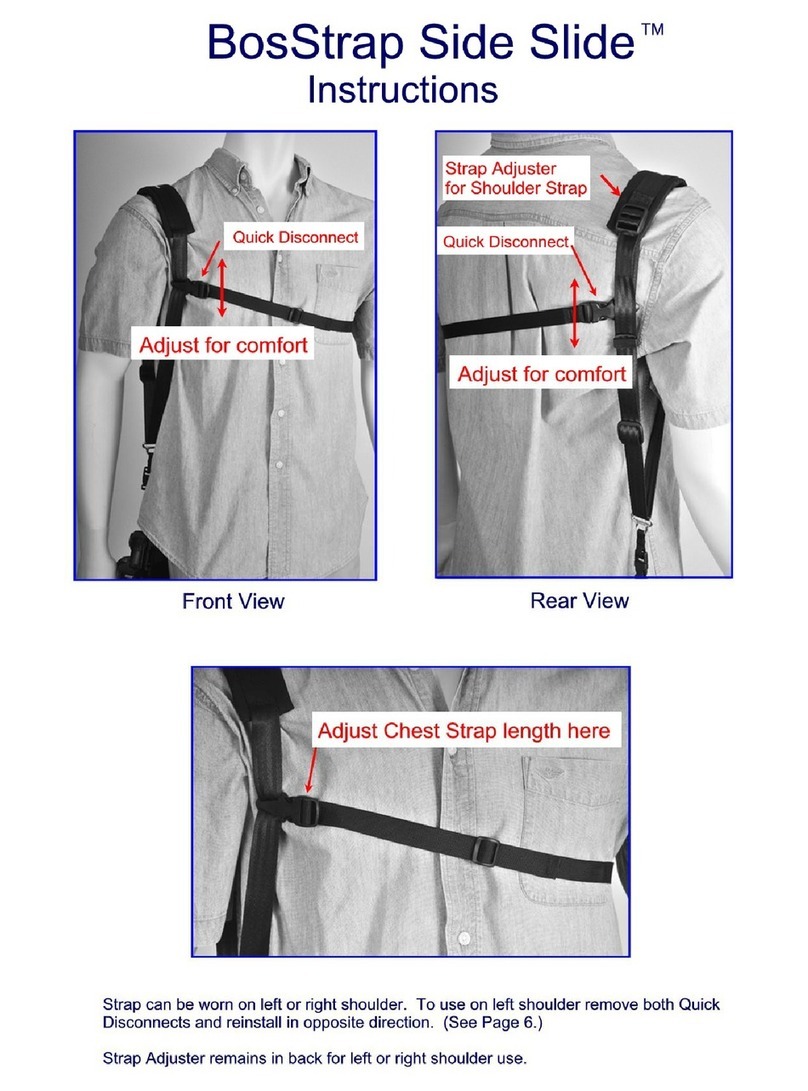

BosStrap

BosStrap Side Slide instructions

MEDIKOKIM

MEDIKOKIM SAFEBELT user manual

Tractel

Tractel FABA-Klassik A11 Operating and maintenance instructions

Innotech

Innotech UNI-EAP-01 manual

ANT+

ANT+ CSN515 Operation manual

Tractel

Tractel skysafe MP 03 Assembly and operating manual

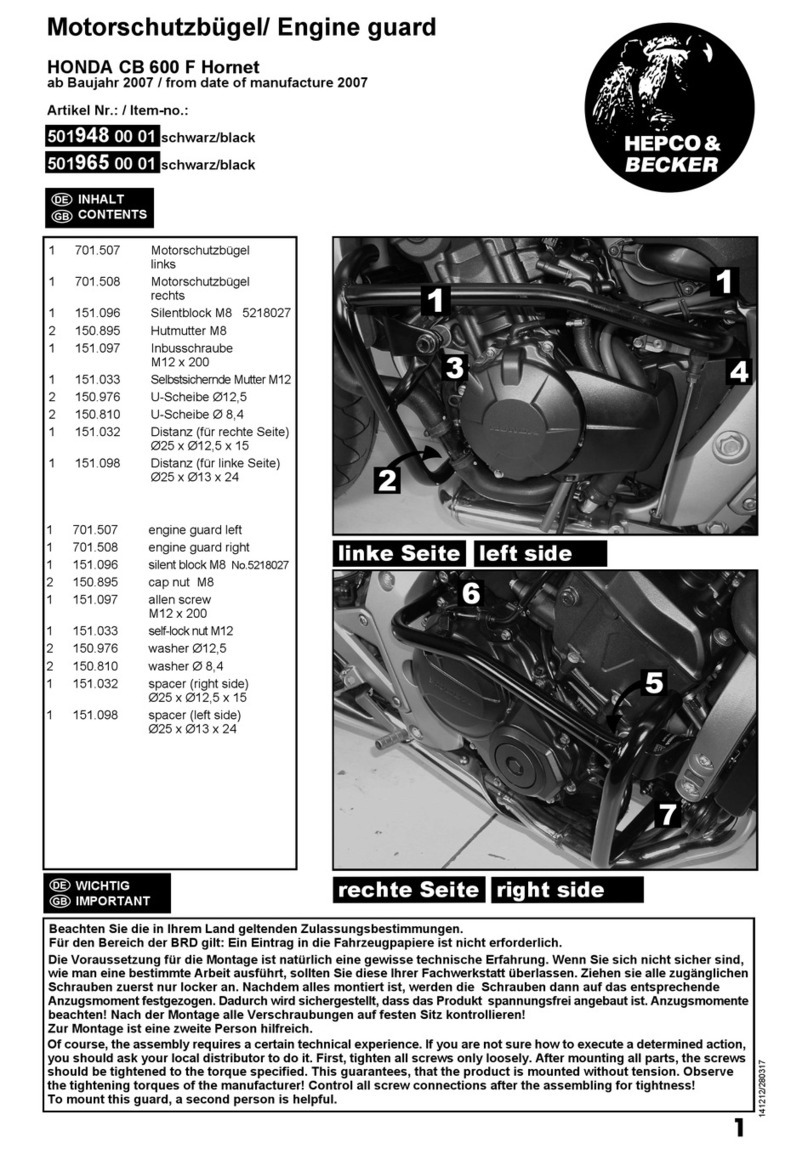

hepco & becker

hepco & becker 501948 00 01 instructions

Powerfix Profi

Powerfix Profi 77309 Instructions for use