2

PRESENTATION OF THE RANGE

MODELS AVAILABLE

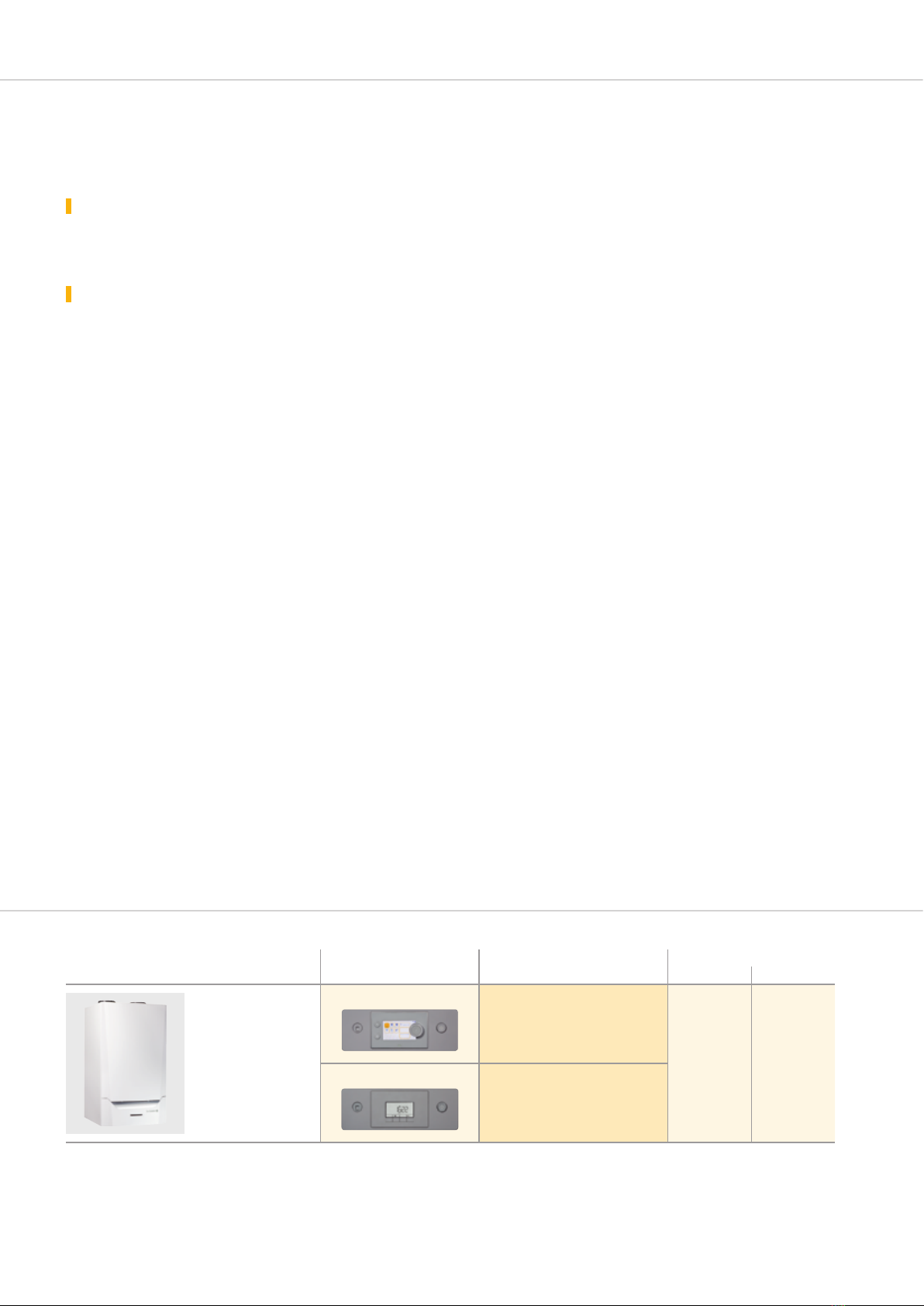

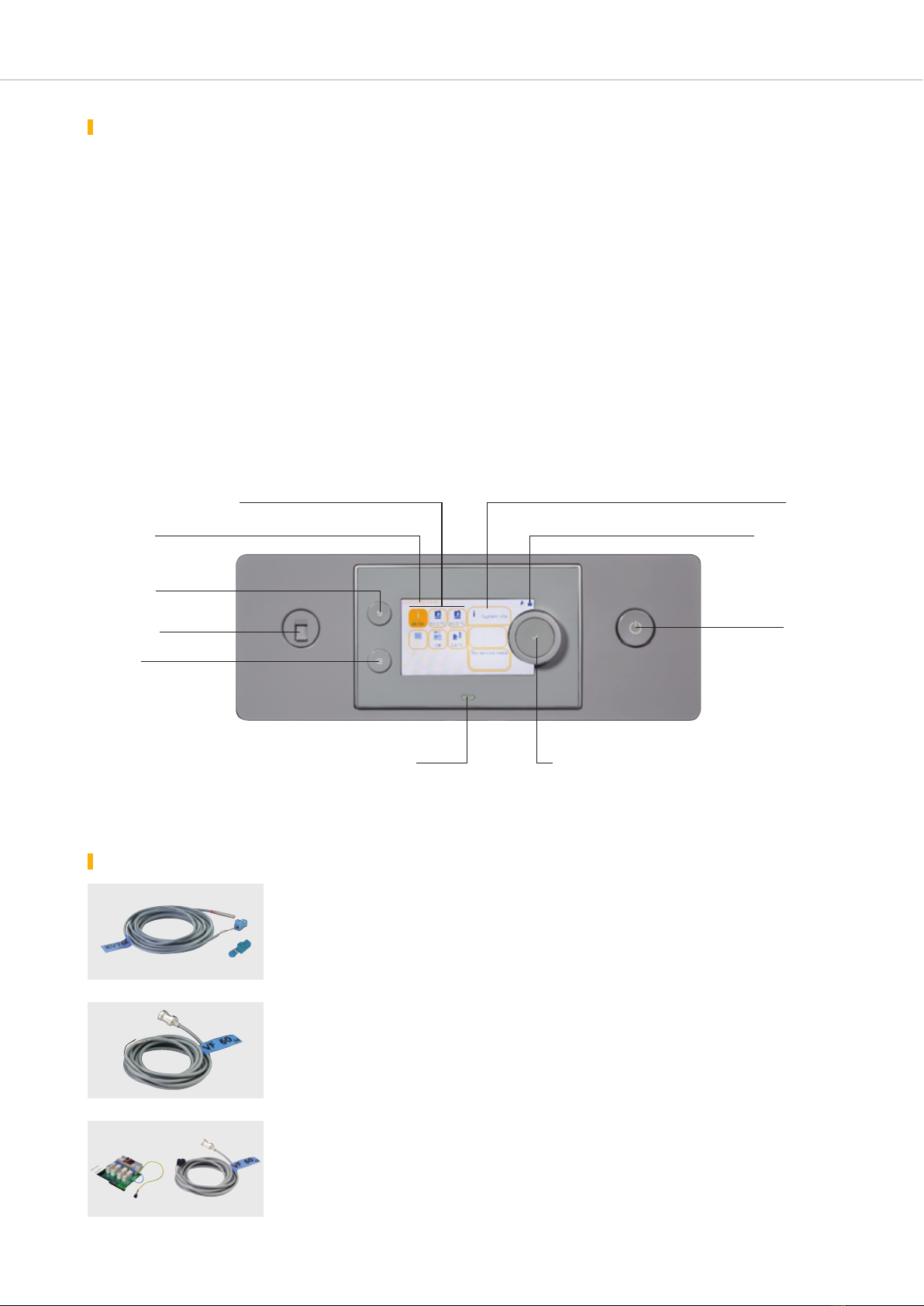

Boiler Control

panel

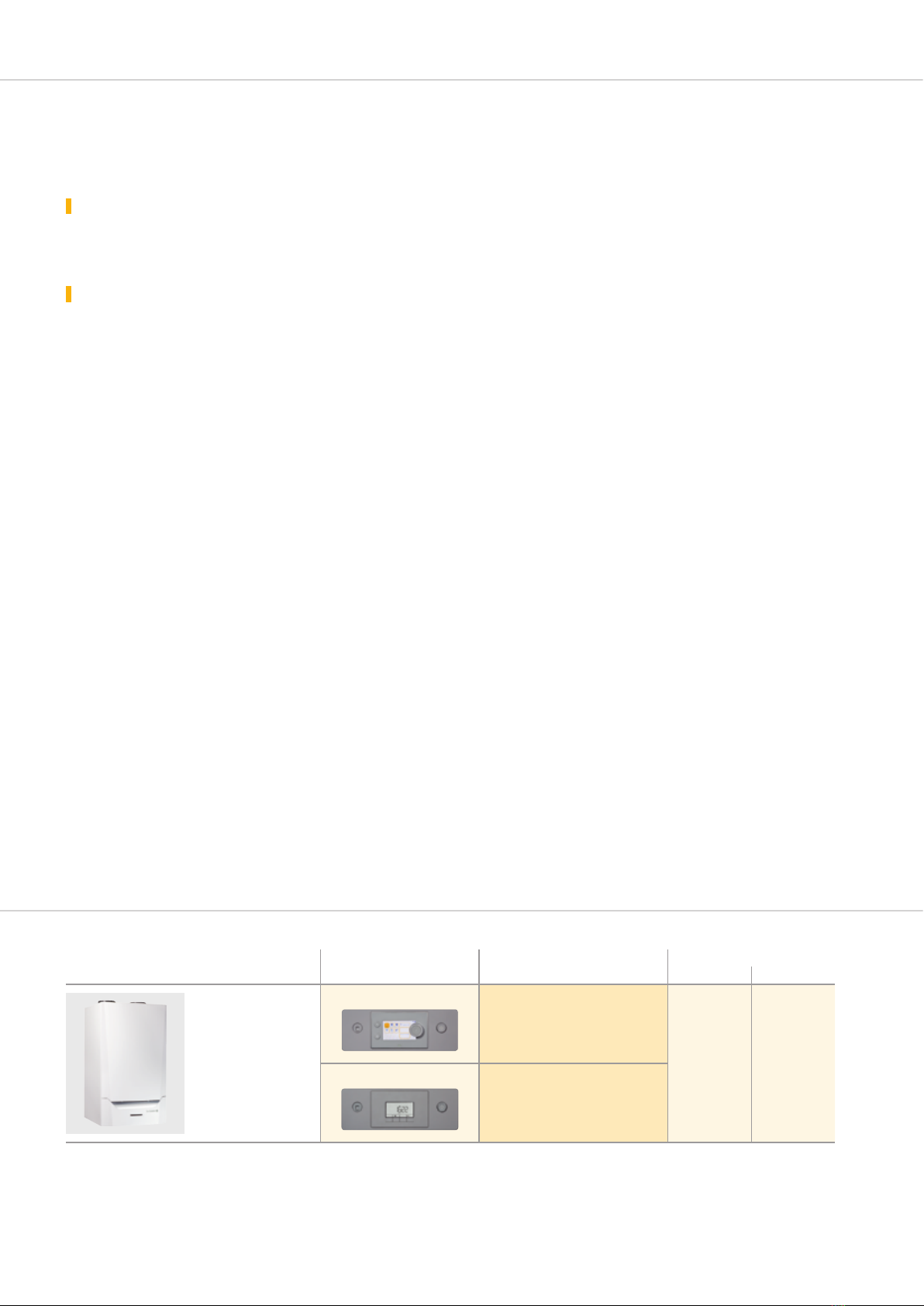

INNOVENS PRO

model

Power range (kW)

at 50/30°C at 80/60°C

MCA_Q0200

For heating only

(option to connect a

domestic hot water

tank*)

DIEMATIC EVOLUTION

MCA 160 DIEMATIC EVOLUTION

34.7 to 161 .6 31.5 to 152.1

IniControl 2

MCA 160 IniControl 2

*Only in combination with the DIEMATIC EVOLUTION control panel

MCA_Q0211MCA_Q0212

enhanced perfOrmance

- Efficiency up to 108.5%

- NOx class 6, in line with EN 15502-1

- Low pollutant emissions: NOx < 39 mg/kWh.

advantages

- Compact packaged heating body made from

aluminium/silicium alloy with a large heat exchange surface

area and moderate pressure losses, providing high resistance

to corrosion and only requiring a very low irrigation flow rate

(except for a flow temperature > 75°C) thanks to the burner

regulator device which manages the transition phases within

the installation which are the source of the very low flow rates

in the boiler. The front access facilitates maintenance,

- Stainless premix burner with braided metal fibre surface,

modulating the output from 18 to 100% to ensure the comfort

level meets requirements, equipped with an air intake silencer.

Low CO and NOx emissions, enabling optimum protection of

the environment,

- Gas line with non-return valve,

Operates using natural gas and propane with conversion

kit

- The INNOVENS PRO MCA 160 boiler can be supplied with

either of the following two control panels:

• DIEMATIC EVOLUTION: suitable for all installation situations,

even the most complex; in its original configuration, it can

be used to control and regulate 2 direct circuits and up to 2

circuits with mixing valve (by adding 2 optional flow sensors).

Add a PCB + sensor to enable a third circuit with mixing

valve to be actuated. A DHW sensor can be fitted to enable

regulation with the DHW circuit prioritised. It is specially

designed to allow optimisation of combined systems.

This control panel can also be used to control an installation

in cascade configuration, where just the first boiler will be

equipped with this panel, and "slave" boilers will be equipped

with an IniControl 2 control panel. To connect more than

the 3 circuits available on the master boiler, it is possible to

insert 1 (or several) additional boiler(s) with the DIEMATIC

EVOLUTION panel into the cascade

• IniControl 2: this is mainly used in installations (cascade or

non-cascade) with an external control cabinet to control all

of the secondary circuits via a 0-10V input, which this panel is

fitted with as part of its original equipment,

- A range of equipment such as an automatic air vent, PPS

flue gas pipes, air-flue gas connection parts with measuring

ports, mains connection cable, internal lighting, heating pump

connector and signalling connector, wall mounting bracket, and

a siphon for draining the condensates,

- Complete cascade hydraulic systems for 2 and up to

8 boilers for installations between 300 and 1216 kW; see

page 12,

- Complete cascade hydraulic systems combining MCA

45/115 and MCA 160 units are also available; see page 17.

- Multiple options to ensure these boilers are as easy to

operate as possible:

• hydraulic connection kit comprising the flow/return valves, the

gas valve, the safety valve, and the filling valve

• primary pump, low-loss header, condensate neutralisation

tray, etc.

- Air-flue gas connection possible via horizontal or vertical

forced flue, on a chimney or bi-flow (see page 22).

The INNOVENS PRO MCA 160 gas condensing boiler is a new

high-power wall-mounted boiler. It boasts an innovative design and

a new aesthetic, with a sleek finish. Exceptionally compact (602 x

600 x 1 112 mm for 160 kW), is its very easy to install and maintain.

It is supplied assembled and factory-tested.