Alternate Configuration (Page 20)

Default Configuration On (1), Off (0) 2028

Delayed Over Current Alarm

CAN Alternative Engine Speed

Under Voltage Shutdown Ena le

Under Voltage Shutdown Trip

Overload Protection Ena le

Under Voltage Warning Ena le

Overload Protection Action

Under Voltage Warning Trip

Over Voltage Warning Ena le

Over Voltage Warning Return

Over Voltage Warning Trip

Mains Under Voltage Ena le

Ena le On (1), Off (0) 2040

Mains Under Voltage Trip 0 V

Under Frequency Shutdown Trip

Mains Under Voltage Return

Ena le On (1), Off (0) 2042

Mains Over Voltage Ena le On (1), Off (0)

Under Frequency Warning Trip

Mains Over Voltage Return

Nominal Frequency 0.0 Hz 2045

Over Frequency Warning Ena le

Mains Under Frequency Trip

Over Frequency Warning Return 0.0 Hz 2047

Over Frequency Warning Trip

Mains Over Frequency Ena le

Ena le On (1), Off (0) 2049

Mains Over Frequency Return

Over Frequency Shutdown Trip

Mains Over Frequency Trip

Under Speed Shutdown Trip

Delayed Over Current Alarm

Battery Over Volts Warning

Battery Under Volts Warning

Generator Over Voltage Shutdown

Over Current Immediate Warning

Delayed Over Current Trip Alarm

Fuel Sender Low Pre-Alarm

Charge Alternator Shutdown

Charge Alternator Warning

Air Filter Maintenance Output

Oil Filter Maintenance Output

Fuel Filter Maintenance Output

Preheat During Preheat Timer

Analogue Input B (Digital

Preheat Until End Of Safety Timer

Analogue Input C (Digital

Preheat Until End Of Warming

Display Heater Fitted and Active

Alternative Configuration

Coolant Temperature Switch

Availa le 26 Maintenance Reset Fuel

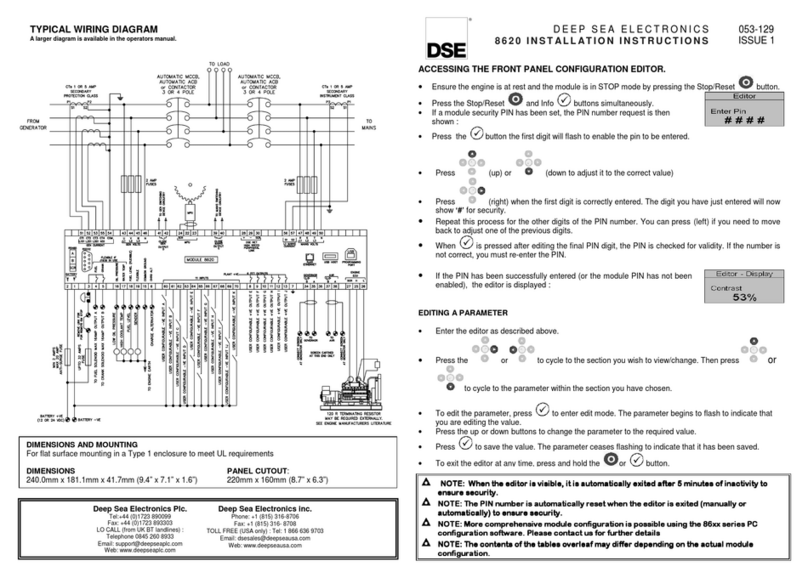

TYPICAL WIRING DIAGRAM

NOTE: A larger version of the typical wiring diagram is included in

the products operator manual. Refer to DSE Publication:

057-171 DSE4510 & DSE4520 Operators Manual

053-157 Issue 2

DEEP SEA ELECTRONICS PLC

DSE 510 & DSE 520 Installation Instructions

Applica le to module version 1.4.46 and upwards.

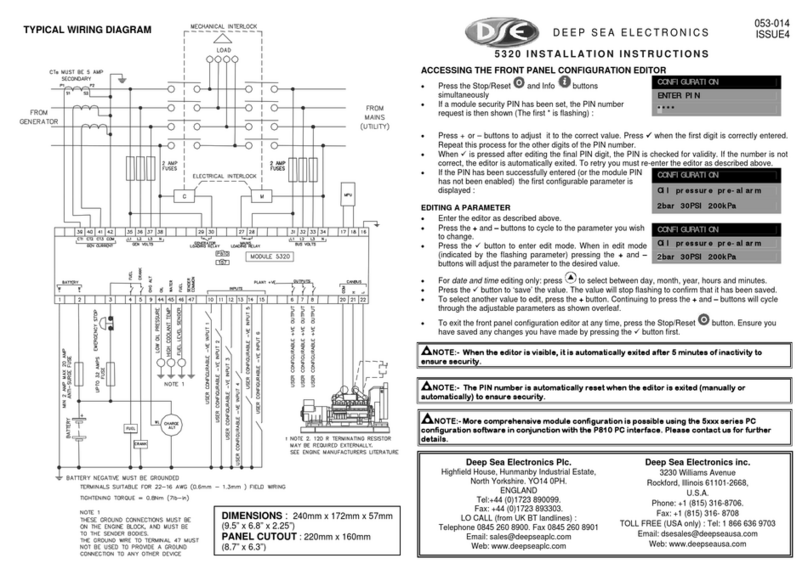

EDITING A PARAMETER

• Press the (

-

) and ()

uttons together to enter the editor

mode.

• Press the (up) or (down) navigation uttons to cycle through the

front panel editor in increments of 100.

• Press the (

+

) or (

-

) navigation uttons to cycle through the front

panel editor in increments of 1.

• When viewing the parameter to e edited, press the()

utton and the value

egins to flash.

• Press the (

+

) or (

-

) navigation uttons to adjust the value to the

required setting.

• Press the ()

utton the save the current value, the value ceases

flashing.

• Press and hold the ()

utton to save and exit the editor, the

configuration icon is removed from the display.

NOTE: Pressing and holding the (

+

) or (

-

) buttons will

give auto-repeat functionality. Values can be changed quickly by holding

the navigation buttons for a prolonged period of time.

(AWG 24 to AWG 10)

NOTE: Terminals 8, 9, 25, 26, 27 & 28 are not fitted to DSE 510

NOTE: Terminals 29, 30, 31 & 32 are fitted to DSE 510 & DSE 520

current sensing variants only

Tel: +44 (0)1723 890099

Fax: +44 (0)1723 893303

We : www.deepseaplc.com

Tel: +1 (815) 316-8706

Fax: +1 (815) 316-8708

We : www.deepseausa.com

REQUIREMENTS FOR UL CERTIFICATION

Screw Terminal Tightening Torque

Terminals suita le for connection of conductor size 12 AWG – 26 AWG (0.5 mm² to 2.0 mm²).

• Conductor protection must e provided in accordance with NFPA 70, Article 240

• Low voltage circuits (35 V or less) must e supplied from the engine starting attery or an isolated secondary circuit.

• The communication, sensor, and/or attery derived circuit conductors shall e separated and secured to maintain at least ¼” (6 mm) separation from the generator and mains connected circuit

conductors unless all conductors are rated 600 V or greater.

Must e connected through UL Listed or Recognized isolating current transformers with the secondary rating of 5 A max.

Must e connected to communication circuits of UL Listed equipment

Suita le for use in type 1 Enclosure Type rating with surrounding air temperature -22 ºF to +158 ºF (-30 ºC to +70 ºC)

• Suita le for pollution degree 3 environments when voltage sensing inputs do not exceed 300 V. When used to monitor voltages over 300 V device to e install in an unventilated or filtered ventilation

enclosure to maintain a pollution degree 2 environment.

-22 ºF to +158 ºF (-30 ºC to +70 ºC)

-40 ºF to +176 ºF (-40 ºC to +80 ºC)