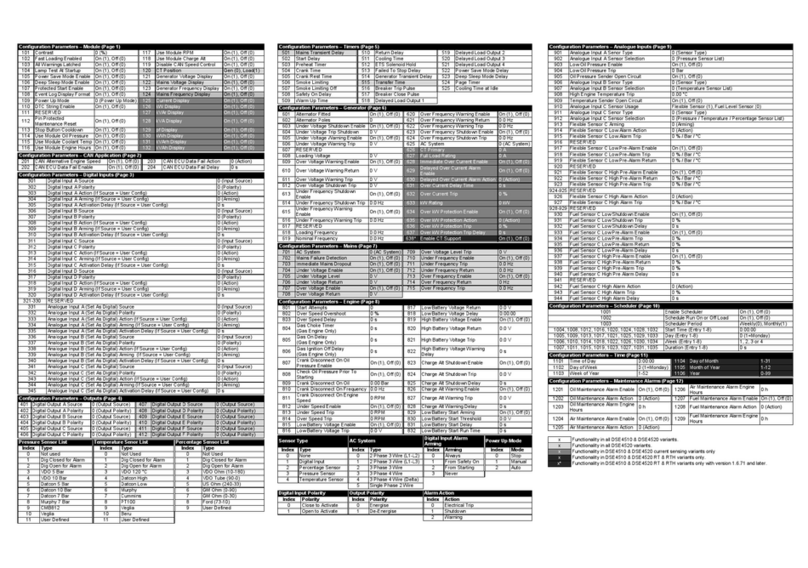

MAIN CONFIGURATION EDITOR PARAMETERS

NOTE: Depending upon module configuration, some values in the Main &

Running Configuration Editors may not be available. For more information refer to

DSE publication 057-243 DSE7310 MKII & DSE7320 MKII Configuraiton Suite PC

Software Manual available from www.deepseaplc.com

Parameter As Shown On Display

Current Date and Time Month, Year, hh:mm

Dual Mutual Mode Engine Hours / Dual Mutual

Hours / Priority

Dual Mutual Duty Time 0 h 0 m

Editor Config To Edit Main Configuration /

Alternative Configuration

1,2,3,4,5

Default Configuration Main Configuration /

Alternative Configuration

1,2,3,4,5

Engine Oil Pressure Low Shutdown 0.00 bar

Oil Pressure Low Pre Alarm 0.00 bar

Coolant Temperature Low Warning 0 ºC

Coolant Temperature High Pre Alarm 0 ºC

Coolant Temperature High Electrical Trip 0 ºC

Coolant Temperature High Shutdown 0 ºC

Fuel Usage Alarm (Running Rate) 0 %

Fuel Usage Alarm (Stopped Rate) 0 %

Specific Gravity 0.00

Pre Heat Temperature 0 ºC

Post Heat Timer 0 h 0 m 0 s

Pre Heat Timer 0 h 0 m 0 s

Post Heat Temperature 0 ºC

Droop Control Active / Inactive

Engine Under Speed Shutdown Active / Inactive

Engine Under Speed Shutdown 0 RPM

Engine Under Speed Warning Active / Inactive

Engine Under Speed Warning 0 RPM

Engine Under Speed Delay 0.0 s

Engine Over Speed Warning Active / Inactive

Engine Over Speed Warning 0 RPM

Engine Over Speed Shutdown 0 RPM

Engine Over Speed Delay 0.0 s

Engine Speed Overshoot 0 %

Engine Speed Overshoot Delay 0.0 s

Battery Under Voltage Warning Active / Inactive

Battery Under Voltage Warning 0 V

Battery Under Voltage Warning Delay 0 h 0 m 0 s

Battery Over Voltage Warning Active / Inactive

Battery Over Voltage Warning 0 V

Battery Over Voltage Warning Delay 0 h 0 m 0 s

Charge Alternator Failure Warning Active / Inactive

Charge Alternator Failure Warning 0 V

Charge Alternator Warning Delay 0 h 0 m 0 s

Charge Alternator Failure Shutdown Active / Inactive

Charge Alternator Failure Shutdown 0.0 V

Charge Alternator Shutdown Delay 0 h 0 m 0 s

AC System 3 Phase, 4 Wire

Generator Under Voltage Shutdown 0 V

Generator Under Voltage Pre Alarm 0 V

Generator Under Voltage Delay 0.0 s

Generator Nominal Voltage 0 V

Generator Over Voltage Pre Alarm 0 V

Generator Over Voltage Shutdown 0 V

Generator Over Voltage Delay 0.0 s

Generator Under Frequency Shutdown 0.0 Hz

Generator Under Frequency Pre Alarm 0.0 Hz

Generator Under Frequency Delay 0.0 s

Generator Nominal Frequency 0.0 Hz

MAIN CONFIGURATION EDITOR PARAMETERS (CONTINUED)

Parameter As Shown On Display

Generator Over Frequency Pre Alarm 0.0 Hz

Generator Over Frequency Shutdown 0.0 Hz

Generator Under Frequency Delay 0.0 s

Generator Over Frequency Overshoot 0 %

Generator Over Frequency Overshoot

Delay 0.0 s

Generator CT Primary Current 0 A

Generator Secondary Current 1 A / 5 A

Generator CT Primary Earth Current 0 A

Delayed Over Current Active / Inactive

Generator Earth Fault Trip Active / Inactive

Generator Earth Fault Trip 0 %

Mains Under Voltage Trip 0 V

Mains Over Voltage Trip 0 V

Mains Under Frequency Trip 0.0 Hz

Mains Over Frequency Trip 0.0 Hz

Start Delay Off Load 0 h 0 m 0 s

Start Delay On Load 0 h 0 m 0 s

Start Delay Mains Fail 0 h 0 m 0 s

Start Delay Telemetry 0 h 0 m 0 s

Mains Transient Delay 0 m 0 s

Crank Duration Timer 0 m 0 s

Smoke Limiting 0 m 0 s

Smoke Limiting Off 0 m 0 s

Safety On Delay 0 m 0 s

Warm Up Timer 0 h 0 m 0 s

Transfer Time 0 m 0.0 s

Return Delay 0 h 0 m 0 s

Cool Down Timer 0 h 0 m 0 s

Fail To Stop Delay 0 m 0 s

LCD Page Timer 0 h 0 m 0 s

Auto Scroll Delay 0 h 0 m 0 s

Sleep Timer 0 h 0 m 0 s

Backlight Power Save 0 h 0 m 0 s

Schedule Active / Inactive

Schedule Bank 1 Period Weekly / Monthly,

On Load / Off Load / Auto Start Inhibit,

Week, Start Time, Run Time and Day

Selection (1-8)

Press to begin editing then

up or down when selecting the

different parameters.

Schedule Bank 2 Period Weekly / Monthly,

On Load / Off Load / Auto Start Inhibit,

Week, Start Time, Run Time and Day

Selection (1-8)

Press to begin editing then

up or down when selecting the

different parameters.

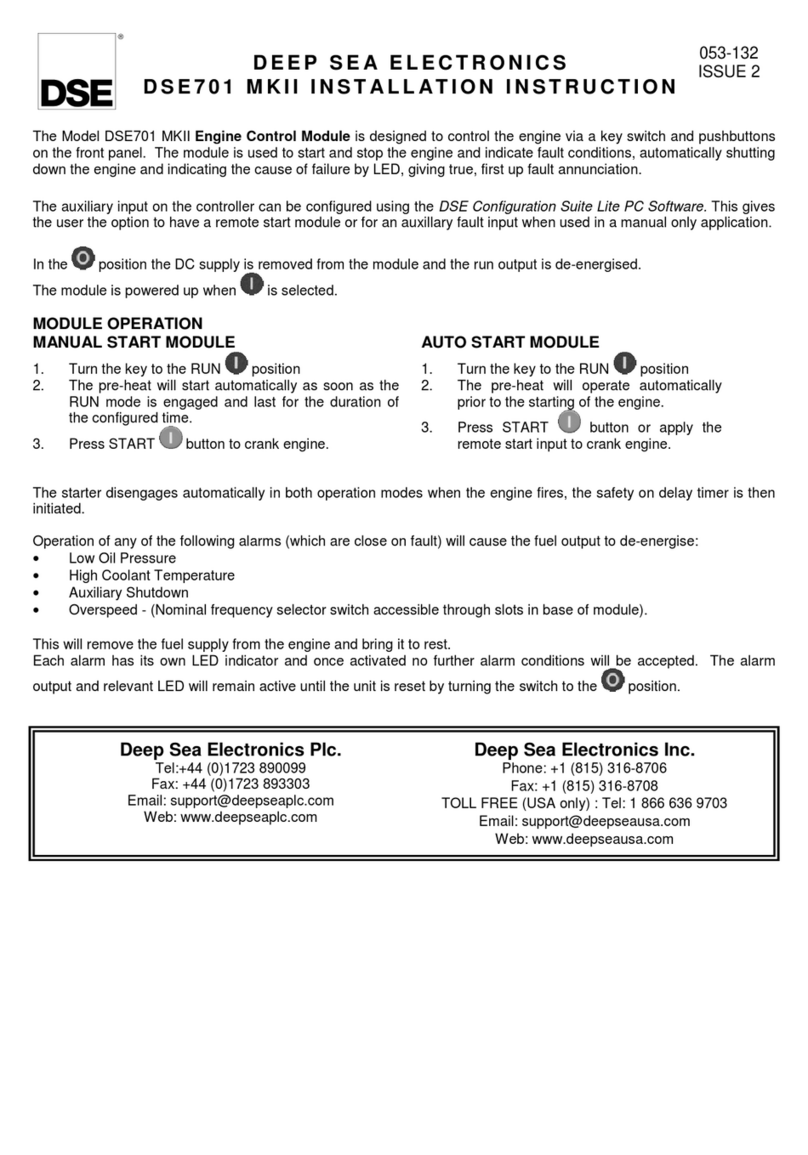

ACCESSING THE ‘RUNNING’ CONFIGURATION EDITOR

•The ‘running’ editor can be entered while the engine is running. All protections remain

active if the engine is running while the running editor is entered.

•Press and hold the (Tick) button to enter the running editor.

RUNNING CONFIGURATION EDITOR PARAMETERS

Parameter As Shown On Display

Manual Frequency Trim 0.0 Hz

Speed Bias 0.0

Governor Gain 0

Frequency Adjust 0.0 %

DPF Auto Regen Inhibit Active / Inactive

DPF Manual Regeneration Request Active / Inactive

ECU Service Mode Active / Inactive

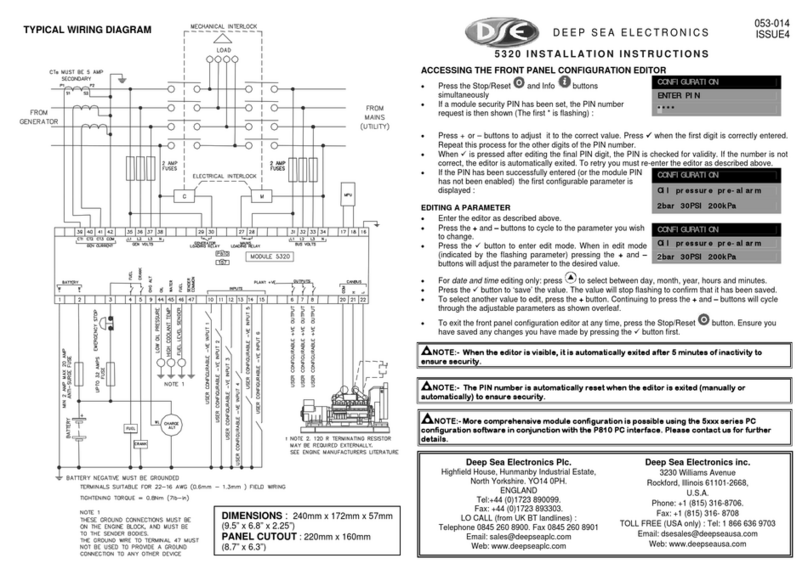

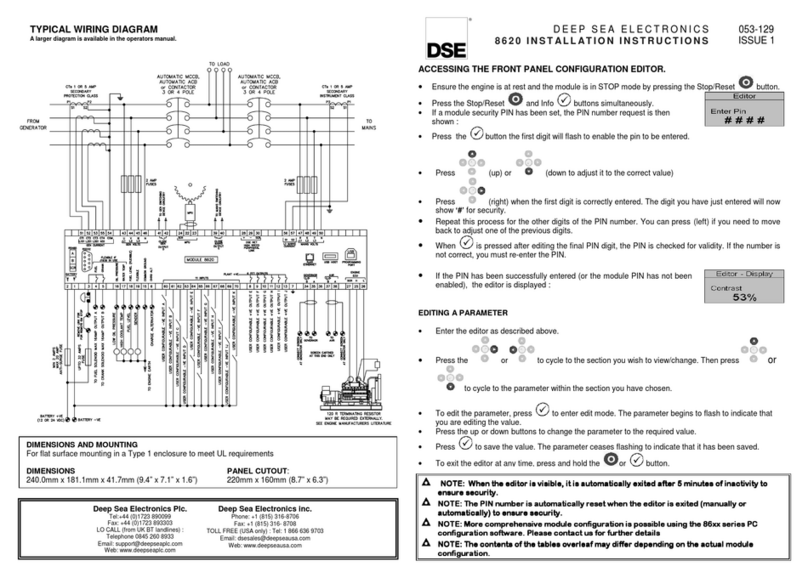

DIMENSIONS AND MOUNTING

245 mm X 184 mm X 51 mm

(9.6” X 7.2” X 2.0”)

220 mm X 160 mm

(8.7” X 6.3”)

Operating: -40 ºC to +70 ºC

(-40 ºF to +158 ºF)

Storage: -40 ºC to +80 ºC

(-40 ºF to +176 ºF)

QUIREMENTS FOR UL CERTIFICATION

WARNING!: More than one live circuit exists, see diagram overleaf for further information.

Screw Terminal Tightening Torque

4.5 lb-in (0.5 Nm)

Conductors

Terminals suitable for connection of conductor size 13 AWG to 20 AWG (0.5 mm² to 2.5 mm²).

•Conductor protection must be provided in accordance with NFPA 70, Article 240

•Low voltage circuits (35 V or less) must be supplied from the engine starting battery or an isolated secondary circuit.

•The communication, sensor, and/or battery derived circuit conductors shall be separated and secured to maintain at least ¼” (6 mm) separation from the

generator and mains connected circuit conductors unless all conductors are rated 600 V or greater.

Current Inputs

Must be connected through UL Listed or Recognized isolating current transformers with the secondary rating of 5 A max.

Communication Circuits

Must be connected to communication circuits of UL Listed equipment

DC Output Pilot Duty

Suitable for flat surface mounting in Type 1 Enclosure Type rating with surrounding air temperature -22 ºF to +122 ºF (-30 ºC to +50 ºC)

•Suitable for pollution degree 3 environments when voltage sensing inputs do not exceed 300 V. When used to monitor voltages over 300 V device to be

installed in an unventilated or filtered ventilation enclosure to maintain a pollution degree 2 environment.

Operating Temperature

-22 ºF to +122 ºF (-30 ºC to +50 ºC)