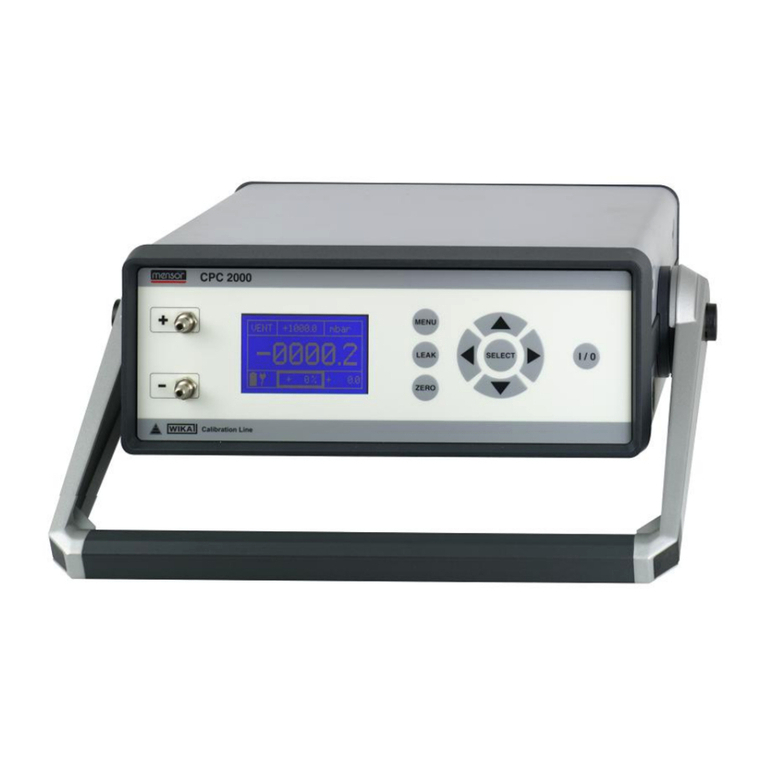

High-Speed Pneumatic Pressure Controller

CPC3000

Operating Instructions - CPC3000 7

1. General information

1.1 Warranty

All products manufactured by Mensor are warranted to be free of defects in workmanship and

materials for a period of one year from the date of shipment. No other express warranty is given,

and no affirmation of Seller, by words or actions, shall constitute a warranty. SELLER DISCLAIMS

ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

PURPOSES WHATSOEVER. If any defect in workmanship or material should develop under condi-

tions of normal use and service within the warranty period, repairs will be made at no charge to

the original purchaser, upon delivery of the product(s) to the factory, shipping charges prepaid.

If inspection by Mensor or its authorized representative reveals that the product was damaged

by accident, alteration, misuse, abuse, faulty installation or other causes beyond the control

of Mensor, this warranty does not apply. The judgment of Mensor will be final as to all matters

concerning condition of the product, the cause and nature of a defect, and the necessity or

manner of repair. Service, repairs or disassembly of the product in any manner, performed without

specific factory permission, voids this warranty.

MENSOR MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS MANUAL, INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE. Mensor shall not be liable for errors contained herein or for incidental

or consequential damages in connection with the furnishing, performance, or use of this material.

1.2 Important notice

Since product improvement is a continuous process at Mensor, we reserve the right to change

specifications and other information contained in this manual without notice.

Mensor has made a concerted effort to provide complete and current information for the proper

use of the equipment. If there are questions regarding this manual or the proper use of the equip-

ment, contact either Mensor or WIKA:

Mensor

201 Barnes Drive

San Marcos, Tx 78666

Tel: 1.512.396.4200 or 1.800.984.4200 (USA only)

Web site: www.mensor.com

Fax: 1.512.396.1820

E-mail: sales@mensor.com

tech.support@mensor.com

quality@mensor.com

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

D-63911 Klingenberg / Germany

Tel: (+49) 93 72/132-9986

Web site: www.wika.de

Fax: (+49) 93 72/132-8767