DeFelsko PosiTest LPD User manual

Introduction

Introduction

The PosiTest Low voltage Pinhole (Porosity) Detector (LPD) is a

handheld electronic instrument designed to locate small defects and

discontinuities (called “pinholes” or “holidays”) in a protective

coating system applied to a conductive substrate. Fundamentally,

the PosiTest LPD consists of a power source, a ground wire, a

probing electrode (a moistened sponge) and a multi-function LED

display.

In use, an operator moves the moistened sponge (electrode) over

the coated surface. When a pinhole is encountered, current flows

from the sponge through the moisture in the hole and into the

substrate below. The current is returned to the detector through the

attached ground wire, completing the circuit and triggering audible

and visible alarms.

To perform its intended function, a coating must be applied as a

continuous film. Pinhole (holiday) detection is useful for locating

pinholes, holidays, cracks, etc. which are not readily visible. Low

voltage pinhole detectors are commonly used to inspect non-

conductive coatings thinner than 500 µm (20 mils) applied to

conductive substrates.

DeFelsko recommends that the operator read and

fully understand this manual prior to using the PosiTest LPD.

This equipment generates voltage. Accidental contact

with the electrode may result in a mild electric shock. The PosiTest

LPD operator should exercise all due care to minimize their risk of

electric shock and be aware of all relevant safety guidelines before

operating this equipment.

1

WARNING:

IMPORTANT:

2

The PosiTest LPD is available in two kit configurations, Basic and

Complete.

PosiTest LPD Basic Kit

The PosiTest LPD Basic Kit includes the following materials:

[a] PosiTest LPD detector with 3 AAA alkaline batteries (installed)

[b] 0.2 m (8”) base tube, rectangle sponge with hardware and

insulating collar (assembled)

[c] 4.5 m (15’) ground (earth) wire

[d] Detachable ground clip

Wrist Strap (not shown)

[e] Wired earbud

[f] Instruction Manual

[g] Long Form Certificate of Calibration traceable to NIST

[h] Small hard shell case

3

PosiTest LPD Complete Kit

The PosiTest LPD Complete Kit includes all materials contained in

the Basic kit plus the following:

The above items are available individually or together in

the PosiTest LPD Accessory Pack (includes items [i] to [v]). See

Accessories on pg. 8.

NOTE:

[i] 12 m (40’) ground wire with

spool

[j] Magnetic ground (earth) clamp

[k] 4.5 m (15’) hot wire (pg.10)

[l] Universal thread adapter (pg. 10)

[m] ACME thread adapter (pg. 10)

[n] oller sponges with hardware

(pg. 10)

[o] 0.3 m (1’) Extension tube (2)

[p] Extension adaptor

[q] Carabiner

[r] 20 cm x 20 cm (8” x 8”) flat

customizable sponge (pg. 11)

[s] ound washers (pg. 11)

[t] Hook & loop fastener wire

ties

[u] Wetting agent

[v] Large hard shell case

4

Assembly Instructions

Assembly Instructions

The base tube and rectangular sponge arrive pre-assembled in both

the PosiTest LPD Basic and Complete kits.

To attach the base tube to the detector body, perform the following

steps:

1. Slide the connector end of the base tube onto the threaded

electrode connector on the PosiTest LPD.

2. Check the alignment of the rectangular sponge and rotate to a

horizontal position.

3. Move the insulating collar to the base of the tube, engage it

with the threaded electrode connector and firmly tighten the

insulating collar.

The materials included with the PosiTest LPD Complete

kit (pg. 3) provide an operator with a wide variety of assembly

options for different inspection situations.

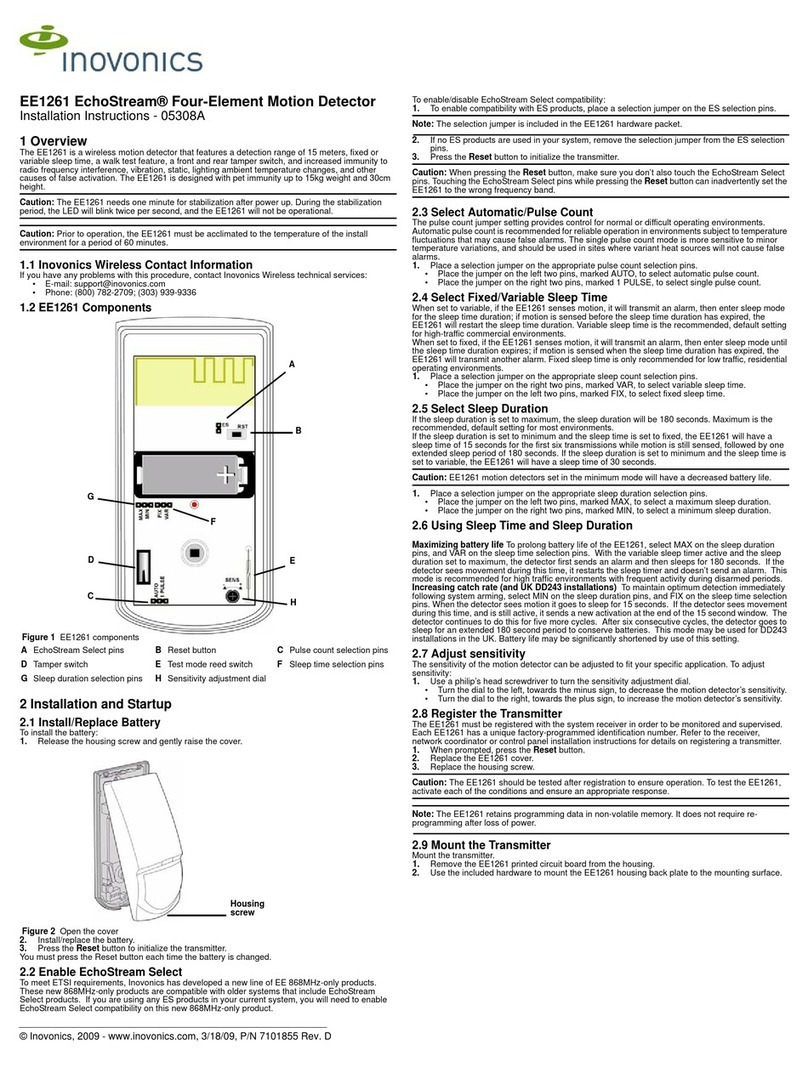

PosiTest LPD (bottom panel)

NOTE:

Threaded electrode connector

Base tube

Insulating collar

Battery compartment

Headphone jack

Ground (earth) wire jack

Carabiner / wrist strap

loop

5

Operating Instructions

Operating Instructions

The PosiTest LPD is typically used on coatings with a measured

thickness less than 500 µm (20 mils). Before performing an

inspection, ensure that the coated surface is fully cured, dry and

free of contaminates.

1. Use clean tap water to wet the test sponge. Squeeze excess

water from the sponge until it no longer drips.

If testing a coating thicker than 250 µm (10 mils), adding a

wetting agent or other low-sudsing surfactant to the water will

reduce the surface tension of the water and promote flow into

discontinuities.

2. Connect the ground (earth) wire clip to an uncoated point of

the part to be tested. Plug the ground wire into the ground wire

jack at the bottom of the PosiTest LPD.

3. Press the Power button to power-up the unit. A self-test is

performed on power-up (pg. 6).

If not using the supplied earbud, press the Audio Alarm

button to activate the audible alarm.

4. Use the Voltage Selector button (pg. 7) to set the required

test voltage.

5. Check correct operation and alarm status by touching the

sponge to the ground clamp or another uncoated point on the

part. This should complete the electrical circuit and trigger the

LED and audio alarms. If no alarm is noted, check all

connections, wires, battery life indicator and sponge wetness.

6. Place the sponge on the coated surface and ensure the

GroundSense™ coupled indicator LED (pg. 7) remains

illuminated and does not blink. If the LED blinks, do the

following:

• Check the ground wire connections at the ground clamp and

detector.

• Attach the ground clip to a different uncoated area on the

part.

TIP:

TIP:

7. Move the sponge over the coated surface at a maximum rate of

0.3 m/s (1 ft/s) and apply sufficient pressure to maintain a wet

surface. If the sponge contacts a pinhole in the coating, all

display LEDs will illuminate and an alarm tone will sound. Alarm

will stop when the sponge is moved away from the pinhole.

8. Precisely locate the pinhole by using a corner of the sponge.

Sponge life depends on use and the abrasive nature of the

surface being tested. Replacement sponges are available with a

comprehensive selection of Accessories (see pg. 8)

PosiTest LPD Control Panel

Buttons:

Power

• Press once to power-up the detector. A self-

test of the 4 test voltages is performed. This

is indicated by a fast flash of each voltage

setting indicator. The self-test should take

approximately 2 seconds to compete. If the

self-test fails, the detector will flash all the

LEDs, sound the alarm then power off.

To conserve battery life, the PosiTest

LPD automatically turns OFF after 5 minutes of no

activity.

•Press and briefly hold to check the battery

status on the LED display.

•Press and hold for 3 seconds to power-down.

Selected Voltage and Audio Alarm settings

are retained.

The self-test can fail if performed while

the sponge/base tube is in contact with a

grounded surface.

6

NOTE:

NOTE:

NOTE:

7

Voltage Selector

• Press repeatedly to cycle through the 4 test voltage settings.

The LED display indicates the currently selected voltage.

Audio Alarm

• Press once to enable the audible alarm, press again to disable.

A green LED illuminates next to the Audio Alarm button when

the alarm is enabled.

The headphone jack is always active.

LED Display:

The four LEDs at the top of the PosiTest

LPD serve multiple functions:

1. Voltage indication

(9V, 67.5V 80KΩ, 67.5K 90KΩ, 90V)

2. Battery state indication – Press and briefly hold the Power

button to check battery status. New, fully charged batteries will

illuminate all four LEDs. Batteries should be changed/recharged

when only one LED illuminates (pg. 12).

3. Pinhole/holiday indication – When a discontinuity is detected,

all LEDs illuminate.

4. Voltage self-test on power-up – See Power button (pg. 6)

5. GroundSense - Successful low voltage pinhole detection

requires that the detector be grounded (earthed) to the test

substrate. If not properly grounded, or if the connection to

ground is lost, the detector will not alarm when a pinhole is

encountered. GroundSense is designed to assure the PosiTest

LPD operator that the detector is grounded while testing.

• The selected voltage LED stays lit when the wet sponge on the

PosiTest LPD is in contact with the coated surface and the

detector is properly grounded.

• When the wet sponge is removed from the coated part, or if the

connection to ground is lost, the selected voltage LED will blink.

NOTE:

8

For example, when a PosiTest LPD operator prepares to test for

coating pinholes on a steel beam he/she first connects the ground

clamp and 4.5 m (15’) ground wire to an uncoated area of the beam.

When the detector is powered-up, GroundSense causes the LED

for the selected voltage to blink until the operator couples the wet

sponge by placing it on the coated beam. When the wet sponge is

lifted from the coated beam, GroundSense causes the LED for the

selected voltage to blink. The LED will also blink if the ground clamp

is accidentally removed from the beam while the wet sponge is in

contact with the beam.

If the 12 m (40’) ground wire is laid near a conductive (i.e.

concrete or metal), grounded surface during testing, it may cause

GroundSense to falsely indicate a coupled condition after the wet

sponge is removed from the coated part. If GroundSense indicates

a coupled condition before the operator contacts the wet sponge to

the coated surface, its indications should be ignored. GroundSense

is for advisory use only, and does not replace the operator’s

responsibility to ensure that the detector is properly grounded.

Accessories

Accessories

A variety of accessories are available to help you get the most out

of your PosiTest LPD.

For a complete list of accessories see: www.defelsko.com/lpd

Item Order Code

Rectangular sponges (3) LPDSPONGESPK

Roller sponges (12) LPDSPONGERPK

20 cm x 20 cm (8” x 8”) flat

customizable sponge LPDSPONGECPK

Wetting agent (2) LPDWET

Accessory Pack - contains items

[i] to [v] as shown on pg. 3 LPDACCPK

NOTE:

9

Customization Options

(using items included with PosiTest LPD Complete kit or

Accessory pack)

Roller Sponge

The roller sponge may be preferred when testing over a large

surface area.

Attach the roller sponge to the base tube and PosiTest LPD.

1. Remove the rectangular sponge from the base tube (if

connected) by rotating it counterclockwise.

2. Attach the roller sponge to the base tube by rotating it

clockwise until tight.

3. Connect the base tube to the PosiTest LPD.

Replacement sponges are available (see Accessories, pg. 8)

Extending the length of the base tube

Extension Tubes

Extend the base tube an additional 0.6 m (2’) using the (2)

extension tubes.

Threaded electrode connector

Roller sponge

Base tube

Insulating collar

Base tube

Extension tube

Rectangular sponge

Extension Poles (paint roller pole / broom handle)

Attach to ACME threaded extension poles using ACME Thread

adapter or most others by using the Universal Thread adapter.

Connect the hot wire and insulating collar to PosiTest LPD.

10

Connect the

hot wire to the

extension adapter

Roller sponge

Extension adapter

ACME thread adapter

ACME threaded extension pole

Other extension poles

Universal thread adapter

Hook & loop

fastener wire ties

Hot wire

Threaded electrode connector

Insulating collar

Create a Custom Sponge

Create a Custom Sponge

Create your own custom sponge shape using the included 20 cm x

20 cm (8” x 8”) flat sponge sheet.

1. Draw your custom shape on the dehydrated sponge and cut it

out. Be sure to cut a hole in the center for connecting to the base

or extension tube.

2. Use clean tap water to wet the custom sponge. Squeeze excess

water from the sponge until it no longer drips.

3. Connect the sponge to the base/extension tube using the two

round washers.

Calibration and Verification

Calibration and Verification

Calibration

The PosiTest LPD is shipped with a Certificate of Calibration

showing traceability to a national standard. For organizations with

re-certification requirements, the PosiTest LPD may be returned at

regular intervals for calibration. DeFelsko recommends that our

customers establish their instrument calibration intervals based

upon their own experience and work environment. Based on our

product knowledge, data and customer feedback, a one year

calibration interval from either the date of calibration, date of

purchase, or date of receipt is a typical starting point.

Verification

A PosiTest LPD Verifier is available for verifying the accuracy of

PosiTest LPD detectors and is an important component in fulfilling

both ISO and in-house quality control requirements. Learn more at:

www.defelsko.com/lpd/verifier.

11

12

Battery Status / Replacement

Battery Status / Replacement

Press and briefly hold the Power button to

check battery status.

New, fully charged batteries will illuminate all four

LEDs. Batteries should be replaced/recharged

when only one LED illuminates. Replace with 3

AAA alkaline batteries as shown.

Technical Data

Technical Data

Specifications:

Sensitivity:

9V (±5%) 90K (±3%)

67.5V (±5%) 80K (±3%)

67.5V (±5%) 90K (±3%)

90V (±5%) 400K (±3%)

Thickness Range: 0 – 500 μm (0 – 20 mils)

Battery Life: > 150 hrs (Depending on battery type used)

Temperature Range: -10° to 50°C (50° to 120°F), 0 to 100% RH

Headphone: 3.5 mm mono 16-32 ohm

Battery Type: 3 AAA alkaline or rechargeable

IP Rating: Meets or exceeds IP65

Conforms To:AS 3894.2, ASTM D-5162 A, ASTM G6, ASTM G62-

A, BS 7793-2, ISO 8289 A, ISO 14654, IS K 6766, NACE SP 0188,

NACE TM 0384.

This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

13

Returning for Service

Returning for Service

Before returning the PosiTest LPD for service –

1. Install new or fully recharged batteries in the proper alignment.

2. Examine all wires, plugs and connectors for damage.

3. Ensure the test sponge is properly moistened.

4. Re-attempt measurement.

If you must return the PosiTest LPD for service,

please fill out and include the Service Form located at

www.defelsko.com/support with the detector. Be sure to also include

your company name, company contact, telephone number and fax

number or email address.

Limited Warranty, Sole Remedy

Limited Warranty, Sole Remedy

and Limited Liability

and Limited Liability

DeFelsko's sole warranty, remedy, and liability are the express

limited warranty, remedy, and limited liability that are set forth on its

website: www.defelsko.com/terms.

www.defelsko.com

© DeFelsko Corporation USA 2016 All Rights Reserved

This manual is copyrighted with all rights reserved and may not be

reproduced or transmitted, in whole or part, by any means, without written

permission from DeFelsko Corporation.

DeFelsko and PosiTest are trademarks of DeFelsko Corporation registered

in the U.S. and in other countries. Other brand or product names are

trademarks or registered trademarks of their respective holders.

Every effort has been made to ensure that the information in this manual is

accurate. DeFelsko is not responsible for printing or clerical errors.

IMPORTANT:

Introducción

Introducción

El Detector Low voltage Pinhole (porosidad) o LPD de PosiTest es

un equipo electrónico portátil diseñado para localizar pequeños

defectos y discontinuidades (llamados agujeros o poros) en un

sistema de capa protectora aplicada a un substrato conductivo.

Fundamentalmente, el PosiTest LPD consiste en una fuente de

energía, un cable de tierra, un electrodo con sonda (tipo esponja

húmeda) y una pantalla LED multifuncional.

Para utilizarla, un operador deberá mover la esponja humedecida

(electrodo) sobre el revestimiento de la superficie. Cuando se

encuentre un poro, la corriente fluirá desde la esponja a través de

la humedad por el orificio y hacia el substrato inferior. La corriente

volverá al detector a través del cable de tierra conectado al sustrato,

completando el circuito y activando las alarmas sonoras y visuales.

Para realizar su función deberá aplicarse una capa a modo de

película continua. La detección de poros (holiday) es útil para la

localización de porosidades, discontinuidades o grietas que no son

fácilmente visibles. Los detectores de poros de baja tensión se

utilizan comúnmente para examinar revestimientos de menos de

500 μm (20 mils) aplicados a substratos conductivos.

DeFelsko recomienda que el operador lea y

entienda completamente este manual antes de utilizar el PosiTest

LPD.

1

IMPORTANTE:

2

Este equipo genera voltaje. El contacto

accidental con el electrodo puede generar una descarga eléctrica

suave. El operador de PosiTest LPD deberá actuar con el debido

cuidado para minimizar el riesgo de descarga eléctrica y estar al

tanto de todas las pautas de seguridad antes de operar con este

equipo.

El PosiTest LPD está disponible en dos configuraciones de

equipo: Básico y Complete.

Equipo básico del PosiTest LPD

El equipo básico de PosiTest LPD incluye los siguientes

materiales:

[a] Detector PosiTest LPD con 3 pilas alcalinas AAA (incluidas)

[b] Tubo base de 0.3 m (1ft), Esponja rectangular con conector y

arandela aislante (ensamblado)

[c] Cable de puesta a Tierra (ground) de 4,5 m (15ft)

[d] Caimán desmontable para puesta a tierra

[e] Auricular con cable

[f] Manual de usuario

[g] Certificado de calibración de formato extenso trazable a NIST

[h] Estuche rígido pequeño

ADVERTENCIA:

3

Equipo completo de PosiTest LPD

El PosiTest LPD Complete incluye todos los materiales

contenidos en el equipo básico más los siguientes:

Los artículos mencionados anteriormente están

disponibles individualmente o en grupo en el Paquete de accesorios

PosiTest LPD (incluye artículos de [i] a [v]). Consulte accesorios

en Pág. 10.

[i] Cable de tierra de 12 m (40 ft)

con carrete

[j] Pinza de tierra con base

magnética

[k] Cable vivo de 4,5 m (15 ft)

(Pág. 11)

[l] Adaptador de rosca Universal

(Pág. 11)

[m] Adaptador de rosca ACME

(Pág. 11)

[n] Rodillos de esponja con

conector (Pág. 11)

[o] Tubo de extensión de 0,3

m (1') (2)

[p] Adaptador para extensión

[q] Gancho tipo Mosquetón

[r] Esponja plana

personalizable 20 cm x 20 cm

(8 "x 8") (Pág. 12)

[s] Arandelas redondas,

(Pág. 12)

[t] Abrazaderas de velcro

para cables

[u] Agente humectante

[v] Estuche rígido amplio

NOTA:

4

Instrucciones de montaje

Instrucciones de montaje

La esponja rectangular y el tubo de base salen de fábrica pre-

ensamblados, tanto en el PosiTest LPD Base como en el

Complete.

Para colocar el tubo de base en la base del detector siga estos

pasos:

1. Deslice el extremo del conector del tubo de base dentro del

conector de electrodo roscado del PosiTest LPD.

2. Verifique la alineación de la esponja rectangular y gire hasta la

posición horizontal.

3. Mueva el collarín aislante hacia la base del tubo, únalo con el

conector de electrodo roscado y apriete firmemente el collarín

aislante.

Los materiales incluidos en el equipo PosiTest LPD

Complete (Pág. 4) proporcionan al operador una amplia variedad

de opciones de montaje para las diferentes situaciones de la

inspección.

PosiTest LPD (panel inferior)

NOTA:

Enrosque el conector de electrodo

Tubo de base

La arandela aislante

Compartimiento de batería

Conector para

auriculares

Conector de cable de masa (tierra)

Mosquetón

5

Instrucciones de uso

Instrucciones de uso

El PosiTest LPD se utiliza normalmente en revestimientos con un

espesor medido de menos de 500 μm (20 mils). Antes de realizar

una inspección, asegúrese de que el revestimiento de superficie

está completamente curado, seco y sin contaminantes.

1. Utilice agua limpia para mojar la esponja de la prueba. Exprima

el exceso de agua de la esponja hasta que no gotee.

Si se realizan pruebas en revestimientos de más de

250 μm (10 mils), agregue un agente humectante u otro surfactante

de baja espuma en el agua para reducir la tensión superficial del

agua y facilitar el flujo en discontinuidades.

2. Conecte la abrazadera del cable de tierra a un punto sin

recubrimiento de la pieza que desee comprobar. Conecte el

cable de tierra al conector de tierra en la parte inferior del

PosiTest LPD.

3. Pulse el botón de encendido para arrancar la unidad. Se

realizará una prueba automática (Pág. 7).

Si no utiliza el auricular suministrado, pulse el botón

de alarma de Audio para activarla.

4. Utilice el botón selector de voltaje (Pág. 8) para configurar

el voltage de prueba requerida.

5. Compruebe el correcto funcionamiento y la alarma presionando

la esponja directamente contra la pinza de tierra o en algún punto

sin recubrimiento en la pieza. Esto completará el circuito eléctrico

y accionará la LED y las alarmas sonoras. Si no se observa

ninguna alarma compruebe todas las conexiones, cables, estado

de la batería y la humedad de la esponja.

6. Coloque la esponja sobre el revestimiento de superficie y

asegúrese de que el indicador GroundSense™ (Pág. 9) se

mantiene encendido y no parpadea. Si la LED parpadea, haga

lo siguiente:

• Compruebe las conexiones de cables de masa en la pinza y el

detector.

CONSE O:

CONSE O:

Other manuals for PosiTest LPD

1

This manual suits for next models

1

Table of contents

Languages:

Other DeFelsko Security Sensor manuals

Popular Security Sensor manuals by other brands

Guardian Fall Protection

Guardian Fall Protection 42001 instruction manual

Zeiss

Zeiss 4QBSD instruction manual

Inovonics

Inovonics EE1261 installation instructions

nest

nest Detect user guide

Huazheng Electric Manufacturing

Huazheng Electric Manufacturing HZJF-9008 user manual

Gewiss

Gewiss CHORUS GW 13 756 installation instructions