DeFelsko PosiTest High voltage Holiday Detector User manual

Instruction Manual v. 1.0

High voltage Holiday Detector

Introduction

1

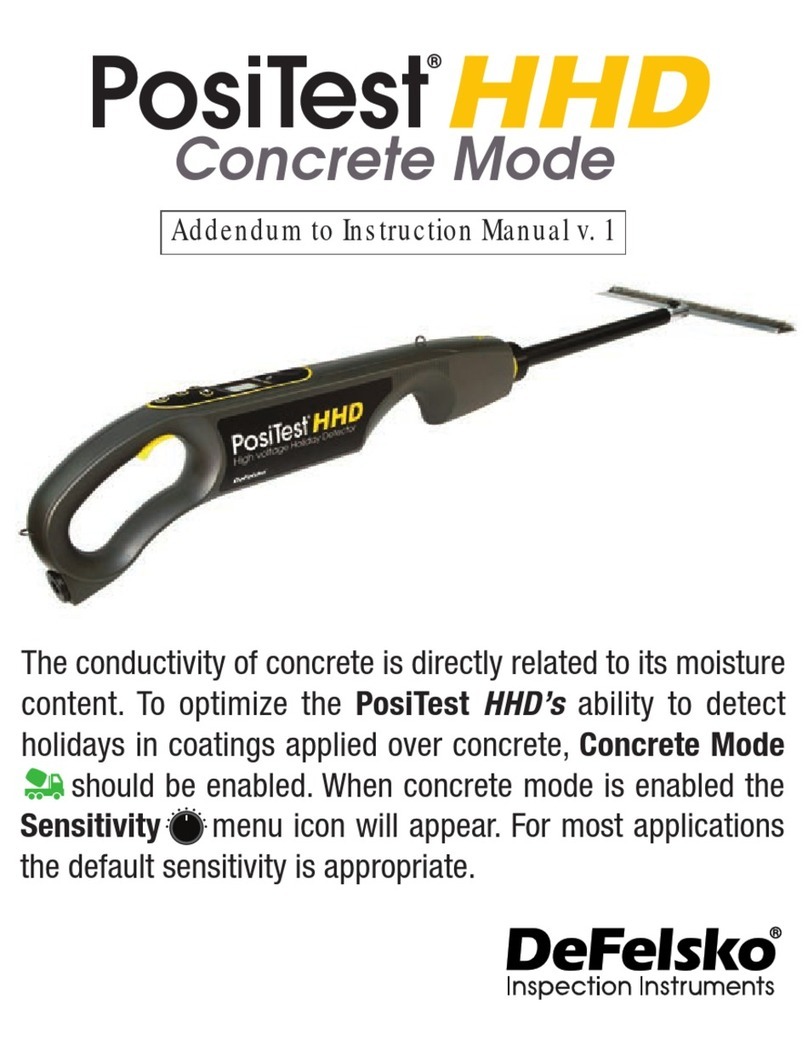

The PosiTest High voltage Holiday Detector (HHD) is a Pulse

Type DC Holiday Detector designed to locate small defects and

discontinuities (called “pinholes” or “holidays”) in a protective

coating system applied to a conductive substrate. High voltage

holiday detectors are commonly used to inspect non-conductive

coatings thicker than 500 µm (20 mils).

Designed for maximum versatility, the

PosiTest HHD

can be used

in either a stick-type or wand-type configuration (when used with the

optional wand accessory). www.defelsko.com/manuals/hhd

The PosiTest HHD has two primary operating modes:

1.Standby Mode: The detector is powered-up but not generating

a high voltage.

2.Detection Mode: The detector is generating a high voltage and

analyzing electrode voltage and current to determine if holidays

are present. Holidays can be detected when the charged

electrode is passed over the coated surface. When a holiday is

encountered, current flows from the electrode into the substrate.

The current returns to the detector through the ground (earth)

wire, completing the circuit and triggering audible and visible

alarms. An integrated peak reading voltmeter measures and

displays the output voltage on the display while in use.

This equipment generates high voltages up

to 35,000V (35kV). Accidental contact with the electrode may result

in an electric shock. Always keep the working end of the electrode

away from your body and never touch it when activated. The

PosiTest HHD operator should exercise all due care to minimize

their risk of electric shock and be aware of all relevant safety

guidelines before using this equipment. When in Detection Mode

(pg. 1) generating high voltage or if an arc is being produced, the

PosiTest HHD will generate broadband Radio requency

emissions. Care must be observed in the vicinity of sensitive

electronics or radio equipment.

2

Operational Safety

De elsko recommends that the operator read and

fully understand this manual prior to using the PosiTest HHD.

IMPORTANT:

WARNING:

or safe PosiTest HHD operation:

DO NOT —

wUse in wet or rainy conditions.

wUse if you are fitted with a pacemaker.

wUse without first connecting the ground (earth) cable.

wTouch or allow anyone else to touch the object being tested.

!

DO —

wEnsure that all connections are secure and tight.

wWear appropriate gloves and footwear

wUse flagging tape and signage to keep other personnel away

from the testing area.

wCommunicate the hazards associated with holiday testing with

all personnel on-site via tailgate meetings or ield Level

Hazard Assessments.

wPower O the detector before touching the spring or brush.

wConfirm the testing voltage requirements and ensure this is

communicated to all personnel involved or working in the area.

3

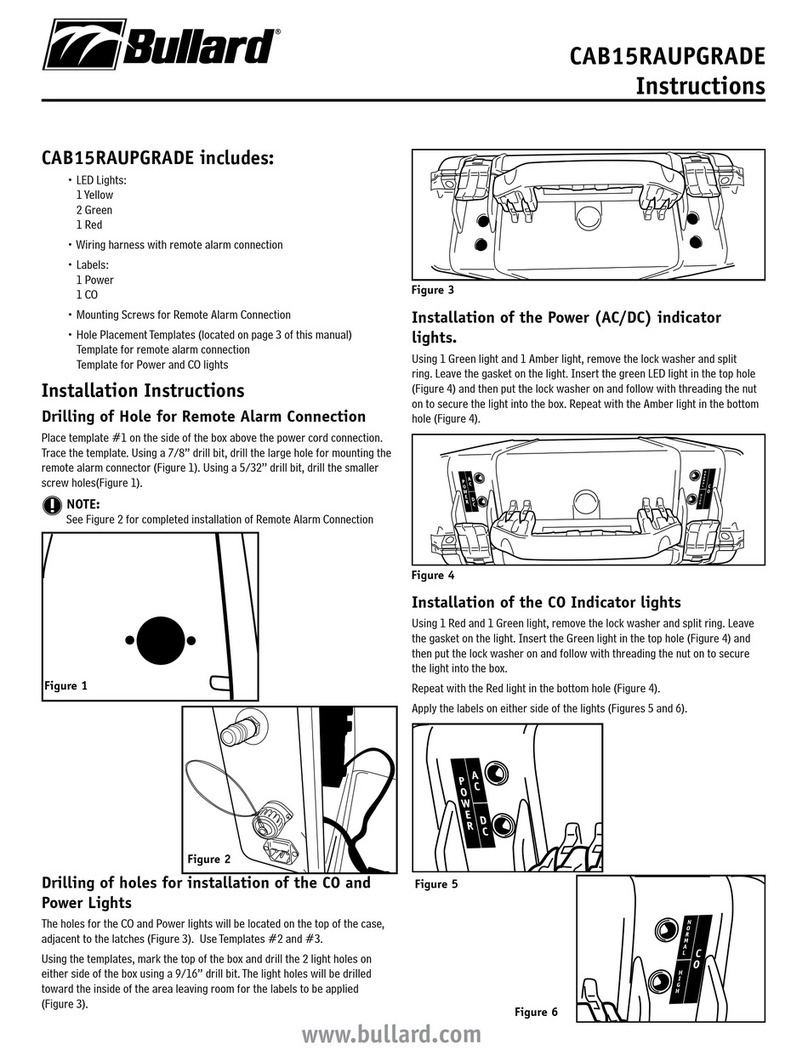

The PosiTest HHD Kit contains the following materials.

APosiTest HHD

B 50 cm (20”) Extension Rod & Thumb Screw

C Stainless Steel an Brush

D 7.6 m (25’) Ground (earth) cable with Ground Clip

E Shoulder Strap

Li-ion Battery Pack with built-in charge state indicator

G Smart Battery charger with universal AC voltage input

H Pelican Storm Case [accommodates rolling spring electrode

for inspecting pipes up to 64 cm OD (25”) and brushes up to

90 cm (36”)]

PosiTest HHD Kit

A variety of optional and replacement accessories are available to

help you get the most out of your PosiTest HHD.

See www.defelsko.com/hhd to learn more.

Accessories

AD

E

CB

H

G

4

PosiTest HHD Overview

Speaker

Strobe alert

LCD display

Control panel

Madein USA

Li-Ion Battery

High voltage Holiday Detector

Madein USA

www.defelsko.com

e

a

f

b d

k

g

h

i

j

l

c

Not Shown

Shoulder Strap

Pelican Case

a an brush

bThumb screw

cAnti-rotation tab

dShoulder strap attachment points

eExtension rod

fLock gate for extension rod

gBattery compartment

hBattery

iBattery cover

jSafety trigger

kGround cable socket

lGround cable

5

Quick Start

The PosiTest HHD powers-up when the power button is

pressed. To preserve battery life, it powers-down after

approximately 5 minutes of no activity. Alternatively, select from

the menu for immediate power-down. All settings are retained.

1. Review Operational Safety (pg. 2)

2. Assemble the detector for the application to be tested –

“Assembly Instructions” (pg. 5).

3. Properly ground the instrument – “Grounding” (pg. 6).

4. Set the test voltage – “Adjusting the Test Voltage” (pg. 7).

5. Confirm that the detector is in proper working condition –

“Operational Check” (pg. 6).

6. Perform the test – “Instrument Operation” (pg. 9).

Assembly Instructions

STEP 1. Attach the Extension Rod: Press and hold the lock gate

button while inserting the rod. Ensure the anti-rotation tab on the rod

is aligned with the corresponding receptacle on the PosiTest HHD.

Release the lock gate button and ensure the rod is securely

attached.

STEP 2. Attach the Electrode: Loosen the thumb screw on the free

end of the extension rod, attach the required electrode (or adaptor),

and re-tighten the thumb screw.

STEP 3. Attach the Ground Cable: Align the flat side of the cable

connector pin with the alignment mark in the ground cable socket on

the detector, insert fully and rotate the connector clockwise 180° to

secure the cable. Rotate the cable connector 180° counter-

clockwise to unlock and remove the ground cable. (see

“Grounding”

pg. 6

)

STEP 4. Attach the Shoulder Strap: Clip the strap to the strap

attachment points.

STEP 5. Install the Battery: Loosen the screw on the battery

compartment and remove the cover. Install the battery in the correct

orientation. Replace the cover and secure with the screw.

6

Grounding

Ensure the ground (earth) cable is uncoiled and fully extended.

Connect the ground clip to an exposed (uncoated) area of the part,

or grounding rod. If no ground is available, a trailing ground wire,

grounding collar, or grounding mat may be used. Verify that the

instrument is properly grounded by touching the electrode to the

grounded substrate, ensuring that the audible and visual alerts are

properly triggered.

Never touch the ground cable while the detector is operating.

WARNING:

Operational Check

Prior to each use, the PosiTest HHD should be checked to ensure

it is operating correctly. This operational check ensures that the

audible and visual alerts are operating properly and the instrument

has voltage output. or Calibration and Verification see pg. 10.

Performing an Operational Check

1. Ensure the instrument and all components are assembled.

2. Visually inspect each cable and connection.

3. Press and release the power button on the top of the

PosiTest HHD

.

4. The

PosiTest HHD

should power on and display the test

voltage.

5. Press and hold the button and then activate and hold the

safety trigger on the

PosiTest HHD

to turn on the high voltage

and activate Detection Mode. The button can now be

released.

6.The

PosiTest HHD

should begin testing at the selected voltage.

The display will show the voltage being generated.

7.Touch the electrode to the bare ground wire or grounded

substrate of the part being inspected. Note the audible and

visual alerts. Repeat this step several times.

A spark may or may not be seen and heard. When

using a lower test voltage and on bright sunny days, the spark

may not be seen or heard.

NOTE:

7

8. Release the safety trigger to turn high voltage O and return

the

PosiTest HHD

to Standby Mode.

The

PosiTest HHD

is now ready to use.

Adjusting the Test Voltage

1.With the detector powered ON and in Standby Mode, press

to open the menu and then select the Voltage Set icon .

2.The detector will display the test voltage

3.Use the or buttons to adjust the voltage. The voltage

adjusts in 10V increments between 500V and 1,000V, and in

100V increments between 1kV and 35kV.

4.Select OK with the button to save the voltage and exit.

-

+

The formula and suggestions for setting voltage are

supplied as a guide. Always consult the coating manufacturer for

recommended voltage settings.

NOTE:

The inspection voltage should be obtained from the coating

manufacturer’s specification or by contacting the coating

manufacturer. Based on international standards, formulas and

tables can be used as a guide for setting voltages on various

coating thicknesses. A sample calculation from NACE International

Standard Practice SP0274-2011 is as follows:

The voltage output of the PosiTest HHD is regulated and maintains

the test voltage under normal electrode loading. When in Detection

Mode, the test voltage being generated is displayed on the

PosiTest HHD. Minor fluctuations on the display are normal during

inspection as the PosiTest HHD is regulating the test voltage.

When the electrode is connected to ground, the display will show

“---" indicating that the generated voltage is less than the minimum

of 500V.

V = 1,250 √T (mils)

V = 7,900 √T (mm)

where V = Voltage in volts

T = Thickness of coating

8

Adjustment using the built-in Voltage Calculator

The Voltage Calculator simplifies the task of setting the correct

test voltage for a particular coating system. It prompts the user to

enter the coating thickness on the part to be tested and the

standard the user is conforming to, and automatically calculates

the correct test voltage.

1. With the detector powered ON and in Standby Mode,

press to open the menu then select the Voltage

Calculator icon from the Menu

2. The gage will display a list of common international standards

3. Use the or button to highlight the desired standard

4. Press the button to select the desired standard

5. Depending on the selected standard, a Units Selection menu

may appear. If prompted, select the desired coating thickness

measurement units.

6. A thickness adjustment screen is now shown. Using the or

button, adjust the coating thickness to the maximum thickness

of the coating to be inspected.

Depending on the standard chosen, the range of

selectable coating thicknesses may be limited.

NOTE:

7. Press the button to select the thickness. The PosiTest HHD

will now calculate the test voltage based on the standard and

units selected.

-

+

-

+

10.5 1

The following standards are available when using the Voltage

Calculator:

AS 3894.1: 1, 2, 3, 4

ASTM D4787, D5162, G62

ISO 29601

NACE SP0274, SP0188, SP0490

Voltage adjustments will be retained when the PosiTest

HHD is powered O . Perform a RESET (pg. 11) to return to the

default voltage setting (1kV).

NOTE:

9

Instrument Operation

The PosiTest HHD is ready for testing only after

performing Steps 1-4 in the Quick Start (pg. 5).

IMPORTANT:

1. Press the power button to power-up the detector. The

PosiTest HHD

is now in Standby Mode (pg. 1).

2. Press the button to access the menu. Navigate using

the or buttons. Press to select.

3. Select the preferred Audio and Strobe Alarm settings (pg. 10).

4. Adjust the test voltage (pg. 7).

5. To activate the high voltage output and enable Detection

Mode, press and hold the power button and activate and

hold the safety trigger. The lightning bolt icon will appear at

the bottom of the display and the

PosiTest HHD

will show the

test voltage being generated.

6. Continue holding the safety trigger and release the power

button .

7. Move the electrode over the coated surface at a travel speed

not to exceed 0.3m/second (1ft/second) to locate defects. If a

holiday is detected, the

PosiTest HHD

will activate the strobe

and/or the audio alarm (depending upon setup).

8. Release the safety trigger to deactivate the high voltage output

and return the

PosiTest HHD

to Standby Mode (pg. 1).

-

+

10

Calibration and Verification

Calibration

The PosiTest HHD is shipped with a Certificate of Calibration

showing traceability to a national standard. De elsko recommends

customers establish calibration intervals based upon their own

experience and work environment. A detector used frequently,

roughly, or in harsh operating conditions may require a shorter

calibration interval than if used less frequently and handled with

care. Based on our product knowledge, data and customer

feedback, a one-year certification interval from either the date of

calibration, date of purchase, or date of receipt is a typical starting

point.

Verification

The PosiTest HHD includes an integrated voltmeter (crest meter,

jeep meter) which measures and displays the peak output voltage

of the detector on the LCD display. This provides the ability to

monitor the generated voltage of the PosiTest HHD to a specific

voltage within the 500V – 1,000V range in 10V steps, and 1kV –

35kV range in 100V steps. The PosiTest HHD integrated voltmeter

is accurate to +/- 5% of the generated test voltage.

The PosiTest HHD Verifier is available for verifying the accuracy

of the PosiTest HHD and other high voltage holiday detectors and

is an important component in fulfilling both ISO and in-house quality

control requirements.

Learn more at: http://defelsko.com/hhd/verifier

Audio Alarm

The PosiTest HHD has three audio alarm modes. Select the

icon from the menu to select an alarm mode.

Audio Alarm is O

The detector emits a continuous tone when high

voltage is on and a loud alarm tone when a holiday

is detected. This is the default audio alarm mode.

The detector emits a loud, continuous tone when

high voltage is on and is silent when a holiday is

detected.

Settings

The selected audio alarm mode is retained during power cycles.

11

Strobe Alarm: The PosiTest HHD uses a high-intensity

white LED to alert the operator when a holiday is

detected.

The strobe alarm can be turned ON or O :

Select the strobe icon or to toggle the strobe alarm

state. A red icon will appear on the display when the

strobe alarm is turned off.

The strobe alarm setting is retained during power cycles.

Reset: Perform a reset of the PosiTest HHD by

selecting from the Menu. A reset restores factory

settings and returns the detector to a known condition.

Settings are returned to the following:

Output voltage = 1kV

Audio Alarm = Continuous tone when high voltage is on

and loud alarm when a holiday is detected

Strobe alarm = ON

Power OFF: Select to power-down the PosiTest HHD.

All settings are retained.

Return/Exit Menu: Select to return to a previous menu

or exit the menu.

and Mode: When the optional wand accessory is used,

it may be desirable to enable Detection Mode (high

voltage output) without the need to keep the trigger

activated continuously. To activate the and Mode press

and hold the power button. Activate the trigger, then

release the trigger while continuing to hold the power

button until a lock icon is displayed on the LCD. Once

the lock icon is displayed, the power button can be

released and the PosiTest HHD will remain in Detection

Mode without the trigger needing to be activated. To

disable and Mode, press any button or activate the

trigger.

This visual alert may affect operators who

are susceptible to photosensitive epilepsy or other

photosensitive conditions.

WARNING:

Strobe

On

Strobe

Off

and Mode is not available if the test voltage is greater

than 15kV.

NOTE:

12

Battery Status, Charging and Installation

The PosiTest HHD Kit includes a removable, rechargeable lithium-

ion battery. It is recommended that the battery be charged after each

use.

The battery icon on the display will turn red with one bar remaining

when the battery is low. This indicates that the battery requires

charging.

Made in USA

Li-Ion Battery

High voltage Holiday Detector

Made in USA

www.defelsko.com

The battery also features a built-in charge state indicator. Press

the button on the battery to display the remaining power.

Battery Charging

The supplied smart battery charger has color LEDs to indicate

charge status:

One time Red/Orange/Green Self-test: Charger is ready for use.

Red/Green blinking: Battery recognition and initialization.

Orange: The inserted battery is of the correct type and is currently

being charged.

Green: The battery is fully charged and can be removed for use.

Red blinking: The battery is too hot or too cold to be charged

without damage. If the battery is too cold it will be charged as soon

as it has warmed up sufficiently. If the battery is too hot it should

be removed and allowed to cool down.

Red: The battery is damaged and cannot be recharged. Replace

it with a new battery.

The charger automatically switches between 110V and 240V AC

making it ideal for use worldwide.

The transport of Li-ion batteries is regulated. The supplied

Li-ion battery is rated at 72Wh (watt-hours) and has been

NOTE:

13

manufactured in accordance with the UN Manual of Tests and

Criteria Part III subsection 38.3. When transporting the PosiTest

HHD or shipping the battery separately, observe all local regulations.

Use care when handling the rechargeable Li-ion battery.

The battery may be damaged if dropped. NEVER use a cracked,

swollen or otherwise damaged battery. DO NOT puncture,

disassemble or modify the battery. DO NOT expose the battery to

high temperatures or dispose in fire.

CAUTION:

Storing the PosiTest HHD

When not in use, the PosiTest HHD should be stored in the supplied

Pelican Storm case.

Keep the instrument clean and dry. After use, clean the instrument

with a soft, damp cloth, then wipe dry. Do not use solvents such as

lacquer thinner, methyl ethyl ketone, etc.

Keep all electrical contacts clean.

IMPORTANT:

PosiTest HHD Troubleshooting

PosiTest HHD will not detect holidays

w

Check Electrode Connections: With the detector powered O ,

check all connections. Ensure the extension rod is fully engaged

within the barrel of the PosiTest HHD and the lock gate is

engaged.

w

Check Ground Connections: With the detector powered O ,

remove the ground cable and fully reinsert it twisting clockwise

180° until locked. Ensure the opposite end is clean and well

connected to the substrate of the coating system being

inspected.

w

Check Test Voltage: If the test voltage is too low, the PosiTest

HHD will not find holidays.

w

Reduce Travel Speed: Recommended travel speed of the

PosiTest HHD is a maximum of 0.3m/second (1ft/second). Since

the PosiTest HHD operates at a pulse repetition rate of 30

pulses per second, it is possible to miss holidays if the travel

speed exceeds the recommended maximum.

Always contact your carrier prior to shipping this

battery to ensure compliance with local regulations.

IMPORTANT:

14

PosiTest HHD turns OFF while in use

w

Check Battery: A low or defective battery will not be able to

sustain the power required to operate the PosiTest HHD. Charge

or replace the battery. To determine if the battery is defective

refer to Battery Charging (pg. 12).

hen generating high voltage, the PosiTest HHD display is

lower than the test voltage.

w

The PosiTest HHD integrated jeep/crest meter ALWAYS displays

the actual voltage being generated. Although the PosiTest HHD

will regulate the output voltage to match the test voltage, there

are circumstances when it is not possible to generate the test

voltage. or example, overloading of the electrode by setting the

voltage higher than recommended for the coating system under

inspection may result in a generated voltage lower than the test

voltage. Reducing the brush or electrode size will also reduce

loading.

Accessories

A variety of optional accessories are available to help you get the

most out of your PosiTest HHD.

w

Handheld Wand w/ 1.5m (5’) Insulated Cable

w

10cm (4”) Conductive Rubber Paddle

w

Steel lat Wire Brushes

w

Steel Rolling Spring Electrodes

w

Rolling Spring Electrode Connector

w

Rolling Spring Coupler (sold in pairs)

w

15cm (6”) Extension Rod for use in areas of limited

clearance/headroom

w

PosiTest HHD Verifier (Calibrated peak reading voltmeter can

be used to verify operation of the PosiTest HHD.)

w

Tinker & Rasor Electrode Adaptor

w

PCWI Electrode Adaptor

or a complete list of accessories see: www.defelsko.com/hhd

15

Technical Data/Specifications

Applicable Standards: AS 3894.1, ASTM D4787,

ASTM D5162, ASTM G62, ISO 29601, NACE SP0274,

NACE SP0188, NACE SP0490.

The PosiTest HHD meets the Electromagnetic

Compatibility Directive and Low Voltage Directive

when operated in Standby Mode.

wType: Pulse DC (30Hz)

wRange: 500 – 35,000V

wResolution: 500 – 1,000V in 10V increments, 1kV – 35kV in

100V increments

wOutput Accuracy: +5%

wOperating Temperature Range: -20° to 60° C (-4° to 140° )

wBattery: Rechargeable Smart 72Wh Li-ion battery

wCharge Time: 3 hours

wLife: Depends on test voltage and electrode load

wTypical Life: Ø 12” Rolling Spring @ 10kV, 40 hours

Ø 40” Rolling Spring @ 10kV, 30 hours

weight: 1.8 kg (4 lbs.) with battery (no electrodes)

wDimensions (no attachments):64 cm x 6.4 cm x 13 cm

(25” x 2.5” x 5”)

Limited arranty, Sole Remedy

and Limited Liability

www.defelsko.com

© 2019 De elsko Corporation USA

All Rights Reserved

This manual is copyrighted with all rights reserved and may not be reproduced or transmitted,

in whole or part, by any means, without written permission from De elsko Corporation.

De elsko, PosiTest, PosiTector, and PosiSoft are trademarks of De elsko Corporation

registered in the U.S. and in other countries. Other brand or product names are trademarks

or registered trademarks of their respective holders.

Every effort has been made to ensure that the information in this manual is accurate.

De elsko is not responsible for printing or clerical errors.

Before returning the PosiTest HHD for service –

1.Install a fully charged battery in the correct orientation.

2.Inspect all wires, plugs, and connectors for damage.

3.Power up PosiTest HHD by pressing the power button .

4.Reset the PosiTest HHD (See pg. 11).

5.Press and hold power button while activating the trigger.

6.Connect end of extension rod to ground (earth) lead to

simulate a holiday.

7.If the PosiTest HHD does not activate the Audio and Strobe

alarms or create an arc, remove the battery and return the

PosiTest HHD without the battery for service.

IMPORTANT:

If you must return the PosiTest HHD for service,

please follow the instructions provided at

https://www.defelsko.com/service-support#Service

De elsko's sole warranty, remedy, and liability are the express

limited warranty, remedy, and limited liability that are set forth on

its website: www.defelsko.com/terms

Returning for Service

Manual de instrucciones v. 1.0

High voltage Holiday Detector

Detector de Porosidad de Alto Voltaje

Introducción

El Detector de porosidad de alto voltaje PosiTest (HHD del inglés

“High-voltage Holiday Detector”) es un detector de corriente

directa (CD) por pulsos diseñado para localizar pequeños defectos

y discontinuidades (llamados porosidades o “holidays”) en un

sistema de recubrimientos protectores aplicados a un substrato

conductivo. Los detectores de porosidad de alto voltaje se utilizan

de manera habitual en inspecciones de recubrimientos no

conductores con espesor superior a 500 µm (20 mils).

Diseñado para una versatilidad máxima, el PosiTest HHD puede

utilizarse tanto en configuración tipo bayoneta o con extensión y

maneral (cuando se utiliza con el accesorio de maneral opcional).

www.defelsko.com/manuals/hhd

El PosiTest HHD tiene dos modos de funcionamiento principales:

1.Modo de esper : El detector está encendido pero no genera

alto voltaje.

2.Modo de detección: El detector está generando un alto voltaje

y simultáneamente analiza la corriente y voltaje en el electrodo

para determinar si hay presencia de poros. Los poros pueden

detectarse cuando el electrodo cargado se desliza sobre la

superficie revestida. Cuando se encuentra un poro, la corriente

fluye desde el electrodo hacia el sustrato. La corriente volverá al

detector a través del cable de tierra (ground), completando el

circuito y activando las alarmas sonoras y visuales. Un voltímetro

integrado de lectura de pico medirá y mostrará el voltaje de

salida en la pantalla mientras esté en uso.

1

This manual suits for next models

1

Table of contents

Languages:

Other DeFelsko Security Sensor manuals

Popular Security Sensor manuals by other brands

Guardian Fall Protection

Guardian Fall Protection 42001 instruction manual

Zeiss

Zeiss 4QBSD instruction manual

Inovonics

Inovonics EE1261 installation instructions

nest

nest Detect user guide

Huazheng Electric Manufacturing

Huazheng Electric Manufacturing HZJF-9008 user manual

Gewiss

Gewiss CHORUS GW 13 756 installation instructions