1

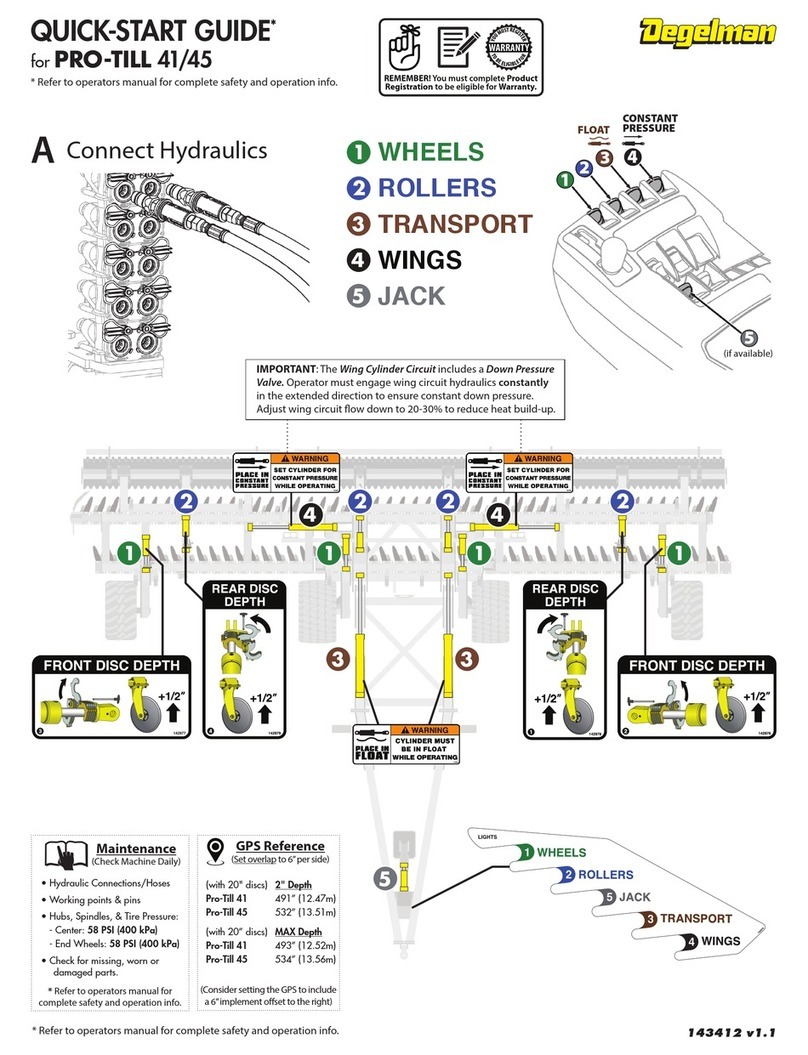

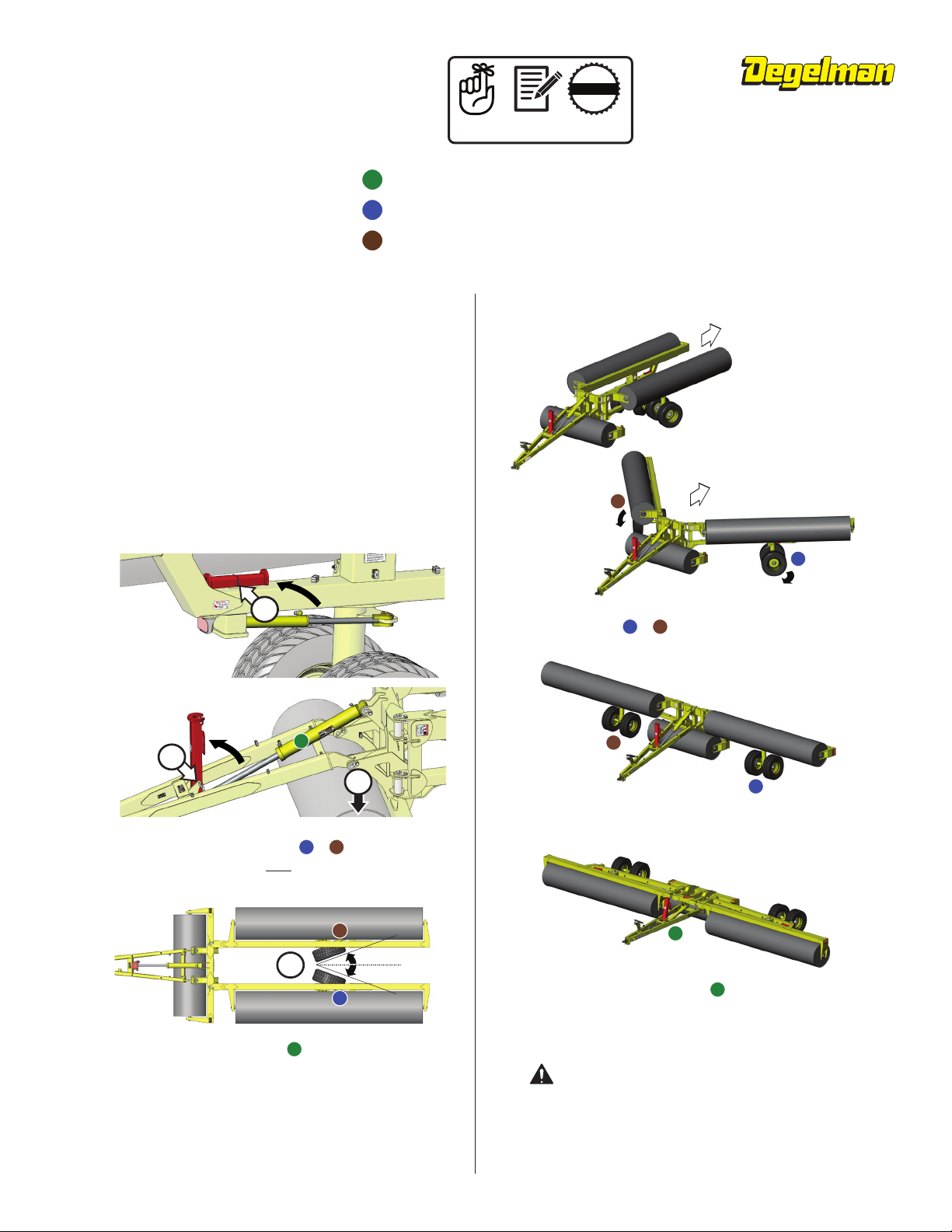

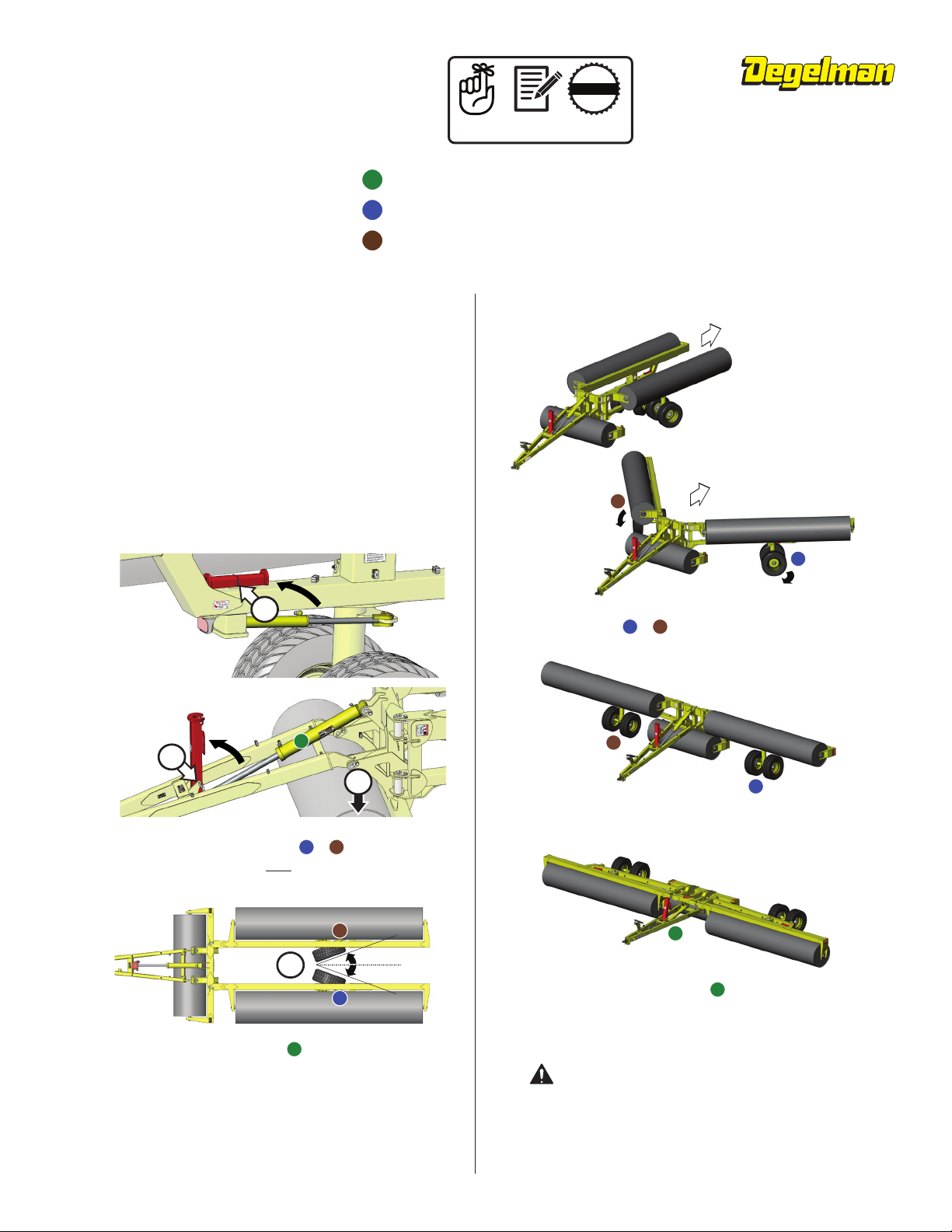

TRANSPORT / FLOAT.....................Transport Cylinder

LEFT HAND WHEEL ..................LH Endwheel Cylinder

RIGHT HAND WHEEL ................RH Endwheel Cylinder

3

2

1

1) Drive landroller onto level ground, straight behind the

tractor.

• Ensure there is plenty of room behind and to the sides

of the landroller for backing into field position.

2) Remove all 3red transport bars. (1 on front transport

cylinder and 2 located on rear endwheel cylinders).

• Place the transport bars into the storage positions

shown and secure with lock-pins.

Note: You may need to activate (slightly extend) the hydraulic

cylinders to allow removal of the cylinder transport bars.

A

B

Connect Hydraulics

Backing Into Field Position

142785 v1.0

QUICK-START GUIDE*

for HY-ROLLER

* Refer to operators manual for complete safety and operation info.

T

O

B

E

E

L

I

G

I

B

L

E

F

O

R

Y

O

U

M

U

S

T

R

E

G

I

S

T

E

R

WARRANTY

REMEMBER! You must complete Product

Registration to be eligible for Warranty.

4) Retract the transport cylinder to lower the center drum

until the weight of the drum is on the ground.

1

3

2

6) Turn the wheels & while backing up. Avoid

pushing on the sidewalls of the tires.

32

7) Backup until the wings are straight in line with the

center frame. Ensure wheels are straight before Step 8.

8) Activate the transport cylinder to retract the cylinder.

Retract until all the roller drums are on the ground. Once

all drums are on ground, set transport circuit to “float”

position.

1

IMPORTANT: Set the tractor hydraulic remote that

activates the transport cylinder into “float” position. This

will allow the hitch pole to contour more effectively and

prevent strain or possible damage to the machine.

3) Activate the End Wheel Circuits & to turn each

Endwheel to around 20°max. Try to match the angles

on each wheel.

32

3

2

320° MAX

20° MAX

(LH & RH)

2

2

4

1

5) Slowly back-up the landroller until wings are slightly

spread.

3

2