-1-

143444 - Silage King (21-April-2023)

Introduction

Important: Check torque on all

hardware periodically. Check after

first 2, 10, 40, then every 200 hours.

• Torque values listed are for general

use only. If a different torque value

or tightening procedure is specified for a specific

application, do not use these values.

• Refer to the “Parts” section for proper grade and

length of bolts for replacement parts.

• Do not replace locknuts with nuts and lock washers.

Replace all parts with original, specified parts only.

• Dry values shown mean the bolt/nut is plain or zinc

plated without any lubrication.

CHECK HARDWARE TORQUE

TORQUE

all hardware

Unless otherwise stated:

Hardware - Hex, GR5 UNC (imperial) or P8.8 (metric)

Hoses - 3/8, ends come with 3/4 JIC female swivel.

The tables below give correct torque values for various

bolts and capscrews. Tighten all bolts to values in

charts unless otherwise noted. Check tightness of bolts

periodically, using torque charts as a guide. Replace

hardware with the same strength (Grade/Class) bolt.

HYDRAULIC FITTING TORQUE

Size lb.ft (N.m)

3/4 75 (100)

7/8 90 (122)

IMPERIAL TORQUE SPECIFICATIONS

(based on “Zinc Plated” values)

Size Grade 5 Grade 8

lb.ft (N.m) lb.ft (N.m)

1/4” 7 (10) 10 (14)

5/16” 15 (20) 20 (28)

3/8” 25 (35) 35 (50)

7/16” 40 (55) 60 (80)

1/2” 65 (90) 90 (120)

9/16” 90 (125) 130 (175)

5/8” 130 (175) 180 (245)

3/4” 230 (310) 320 (435)

7/8” 365 (495) 515 (700)

1” 550 (745) 770 (1050)

1-1/8” 675 (915) 1095 (1485)

1-1/4” 950 (1290) 1545 (2095)

1-3/8” 1250 (1695) 2025 (2745)

1-1/2” 1650 (2245) 2690 (3645)

SAE-5 SAE-8

METRIC TORQUE SPECIFICATIONS

(based on “Zinc Plated” values)

Size Class 8.8 Class 10.9

lb.ft (N.m) lb.ft (N.m)

M6 7 (10) 10 (14)

M8 16 (22) 23 (31)

M10 30 (42) 45 (60)

M12 55 (75) 80 (108)

M14 90 (120) 125 (170)

M16 135 (185) 195 (265)

M18 190 (255) 270 (365)

M20 265 (360) 380 (515)

M22 365 (495) 520 (705)

M24 460 (625) 660 (895)

M27 675 (915) 970 (1315)

M30 915 (1240) 1310 (1780)

M33 1250 (1695) 1785 (2420)

M36 1600 (2175) 2290 (3110)

8.8 10.9

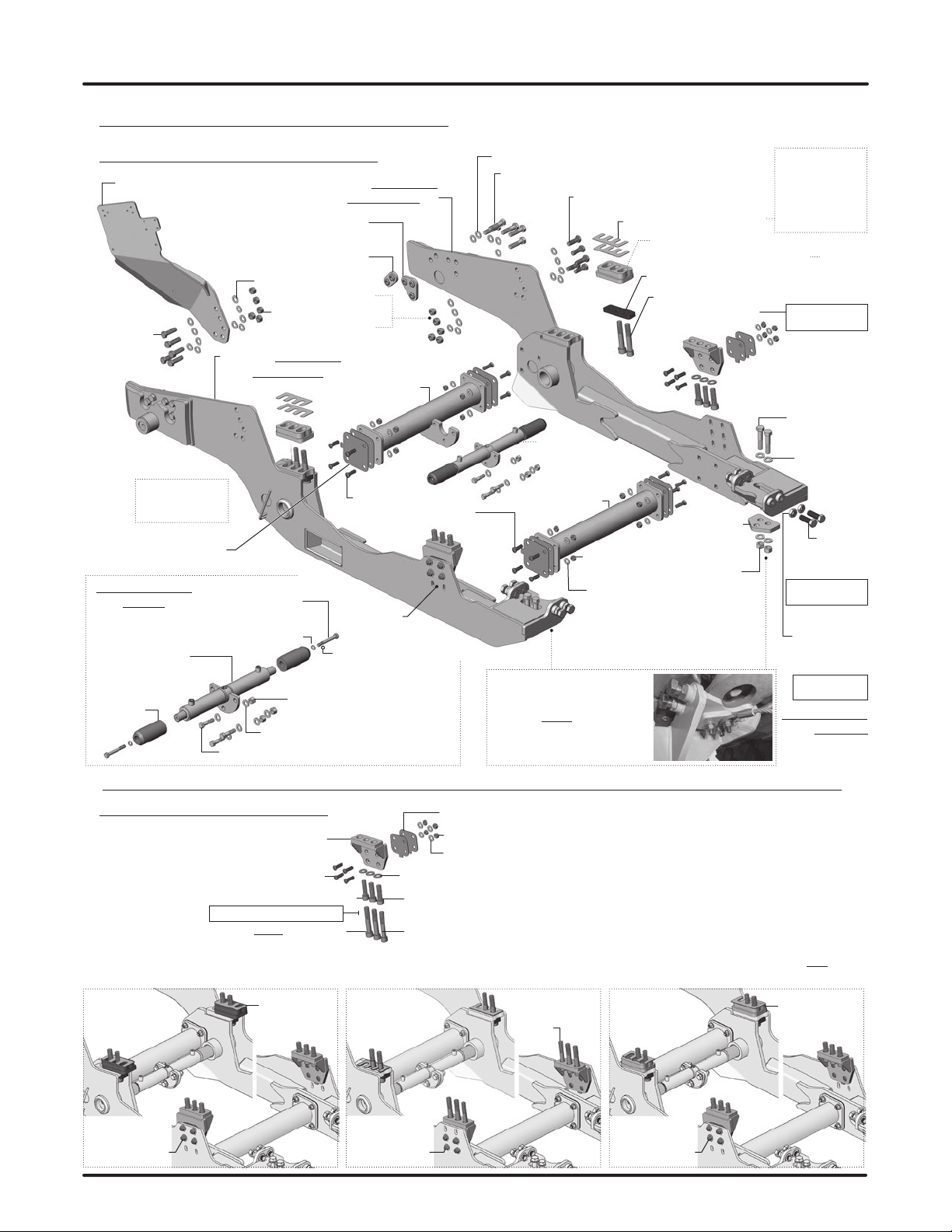

Overview of Silage King Blade Manual (143415)

• Safety

• Operation

• Transport & Storage

• Blade Components / Attachments

• Tilt Bell Assembly

• Blade Tilt Options

• Blade Hydraulic Options

• Fold-Back Overview for Hinge Kit

• Maintenance

• Optional Blade Attach/Detach (NANT & NAHT)

• Troubleshooting

• Warranty

The documentaion for this particular fit-up has been

divided into two manuals:

1) Silage King Blade Components, Operation,

Safety, and Maintenance. (Manual 143415)

2) Tractor Fit-up & Frame Components, Hydraulic

Routing, and Mounting Procedure. (This Manual)

It is strongly recommended that you familiarize

yourself and completely read through both manuals,

have them both available for quick-reference, and

that you review them annually.

MANUAL OVERVIEW HARDWARE TORQUE SETTINGS