Deitz PHARMAFILL HT6-B User manual

Model HT6-B Heat Shrink Tunnel

Operation Manual

Rev B

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

I

CONTENTS

1. GENERAL ILLUSTRATIONS ........................................................................ pgs II thru VI

2. SAFETY REMINDER..................................................................................................... 1

3. INTRODUCTION.......................................................................................................... 2

4. SPECIFICATIONS ......................................................................................................... 4

5. GENERAL INFORMATION ........................................................................................... 5

6. INSTALLATION............................................................................................................ 7

7. SET-UP........................................................................................................................ 8

8. OPERATION ................................................................................................................ 9

9. MAINTENANCE........................................................................................................... 10

10. TECHNICAL INFORMATION ........................................................................................ 11

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

II

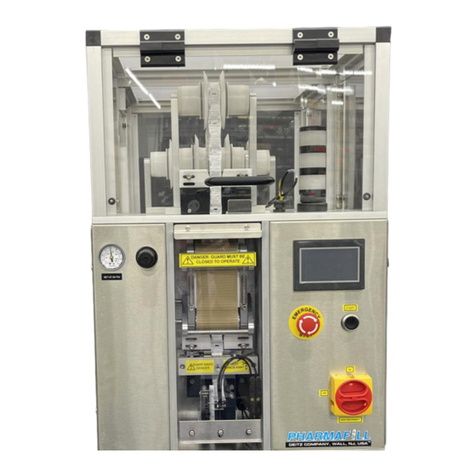

Section 1 - GENERAL ILLUSTRATIONS

HT6B Heat Tunnel–Front View

1. Blower Intake Cover

2. Blower

3. Control Panel

4. Tunnel Enclosure

5. Handle

6. Lift Stand –with manual height adjustment

5

4

6

3

2

1

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

III

HT6B Heat Tunnel–Rear View

1. Power Cord

2. Power Requirements

3. Mounting Rods

2

1

3

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

IV

HT6B Heat Tunnel–Control Panel

1. Main Power and Fan Switch –circuit breaker

2. Heater Element Temperature Controls –Front and Rear

1

2

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

V

HT6B Heat Tunnel –Left End View

1. Intake End of Tunnel Enclosure

2. Rubber Curtain

2

1

Belt Moves

This Way

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

VI

HT6B Heat Tunnel–Bottom View

1. Air Blade - Left Bottom

2. Air Blade - Right Bottom

3. Heating Elements –(not visible)

4. Inner Slotted Panels –(not visible)

3

1

2

4

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

1

Section 2 - SAFETY REMINDER

Warning

This machine contains moving parts and

operates automatically. This may present a

hazard to personnel.

Never operate this machine with any covers or guards removed or any guard switches or

safety devices removed or bypassed.

Only people who have been correctly trained should operate or clean this machine.

Only people who are correctly qualified and trained should carry out maintenance,

installation or any other service work.

Never clean or service the machine without isolating the

electrical supply and isolating the air supply.

Always test for the presence of voltage before touching or working on electrical components.

Note that there might be other requirements that could apply.

Refer to the manuals supplied by the component manufacturers for further safety

instructions.

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

2

Section 3 - INTRODUCTION

Thank you for purchasing a Pharmafill Model HT6B Heat Tunnel. We at Deitz Company hope you will find

that the Model HT6B meets or exceeds your expectations and requirements for an affordable, reliable

and innovative addition to your packaging operation.

Pharmafill products are designed and manufactured by Deitz Company Inc., in Wall, NJ, USA. We have

manufactured machinery for the bottle filling industry since 1966 and started our Pharmafill line in

1993. We are a small (but growing) family-owned business that emphasizes quality, innovation and

superior customer service.

If you have any questions or comments, please contact us by phone or visit our website. Chances are

someone whose last name is Deitz will handle your inquiry personally.

Deitz Company Inc.

PO Box 1108

1750 Route 34

Wall, NJ, USA 07719

Tel 732-681-0200

Fax 732-681-8468

E-mail support@deitzco.com or

Web site deitzco.com or

pharmafill.com

The operation manual is designed to make it easier for you to know the machine and to make use of its

intended range of operation. It contains important instructions on how to operate the machine safely,

adequately and economically. Observing these instructions helps to avoid risks, to reduce cost for repair

work and machine downtime, and enhances the machine’s operational reliability and lifetime.

The operation instructions are to be supplemented by further instructions due to existing national

regulations on accident prevention and environmental protection.

If used in compliance with the instructions contained in this manual and provided that safety devices are

regularly maintained and properly working, this machine is not dangerous to the operator.

This manual is to be kept accessible to all operators using this machine and it is assumed that before use

the operator will read fully, and understand, this manual and will follow instructions stated within.

(continued)

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

3

Section 3 –INTRODUCTION (cont’d)

As this machine may be used in the packaging of hazardous substances the operator should be aware of

the precautions required for these substances.

In addition to the operating instructions and the binding regulations on accident prevention valid in the

country where the machine is being used and at its operational site, the recognized technical rules on

safe and proper working must be observed as well.

These operating instructions and the information contained therein have been compiled with due care

and attention. However, DEITZ COMPANY does not take any responsibility for misprints, translation

errors or other errors and any damages resulting there from.

DEITZ COMPANY retains the right to make changes in the described products to improve functionality,

reliability and other design considerations. The measurements or data shown on schematics, sketches

and photos are not binding. They are for description purposes.

The information and drawings found in the operation manual are the intellectual property of DEITZ

COMPANY and may not be copied or given to third parties.

LEGAL NOTICE: DEITZ COMPANYTM, PHARMAFILLTM and any graphic representations of the same

are legal trademarks of Deitz Company Inc. and may not be used by others without specific

written permission from Deitz Company.

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

4

Section 4 - SPECIFICATIONS (Also see technical info at end of manual)

GENERAL

Model HT6B Heat Tunnel

Part Number AD1177

Heating Element Types 208 VAC or 240 VAC (must match receptacle voltage)

Temperature Range Variable up to 450˚(air temp)

Product Capability Most heat-shrink materials used for tamper evident neck banding

Container Size Up to 10” high on standard container 1

Neck or top section maximum width 3”

Containers which may be exposed to temperatures of up to 450˚ F

Maximum Rate up to 100 containers/minute

INPUT

Receptacle Voltage 208 VAC or 240 VAC (must match heating elements)

Cycles 50/60 HZ

Phase 1

Amperage 30.0 Amps

Power 6000 Watts

Compressed Air NA

Room Humidity NA

DIMENSIONS

Floor Footprint 22”wide x 24” deep (56 cm X 61 cm)

Height1Variable 48”to 58” (120 cm to 146 cm)

Container Height From 1” to 10” (2.5cm to 25.4cm) 1

Weight HT6B Heat Tunnel less mounting: 40 lbs (19 Kg)

HT6B with Conveyor Mounting option: 45 lbs (21 Kg)

HT6B with LS-HT Lift Stand option: 70 lbs (32 Kg)

HT6B with LS-HT EAL option: 85 lbs (39 Kg)

CONVEYOR Requirements

Ideal height 36” +/- 1” (92cm +/- 2.5cm)

Wear Strips Non-plastic directly under heat tunnel

Rails No rails directly under heat tunnel

CONSTRUCTION MATERIALS

Stainless Steel, Anodized Aluminum

There are no contact parts- the container is not touched.

Notes:

1. May be adjusted further by adjusting or modifying leveling feet.

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

5

Section 5 –GENERAL INFORMATION

1. Description

The HT6B is a small forced-hot-air heat tunnel with simple circuitry, designed to efficiently

shrink neck bands around the top of glass or plastic bottle. Bottles must be carried through the

tunnel by a suitable conveyor at a certain speed (to be determined). The size of the bottle and

cap must fit through a 3.5” W x 3” H opening.

2. Power requirements (also see Section 4)

Ideally, the tunnel is designed for use with 230 VAC. However, it can be used with 208 VAC with

a slight reduction in maximum temperature and slower shrinking speeds. We normally do not

supply a connector on the end of the power cable because we do not know what type of

connection you plan to use. If a specific connector is requested with the order, we will supply

the tunnel with a connector.

3. Mounting

This heat tunnel must be supported over a conveyor. There are two methods.

The most basic mounting is a simple assembly that is permanently attached to the side of the

conveyor. The conveyor must be of sufficient construction to be able to support the weight of

the tunnel without sagging. To change height of the tunnel over the conveyor, the tunnel must

be manually supported while the two mounting rods are raised or lowered.

The tunnel can also be ordered with a floor-mounted adjustable-height lift stand (Model LS-HT).

The light-weight lift stand has a screw-type height adjustment which is operated via a hand

wheel. This allows the HT6B to be easily raised or lowered, or moved away from the conveyor

for cool-down, or for use on another line.

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

6

Section 5 –GENERAL INFORMATION (cont’d)

4. Design Features:

a. Heating elements - two 3000-Watt tubular heaters, one in front and one in back.

b. Blower - located on top of the enclosure. Room air is blown through the heating

elements toward the center of the tunnel.

c. Blower Intake Cover –a round cover that can be closed over the blower air intake

opening to regulate air flow. The tunnel heats up faster if this cover is closed. It also

reduces air movement through the tunnel. After the tunnel heats up, this cover should

be at least half open. Adjust the cover so there is a balance of sufficient air movement

and heat in the tunnel.

d. Inner panels of tunnel - slotted panels that that direct hot air to a specific area of the

tunnel. The shrinking process is a combination of convection and radiant heat causing a

thin plastic band to shrink around the top of the bottle and cap. The slots in the panels

direct air toward the bottom of the neck band for the first half of the bottle passage to

tighten the bottom of the band before the top is heated.

e. Main Power Switch –mounted in the control panel, is also a 40 Amp circuit breaker.

f. Rotary Temperature Controls –two are mounted in the control panel. Each control one

of the heating elements. You can select low, medium and high temperature settings.

There is no temperature readout.

g. Heat Resistant Curtain - covers the entrance of the tunnel. It helps to hold heat inside

the tunnel and reduces the hot air escaping coming from the tunnel entrance.

h. Adjustable Neck Blades –two are mounted on the bottom of the tunnel. These blades

should be adjusted so they are close to the bottle as it passes through the tunnel.

Proper adjustment keeps the tunnel hotter and deflects hot air toward the bottle.

i. Double-wall Construction- used so that the outer cover is not directly exposed to the

heat elements and is cooled by the fan air flow. The exit for the cooling air is through

several holes in the bottom edge of the outer cover. Do not block these holes.

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

7

Section 6–INSTALLATION

1. When the tunnel is ordered, a method of attaching the tunnel to the conveyor is selected.

a. A simple bolt-on mounting plate can be attached to a non Pharmafill conveyor, or more

easily clamped on a Pharmafill CV4.5 type conveyor using a Pharmafill CV clamping

bracket assembly. Two vertical L- shaped rods with clamping collars are adjusted to hold

the tunnel at the ideal height and location over the conveyor.

b. A floor mounted light weight stand can be used to support the tunnel using the same L-

shaped rods. One advantage of the floor stand is a hand crank that easily raises/lowers

the tunnel. It can also be easily moved away from the conveyor if the conveyor belt is

stopped under a hot tunnel.

2. A method of connecting the tunnel power cable to power must be determined. It can be

hard wired to a circuit breaker box, or a plug can be wired to the end of the cable that

matches a mating cable connector or a wall mounted fixture. Power breaker should be at

least 30 Amps. The current for 220 Vac is about 26A. For 208 Vac, about 29 A. The tunnel

control panel breaker will trip at 40A.

3. The conveyor that serves the heat tunnel must be suitable for the heat that is emitted from

the bottom of the tunnel. A plastic chain type belt can be used but there can not be plastic

standoffs or low friction plastic wear strips under the belt that will melt. Normally there are

no side rails under the tunnel. The belt should never be stopped under a hot tunnel. A

Pharmafill CV4.5 conveyor is modified by replacing plastic wear strips with brass substitutes.

4. The tunnel should be located along the conveyor where the heat from the tunnel will not

affect other machines nearby. The recommended clearance is 24” from each end, however

as little as 12” is often used.

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

8

Section 7 –Set Up

1. Adjust the height of the heat tunnel over the conveyor. Height will depend on the bottle

dimensions. The lower edge of the tunnel should be about 1/2 inch below the neck

band. This will direct hot air toward the bottom of the band when the bottle enters the

tunnel.

2. Line up the centerline of the tunnel over the center line of the conveyor belt. Both

centerlines should be parallel.

3. Bottles must move from the entrance end of the tunnel which will heat the bottom of

the band first. Tunnels are designed for bottles moving left to right. If the conveyor

moves in the opposite direction, the tunnel can be mounted with the back side facing

toward the front. Controls will not be as accessible, but this arrangement will work.

4. Adjust the bottom blades so they close the bottom opening as much as possible without

touching the bottle.

5. Turn on the conveyor and pass bottles through the tunnel as a ‘dry run’ to be sure they

are not touching the bottom blade and that they fit through the 3” x 3.5” opening.

Adjust the conveyor side rails so they deliver the bottle to the center of the tunnel

opening. The tunnel centerline should parallel to the conveyor belt movement.

6. Conveyor side rails will be exposed to heat from the tunnel. Plastic rails may melt, and

metal rails will get very hot. The rail ends should be no closer than about 3” from the

tunnel

7. Turn on the conveyor so a plastic belt will be moving under the heat tunnel. If the belt is

not moving, the heat from the tunnel can melt the plastic links.

8. Turn on the HT6B power switch and set the temperature controls to Hi. Close the

blower intake cover to speed up the heating process. The hole on the center of the

cover lets some air always move through the blower. The tunnel will heat up to about

350 degrees in about 5 minutes.

9. After about 5 minutes open the blower cover halfway. To determine if the tunnel is hot

enough, pass a bottle with a neck band through the tunnel and examine the shrinking

results.

10. Set the conveyor speed so the bottle is inside the tunnel for as long as necessary to get a

proper shrink.

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

9

Section 8–OPERATION

1. The number of bottles that can pass through the tunnel with a good shrink band result

will depend on the following:

a. There are different types of plastic (PET-G, PLA, and PVC) that begin to shrink at a

certain temperature and will shrink a maximum percentage of original size.

b. As a cold bottle passes through a hot tunnel it will bring the inside temperature

down slightly. The size of the bottle and the space between bottles determines how

much cold bottle mass is inside the tunnel at any one time. One small bottle passing

through the length of the tunnel has a very small effect on the heat inside the

tunnel. Ten large bottles passing through end to end will drop the heat significantly

and may impair the shrinking process.

c. Conveyor speed determines how long the bottle is inside the hot tunnel. If conveyor

speed is high, the shrink process may not be complete for the period the bottle is

inside the tunnel. Set the speed to get the necessary results. Speed will change

depending on bottle size, number passing through at the same time, type of plastic

being used, temperature control settings, and how correctly mechanical

adjustments like the blower cover opening and bottom blades have been made.

2. You can reduce the temperature control settings if the shrinking process is good at a

lower setting and conveyor speed is low.

3. You can make the tunnel hotter or get more air movement by adjusting the blower

cover. You should select a percentage of opening that gives you the desired results. If

you close the cover the tunnel will be hotter, but the low air movement may cause a

less uniform shrink. If the cover is wide open, you will get maximum air movement but

lower temperature. The recommended position for the cover is half closed.

4. SHUTTING DOWN:

•NEVER STOP THE CONVEYOR BELT UNDER A HOT HEAT TUNNEL.

The conveyor belt material may be damaged by heat.

•NEVER TURN OFF THE MAIN POWER WITHOUT COOLING DOWN FIRST

Without a cool down period, heat from the elements can damage the controls.

•To shut down the tunnel operation, first TURN THE TEMPERATURE CONTROLS TO

OFF FOR AT LEAST 5 MINUTES. The blower will continue to run. After five minutes, it

is safe to turn off the Main Power Switch.

•If you have the floor stand type mount, you can push the heat tunnel back away

from the conveyor if it is necessary to turn off the conveyor belt. If there is a

complete power failure for both the hot tunnel and conveyor, and the conveyor belt

stops, raise the tunnel by whatever means necessary.

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

10

Section 9–MAINTENANCE

1. Maintenance –No maintenance other than cleaning. Keep the inside of the tunnel clean

and free of melted neck bands. Keep the louvers open on the 4 vent plugs in the top of

the control panel. Keep the ventilation holes at the bottom clear.

2. Lubrication –there is no lubrication required.

3. Spare parts consist of a heating element, a main power switch with 40A circuit breaker,

a temperature controller, and a blower.

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

11

Section 10 –TECHNICAL INFORMATION

1. PRINCIPLE OF OPERATION

The Pharmafill Model HT6B applies heat in the form of forced hot air to a pre-applied tamper

evident seal on a container that is passing through the tunnel on a conveyor. The seal is made of

heat-shrinkable material and the HT6B will shrink the band material so that it conforms tightly

around the container.

2. CYCLE OF OPERATION

(Connected to electrical power, Heater Element Temperature Controls at lowest setting)

Turn power on with Main Power/Fan switch.

•Electric power goes to the Heater Element Temperature Controls.

•Fan turn on and blow cool air into tunnel and across heater elements.

Turn either or both Heater Element Temperature Controls clockwise.

•Heater elements heat up in proportion to the setting of the temperature controls.

•Heated air is forced through the inner wall of the tunnel and into the center space.

Turn either or both Heater Element Temperature Controls fully counterclockwise.

•Heater elements begin to cool down.

•Fan continues to blow cool air into tunnel and across heater elements.

Turn power off with Main Power/Fan switch.

•Electric power is discontinued to the Heater Element Temperature Controls.

•Fan stops blowing.

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

12

Section 10 –TECHNICAL INFORMATION (cont’d)

3. TROUBLESHOOTING

a. No power overall or to some components.

❑Check power cord is plugged in and in good condition.

❑Check Main Power Switch is in ON position.

❑Check that circuit breaker feature of Main Power Switch is not tripped

- if breaker is tripped, wait for it too cool down, then reset.

- if it trips again, you must find the cause of the overload.

b. Blower fan runs but both heater elements do not heat up

❑Check Temperature Controls are not in OFF position.

❑Turn Temperature Controls to higher number

c. Blower fan runs but one heater element does not heat up

❑Check respective Temperature Controls is not in OFF position.

❑Turn respective Temperature Control to higher number

❑Have a qualified electrician check for presence of voltage of both sides of suspect

temperature control.

❑If temperature controls are good, heater element is bad.

2022-06-29 Rev B Pharmafill Model HT6B User Manual

Deitz Company Inc. HT6B User Manual Page

13

Index of Technical Notes/Drawings (document section begins after this page)

Doc. No. Title No. of Pages

AD1172-DIM Dimensional Drawing 1

WD1018 Electrical Diagram 1

TD-HT6-0001 Receptacle Voltage 1

AD1177_PM Preventative Maintenance 1

EAL Series 2 Auto-Lift Operator Manual 5

Addendums or additional technical data

________________ __________________________________ __

________________ __________________________________ __

________________ __________________________________ __

________________ __________________________________ __

________________ __________________________________ __

________________ __________________________________ __

________________ __________________________________ __

________________ __________________________________ __

Table of contents

Other Deitz Industrial Equipment manuals